Specifications for - ISRO

Transcript of Specifications for - ISRO

Page 1 of 19

Specifications for Supply, Erection, Commissioning and Testing of above ground

fire protection MS ERW pipe line Indent No: SHAR/SMPETF/2019011093

LIST OF WORKS:

a. Extension of pump house pipe line at location A b. Interconnecting of fire protection lines at location B c. Connecting fire protection pipe line at location C

1.0 SCOPE OF WORK:

• Supply, Erection, testing and commissioning of MS ERW above ground fire protection pipe line for a length of 1230m comprising 200NB & 150NB at SDSC-SHAR, Sriharikota as per the enclosed drawings (Drawing Nos:TO/19/00, TO/19/01, TO/19/02, TO/19/03, TO/19/04,TO/19/04A & TO/19/05) as per specifications, terms & conditions.

• Supply of necessary flanges, tees, fire hydrant landing valves, pressure gauges, relief valves, bends, structural materials, gaskets, fasteners, construction materials and paints etc. are also in the scope of tender.

• Construction of 180 nos. of pipe support RCC pedestals as per drawing no: TO/19/04 and laying of RCC Hume pipe for road crossings and wrapper coating for underground pipe line.

• Painting of newly laid pipe line with approved quality & fire red color as mentioned in 5.8. Also painting of pedestals as per approved procedures.

• Conducting the Hydro test and other tests at site as required for validating the functional requirements and specifications as mentioned in 5.4 & 5.5.

2.0 LIST OF DRAWINGS : Sl. No. Drawing No. Description

1 TO/19/00 Overall layout of proposed fire hydrant line. 2 TO/19/01 Extension of pump house pipe line at location A 3 TO/19/02 Interconnection of fire protection lines at location B 4 TO/19/03 Connecting fire protection pipe line at location C 5 TO/19/04 RCC pipe support pedestal for above ground pipe

6 TO/19/04A Two 200NB pipe lines erection layout on existing pedestals

6 TO/19/05 Details of typical fire hydrant post.

3.0 DETAILED SCOPE OF TENDERER:

Understanding the functional requirements of fire protection pipe line, procurement, fabrication and laying of pipe line along with pipe fittings, fit-up, erection, testing and commissioning as per the enclosed drawings and specifications.

Page 2 of 19

The following are in the scope of Tenderer:

3.1 Materials supply :

� 150NB MS ERW, Heavy grade as per IS1239 (Part 1):2004.

� 200NB MS ERW, Pipe of thickness 6.35 mm as per IS 3589 (Part 1):2004.

� 250NB MS ERW, Pipe of thickness 6.35 mm as per IS 3589 (Part 1):2004.

� 300NB MS ERW, Pipe of thickness 8.00 mm as per IS 3589 (Part 1):2004.

Make:TISCO/JINDAL/SAIL/MSL/Ratnamani/PSL/ Suryaroshini/ Welspun

3.2 Quantity of pipes :

Pipe size Erection length Supply scope

150 NB 330 m 220 m

200 NB 900 m 960 m

250 NB --- 60 m

300 NB --- 30 m

Total length 1230 m 1270 m

• Total length of the proposed line to be executed is 1230 m.

• Total length of the pipe to be supplied is 1270 m

3.3 All the required L bends, Tee joints, Reducers, Flanges etc., where ever

necessary are in the scope of tenderer.

3.4 Butterfly valves:

• 150 NB lever operated manual butterfly valves – 12 nos.

• 200 NB gear operated butterfly valves- 10 nos.

• 250 NB gear operated butterfly valves- 5 nos.

Make: L&T/AUDCO

Note: Material test certificate and other test certificates like body hydro test, leak test etc shall be furnished for all the butterfly valves during inspection at work site.

3.5 Pressure gauges of range 0-16 Bar of 06 nos (100 mm dia) with calibration certificate. Make: Wika, SS body. Location of the gauges and pressure relief valves shall be as per the drawing or as instructed by the department engineer at the time of commissioning.

3.6 RCC pipe supports: Construction of RCC pipe support pedestals of 180 Nos (above ground, Drg. No: TO/19/04) shall be carried out as per the approved

Page 3 of 19

drawings. Additional supports up to 5% of the quantity should be supplied by the tenderer with free of cost. Length /depth of pedestals may vary as per the site conditions.

3.7 Hume pipe 80m (Dia 450mm -60m & Dia 300mm -20m) approximately and Wrapper coating material for road crossing pipe line at 6 locations as shown in TO/19/00.

3.8 Pressure relief valves- 3 nos. Make: Tyco/AIRA

3.9 Fire hydrant stand post with 02 single hydrants – 05 nos. Make: NEWAGE

3.10 Required gaskets & hydrants for each post – Studs with 2 nuts, lock nuts and washers (For landing valves).

3.11 Manpower: Adequate skilled, semi skilled manpower like arc welders, filters fabricators, grinders etc and unskilled helpers for site works.

3.12 Machinery: Requisite machinery like arc welding machine, angle grinders, gas cutting sets and concrete drillers, pipe cutting machines and hydro test pump.

3.13 Preparation & submission of final drawings for the pipelines laid and commissioned. 3 Sets of approved drawings shall be compiled and handed over to the department. (2 nos. of hard copies and 01 no. of soft copy)

4.0 DETAILS OF WORKS TO BE CARRIED OUT:

Sl.No Description of Work Qty

4.1

Supply, erection,testing and painting of MS pipe line : a. Extension of pump house pipe line at location A: 150NB-

140m & 200NB-420m (Total-560m) b. Connecting of fire protection line at location B : 150NB-

50m c. Connecting fire protection pipe line at location C :

140NB-140m & 200NB-480m (Total-620m)

1230 m As per drawing

TO/19/00

4.2 Laying of road crossings with RCC Hume pipes at 06 locations

As per drawing TO/19/00

4.3 Construction of RCC pipe support pedestals, footings and painting of the same.

180 nos. As per drawing

TO/19/04

4.4

RCC Pipe support pedestals for pipelines, foundation /grouting of platforms, equipments etc as per approved drawings- which includes supply of construction materials like cement, steel, sand and shuttering materials etc, excavation, reinforcement, shuttering, casting, curing & back filling and painting of pedestals with standard makes.

As per drawing TO/19/04

4.5 MS piping fabrication, erection, installation of flow components as per drawing and providing adequate support clamping, testing, painting and commissioning

As per drawings TO/19/00

4.6 Fabrication, erection & painting of MS Structural As per

drawings TO/19/04 &04A

Page 4 of 19

4.7 MS welding: Butt welding of pipes, fittings, etc by GTAW welding process for root and SMAW for subsequent passes

As indicated in the detailed

scope of work

4.8 No. of Butt welding joints of 150 NB & 200 NB pipe As per site conditions

4.9 Wrapper coating with 4mm thick AWWAC 203 tape, earth excavation, positioning of pipeline as per specifications. size :150 NB at 2 locations

As per site condition &

drawing TO/19/00

4.10 Wrapper coating with 4mm thick AWWAC 203 tape, earth excavation, positioning of pipeline as per specifications. size :200 NB at 4 locations

As per site condition &

drawing TO/19/00

4.11 Leveling & alignment of support pedestals and pipe line

Theodolite, Quick set leveling

instruments shall be used

4.12 Hydro testing of newly laid fire protection pipeline segments.

15 bar pressure, 30 minutes hold

4.13 Functional testing of integrated pipelines 10.0 bar and

24 hours hold

4.14 Painting :Epoxy mastic coating: 120 - 130 microns (primer coat)

Total DFT: 160±10 microns 4.15 Aliphatic polyurethane: 30 - 40 microns (final coat)

Notes:

1. The quantities indicated above as per drawing are tentative. A quantity variation of 5% of the estimated quantity is expected based upon the site conditions. 5% deviation of the quantity should be supplied by the tenderer at free of cost.

2. Tenderer should verify and provide the required no. of RCC pedestals and pipe line based on the site conditions. However, if more than 5% variation in quantities is required, the same should be intimated to department and get prior approval for getting the additional amount on pro-rata basis.

3. RCC pedestal should be at a maximum distance of 400 mm from the fire hydrant post location.

5.0 DETAILED SCOPE OF WORK: 5.1 Laying of pipes:

• Before starting the work party has to check & survey the area for any obstructions etc and ensure that routing of pipe line is as per Drawing. If site conditions calls for a change the same is to be brought to the notice of the Department and after approval only work is to be started.

Page 5 of 19

• Laying of pipeline above the ground using butt welded joints laid on RCC Pedestal blocks, above the ground.

• Excavation to the required depth as per drawing for construction of RCC pedestals. The depth and height of the RCC pedestals may vary at few locations according to site condition.

• The span between two RCC pedestals shall be maintained as 5.0 m. • It may be noted that all pipe fittings are of flanged bevel edge type. • Pipes shall be joined by using standard welding procedures. • Pipes passing through road crossing with RCC Hume pipes shall be wrapped

with standard wrapper coating with 4mm thick AWWAC 203 tape. • Road crossing with RCC Hume pipes shall be wrapped with standard wrapping

material. Pipe Size Hume pipe sizes

200NB pipe ø450

150NB pipe ø300

• Wherever straight length of pipe line laid greater than 100 m, thermal expansion loops shall be provided in the line.

5.2 Fabrication/ Welding of pipe line:

• The scope shall include fabrication, welding, erection along with flow components, clamping, hydro testing, leak checking and painting of pipelines.

• Welding of pipe lines shall be by manual metal arc welding (SMAW) with electrodes confirming to AWS classification E 7018

• Welder qualification certificate shall be provided prior to the start of fabrication work.

5.3 Piping Erection:

• Pipe line shall be laid above the ground on the new support pedestals (180 nos.) for a length of 910m as per the enclosed Drg no: TO/19/00. And remaining length of 320m pipe line shall be laid above the ground on the existing support pedestals (30 nos. at location-A) as shown in drawing no: TO/19/04A, after removing the existing 150NB line on the support pedestals.

• Removed 150NB line (Approximately 160m) should be erected at Location-A. • No. of pipe support blocks shall be as per IS: 12288 with proper mild steel straps.

Min. spacing between two saddles shall be 5 m. • Erection of piping includes positioning of completed pipeline segments at

required location as per drawing and/or instructions of department engineer depending on the site conditions. This work includes alignment of pipes, proper fixing of flow components, pipe fittings & instruments and laying such pipelines over structural pipe supports/concrete pedestals.

• Proper care shall be taken for expansion / contraction due to temperature fluctuations.

Page 6 of 19

• As per the existing site conditions, changes in the layout (if any) shall be carried out by the tenderer at free of cost with the consultation & approval of the department engineer.

• Leveling & alignment of the pipeline shall be carried out at appropriate locations where ever necessary using alignment instruments like Theodolite, inclinometer etc.

• Piping shall be routed to avoid interference. If any interference is noticed at site, piping shall be suitably modified by the contractor without any extra cost to the SDSC-SHAR.

5.4 Weld inspection:

• Tenderer shall satisfy himself and SDSC-SHAR for the quality of welds by visual and DP test inspection as applicable and shall submit the subsequent reports for examination.

• The Procedure for testing the preparation of surfaces of the welded area shall be as per relevant Indian Codes and standards or other equivalents.. All defects shown shall be repaired and rechecked.

• Weld Inspection: (As per ASTM section-IX) • Dye-Penetrant test for root pass for butt-welding and after final pass for fillet and

butt welding. • X- Ray Radiography of 10% of butt-welded joints with 2-2T sensitivity as per

ASME sec. V

5.4.1 Radiography:

• Interpretation of weld joints radiographs shall be done by Department representative as per relevant codes such as ANSI B 31.3 and ASME-Sec.V

• Exclusive radiography machine / Gamma ray source has to be arranged by the contractor.

• D2 films shall be used for Gamma Rays and D5 films shall be used for X-rays. Elliptical shots (double wall double image) may be employed up to 2” size.

• The penetrometer used shall conform to ASTM E 1025/ASTM E747 (or) relevant DIN standards.

• Retake due to rejection of Radiograph owing to bad image quality shall at the cost of contractor.

• Radiography shall be carried out by qualified technicians (i.e.) minimum level- I of ISNT/ ASNT and qualification certificates shall be produced with latest renewal to the Department before proceeding with the work.

• Radiography film shall be evaluated and report shall be submitted by Level II ISNT/ ASNT (or) equivalent qualified person. However department Engineer will carry out the final Evaluation.

5.5 Testing & commissioning:

• A comprehensive test plan comprising of the following are to be made. The approval will be given by the SDSC-SHAR.The testing should be carried out in

Page 7 of 19

presence of department Engineer as per the approved plan. The test plan should include.

� Inspection and testing of the above ground lines. � Hydrotesting of the total line. � Testing of fire protection pipe line and fire hydrants.

• Hydro testing: Hydro testing of newly laid fire water pipeline segments at 15 bar. Pressure and holding time of 30 minutes excluding observation period.

• Hydro test set up: Valves, flanges, spool pieces etc., including Pump, Hose and pressure gauges etc., required for conducting Hydro Tests is the scope of contractor.

• Leveling & alignment: Leveling & alignment of underground laid RCC Hume pipes as per IS 3114. (Theodolite, Quick set leveling instruments shall be used.)

• Functional testing: Testing of integrated pipelines at 10.0 bar with observation time of 24 hours

5.6 Civil works:

• Clearance of bushes and shrubs for the purpose of erection of pipe lines along the pipe line routing.

• Construction of RCC pipe support pedestals for above ground pipe line as per drawing TO/19/04.

• Laying of underground RCC Hume pipe of good quality for road crossing and should confirm to IS 458, class NP3. This includes excavation, leveling to maintain uniform slope of pipe line, back filling after casting the pipe support with a top layer of PCC 1:4:8 of minimum 75 mm thick. The width and length of the PCC shall be more than the diameter of the Hume pipe.

5.6.1 Earth work: Earthwork in excavation for Pipe pedestals in all kinds of soils including dressing of

sides, ramming of bottom prior to casting of pedestals and back filling and leveling after completion of casting and curing.

5.6.2 Shuttering: Providing rigid and water tight centering and shuttering using best quality wood/

plywood/ steel forms and centering with steel props, acorn tubes etc., including strutting, propping, bracing, staging etc., complete for all RCC items fixed in position as required including labor for careful removal of form work etc.,

5.6.3 RCC: Providing & laying in position machine batched, machine mixed and machine

vibrated design mix cement concrete of specified grade for reinforced cement concrete structural elements, using graded hard granite stone aggregates of

Page 8 of 19

maximum 20mm nominal (downgraded) size obtained from approved quarry including fine aggregates conforming to latest IS 383 and cement all as per approved design mix proportions conforming to latest IS 10262 with minimum cement content for durability and plasticizer including supplying and providing concrete cover blocks etc., which shall be followed as per latest IS456-2000 including mixing, transporting, placing, vibrating, compaction, finishing to required levels, curing etc.

5.6.4 Reinforcement: Steel reinforcement with high yield strength deformed bars of SAIL/RINL/TATA or

equivalent approved brands for all R.C.C items including decoying, cutting, hooking, bending, cranking, fabricating to required shape, placing in position and tying the system with soft drawn annealed binding wire of diameter not less than 1.00mm with 2 strands etc., as per specifications.

5.6.5 Road cutting and erection of Hume pipe:

• Shall be executed with clearance of CMG, safety etc. and the work at the main roads shall be taken up preferably during night times and the same shall be completed by overnight.

• After laying Hume pipe a minimum thickness of 150 mm concrete shall be filled on the road to ensure original load & road conditions.

5.7 Wrapper coating: Wrapper coating of buried RCC Hume pipe with 4 mm thick multi layer. Wrapper coating tapes as per AWWA C203.

5.8 Painting:

• Paints and other materials used for painting shall conform to relevant Indian Standards.

• Surface preparation shall comply with IS-1477 part-II and this standard shall be considered as the minimum standard acceptable, wherever not specifically mentioned.

• Each coat of material applied shall be free of runs, sags, blisters, bubbles and mud cracking; variations in color and gloss, excessive film build up, foreign contaminants, etc. Special care shall be taken to ensure complete coverage and proper thickness on welds, corners, sharp edges, bolts and nuts. Colour for the pipe line – Fire Red

The following brands are acceptable.

1. GP Bond 141 of Grand Polycoats (Aliphatic polyurethane) 2. Berger thane enamel of Berger (Acrylic polyurethane) 3. Apcothane CF674 of Asian paint (Acrylic- Aliphatic polyurethane) 4. Pentathane finish paint 4513 of Bombay Paints (Aliphatic isocyanate

polyurethane) 5. CDC Carboline 6. Kansai Nerolac

Page 9 of 19

Types of Paints and Thickness of the coating (Total DFT: 160±10 microns)

A. High Build Epoxy coating 120 - 130 microns (primer coat) B. Aliphatic polyurethane 30 - 40 microns (final coat)

5.9 Paint Inspection:

The inspection consisting of the following stages shall be offered to ISRO. No materials shall be painted without inspection and approval by the DEPARTMENT unless such inspection is waived.

i) Determination of surface preparation. ii) Dry film thickness after completion of primer application iii) Dry film thickness after completion of final coat of paint

Necessary inspection equipment like paint thickness measuring gauges and other tools required are to be supplied by the Tenderer.

5.10 Documentation: The party has to provide all test certificates, material test certificates etc. in

document form and also 03 copies of “as built drawing of A1 size at site with all details, dimensions etc., in AutoCAD format (02 hard copies + 01 soft copy)

5.11 Quality Assurance Plan (QAP):

� The following Quality Assurance Plan (QAP) for fabrication, Erection, testing, and Commissioning is tentative. The bidder shall submit detailed QAP after awarding contract for approval and strictly follow the same during execution of work at site. The inspection shall be carried out by Purchaser’s representative.

� The Bidder has to check and produce all the necessary certificates, procedures

and plan, at various stages during progress of work for approval to the purchaser.

QAP for fabrication Erection, Testing, & commissioning works:

Sl No

Characteristics/ Type of Test

Method of Check Quantum of Check

Suppliers QC

Purchasers Inspector

1. Identification of materials

Visual Inspection and material identification

100% P 100% R

2. Testing of all materials

Verification of material test certificates for all bought out items

100% R 100% R

3. Fit-up reports of joints

Physical Verification at site. 100% P 100% R

4. Dye Penetrant test for root and final weld of butt joints and final run for fillet joints

On-site participation 100% P 10% W

Page 10 of 19

5. 10% Radiography for butt joints

Review of films 100% R 100% R

6. Hydro Test of pipelines On-site participation 100% P 100% W

7. Painting Visual measurement of

DFT as per PO Spec. 100% P 10% W

8. Functional testing of system

On-site participation 100% P 100% W

Legend: R: Review P: Perform W: Witness

6.0 Specifications of MS Pipes:

1 Code of Manufacturing & Testing

IS 3589 / IS1239 (Part 1):2004.

2 Diameter of the pipe & Material of construction

150 NB: MS-ERW 200 NB: MS-ERW 250 NB: MS-ERW 300 NB: MS-ERW

3 Service fluid Water 4 Hydro test pressure IS 3589 / IS1239 (Part 1):2004 5

Finish Degreased and applied with anticorrosive protective coating.

6 Tolerances on thickness As per IS:3589 / IS:1239 7 Length of each pipe 6 m (minimum)

8 Marking on the pipes

Manufacturer’s reference (Pipe Sl. No.), heat /lot number, Code of manufacture, Dimensions of pipe (Size, OD, and Thickness)

9 Test certificates Material test certificates & Hydro test certificates for all supplied pipe lengths.

6.1 General conditions for pipes:

• Pipes shall be cleaned and dried before dispatch. Ends shall be protected with suitable metal end protection caps to protect bevel ends to avoid entry of dust and foreign materials during storage & transportation.

• Pipes shall be supplied form the latest batch and the age of the pipe shall not exceed 6 months form the date of manufacture.

• Supplied pipes shall be re-rolled ones.

• Chemical and Mechanical test certificates shall be provided.

• Mechanical and hydrostatic test certificates shall be supplied along with dispatch documents.

Page 11 of 19

• Marking required on pipes: Manufacturer’s reference (Pipe Sl. No.), heat /lot number, Material, Code of manufacture, Dimensions of pipe (Size, OD, and Thickness).

• Warranty/Guarantee: Material supplied shall be guaranteed for 18 months from the date of supply.

6.2 Butterfly valve specifications:

Sl.NoDescription Specification 1 Make L&T/AUDCO 2 Type Wafer design lever operated 3 Body Material CI

4 Size 150 NB – 12 nos. 200 NB – 10 nos. 250 NB – 5 nos.

5 Liner Black Nitrile 6 Disc material Stainless steel (SS316) 7 Temperature 90 deg 8 Rating PN 16

9 Operating pressure 16 bar

10 End Connection Wafer body to be fit in between RF flanges as per ANSI B16.5

11 Stem SS-AISI 420/410 Note: Test certificate shall be supplied along with items .

6.3 Pressure gauge specifications:

Sl.No Description Specification

1 Type Bourdon tube, glycerin filled pressure

gauges. 2 Make WIKA 3 Dial size 100 mm 4 Body & Tube Material Stainless steel 5 Accuracy 0.25% 6 Working medium Water 7 Range 0-16 bar 8 Quantity 06 nos.

Note: Calibration Test certificate shall be supplied along with items. 6.4 Pressure relief valves specification:

S. No. Description Specification

1 Make Tyco/AIRA 2 Set pressure 10 bar

Page 12 of 19

3 Manufacture code As per IS 12992 4 Quantity 03 nos

Note: Test certificate shall be supplied along with items

6.5 Gaskets for flanged joints

Material CAF- Gr. W/2 / Neoprene Rubber Code of Manufacturing IS 2712 Thickness 3.0 mm

Make: Champion/ Spittman

6.6 Wrapper coating Material:

Multi layer wrapper-coating tapes as per AWWA C203. Make: IWL (4 mm thick).The wrapper-coating is to be provided right from entry point to exit point (till 1 m above the entry and exit points of the pipe) where it leaves the ground including the full length inside the Hume pipe.

6.7 Inspection equipments:

Necessary inspection equipment like Theodolite/ Autolevel/spirit level for leveling check, Hydro-test pump etc. shall be supplied by contractor only.

6.8 Consumables:

The consumables such as electrodes (E 7018), grinding wheels, industrial gases (Oxygen / Acetylene), gas cutting set, Dye-Penetrant test kit, flow Meters, face shields, gloves, emery cloth and cleaning materials etc.,

• Electrodes for Structures: Size 2.5 mm / 3.15 mm • Root pass – GTAW, Filler wire – 70S2 • Filler pass – SMAW – E 7018 • Oxy / Acetylene cylinders: Grade Commercial, Purity 99.99%, Cylinder

Capacity 50 Ltrs • Dye-Penetrant test kit Containing cleaner / Penetrant / Developer • Calibrated pressure gauges for conducting Hydro test.

6.9 Apart from the above, if any material is required as per site condition, it is the

responsibility of the contractor to supply the same. 7.0 Supply of material under Department scope:

• Electricity required for machine tools like grinders, welding machine etc., will be provided at the nearest available power point free of cost as per the departmental norms.

• Water required for the hydro test from the nearest source of water.

Page 13 of 19

8.0 Precautions to be followed by tenderer during execution:

• Utmost care shall be taken while handling pipes, fittings, loading & unloading at site.

• Pipes shall never be thrown, dropped or dragged. Pipes shall be handled only with cotton / nylon ropes.

• Any minor changes (approx. 5%) in the layout have to be carried out by the contractor without any extra cost.

• Contractor shall take enough care to ensure the progress of work without any material and personnel damage. It is the sole responsibility of contractor to ensure all safety norms to his personnel. Department will not hold responsibility to any mishap to the contractor personnel.

• Minor deviations if any from the specifications for the work will be accepted, if found technically acceptable.

• The Contractor shall successfully demonstrate the performance during the commissioning / acceptance trials.

9.0 Jungle cutting:

• Wherever jungle cutting and clearance is involved, the same is the responsibility of the contractor only.

• Party has to clear the shrubs and bushes neatly on the way of pipe line to be executed with a distance of 1 m either side.

• If any big trees are obstructing the way of pipe line, it is the responsibility of the contractor to reroute the pipe line after getting approval from department engineer.

10.0 General conditions of Contract: 10.1 Sriharikota is an island and situated around 100 kms north of Chennai and the work

spot is located at about 8 kms from main entrance gate. Conveyance for Contractor personnel from and to work spot has to be arranged by the contractor.

10.2 The offers shall be accompanied by deviations if any, from the technical

specifications, and general / additional / special conditions of contract. If the deviations are not submitted, it will be understood that the Tenderer abides by all the stipulations of the tender documents. The Tenderer should quote in figures as well as in words the amount quoted by him.

10.3 Tenderer should submit documentary proof in support of similar type of works carried out and work completion certificates for the same from state/ central govt. departments/ ISRO and its units /PSU/ any other reputed private limited companies. Tender will be summarily rejected if no documentary proof is provided.

10.4 Tenderer should indicate point wise compliance along with quotation. 10.5 Deviations if any, from specifications shall be clearly indicated in the quotation.

Page 14 of 19

10.6 License for Contract Workers: The contractor shall wherever applicable, obtain license under the contract Labour (Regulation & Abolition) Act according to the number of workers engaged by him on contract basis, depositing the prescribed fees and complying with the formalities.

10.7 The contractor should comply with all Labour Laws, Minimum wages Act, payment of Employees Provident Fund and ESI/Insurance and other laws, if any, applicable from time to time. Contractor should also ensure that minimum wages at prescribed rates are payable to the labourers engaged.

10.8 Entry permit for the contractor’s personnel will be issued by SDSC SHAR. To enable to issue entry passes, the contractor shall submit the list of personnel. It is the responsibility of the Contractor to return/surrender the passes after expiry and in case of non-compliance in this regard, SDSC SHAR reserves its right to withhold his payment till such time the passes are returned.

10.9 The contractor and/or his personnel shall adhere to all the security provisions of SDSC SHAR. Contractor and his personnel are responsible for any violation of security provisions and indiscipline/agitation when they are inside the Centre. Any resultant liabilities/damages due to violation / indiscipline /agitation shall be borne by the Contractor.

10.10 Execution of work:

• The system shall be realized strictly as per technical specifications, manufacturing / fabrication drawings and bill of materials. Tenderer may suggest any improvement for the betterment of the operation of the system, which shall be reviewed by SDSC-SHAR as necessary.

• Tenderer shall procure all bought out items only from the approved parties listed in the technical specification. Department shall reserve the right to specify particular type and make of items.

• The specifications of the contract are intended to describe and provide for a finished piece of work. It is to be understood and agreed by the Tenderer, that the work described shall be complete in every detail, even though every item necessarily involved is not particularly mentioned.

• The tenderer shall be responsible during work for protection of the work; Necessary care shall be taken to see that no damage to the same is caused by his men during the course of execution of their work.

10.11 Guarantee: Tenderer shall produce a guarantee certificate for the system, for a period of 12 months from the date of completion of installation at SHAR, against defective materials and workmanship. Problems faced during the guarantee period for the fabrication and manufacturing defects shall be solved by the Tenderer free of cost (including replacement of defective materials, if any).

10.12 Compensation for delay: The Tenderer, as per PO schedule shall strictly observe the time allowed for carrying out the work. If the Tenderer fails to deliver the system or fails to meet

Page 15 of 19

delivery mile stones within the time specified in the contract the Department shall recover from the Tenderer as liquidated damages a sum of one half of one percent (0.5%) of the payment due for the concerned milestone for each calendar week of delay. The total liquidated damages shall not exceed Ten percent (10%) of the contract price.

10.13 Cancellation of contract:

The Department at any time shall have the right to cancel a contract either wholly or in part by giving written notice.

10.14 Changes and modifications to qualitative requirements

Party should accept any minor modification, correction and deviation in the system after placement of order or during execution of work without any extra cost.

10.15 Price:

• The tenderer shall submit a firm and fixed price in his quotation. Applicable taxes, duties, or any other charges levied by any Central, State or other governmental authorities which the tenderer is required to pay and intended to be claimed from the Purchaser shall clearly be shown indicating the percentages separately.

• Parties have to quote for the entire stipulated work on Lumpsom basis only. The

party shall give undertaking to hold the same quote for the additional quantities of 5 % of order quantities if site requirement calls for.

10.16 Security Deposit

The contractor shall deposit a sum equivalent of 10% of Purchase Order value as Security deposit in the form of bank guaranty or by demand draft valid till the contract period. In case cancellation of contract due to default contractor, the security deposit will be forfeited (in case of bank guaranty the same will be encashed). In case of successful completion of contract, the security deposit will be refunded without any interest.

10.16 Performance Bank Guarantee:

The tenderer shall furnish performance guarantee in the form of an unconditional irrevocable bank guarantee to the extent of 10% of the total contract value valid during the defect liability period of 12 months.

10.17 Accommodation & Transport:

During the erection of the total system at site in Sriharikota, the tenderer has to make his own arrangements for boarding, lodging, transportation of his men and materials. No labour camp is permitted at work place. However accommodation for supervisory staff will be provided on chargeable basis subject to availability.

Page 16 of 19

10.18 Personnel insurance

SDSC SHAR will not be responsible for any injury, accident, death occurs to the contractor’s personnel while discharging the duties at SDSC SHAR. All the liabilities in this regard shall rest with the tenderer only and no claim will be entertained in this regard. Before starting the site work, the Tenderer has to insure all his personnel working at site in Sriharikota against accidents.

10.19 Payment Terms:

The suggested payment terms are as given in the below table:

S.No Payment (% of PO value) Remarks

1 10% As advance after placement of purchase order after submission of Bank Guarantee (BG)

2 40%

After supply of bought out items like pipes, valves, pressure gauges, bends, T joints, fire hydrant posts etc & construction of RCC pipe support pedestals and acceptance of the same by the department engineer.

3 50% Erection of the pipe line with alignment and Testing & commissioning and acceptance of the same by the department engineer.

. 10.20 Parties may visit the site for assessment of the scope of work and site

conditions clearly before submitting the offer.

11.0 Delivery Schedule:

Supply, erection, commissioning and testing of fire hydrant line shall be completed within 6 months from the date of receipt of purchase order by the successful tenderer.

11.1 Successful tenderer after placement of PO shall strictly follow the work execution plan as per the detailed schedule given below:

S.N 1st & 2nd Month 3rd , 4th & 5th

month 6th month

1 Supply of all bought out items like pipes, valves, dial gauges, fire hydrant posts etc.,

2

Supply of all construction materials like cement, reinforcement rods etc and construction of RCC pipe support pedestals

3 -------------- Erection of the pipeline with valves & alignment

Page 17 of 19

4

--------------

Testing & Commissioning of the pipe line

12.0 COMMERCIAL TERMS & CONDIITONS:

The quotation should be submitted in two parts. 1) Part –I: Technical and commercial bid along with copy of the price bid without mentioned prices but indicating % of applicable taxes & duties. 2 ) Part –II: Price bid.

13.0 Parties shall quote in lumpsum and they should attach a separate page indicating

the prices as per the below table without which the offer will be considered as invalid.

Sl. No.

Description Unit cost

(Rs) Total cost

(Rs.) 1 Supply of all bought out items like :

• MS ERW pipe � MS ERW 150 NB pipe 220m � MS ERW 200 NB pipe 960m � MS ERW 250 NB pipe 60m � MS ERW 200 NB pipe 30m

• Lever operated manual butterfly valve of size: 150 NB: 12 nos. Make: L&T/AUDCO

• Gear operated manual butterfly valve of size: 200 NB: 10 nos. Make: L&T/AUDCO

• Gear operated manual butterfly valve of size: 250 NB: 5 nos. Make: L&T/AUDCO

• 16 bar Pressure gauges (100mm dial) - 06 nos. Make: WIKA

• Fire hydrant posts with 02 single hydrants – 05 nos. Make: NEWAGE (Landing valves)

• T joints, bends, flanges, fasteners & gaskets • Hume pipe ɸ450-60m & ɸ300-20m • Wrapper coating material as per AWWAC

203 for 150 NB & 200 NB pipes • Welding and fabrication Note: Party shall mention the individual cost of the bought out items.

Rate per unit length/number --- do ---

--- do ---

--- do ---

--- do ---

--- do --- --- do --- --- do ---

--- do ---

--- do ---

2 Supply of construction materials like cement, reinforcement rods and construction of RCC pedestals, 180 nos. as per the approved drawing.

--- do ---

3 Welding, fabrication & erection of the pipe line

Page 18 of 19

with valves, hydrant posts in position with levelling & alignment

--- do ---

4 Painting of pipe lines & pedestals --- do --- 5 Testing & commissioning of the entire pipeline --- do ---

14.0 Check list to be filled by the parties: For evaluations of tenders, all the parties shall strictly submit their offers as per the

prescribed format, without which offer will be considered as invalid.

Sl No Description Compliance

1 Understanding the total work as per tender/ technical specifications

2

Scope of supply by tenderer: • MS ERW pipe as per IS:3589/IS1239

� 150 NB, Heavy grade pipe :220 m � 200 NB, Pipe Thickness 6.35 mm : 960 m � 250 NB, Pipe Thickness 6.35 mm : 60 m � 300 NB, Pipe Thickness 8.00 mm : 30 m

• Butterfly valves: Make – L&T/AUDCO � Lever operated valve of size 150 NB – 12 nos. � Gear operated valve of size 200 NB – 10 nos. � Gear operated valve of size 250 NB – 5 nos.

• Bends, flanges, T- joints, reducers etc. as per drawing and site conditions

• 16 bar Pressure gauges (100mm dial) - 06 nos. • Fire hydrant posts with 02 single hydrants – 05 nos.

Make: Newage • Pressure relief valves -3 nos. Make: Tyco/AIRA • Wrapper coating Material • Fasteners & gaskets • Any other material required as per site conditions

3 Providing P&I diagram before starting of the work.

4 Underground RCC Hume Pipe: Road cutting as per SDSC-SHAR rules/permits

5 Construction of RCC pipe support pedestals as per drg no: TO/19/04 (Total : 180 nos. approx)

6 Mild steel fabrication as per the drawing specifications

7 Multi-layer Wrapper coating (As per AWWA C 203)

8 Welding as per the standards mentioned in the specifications S.No.5.2

9 DP testing of welded joints as per S.No 5.4

10 Radiography testing of 10% of butt-welded joints with 2-2T sensitivity as per S.No 5.4.1

Page 19 of 19

11 Painting of pipe lines & Structural materials as per tender specifications S.No.5.8

12 Hydro test of the completed pipe line @15 ksc.

13 Testing of the total system as per applicable standards & the specifications S.No. 5.4 & 5.5.

14 Deployment of highly skilled fabricators, erectors & masons.

15 Acceptance, if any deviations without any extra cost (limited to 5% the PO cost)

16 Providing test certificates, material analysis certificates in document format.

17 Providing a comprehensive layout of the completed work as built drawing in AutoCAD (02 hard copies + 01 soft copy)

18 Providing Security Deposit.

19 Providing performance Bank Guarantee.

20 Acceptance for LD clause.

21 Acceptance for payment terms Sl.no. 10.19

22 Acceptance of delivery schedule S.No.11 & work execution plan S.No.11.1

23 Acceptance for cancellation of contract at any time.

24

Submission of documentary proof in support of similar type of works carried out and work completion certificates for the same from state/ central govt. departments/ ISRO and its units /PSU/ any other reputed private limited companies.

25 Understanding the commercial terms & conditions of two part bid (S.No12.0 in page no. 17)

26 Apart from all the above, the bidders shall submit all the papers of tender specifications by signing on every page.

15.0 Tenderer shall strictly submit the format as per S.No.14 (check list to be

filled by the parties) and S.No.13 (Estimated cost as per the prescribed format) without which the offer will be considered as invalid.

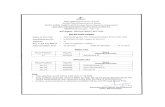

S a t i sh Dhawan Spac e Cen t e r SHAR S a t i sh Dhawan Spac e Cen t e r SHAR S a t i sh Dhawan Spac e Cen t e r SHAR S a t i sh Dhawan Spac e Cen t e r SHAR

Welcome, Materials Master (isro)31 August 2017,

17:16:08 IST

MAIN VIEW HELP

Preview For STANDARD TERMS AND CONDITIONS

Page Destination: Tender Header Format Type : Normal

. :

GOVERNMENT OF INDIA

DEPARTMENT OF SPACE

SATISH DHAWAN SPACE CENTRE

PURCHASE DIVISION

Tele No.08623-225023/225174/225127 Fax No.08623-225170/22-5028 e-Mail ID : [email protected], [email protected], [email protected]

STANDARD TERMS & CONDITIONS

1.OFFERS SHALL BE SENT ONLINE ONLY USING STANDARD DIGITAL SIGNATURE CERTIFICATE OF CLASS III WITH ENCRYPTION / DECRYPTION. THE TENDERS AUTHORISED ONLINE ON OR BEFORE THE OPEN AUTHORISATION DATE AND TIME ONLY WILL BE CONSIDERED AS VALID TENDERS EVEN THOUGH THE BIDS ARE SUBMITTED ONLINE.

2.THE TENDERER MUST AUTHORISE BID OPENING WITHIN THE TIME STIPULATED IN THE SCHEDULE BY SDSC SHAR. OTHERWISE THE ONLINE BID SUBMITTED WILL NOT BE CONSIDERED FOR EVALUATION. PHYSICAL COPY WILL NOT BE CONSIDERED EVEN THOUGH IT IS RECEIVED BEFORE THE BID SUBMISSION DATE. In case of two-part tenders, parties shall submit their offers as follows:-

1) Part-I – Techno-commercial Bid (No price details shall be mentioned in this bid and shall not upload the details of price along with the techno-commercial bid) 2) Part-II – Price Bid

In view of Two Part Tender, the Offers submitted contrary to above instructions will be summarily rejected. 3.In case, the tenderer is not interested to participate in the tender, the tenderer shall submit regret letter giving reasons, failing which future enquiries will not be sent. 4.Offer Validity: The validity of the offers / tenders should be 90 days (in case of single part tender) and 120 days (in case two part

tender) from the date of opening of the tenders. Tenders with offer validity less than the period mentioned above, will not be considered for evaluation. 5.GST - GST and/or other duties/levies legally leviable and intended to be claimed should be distinctly shown separately in the tender. GST details are given below

GSTIN: 37AAAGS1366J1Z1 LEGAL NAME : SATISH DHAWAN SPACE CENTRE SHAR VALIDITY FROM:29/08/2017

TYPE OF REGISTRATION:REGULAR 6.Customs Duty - SDSC-SHAR is eligible for 100% Customs Duty exemption as per Notification No. 050/2017 539 (b) Dt: 30.06.2017.

This may be taken into account while quoting for import items, if any. In case tenderers offering items considering customs duty exemption, they should also indicate the bill of materials and price, separately, with Customs Duty component and terms and conditions thereto. 8.Advance Payment - Wherever advance payment is requested, Bank Guarantee from any Nationalized Bank/Scheduled Bank should be

furnished. In case of advance payments, if the party is not supplying the material within the delivery schedule, interest will be levied as per the Prime Lending Rate of RBI plus 2% penal interest. Interest will be loaded for advance payments/stage payments as per the prime lending rate of RBI and will be added to the landed cost for comparison purpose. In case of different milestone payments submitted by the parties, a standard and transparent methodology like NPV will be adopted for evaluating the offers.

9.Liquidated Damages - In all cases, delivery schedule indicated in the Purchase Order/Contract is the essence of the contract and if the party fails to deliver the material within the delivery schedule, Liquidated Damages will be levied @ 0.5% per week or part thereof subject to a maximum of 10% of total order value. 10.Performance Bank Guarantee - Performance Bank Guarantee for 10% of the order value should be furnished in the form of Bank

Guarantee from nationalized/scheduled bank or by Demand Draft valid till warranty period plus sixty days as claim period.

Page 1 of 3

11.Security Deposit – Security Deposit for 10% of the order value is mandatory, if the ordered value is Rs.5.00 lakhs and above. Party shall furnish the Security Deposit in the form of Bank Guarantee from nationalized/scheduled bank or by Demand Draft valid till

completion of the contract period plus sixty days towards claim period for faithful execution of the contract. 12.BANK GUARANTEE FOR FIM: Supplier has to submit Bank guarantee for equal value of Free Issue of Materials (FIM) issued by the Department from Nationalised / Scheduled Bank valid till receipt and acceptance of supply and satisfactory accounting of FIM plus sixty days as claim period.

13.The delivery period mentioned in the tender enquiry, IF ANY, is with the stipulation that no credit will be given for earlier deliveries and offers with delivery beyond the period will be treated as unresponsive. 14.The Department will have the option to consider more than one source of supply and final orders will be given accordingly.

15.The bidders should note that conditional discounts would not have edge in the evaluation process of tenders. 16.Non-acceptance of any conditions wherever called for related to Guarantee/ Warranty, Performance Bank Guarantee, Security Deposit, Liquidated damages are liable for disqualification. 17.Wherever installation/ commissioning involved, the guarantee/warrantee period shall reckon only from the date of installation and

commissioning. 18.Purchase/Price Preference will be extended to the MSMEs under the Public Procurement Policy for MSMEs formulated under the Micro, Small and Medium Enterprises Development Act, 2006 and instructions issued by Government of India from time to time. Vendors who would like to avail the benefit of MSME should clearly mention the same and submit all the documentary evidences to substantiate their claim along with tender itself.

19.The drawings, specifications, end use etc., given by the Centre/Unit along with the tender enquiry are confidential and shall not be disclosed to any third party. 20.SPECIAL CONDITIONS FOR SUBMITTING QUOTATIONS IN FOREIGN CURRENCY BY THE INDIAN AGENTS

The Tenderer should submit the following documents/information while quoting:- a)Foreign Principal's proforma invoice/quote indicating the commission payable to the Indian Agent and nature of after sales service to be rendered by the Indian Agent. b)Copy of Agency agreement with the Foreign Principal and the Indian Agent, precise relationship between them and their mutual

interest in the business. c)Registration and item empanelment of the Indian Agent. d)Agency Commission will be paid only Indian Currency.

e)Compliance of the tax laws by the Indian Agent. 21. High Sea Sales- Against High Sea Sale transactions: a.Offers shall be on all inclusive basis including delivery upto Sriharikota at the risk and cost of the supplier. Customs Clearance is the responsibility of the supplier and at his cost and risk.

b.100% payment will be made within 30 days after receipt and acceptance of the items at our site. c. GST as applicable d.Customs Duty Exemption Certificate and other relevant documents required for Customs clearance will be provided.

e.High Sea Sales Agreement furnished by the supplier in accordance with the terms and conditions of our purchase order will be signed and issued by SDSC-SHAR. 22.The following information/ documents are to be submitted wherever applicable.

1.Product Literature 2.Core banking account number of SBI, RTGS Details 3.PAN No. in quotation and invoices

4.GST Registration details. 5.In case of MSME, registration details / documents from Competent Authority. 23.EXCLUSION OF TENDERS

The following tenders shall be summarily rejected from the procurement process a.Tenders received from vendors who have not qualified in terms of their registration. b.Tenders received against publishing of a limited tender in the CPP portal.

c.Tenders of vendors who have been removed from the vendor list or banned/debarred from having business dealings. d.Unsolicited tenders from vendors. e.The tenders which materially depart from the requirements specified in the tender document or which contain false information.

f.The tenders which are not accompanied by the prescribed Earnest Money Deposit. g.The tenders of vendors who have not agreed to furnish Security Deposit, Performance Bank Guarantee and Liquidated Damages. h.The validity of the tenders is shorter than the period specified in the tender enquiry.

i.The tenders received from vendors or their agents or anyone acting on their behalf, who have promised or given to any official of the Centre/Unit/Department, a gratification in any form, or anything of value, so as to unduly influence the procurement process. j.The tenders received from vendors, who, in the opinion of the Centre/Unit, have a conflict of interest materially affecting fair competition.

Page 2 of 3

k.The tenders received from Indian agents on behalf of their foreign Principals/OEMs (in cases where the Principals/OEMs also submit their tenders simultaneously for the same item/product in the same tender).

l.In case two or more tenders are received from an Indian agent on behalf of more than one foreign Principal/OEM, in the same tender for the same item/product. m.If a firm quotes ‘NIL’ charges / consideration, the bid shall be treated as un-responsive and will not be considered.

Page 3 of 3