Specalog for 318C L 318C LN Hydraulic Excavator, AEHQ5481-01 · 2018-12-17 · 2 318C L/318C LN...

Transcript of Specalog for 318C L 318C LN Hydraulic Excavator, AEHQ5481-01 · 2018-12-17 · 2 318C L/318C LN...

®®

EngineEngine Model Cat® 3066TFlywheel Power 93 kW 125 hpGross Power 97 kW 130 hp

WeightsOperating Weight – 19 650 kg 43,320 lbLong Undercarriage

• 318C L – one-piece boom, 3200 mm (10'6") stick, 770 mm(30") bucket, 0.54 m3 (0.71 yd3) bucket capacity, and 600 mm(24") shoes.

Operating Weight – 19 350 kg 42,660 lbLong Narrow Undercarriage

• 318C LN – one-piece boom, 3200 mm (10'6") stick, 770 mm(30") bucket, 0.54 m3 (0.71 yd3) bucket capacity, and 500 mm(20") shoes.

318C L318C LNHydraulic Excavator

2

318C L/318C LN Hydraulic ExcavatorImproved performance and rugged durability combine to maximize productivity.

Increased horsepower, better controllability,extended service intervals and a redesignedoperator station increase your productivityand lower your operating costs.

Complete Customer Support

Your Cat dealer offers a wide rangeof services that can be set up under acustomer support agreement when youpurchase your equipment. The dealer willhelp you choose a plan that can covereverything from machine configurationto eventual replacement. pg. 11

Hydraulics

The open-center, two-pump hydraulicsystem provides high efficiency andreliability. The machine’s pump flowcontrol ensures smooth control, reducessound levels and extends componentlife. pg. 6

Front Linkage

Front linkage variations allow the use ofone boom, three sticks and five bucketsizes for maximum productivity on awide range of jobs. pg. 5

Engine

The new Cat 3066T engine deliversoutstanding performance, high powerand reliability. This compact engineprovides lower sound and vibrationlevels as part of the basic engine design.pg. 4

✔

✔ New Feature

3

Serviceability

Longer service intervals and easiermaintenance result in better machineavailability and lower owning andoperating costs. To simplify servicing,most maintenance items can be reachedfrom ground level. pg. 10

Operator Station

The redesigned operator stationmaximizes operator comfort andvisibility. To increase productivity,all controls, gauges, and pedals arepositioned within easy reach ofthe operator. pg. 9

✔

Undercarriage

Rugged Cat undercarriage designand proven structural manufacturingtechniques ensure outstanding durabilityin the toughest conditions. pg. 8

Torque Rise. The engine is designed forhigh torque rise at medium speeds — afeature that is especially beneficial forheavy-duty use.

Low Sound and Vibration Levels.The engine is attached to the main framewith four rubber mounts. These mountsreduce vibration transmitted to theframe and decrease sound levels.

Maintenance Access. The oil leveldipstick, oil filter, fuel filter and primingpump are located in front of the enginefor easy maintenance. To reducedowntime, the engine oil filter andfuel filter change intervals have beenextended. Valves for engine oil andcoolant have been added on top of theengine to make fluid sampling easier.

Fuel System. Fuel injector pump andinjector nozzle design provide startingease and low sound and emission levels.The spin-on Cat fuel filter makesreplacement quick and easy. A standardfuel system water separator uses a filterto remove water from the fuel system.

Cooling System. A corrugated-wave fin,four-row radiator design makes it easyto clean. A wire mesh screen thatmounts in front of the radiator helpsprevent clogging.

Air Cleaner. The radial seal air filterfeatures a double-layered filter corefor more efficient filtration.

Turbocharger. The turbochargerincreases engine power and efficiencyby compressing atmospheric air boundfor the cylinders. Compressed air givesthe engine more power because itallows the engine to burn additionalfuel more efficiently.

Air Intake Heater. A standard engine airintake heater assists engine starting incold weather.

Emission Countermeasure. The Cat3066T meets all domestic emissioncontrol standards, U.S. EPA standardsand European primary emissioncontrol standards.

High Ambient Cooling Package.Ambient working temperature forthe standard 318C is 43° C (109° F).The optional high ambient coolingpackage has a 52° C (125° F) capacity.The high ambient package attachmentprovides increased radiator fan speedand increased air inlet and outlet ofside covers.

4

EngineThe Cat 3066T engine is built for world-class performance, power, reliability, economyand low emissions.

Front Linkage Attachments. Allows thechoice of one boom, three sticks andfive buckets. Using these combinationsmakes the excavator productive in awide range of applications.

Boom. The reach boom is designed toprovide maximum digging capability.The boom features a box-section designand high-tensile strength steel for highdurability and consistency.

Sticks. The customer’s working envelopeand bucket capacity requirementsdetermine stick choice. Three stickattachments are available: a long stickto maximize reach, medium stick forthe most versatile front linkage or shortstick for a good digging envelope withlarge bucket sizes and good stabilityfor hammer work. All sticks use a box-section design made of high tensile-strength steel and a baffle plate.

Linkage Bearings. Self-lubricated,sintered bearings greatly extend thegreasing interval on front linkage pins byreducing pin friction. Greasing intervalson the bucket swing pin connectionare also extended using a meshbearing design.

Linkage Pin. All pins have thick chromeplating, making them resistant againstgalling and squealing. To smoothlydistribute the shear and side loadsassociated with the stick, the diameterof each pin is made as large as possible.

Buckets. To meet customer needs,five bucket sizes are available forheavy-duty applications. High tensile-strength steel is used in high-stressareas for excellent wear and shockresistance. The side and bottom wearplates and cutting edges are reinforcedfor extra protection.

Bucket-Flop Adjustment Mechanism.Each Cat bucket is equipped with thisfeature, allowing the operator or serviceperson to reduce the side play at thebucket to stick-nose connection.

5

Front LinkageDesigned for maximum flexibility to keep productivity and efficiency high on all jobs.

Precise Control. Hydraulics deliversmooth changes in speed and outstandingoverall control, so operators remaincomfortable and productive throughoutthe day.

Pilot System. The hydraulic pilot systemcontrols the front linkage, swing andtravel operations.

Pilot Control Valve. Pilot control valveoperation is directly proportional tocontrol lever movement, and pilotpressure operates the main control valvespool. This relationship between controllever movement and pilot pressuredelivers outstanding operator control.

Component Layout. The 318C hydraulicsystem was designed to provide a highlevel of efficiency. With all majorcomponents located close together,shorter tubes and lines are needed,resulting in less friction loss in thelines and reduced pressure drops.

Flow Control System. When controls arein neutral position, flow is minimizedresulting in longer component life andlower fuel consumption and sound levels.

Hydraulic Cross-Sensing System.The system utilizes the two mainhydraulic pumps to maximize enginepower under all operating conditions,resulting in faster implement speedsand pivot turns.

Boom and Stick Regeneration Circuit.Saves energy during boom-down andstick-in operation, providing shortercycle times and lower operating costs.

Automatic Boom and Swing Priority.For simpler operation, work modeand power mode switches have beeneliminated. Instead, the automatic boomand swing priority function selects thebest mode, based on joystick movement.

6

Cat hydraulics deliver power and precise control to keep material moving at high volume.

Hydraulics

Boom Priority. The boom-up prioritycircuit is in effect when the boom-uplever is at the point where the boomneeds priority flow during combinedoperations. The boom receives maximumpriority flow when the lever is at fullshift. By setting gradually modulatedboom priority, the 318C avoids boomjump due to sudden priority flow.The boom priority circuit greatly assistsoperators in digging to depths andworking through small swing angles.Because boom priority varies in responseto boom lever stroke, this mode meets awide range of operating requirements.

Boom/Stick Drift Reducing Valves.Valves reduce the natural drift of theboom and stick, so lifted material willremain suspended for long periodswith virtually no drift.

Reverse Swing Damping Valve.Standard reverse swing-damping valvesreduce swing wag.

Auxiliary Hydraulic Valve. The auxiliaryhydraulic valve is standard on the 318Cfor use with optional hydraulic circuits.

Stackable Valves. Up to two stackablevalves can be used in combinationwith the main control valve, allowingadditional tool circuits to be added.

Hydraulic Cylinder Snubbers.Snubbers are located at the rod-endof the boom cylinders and both endsof the stick cylinders to cushion shockswhile reducing sound levels andextending cylinder life.

Electronic Power Unit Control System.Protection of the Electronic PowerUnit Control System (EPC) has beenimproved. Input-output terminals andelectric terminals are fully protectedso reverse connections or shorts donot affect the main unit.

Automatic Engine Speed Control.During no-load and lighter-loadconditions, the automatic engine speedcontrol reduces engine speed and iscontrolled by the EPC.

Fine Swing Control. A fine swingcontrol mechanism is available as anattachment for applications requiringsmoother movements at swing stop.

7

Track Types. The 318C is availablewith two different track types: longand long narrow.

Carbody and Track Roller Frame.X-shaped, box-section carbody provideshigh rigidity and excellent resistanceto torsional bending. The track frame ismade from a press-formed pentagonalsection for maximum strength and longservice life.

Grease-Lubricated Track. Grease-lubricated seals protect the track linkand provide longer wear life by helpingto keep dirt and debris from enteringthe pin and bushing joint.

Roller Lubrication. All rollers, sprocketsand idler joints are closed with floatingseals. Lubricating oil from the sealsprevents water and dirt from entering.The seals also make lubricationmaintenance-free.

Travel Motors. Automatic speedselection enables the machine toautomatically shift up and downfrom high and low speeds in a smooth,controlled manner. The 318C featuresincreased drawbar pull for excellentmaneuverability on slopes and inmuddy underfoot conditions.

Track Guards. The idler guard andbolt-on center guard are standardequipment. They help maintain trackalignment while traveling or workingon slopes. For applications that requireadditional track protection or alignment,optional guards are available.

Straight-Line Travel Circuit. This circuitallows the 318C to maintain low-speed,straight-line travel, even when operatingthe front linkage. This circuit is especiallyuseful when turning the upper structurewhile traveling, using a wrecking ball orsimilar tool, and for precise finishingor final leveling.

Final Drive. Two-stage reductionplanetary drives feature a completedrive/brake unit, delivering excellentperformance, reliability and compact size.

8

UndercarriageDurable undercarriage absorbs stresses and provides excellent stability.

Cab Design. The cab has beenredesigned to maximize operatorcomfort and space. The air conditionerand attachment switches are convenientlylocated on the right-hand wall, and thekey switch and throttle dial are situatedon the right-hand console.

Monitor. The compact monitorenhances viewing while displaying avariety of easy-to-read and understandlanguage-based information.

Cab Exterior. The new exterior designuses thick steel tubing, running fromthe rear to the bottom of the front of thecab for improved resistance to fatigueand vibration.

Cab Mounts. The cab shell is attachedto the frame with viscous rubber cabmounts, reducing vibrations and soundlevels for enhanced operator comfort.

Windows. The right side glass isattached directly to the window framewith adhesive for improved visibility.The upper front windshield opens,closes and stores above the operatorwith a one-touch action release system.The lower front windshield featuresa rounded design to maximizedownward visibility.

Skylight. An enlarged skylight withsunshade provides excellent visibilityand good ventilation.

Wipers. Pillar-mounted wipers increasethe operator’s viewing area and offercontinuous and intermittent modes.

Consoles. Redesigned consoles feature asimple, functional design. Both consoleshave attached adjustable armrests.

Seat. The new seat features two types ofcushions, soft and firm, to reduce operatorfatigue and support the operator in theproper position.

Automatic Climate Control. The 318Cfeatures a fully automatic climatecontrol. The air conditioner adjuststemperature and flow and determineswhich air outlet would be best usedin particular situations.

Standard Cab Equipment. To enhanceoperator comfort and productivity, thecab includes a lighter, drink holder, coathook, service meter, literature holder,magazine rack and storage compartment.

9

Operator StationDesigned for simple, easy operation, the 318C allows the operator to focus on production.

Prestart Monitoring System. The prestartmonitoring system allows the operatorto check coolant, hydraulic oil andengine oil levels from the monitorinside the cab.

Diagnostics and Monitoring. The 318Cis equipped with S•O•SSM sampling portsand hydraulic test ports for the hydraulicsystem, engine oil and coolant.

Engine Inspection. The engine canbe accessed from the upper structure.The oil level gauge, oil filter, fuel filterand priming pump are all located infront of the engine for easy maintenance.

Air Filter Compartment. The air filterfeatures a double-element constructionfor superior cleaning efficiency.When the air cleaner clogs, a warning isdisplayed on the monitor inside the cab.

Radiator Compartment. The left rearservice door allows easy access to theengine radiator and oil cooler. A reservetank simplifies maintenance.

Swing-Out Oil Cooler. Oil cooler swingsout horizontally for easy cleaning.

Fan Guard. Engine radiator fan iscompletely enclosed by fine wire mesh,reducing the risk of injury.

Pump Compartment. A service dooron the right side of the upper structureallows ground-level access to the pumpand pilot filter.

Handrail and Steps. Large handrails andsteps assist the operator in climbing onand off the machine.

Punched-Star Plate. Anti-skid punched-star plate covers the top of the storagebox and upper structure to help preventslipping during maintenance.

Capsule Filter. The hydraulic returnfilter, a capsule filter, is situated insidethe hydraulic tank. This filter preventscontaminants from entering the systemwhen hydraulic oil is changed.

Extended Service Intervals.Extended service and maintenanceintervals reduce service time andincrease machine availability.

Ground Level Service. Many servicelocations are easily accessible at groundlevel allowing critical maintenance toget done quickly and efficiently.

Greasing Points. A concentrated remotegreasing block on the boom deliversgrease to hard-to-reach locations.

Storage Box. The storage box islocated at the front of the upperstructure. Tools, grease guns and otherrepair equipment can be stored in thisspace. The lockable storage box alsoaccommodates a refueling pump, whichis available as an attachment; however,adding these attachments eliminatesstorage area.

10

ServiceabilitySimplified service and maintenance save you time and money.

Selection. Make detailed comparisonsof the machines you are consideringbefore you buy. What are the jobrequirements, machine attachmentsand operating hours? What productionis needed? What is the true cost of lostproduction? Your Cat dealer can giveprecise answers to these questions.

Purchase. Look past the initial price;look at the value the 318C offers.Consider the resale value and compareproductivity and day-to-day operatingcosts. Consult your local Cat dealerfor financing options.

Operation. For the best operatingtechniques to increase productivityand your profit, turn to your Cat dealerfor the latest training literature andtrained staff.

Maintenance. Repair option programsguarantee the cost of repairs up front.Diagnostic programs such as S•O•Sand Technical Analysis help youavoid unscheduled repairs.

Replacement. Repair, rebuild or replace?Your Cat dealer can help you evaluatethe cost involved so you can make theright choice.

Product Support. You will find nearlyall parts at our dealer parts counter.Cat dealers utilize a worldwide computernetwork to find in-stock parts to minimizemachine downtime. You can save moneywith Cat remanufactured components.

Warranty. Your local Cat dealer isthere to support and protect you.Extended warranty options arealso available.

11

Complete Customer SupportCat dealer services help you operate longer with lower costs.

12 318C L/318C LN Hydraulic Excavator specifications

Hydraulic System

Main Implement System – 190 L/min 50.2 gal/minMaximum Flow (2x)Maximum Pressure – Implements 34 320 kPa 4,980 psiMaximum Pressure – Travel 34 320 kPa 4,980 psiMaximum Pressure – Swing 20 100 kPa 2,915 psiPilot System – Maximum Flow 32.4 L/min 8.6 gal/minPilot System – Maximum Pressure 3930 kPa 570 psiBoom Cylinder – Bore 120 mm 5 inBoom Cylinder – Stroke 1193 mm 47 inStick Cylinder – Bore 130 mm 5.1 inStick Cylinder – Stroke 1364 mm 54 inBucket Cylinder – Bore 110 mm 4.3 inBucket Cylinder – Stroke 1048 mm 41 in

Service Refill Capacities

Fuel Tank 320 L 85 galCooling System 14 L 3.7 galEngine Oil 30 L 7.9 galSwing Drive 8 L 2.1 galFinal Drive (Each) 10 L 2.6 galHydraulic System (Including Tank) 255 L 67.4 galHydraulic Tank 127 L 33.6 gal

Sound Performance

Performance ANSI/SAE J1166 OCT98

• The operator sound exposure Leq (equivalent soundpressure level) measured according to the work cycleprocedures specified in ANSI/SAE J1166 OCT98 is 74 dB(A),for the cab offered by Caterpillar, when properly installedand maintained and tested with the doors andwindows closed.

• Hearing protection may be needed when operating withan open operator station and cab (when not properlymaintained or with doors/windows open) for extendedperiods or in a noisy environment.

Engine

Engine Model Cat 3066TFlywheel Power 93 kW 125 hpGross Power 97 kW 130 hpISO 9249 93 kW 125 hpSAE J1349 93 kW 125 hpEEC 80/1269 93 kW 125 hpBore 102 mm 4 inStroke 130 mm 5.1 inDisplacement 6.37 L 389 in3

• The 318C L/318C LN meets US Tier 2 and EU Stage IIemissions requirements.

Weights

Operating Weight – 19 650 kg 43,320 lbLong Undercarriage

• 318C L – one-piece boom, 3200 mm (10'6") stick, 770 mm(30") bucket, 0.54 m3 (0.71 yd3) bucket capacity, and 600 mm(24") shoes.

Operating Weight – 19 350 kg 42,660 lbLong Narrow Undercarriage

• 318C LN – one-piece boom, 3200 mm (10'6") stick, 770 mm(30") bucket, 0.54 m3 (0.71 yd3) bucket capacity, and 500 mm(20") shoes.

Swing Mechanism

Swing Torque 50 000 N·m 36,875 lb ftSwing Speed 10.8 RPM

Drive

Maximum Drawbar Pull 202 kN 45,500 lbTravel Speed 5.5 kph 3.3 mph

13318C L/318C LN Hydraulic Excavator specifications

3

2

1

54

87

6

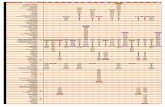

DimensionsAll dimensions are approximate.

Boom 5.30 m (17'5") 2250 mm (7'5") Stick 2700 mm (8'10") Stick 3200 mm (10'6") Stick1 Shipping height 3080 mm (10'1") 3120 mm (10'3") 3480 mm (11'6")

2 Shipping length 8870 mm (29'1") 8820 mm (28'11") 8830 mm (29')

3 Tail swing radius 2540 mm (8'4") 2540 mm (8'4") 2540 mm (8'4")

4 Length to centers of rollers318C L 3450 mm (11'4") 3450 mm (11'4") 3450 mm (11'4")318C LN 3450 mm (11'4") 3450 mm (11'4") 3450 mm (11'4")

5 Track length318C L 4250 mm (13'11") 4250 mm (13'11") 4250 mm (13'11")318C LN 4250 mm (13'11") 4250 mm (13'11") 4250 mm (13'11")

6 Ground clearance 460 mm (1'6") 460 mm (1'6") 460 mm (1'6")

7 Track gauge318C L 2200 mm (7'3") 2200 mm (7'3") 2200 mm (7'3")318C LN 1990 mm (6'6") 1990 mm (6'6") 1990 mm (6'6")

8 Transport width500 mm (20") shoes

318C L —318C LN 2550 mm (8'4")* 2550 mm (8'4")* 2550 mm (8'4")*

600 mm (24") shoes318C L 2800 mm (9'2") 2800 mm (9'2") 2800 mm (9'2")318C LN 2590 mm (8'6") 2590 mm (8'6") 2590 mm (8'6")

700 mm (28") shoes318C L 2900 mm (9'6") 2900 mm (9'6") 2900 mm (9'6")318C LN —

800 mm (32") shoes318C L 3000 mm (9'10") 3000 mm (9'10") 3000 mm (9'10")318C LN —

—

—

—

—

—

—

* Width defined by upper structure.

14 318C L/318C LN Hydraulic Excavator specifications

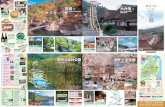

Working Ranges

Stick Length 2250 mm (7'5") 2700 mm (8'10") 3200 mm (10'6")Bucket (SAE m3/yd3 0.86 m3 (1.12 yd3 0.70 m3 (0.92 yd3) HD 0.54 m3 (0.71 yd3) HD

1 Maximum Digging Depth 5920 mm (19'5") 6370 mm (20'10") 6870 mm (22'6")

2 Maximum Reach on Ground 8650 mm (28'5") 9110 mm (29'11") 9630 mm (31'7")

3 Maximum Reach 8820 mm (28'11") 9260 mm (30'7') 9780 mm (32'1")

4 Minimum Loading Height 2810 mm (9'3") 2350 mm (7'6") 1860 mm (6'1")

5 Maximum Loading Height 6160 mm (20'3") 6460 mm (21'3") 6860 mm (22'6")

Minimum Front Swing Radius 3120 mm (10'3") 3120 mm (10'3") 3070 mm (10'1")

6 Maximum Depth Cut for2440 mm (8') Level Bottom 5600 mm (18'4") 6070 mm (19'11") 6590 mm (21'7")

7 Maximum Vertical Wall Digging Depth 4830 mm (15'10") 5400 mm (17'8") 6010 mm (19'9")

8 Maximum Height to Bucket 8920 mm (29'3") 9240 mm (30'4") 9650 mm (31'8')Teeth at Height Arc

Bucket Digging Force (SAE) 130 kN (29,200 lb) 111 kN (25,000 lb) 112 kN (25,200 lb)

Stick Digging Force (SAE) 103 kN (23,200 lb) 88 kN (19,800 lb) 79 kN (17,800 lb)

➤

2700 mm (8'10")3200 mm (10'6")

2250 mm (7'5")

➤

2

1

8

7

4

➤

➤

➤

➤

➤

➤➤

➤➤

3➤➤

➤

5

6

➤

➤0

1

2

3

4

5

6

7

8

6

7

5

4

3

2

1

012345678910 1

05101520253035

Meters

Feet

15

10

20

5

0

5

10

15

20

25

30 9

MetersFeet

) HD)

15318C L/318C LN Hydraulic Excavator specifications

318C LNTrack width Operating Weight Operating Weight Operating WeightStick 2250 mm (7'5") 2700 mm (8'10") 3200 mm (10'6")Standard

500 mm (20") triple grouser 19 450 kg (42,880 lb) 19 250 kg (42,440 lb) 19 350 kg (42,660 lb)Optional

600 mm (24") triple grouser 19 700 kg (43,410 lb) 19 500 kg (42,970 lb) 19 600 kg (43,190 lb)

Operating WeightsCaterpillar designed and built track-type undercarriage.

318C LTrack width Operating Weight Operating Weight Operating WeightStick 2250 mm (7'5") 2700 mm (8'10") 3200 mm (10'6")Standard

600 mm (24") triple grouser 19 750 kg (43,540 lb) 19 650 kg (43,320 lb) 19 650 kg (43,320 lb)Optional

700 mm (28") triple grouser 20 100 kg (44,340 lb) 20 000 kg (44,120 lb) 20 000 kg (44,120 lb)800 mm (32") triple grouser 20 350 kg (44,910 lb) 20 250 kg (44,690 lb) 20 250 kg (44,690 lb)

UndercarriageCaterpillar designed and built track-type undercarriage.

Ground PressureTrack width 318C L 318C LNStandard

500 mm (20") triple grouser — 50.9 kPa (7.4 psi)

600 mm (24") tripler grouser 43.1 kPa (6.2 psi) —

Optional

600 mm (24") triple grouser — 42.9 kPa (6.2 psi)

700 mm (28") triple grouser 37.6 kPa (5.5 psi) —

800 mm (32") triple grouser 33.3 kPa (4.8 psi) —

16 318C L/318C LN Hydraulic Excavator specifications

BucketsBuckets have tapered sides, angled corner teeth, dual radius curvature, horizontal wear strips, and holes for optional side cutters.

Heavy Duty Rock BucketWidth Capacity Number Weight with Teeth Tip Radius

mm in m3 yd3 of Teeth kg lb mm in620 24 0.40 0.52 3 694 1530 1520 60770 30 0.54 0.71 4 770 1698 1520 60930 36 0.70 0.92 5 854 1883 1520 60

1080 42 0.86 1.12 5 878 1936 1420 561230 48 1.02 1.33 6 983 2167 1420 56

318C LRecommended Maximum Material Density

Width Capacity Short Stick Medium Stick Long Stickmm in m3 yd3 kg/m3 lbs/yd3 kg/m3 lbs/yd3 kg/m3 lbs/yd3

620 24 0.40 0.52 1800 3000 1800 3000 1800 3000770 30 0.54 0.71 1800 3000 1800 3000 1800 3000930 36 0.70 0.92 1800 3000 1800 3000 1800 3000

1080 42 0.86 1.12 1800 3000 1800 3000 1200 20001230 48 1.02 1.33 1500 2500 1200 2000 900 1500

318C LNRecommended Maximum Material Density

Width Capacity Short Stick Medium Stick Long Stickmm in m3 yd3 kg/m3 lbs/yd3 kg/m3 lbs/yd3 kg/m3 lbs/yd3

620 24 0.40 0.52 1800 3000 1800 3000 1800 3000770 30 0.54 0.71 1800 3000 1800 3000 1800 3000930 36 0.70 0.92 1800 3000 1800 3000 1500 2500

1080 42 0.86 1.12 1500 2500 1500 2500 900 15001230 48 1.02 1.33 1200 2000 900 1500 900 1500

Material DensitiesMaterial kg/m3 lb/yd3 Material kg/m3 lb/yd3

Clay, dry 1480 2500 Gravel, pitrun 1930 3250Clay, wet 1660 2800 Rock/dirt, 50% 1720 2900Earth, dry 1510 2550 Sand, dry 1420 2400Earth, wet 1600 2700 Sand, wet 1840 3100Loam 1250 2100 Sand and clay 1600 2700Gravel, dry 1510 2550 Stone, crushed 1600 2700Gravel, wet 2020 3400 Top soil 950 1600

17318C L/318C LN Hydraulic Excavator specifications

Load atMaximum Reach

Load PointHeight

Load RadiusOver Front

Load RadiusOver Side

Reach Boom Lift Capacities (318C L)

STICK – 2700 mm (8'10")BUCKET – 0.70 m3 (0.92 yd3)/36"

UNDERCARRIAGE – LongSHOES – 600 mm (24") triple grouser

BOOM – 5300 mm (17'5")

* Limited by hydraulic capacity rather than tipping load. The above loads are in compliance with SAE hydraulic excavator lift capacity rating standard J1097.They do not exceed 87% of hydraulic lifting capacity or 75% of tipping capacity. Weight of all lifting accessories must be deducted from the abovelifting capacities.

STICK – 2700 mm (8'10")BUCKET – 0.70 m3 (0.92 yd3)/36"

UNDERCARRIAGE – LongSHOES – 700 mm (28") triple grouser

BOOM – 5300 mm (17'5")

1.5 m (5.0 ft) 3.0 m (10.0 ft) 4.5 m (15.0 ft) 6.0 m (20.0 ft) 7.5 m (25.0 ft)

m

ft

7.5 m kg *1860 *1860 6.9025.0 ft lb *4130 *4130 22.22

6.0 m kg *3630 *3630 *1720 *1720 8.0620.0 ft lb *7960 *7960 *3800 *3800 26.24

4.5 m kg *4130 3700 *3100 2430 *1700 *1700 8.7215.0 ft lb *9010 7930 *6820 5350 *3750 *3750 28.53

3.0 m kg *9620 *9620 *6130 5700 *4860 3530 4070 2340 *1770 1670 9.0210.0 ft lb *20,440 *20,440 *13,200 12,270 *10,540 7580 *8630 4990 *3890 3680 29.57

1.5 m kg *7780 5240 *5670 3330 3980 2260 *1930 1620 9.005.0 ft lb *16,780 11,290 *12,280 7160 8530 4830 *4240 3570 29.54

Ground kg *5130 *5130 *8820 4950 5620 3180 3900 2190 *2200 1710 8.67Line lb *11,850 *11,850 *19,060 10,650 12,060 6820 8370 4680 *4850 3760 28.44

–1.5 m kg *4800 *4800 *8720 *8720 8940 4850 5530 3100 *2690 1980 7.98–5.0 ft lb *10,770 *10,770 *19,920 *19,920 19,160 10,420 11,890 6660 *5940 4370 26.13

–3.0 m kg *8830 *8830 *12,630 9660 *8520 4890 5570 3130 *3540 2650 6.80–10.0 ft lb *19,870 *19,870 *27,320 20,700 *18,380 10,530 11,970 6740 *7680 5900 22.16

–4.5 m kg *9890 *9890 *6640 5110 *5520 4250 5.08–15.0 ft lb *21,100 *21,100 *13,980 11,020 *12,180 9670 16.36

* Limited by hydraulic capacity rather than tipping load. The above loads are in compliance with SAE hydraulic excavator lift capacity rating standard J1097.They do not exceed 87% of hydraulic lifting capacity or 75% of tipping capacity. Weight of all lifting accessories must be deducted from the abovelifting capacities.

1.5 m (5.0 ft) 3.0 m (10.0 ft) 4.5 m (15.0 ft) 6.0 m (20.0 ft) 7.5 m (25.0 ft)

m

ft

7.5 m kg *1860 *1860 6.9025.0 ft lb *4130 *4130 22.22

6.0 m kg *3630 *3630 *1720 *1720 8.0620.0 ft lb *7960 *7960 *3800 *3800 26.24

4.5 m kg *4130 3700 *3100 2480 *1700 *1700 8.7215.0 ft lb *9010 8080 *6820 5460 *3750 *3750 28.53

3.0 m kg *9620 *9620 *6130 5800 *4860 3600 4150 2390 *1770 1710 9.0210.0 ft lb *20,440 *20,440 *13,200 12,480 *10,540 7720 *8630 5100 *3890 3770 29.57

1.5 m kg *7780 5340 *5670 3400 4060 2310 *1930 1660 9.005.0 ft lb *16,780 11,500 *12,280 7300 8710 4940 *4240 3660 29.54

Ground kg *5130 *5130 *8820 5050 5730 3240 3980 2240 *2200 1750 8.67Line lb *11,850 *11,850 *19,060 10,860 12,300 6960 8550 4790 *4850 3850 28.44

–1.5 m kg *4800 *4800 *8720 *8720 *9070 4950 5640 3170 *2690 2030 7.98–5.0 ft lb *10,770 *10,770 *19,920 *19,920 19,530 10,630 12,120 6810 *5940 4480 26.13

–3.0 m kg *8830 *8830 *12,630 9830 *8520 4990 5680 3200 *3540 2700 6.80–10.0 ft lb *19,870 *19,870 *27,320 21,080 *18,380 10,740 12,210 6890 *7680 6030 22.16

–4.5 m kg *9890 *9890 *6640 5200 *5520 4340 5.08–15.0 ft lb *21,100 *21,100 *13,980 11,230 *12,180 9860 16.36

18 318C L/318C LN Hydraulic Excavator specifications

Load atMaximum Reach

Load PointHeight

Load RadiusOver Front

Load RadiusOver Side

Reach Boom Lift Capacities (318C L)

STICK – 2700 mm (8'10")BUCKET – 0.70 m3 (0.92 yd3)/36"

UNDERCARRIAGE – LongSHOES – 800 mm (32") triple grouser

BOOM – 5300 mm (17'5")

* Limited by hydraulic capacity rather than tipping load. The above loads are in compliance with SAE hydraulic excavator lift capacity rating standard J1097.They do not exceed 87% of hydraulic lifting capacity or 75% of tipping capacity. Weight of all lifting accessories must be deducted from the abovelifting capacities.

STICK – 3200 mm (10'6")BUCKET – 0.54 m3 (0.71 yd3)/30"

UNDERCARRIAGE – LongSHOES – 600 mm (24") triple grouser

BOOM – 5300 mm (17'5")

1.5 m (5.0 ft) 3.0 m (10.0 ft) 4.5 m (15.0 ft) 6.0 m (20.0 ft) 7.5 m (25.0 ft)

m

ft

7.5 m kg *1860 *1860 6.9025.0 ft lb *4130 *4130 22.22

6.0 m kg *3630 *3630 *1720 *1720 8.0620.0 ft lb *7960 *7960 *3800 *3800 26.24

4.5 m kg *4130 3810 *3100 2520 *1700 *1700 8.7215.0 ft lb *9010 8180 *6820 5540 *3750 *3750 28.53

3.0 m kg *9620 *9620 *6130 5870 *4860 3640 4210 2430 *1770 1740 9.0210.0 ft lb *20,440 *20,440 *13,200 12,630 *10,540 7830 *8630 5180 *3890 3830 29.57

1.5 m kg *7780 5410 *5670 3450 4120 2350 *1930 1690 9.005.0 ft lb *16,780 11,650 *12,280 7400 8830 5020 *4240 3720 29.54

Ground kg *5130 *5130 *8820 5120 5810 3290 4040 2280 *2200 1780 8.67Line lb *11,850 *11,850 *19,060 11,010 12,470 7070 8680 4870 *4850 3920 28.44

–1.5 m kg *4800 *4800 *8720 *8720 *9070 5010 5720 3220 *2690 2060 7.98–5.0 ft lb *10,770 *10,770 *19,920 *19,920 *19,630 10,780 12,290 6910 *5940 4550 26.13

–3.0 m kg *8830 *8830 *12,630 9660 *8520 5060 5760 3250 *3540 2740 6.80–10.0 ft lb *19,870 *19,870 *27,320 21,350 *18,380 10,880 12,380 6990 *7680 6120 22.16

–4.5 m kg *9890 *9890 *6640 5270 *5520 4400 5.08–15.0 ft lb *21,100 *21,100 *13,980 11,380 *12,180 9990 16.36

* Limited by hydraulic capacity rather than tipping load. The above loads are in compliance with SAE hydraulic excavator lift capacity rating standard J1097.They do not exceed 87% of hydraulic lifting capacity or 75% of tipping capacity. Weight of all lifting accessories must be deducted from the abovelifting capacities.

1.5 m (5.0 ft) 3.0 m (10.0 ft) 4.5 m (15.0 ft) 6.0 m (20.0 ft) 7.5 m (25.0 ft)

m

ft

7.5 m kg *1620 *1620 7.6025.0 ft lb *3610 *3610 24.58

6.0 m kg *3160 *3160 *2520 *2520 *1500 *1500 8.6420.0 ft lb *6930 *6930 *5030 *5030 *3320 *3320 28.19

4.5 m kg *3700 *3700 *3340 2490 *1480 *1480 9.2615.0 ft lb *8070 *8070 *7020 5330 *3250 *3250 30.30

3.0 m kg *7930 *7930 *5460 *5460 *4470 3610 *3990 2400 *1520 1510 9.5410.0 ft lb *16,860 *16,860 *11,760 *11,760 *9700 7750 *8710 5120 *3350 3330 31.28

1.5 m kg *7240 5370 *5360 3390 4020 2300 *1640 1470 9.535.0 ft lb *15,610 11,560 *11,600 7280 8620 4910 *3610 3230 31.26

Ground kg *5190 *5190 *8520 5010 5650 3200 3920 2200 *1850 1530 9.22Line lb *12,000 *12,000 *18,430 10,780 12,140 6880 8410 4720 *4070 3380 30.25

–1.5 m kg *3930 *3930 *7720 *7720 8940 4850 5530 3100 3870 2160 *2210 1740 8.59–5.0 ft lb *8820 *8820 *17,630 *17,630 19,170 10,420 11,880 6660 8310 4620 *4880 3850 28.12

–3.0 m kg *7210 *7210 *12 080 9540 *8790 4840 5520 3090 *2890 2220 7.53–10.0 ft lb *16,240 *16,240 *27,670 20,450 *19,000 10,410 11,870 6640 *6430 4950 24.55

–4.5 m kg *11 780 *11 780 *11 170 9840 *7500 4990 *2840 *2840 5.77–15.0 ft lb *26,760 *26,760 *23,950 21,130 *16,010 10,750 *6210 *6210 18.56

19318C L/318C LN Hydraulic Excavator specifications

Load atMaximum Reach

Load PointHeight

Load RadiusOver Front

Load RadiusOver Side

Reach Boom Lift Capacities (318C L)

STICK – 3200 mm (10'6")BUCKET – 0.54 m3 (0.71 yd3)/30"

UNDERCARRIAGE – LongSHOES – 700 mm (28") triple grouser

BOOM – 5300 mm (17'5")

* Limited by hydraulic capacity rather than tipping load. The above loads are in compliance with SAE hydraulic excavator lift capacity rating standard J1097.They do not exceed 87% of hydraulic lifting capacity or 75% of tipping capacity. Weight of all lifting accessories must be deducted from the abovelifting capacities.

STICK – 3200 mm (10'6")BUCKET – 0.54 m3 (0.71 yd3)/30"

UNDERCARRIAGE – LongSHOES – 800 mm (32") triple grouser

BOOM – 5300 mm (17'5")

1.5 m (5.0 ft) 3.0 m (10.0 ft) 4.5 m (15.0 ft) 6.0 m (20.0 ft) 7.5 m (25.0 ft)

m

ft

7.5 m kg *1620 *1620 7.6025.0 ft lb *3610 *3610 24.58

6.0 m kg *3160 *3160 *2520 *2520 *1500 *1500 8.6420.0 ft lb *6930 *6930 *5030 *5030 *3320 *3320 28.19

4.5 m kg *3700 *3700 *3340 2540 *1480 *1480 9.2615.0 ft lb *8070 *8070 *7020 5440 *3250 *3250 30.30

3.0 m kg *7930 *7930 *5460 *5460 *4470 3680 *3990 2450 *1520 *1520 9.5410.0 ft lb *16,860 *16,860 *11,760 *11,760 *9700 7890 *8710 5230 *3350 *3350 31.28

1.5 m kg *7240 5470 *5360 3460 4100 2350 *1640 1510 9.535.0 ft lb *15,610 11,770 *11,600 7420 8800 5020 *3610 3320 31.26

Ground kg *5190 *5190 *8520 5110 5760 3270 4000 2250 *1850 1570 9.22Line lb *12,000 *12,000 *18,430 10,990 12,370 7030 8590 4830 *4070 3460 30.25

–1.5 m kg *3930 *3930 *7720 *7720 *9050 4940 5640 3170 3950 2210 *2210 1790 8.59–5.0 ft lb *8820 *8820 *17,630 *17,630 19,530 10,630 12,120 6800 8480 4730 *4880 3940 28.12

–3.0 m kg *7210 *7210 *12 080 9710 *8790 4940 5630 3160 *2890 2280 7.53–10.0 ft lb *16,240 *16,240 *27,670 20,820 *19,000 10,620 12,100 6790 *6430 5060 24.55

–4.5 m kg *11 780 *11 780 *11 170 10 020 *7500 5080 *2840 *2840 5.77–15.0 ft lb *26,760 *26,760 *23,950 21,510 *16,010 10,950 *6210 *6210 18.56

* Limited by hydraulic capacity rather than tipping load. The above loads are in compliance with SAE hydraulic excavator lift capacity rating standard J1097.They do not exceed 87% of hydraulic lifting capacity or 75% of tipping capacity. Weight of all lifting accessories must be deducted from the abovelifting capacities.

1.5 m (5.0 ft) 3.0 m (10.0 ft) 4.5 m (15.0 ft) 6.0 m (20.0 ft) 7.5 m (25.0 ft)

m

ft

7.5 m kg *1620 *1620 7.6025.0 ft lb *3610 *3610 24.58

6.0 m kg *3160 *3160 *2520 *2520 *1500 *1500 8.6420.0 ft lb *6930 *6930 *5030 *5030 *3320 *3320 28.19

4.5 m kg *3700 *3700 *3340 2580 *1480 *1480 9.2615.0 ft lb *8070 *8070 *7020 5520 *3250 *3250 30.30

3.0 m kg *7930 *7930 *5460 *5460 *4470 3720 *3990 2480 *1520 *1520 9.5410.0 ft lb *16,860 *16,860 *11,760 *11,760 *9700 8000 *8710 5310 *3350 *3350 31.28

1.5 m kg *7240 5530 *5360 3500 4160 2380 *1640 1530 9.535.0 ft lb *15,610 11,910 *11,600 7530 8920 5100 *3610 3380 31.26

Ground kg *5190 *5190 *8520 5180 5840 3320 4060 2290 *1850 1600 9.22Line lb *12,000 *12,000 *18,430 11,140 12,540 7130 8720 4910 *4070 3530 30.25

–1.5 m kg *3930 *3930 *7720 *7720 *9050 5010 5720 3210 4010 2240 *2210 1820 8.59–5.0 ft lb *8820 *8820 *17,630 *17,630 *19,580 10,780 12,290 6900 8610 4810 *4880 4010 28.12

–3.0 m kg *7210 *7210 *12 080 9840 *8790 5010 5710 3200 *2890 2310 7.53–10.0 ft lb *16,240 *16,240 *27,670 21,100 *19,000 10,770 12,270 6890 *6430 5140 24.55

–4.5 m kg *11 780 *11 780 *11 170 10 150 *7500 5150 *2840 *2840 5.77–15.0 ft lb *26,760 *26,760 *23,950 21,780 *16,010 11,100 *6210 *6210 18.56

20 318C L/318C LN Hydraulic Excavator specifications

Load atMaximum Reach

Load PointHeight

Load RadiusOver Front

Load RadiusOver Side

Reach Boom Lift Capacities (318C LN)

STICK – 2700 mm (8'10")BUCKET – 0.70 m3 (0.92 yd3)/36"

UNDERCARRIAGE – Long NarrowSHOES – 500 mm (20") triple grouser

BOOM – 5300 mm (17'5")

* Limited by hydraulic capacity rather than tipping load. The above loads are in compliance with SAE hydraulic excavator lift capacity rating standard J1097.They do not exceed 87% of hydraulic lifting capacity or 75% of tipping capacity. Weight of all lifting accessories must be deducted from the abovelifting capacities.

STICK – 2700 mm (8'10")BUCKET – 0.70 m3 (0.92 yd3)/36"

UNDERCARRIAGE – Long NarrowSHOES – 600 mm (24") triple grouser

BOOM – 5300 mm (17'5")

1.5 m (5.0 ft) 3.0 m (10.0 ft) 4.5 m (15.0 ft) 6.0 m (20.0 ft) 7.5 m (25.0 ft)

m

ft

7.5 m kg *1860 *1860 6.9025.0 ft lb *4130 *4130 22.22

6.0 m kg *3630 3390 *1720 *1720 8.0620.0 ft lb *7960 7280 *3800 *3800 26.24

4.5 m kg *4130 3260 *3100 2110 *1700 1590 8.7215.0 ft lb *9010 6990 *6820 4650 *3750 3530 28.53

3.0 m kg *9620 9600 *6130 5010 *4860 3090 4000 2030 *1770 1420 9.0210.0 ft lb *20,440 *20,440 *13,200 10,790 *10,540 6640 8570 4320 *3890 3130 29.57

1.5 m kg *7780 4570 *5670 2900 3910 1940 *1930 1380 9.005.0 ft lb *16,780 9830 12,250 6230 8390 4150 *4240 3030 29.54

Ground kg *5130 *5130 *8820 4280 5530 2750 3840 1880 *2200 1450 8.67Line lb *11,850 *11,850 *19,060 9210 11,870 5900 8230 4010 *4850 3190 28.44

–1.5 m kg *4800 *4800 *8720 8020 8800 4180 5450 2670 *2690 1690 7.98–5.0 ft lb *10,770 *10,770 *19,920 17,210 18,870 8990 11,700 5740 *5940 3740 26.13

–3.0 m kg *8830 *8830 *12,630 8210 *8520 4230 5480 2700 *3540 2290 6.80–10.0 ft lb *19,870 *19,870 *27,320 17,610 *18,380 9090 11,780 5820 *7680 5100 22.16

–4.5 m kg *9890 8570 *6640 4430 *5520 3700 5.08–15.0 ft lb *21,100 18,430 *13,980 9570 *12,180 8410 16.36

* Limited by hydraulic capacity rather than tipping load. The above loads are in compliance with SAE hydraulic excavator lift capacity rating standard J1097.They do not exceed 87% of hydraulic lifting capacity or 75% of tipping capacity. Weight of all lifting accessories must be deducted from the abovelifting capacities.

1.5 m (5.0 ft) 3.0 m (10.0 ft) 4.5 m (15.0 ft) 6.0 m (20.0 ft) 7.5 m (25.0 ft)

m

ft

7.5 m kg *1860 *1860 6.9025.0 ft lb *4130 *4130 22.22

6.0 m kg *3630 3440 *1720 *1720 8.0620.0 ft lb *7960 7380 *3800 *3800 26.24

4.5 m kg *4130 3310 *3100 2150 *1700 1620 8.7215.0 ft lb *9010 7090 *6820 4730 *3750 3600 28.53

3.0 m kg *9620 *9620 *6130 5080 *4860 3140 4070 2060 *1770 1450 9.0210.0 ft lb *20,440 *20,440 *13,200 10,930 *10,540 6740 *8630 4390 *3890 3200 29.57

1.5 m kg *7780 4630 *5670 2950 3980 1980 *1930 1400 9.005.0 ft lb *16,780 9980 12,280 6330 8530 4230 *4240 3090 29.54

Ground kg *5130 *5130 *8820 4350 5620 2790 3900 1910 *2200 1480 8.67Line lb *11,850 *11,850 *19,060 9360 12,060 6000 8370 4090 *4850 3260 28.44

–1.5 m kg *4800 *4800 *8720 8150 8940 4250 5530 2720 *2690 1730 7.98–5.0 ft lb *10,770 *10,770 *19,920 17,480 19,160 9140 11,890 5850 *5940 3810 26.13

–3.0 m kg *8830 *8830 *12,630 8330 *8520 4290 5570 2750 *3540 2330 6.80–10.0 ft lb *19,870 *19,870 *27,320 17,880 *18,380 9240 11,970 5920 *7680 5200 22.16

–4.5 m kg *9890 8690 *6640 4500 *5520 3760 5.08–15.0 ft lb *21,100 18,700 *13,980 9720 *12,180 8550 16.36

21318C L/318C LN Hydraulic Excavator specifications

Load atMaximum Reach

Load PointHeight

Load RadiusOver Front

Load RadiusOver Side

Reach Boom Lift Capacities (318C LN)

STICK – 3200 mm (10'6")BUCKET – 0.54 m3 (0.71 yd3)/30"

UNDERCARRIAGE – Long NarrowSHOES – 500 mm (20") triple grouser

BOOM – 5300 mm (17'5")

* Limited by hydraulic capacity rather than tipping load. The above loads are in compliance with SAE hydraulic excavator lift capacity rating standard J1097.They do not exceed 87% of hydraulic lifting capacity or 75% of tipping capacity. Weight of all lifting accessories must be deducted from the abovelifting capacities.

STICK – 3200 mm (10'6")BUCKET – 0.54 m3 (0.71 yd3)/30"

UNDERCARRIAGE – Long NarrowSHOES – 600 mm (24") triple grouser

BOOM – 5300 mm (17'5")

1.5 m (5.0 ft) 3.0 m (10.0 ft) 4.5 m (15.0 ft) 6.0 m (20.0 ft) 7.5 m (25.0 ft)

m

ft

7.5 m kg *1620 *1620 7.6025.0 ft lb *3610 *3610 24.58

6.0 m kg *3160 *3160 *2520 2260 *1500 *1500 8.6420.0 ft lb *6930 *6930 *5030 4830 *3320 *3320 28.19

4.5 m kg *3700 3350 *3340 2170 *1480 1430 9.2615.0 ft lb *8070 7180 *7020 4650 *3250 3160 30.30

3.0 m kg *7930 *7930 *5460 5160 *4470 3170 *3990 2080 *1520 1280 9.5410.0 ft lb *16,860 *16,860 *11,760 11,110 *9700 6810 8710 4440 *3350 2830 31.28

1.5 m kg *7240 4690 *5360 2960 3960 1980 *1640 1240 9.535.0 ft lb *15,610 10,090 *11,600 6350 8480 4230 *3610 2730 31.26

Ground kg *5190 *5190 *8520 4340 5560 2780 3860 1890 *1850 1300 9.22Line lb *12,000 *12,000 *18,430 9330 11,950 5960 8270 4040 *4070 2850 30.25

–1.5 m kg *3930 *3930 *7720 *7720 8810 4180 5440 2670 3800 1840 *2210 1480 8.59–5.0 ft lb *8820 *8820 *17,630 17,140 18,870 8980 11,690 5740 8170 3950 *4880 3270 28.12

–3.0 m kg *7210 *7210 *12 080 8100 *8790 4180 5430 2660 *2890 1910 7.53–10.0 ft lb *16,240 *16,240 *27,670 17,370 *18,860 8980 11,680 5720 *6430 4260 24.55

–4.5 m kg *11 780 *11 780 *11 170 8380 *7500 4320 *2840 *2840 5.77–15.0 ft lb *26,760 *26,760 *23,950 18,020 *16,010 9300 *6210 *6210 18.56

* Limited by hydraulic capacity rather than tipping load. The above loads are in compliance with SAE hydraulic excavator lift capacity rating standard J1097.They do not exceed 87% of hydraulic lifting capacity or 75% of tipping capacity. Weight of all lifting accessories must be deducted from the abovelifting capacities.

1.5 m (5.0 ft) 3.0 m (10.0 ft) 4.5 m (15.0 ft) 6.0 m (20.0 ft) 7.5 m (25.0 ft)

m

ft

7.5 m kg *1620 *1620 7.6025.0 ft lb *3610 *3610 24.58

6.0 m kg *3160 *3160 *2520 2290 *1500 *1500 8.6420.0 ft lb *6930 *6930 *5030 4890 *3320 *3320 28.19

4.5 m kg *3700 3390 *3340 2200 *1480 1450 9.2615.0 ft lb *8070 7270 *7020 4710 *3250 3210 30.30

3.0 m kg *7930 *7930 *5460 5220 *4470 3210 *3990 2110 *1520 1310 9.5410.0 ft lb *16,860 *16,860 *11,760 11,240 *9700 6890 *8710 4500 *3350 2880 31.28

1.5 m kg *7240 4740 *5360 3000 4010 2010 *1640 1260 9.535.0 ft lb *15,610 10,210 *11,600 6430 8600 4300 *3610 2780 31.26

Ground kg *5190 *5190 *8520 4400 5640 2810 3910 1920 *1850 1320 9.22Line lb *12,000 *12,000 *18,430 9460 12,100 6040 8390 4110 *4070 2900 30.25

–1.5 m kg *3930 *3930 *7720 *7720 8920 4240 5520 2710 3860 1870 *2210 1510 8.59–5.0 ft lb *8820 *8820 *17,630 *17,350 19,120 9110 11,850 5820 8280 4010 *4880 3330 28.12

–3.0 m kg *7210 *7210 *12 080 8200 *8790 4230 5510 2700 *2890 1940 7.53–10.0 ft lb *16,240 *16,240 *27,670 17,590 *19,000 9100 11,830 5810 *6430 4330 24.55

–4.5 m kg *11 780 *11 780 *11 170 8490 *7500 4370 *2840 *2840 5.77–15.0 ft lb *26,760 *26,760 *23,950 18,240 *16,010 9420 *6210 *6210 18.56

22 318C L/318C LN Hydraulic Excavator specifications

Standard EquipmentStandard equipment may vary. Consult your Caterpillar® dealer for details.

Door and caps lock with one-key security systemMirrors (frame right and cab left)Power train

– Cat 3066T diesel engine– 24-volt electric starting– Air intake heater

– One touch low idle– Swing-out oil cooler– Water separator– Two speed auto-shift travel– Straight line travel– Muffler

Undercarriage– Track-type undercarriage with grease lubricated seals– 500 mm (20") triple grouser shoes – 318C LN– 600 mm (24") triple grouser shoes – 318C L– Hydraulic track adjusters– Idler and center section track guiding guards

Working light, chassis mounted

Alternator, 50 ampAutomatic engine speed controlAutomatic swing brakeAutomatic work modesAuxiliary hydraulic valve (1)Cab

– AM/FM radio, 24-volt– Ash tray and cigar lighter– Bi-level air conditioner with defroster– Bolt-on Falling Objects Guard System (FOGS) capability– Drink holder– Floor mat– Fully adjustable suspension seat– Horn– Hydraulic neutralizer lever for all controls– Joysticks, adjustable pilot-operated– Language display monitor with gauges

– Clock– Filter/fluid change information– Level check for hydraulic oil, engine oil and coolant– Warning messages– Working hour information

– Light, interior– Literature compartment– Openable front windshield– Openable skylight with sunshade– Storage compartment– Travel control pedals with removable hand levers

23318C L/318C LN Hydraulic Excavator specifications

Optional EquipmentOptional equipment may vary. Consult your Caterpillar dealer for details.

Headrest for standard seatHeavy-duty bottom guardLight, boom right sideLights, working, cab mounted, twoPower supply, 12V-7ARain protection, cab frontSeat, suspension, KAB 527Seat, suspension, KAB 527, with heaterSticks

– 3200 mm (10'6")– 2700 mm (8'10")– 2250 mm (7'5")

Sun visor, windshieldSwivel guardTrack

– 600 mm (24") triple grouser shoes (318C LN only)– 700 mm (28") triple grouser shoes– 800 mm (32") triple grouser shoes (318C L only)

Track guiding guard, front and rear sectionVandalism protectionWiper and washer, lower windshield

Air pre-filterAlarm, travel (mandatory in certain countries)Auxiliary hydraulics – dual directions and a

medium pressure circuitAuxiliary hydraulics for hydraulic hammerAuxiliary hydraulics for hydraulic thumbAuxiliary hydraulic lines for booms and sticksBoom, with light, left sideBucket linkageBucket sidecutters and tipsBucketsBumpers, rubberCab fanCabs, optional

– Cab with polycarbonate windows(mandatory in certain countries)

– Cab with tempered windowsCold weather startCoolant, extended lifeCooling, high ambient 52° C (125° F)Falling Object Guard SystemFront windshield guardHand control pattern changer

R

For more complete information on Cat products, dealer services,and industry solutions, visit us on the web at www.cat.com

© 2004 CaterpillarAll Rights Reserved

Printed in U.S.A.

Materials and specifications are subject to change without notice.Featured machines in photos may include additional equipment.

See your Caterpillar dealer for available options.AEHQ5481-01 (8-04)

Replaces AEHQ5481

318C L/318C LN Hydraulic Excavator

![Samsung Ln-s3292d Ln-s4092d Ln-s4692d Bn94-01037a Schematic Diagram [Sch]](https://static.fdocuments.net/doc/165x107/563db88d550346aa9a94b946/samsung-ln-s3292d-ln-s4092d-ln-s4692d-bn94-01037a-schematic-diagram-sch.jpg)