Sitron-Manual VT Fork Vibration Level Sensor

-

Upload

veederline -

Category

Documents

-

view

240 -

download

3

description

Transcript of Sitron-Manual VT Fork Vibration Level Sensor

INSTALLATION, OPERATION ANDMAINTENANCE INSTRUCTIONS

2Phone (516) 935-8001 / Fax (516) 935-6001

Contents

34, 5

67, 8

91011

12, 131415161718

Introduction ...........................................................................Features & Dimensions ....................................................... Handling ................................................................................Installation ............................................................................. Time delay adjustment ..........................................................Selection DRY or WET mode ................................................ Wiring diagram .......................................................................Electrical connections .......................................................Magnetic test point ................................................................Maintenance ..........................................................................Technical specifications .........................................................Trouble shooting ....................................................................Ordering information ..............................................................

Introduction

3

The V-Tork is a point level switch that is designed to detect low or high levels of liquids, as well as some types of fine granular solids.

Sitron's V-Tork is based on the vibrating tuning fork principle, using piezo-electric crystals. The switch vibrates at a resonant frequency. When the tuning fork is submerged in the product, the frequency changes. This change is detected by the integrated oscillator and converted into a switching output.

All models are made with 316 Stainless Steel and are available with Teflon coatings or hygienic fittings for sanitary applications. The V-Tork can operate in temperatures up to 176ºF and have a maximum working pressure of 725 PSI.

Min

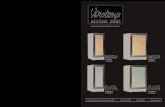

i V-Tork

Mini V-Tork

V-Tork V-Tork “EX”

4

Features and Dimensions

Phone (516) 935-8001 / Fax (516) 935-6001

L

1 3

/16

” (3

0 m

m)

2”

(50

mm

)

31

/8”

(80

mm

)

3/4” or 1”BSP ou NPT

L= Insertion length

3 1/2” (88 mm)

Unaffected by product variations in density, conductivity, dielectric constant or viscosity.Unaffected to foam, tank agitation or vibration.Various process connections: Thread, Tri-Clamp, HygienicFittings, Flanges etc.Various length options the best suit your application.Made with 316 SS as standard or Hastelloy-C and PTFE coatings when necessary.Relay and Transistor outputs available.

5

Features and Dimensions

3 1

/8”

(80

mm

)

1 1/6ӯ

1 3

/8”

(35

mm

)

1 3

/4”

(45

mm

)

1 3

/4”

(45

mm

)

5”

(12

5 m

m)

3 1/2”

1 or 3/4”BSP or NPT

/2”

Ø

Hygienic fitting 316SSwith viton o´ring andinternal thread 1”BSP

3/16” (4,5 mm)

1 3/16” (30,5 mm)

2 3

/8”

(60

mm

)

Ø

Min

i V-Tork

1 3

/8”

(35

mm

)

6

Handling

Phone (516) 935-8001 / Fax (516) 935-6001

Do not hold V-Tork by the forks Correct way

of handling

Do not alter or bend the shape of the forks

Installation

7

The “S” logo is used as reference for the correct position of the forks when installing the V-Tork

Do not turn or handle by the housing

Seal the threadwith teflon tapebefore screwing

The V-Tork can be installed at any angle of the pipe or vessel to detect the presence of liquids.

Use the correct tool to screw the V-Torkby the hexagon part

Installation

Phone (516) 935-8001 / Fax (516) 935-6001 8

Switchingpoint = 1/2” (12 mm)

Switchinghysteresis1mm

Switchinghysteresis1mm

Sugestions of installations

Switchingpoint = 1/2” (12 mm)

9

Time delay adjustment

( 1 ; 5 ; 10 ; 20 seconds )

1

1 2 1 2 1 2 1 2

ON ON ON ON

5 10 20

Different positions for keys # 1 & # 2 delineate time delay adjustment.

Led statusContinuosly = no levelBlinking fast = levelBlinking slowly = failure

10

Selection DRY or WET mode

Phone (516) 935-8001 / Fax (516) 935-6001

Selection of DRY / WET mode V-TORK ALL MODELS

Selection of DRY / WET mode Mod. MVTK-AC

Forks

Blinking High level

Low level

Low level

High level

Blinking

Dry

Dry

Wet

Wet

Dry

Wet

Wet

Dry

ON

ON

Blinking

ON

ON

Blinking

ON

ON

OFF

OFF

StatusLed

SwitchPosition Output

InØ

Ø

IminØ

Ø

IminØ

Ø

InØ

Ø

The V-Tork has a switch to adjust the DRY and WET mode.The DRY adjustment is used for high level detectionThe WET adjustment is used for low level detection.

VoltageSupply

ON

ON

11

Wiring Diagram

Load V 85 … 264 Vac

- 0 V

I máx = 100 mA

Max. Relay current = 5A

0 V

24 VDC

I max = 500 mA

0

Signal

+

_

PLC

+ 20 … 60 VDC and 20 … 264 Vac

NC CNO

PLC

Two wires (direct load switching)

PNP output

Relay output

12

Electrical connections

Phone (516) 935-8001 / Fax (516) 935-6001

1 2 3 4 5 6

ModeDRY

LED

N

N

110-230 Vac (50/60Hz)

( I ) < 3 mA

N

L

Fuse

DRY

WET

WET

DRY

WET

DRY

WET

L

L

12

3

1 2 3 4 5 6

NNO

20-264 Vac (50/60Hz)20-60 V dc( I ) < 3 mA

C NCL

DRY

WET

+

_ OUT

PLC

Mode

DRY

LED

DRY

WET

WET

11

22

33

44

18 … 60 V dc( IL ) 500 mA Máx

1 5 10 20ON

1 2

ON

1 2

ON

1 2

ON

1 2

1 5 10 20ON

1 2

ON

1 2

ON

1 2

ON

1 2

1 5 10 20ON

1 2

ON

1 2

ON

1 2

ON

1 2

1 5 10 20ON

1 2

ON

1 2

ON

1 2

ON

1 2

ON

1 2

ON

1 2

ON

1 2

ON

1 2

VTK RG

Direct load switching (2 wires)(model: VTK-AC R)

PLC connection(model: VTK-DC)

Relay output V-Tork (”EX”)(model: VTK-EX)

Relay output(model: VTK-R)

13

Electrical connections

18 … 60 V DC 18 … 60 V DC

1 12 2

3 3

4 4

1 2

+V PLC 0V

3 2 1

PLC +V 0V

3 2 1

Mini V-Tork

Mini V-Tork

14

Magnetic test point

Phone (516) 935-8001 / Fax (516) 935-6001

Mini V-Tork

Magnetictest point

N

S

15

Maintenance

When cleaning the forks use a soft brush or any other similar object.It is not necessary to clean the forks periodically.

16

Technical specifications

Phone (516) 935-8001 / Fax (516) 935-6001

MODELS VTK-DC VTK-R MVTK-DC VTK-EXMVTK-AC

Application

Mediumviscosity

OperatingVoltage

Currentconsumption

Electricalconnection

LoadCurrent

PNP (3 wires)

+/- 3mA+/- 3mA +/- 3mA +/- 3mA

+/- 3mA

Max.:20.000cs Max.: 20.000cs Max.: 20.000cs Max.: 20.000cs Max.: 20.000cs

-- --500mA

12mm from tip 12mm from tip 12mm from tip 12mm from tip 12mm from tip

500mA 500mA

PNP (3 wires) Direct Load Switching(2 wire)

½” , M12 conectoror cable gland

½” , M12 conectoror cable gland Plug DIN 43650 Plug DIN 43650 ½” NPT

Relay (SPDT)A max (250Vac)

Relay (SPDT)A max (250Vac)

20 .. 60 Vdc 20 .. 60 Vdc20 .. 60 Vdc20 - 264 Vac (50/60Hz)

20 .. 60 Vdc20 - 264 Vac (50/60Hz)85 - 264 Vac

Level switch for liquids

Level switch for liquids

Level switch for liquids

Level switch for liquids

Level switch for liquids

Output

Switching Point

Repeatability

Time Delay

IP 65

725 PSI (50 Bar) 725 PSI (50 Bar) 725 PSI (50 Bar) 725 PSI (50 Bar) 725 PSI (50 Bar)

IP 65 IP 65 IP 65 (EExia) IIC, IID

Accuracy/Stability 0,1%

< 0,5mm

1 to 20 seconds 1 to 20 seconds 1 to 20 seconds 1 to 20 seconds 1 to 20 seconds

< 0,5mm < 0,5mm < 0,5mm < 0,5mm

0,1% 0,1% 0,1% 0,1%

Enclosurematerial

316 Stainless Steel Alluminum Die CastExplosion Proof

316 Stainless Steel

Wetted material

316 Stainless Steel 316 Stainless Steel 316 Stainless Steel 316 Stainless Steel 316 Stainless Steel

Glass fillednylon

Glass fillednylon

Class Protection

Processconnection

3/4” to 1 1/2” BSP or NPT or sanitary

connections

3/4” to 1 1/2” BSP or NPT or sanitary

connections

3/4” to 1 1/2” BSP or NPT or sanitary

connections

3/4” to 1 1/2” BSP or NPT or sanitary

connections

3/4” to 1 1/2” BSP or NPT or sanitary

connections

OperatingTemperature

Max pressure

-14 to 176º F (-10 to 120ºC)

-14 to 176º F (-10 to 120ºC)

-14 to 176º F (-10 to 120ºC)

-14 to 176º F (-10 to 120ºC)

-14 to 176º F (-10 to 120ºC)

17

Trouble shooting

Fault

Does not switch

IncorrectSwitching

Dry = onWet = off

Turbulance Adjust time delay

Select the right option

No LED, no powerLED blinking slowlyBuild up on forks Clean forks

Check power supplyCheck position of the forks

Cause Solution

18

Ordering Information

Phone (516) 935-8001 / Fax (516) 935-6001

CodeVTK - DCVTK - R

MVTK - DCMVTK - AC

Code123456

CodeBNH0

CodeSL

CodeNA

CodeC MT

CodePTFE

0X

- - - - - -

NOTE: The hygienic fitting is available only with 1"BSP threaded connection.

Flange 2" ANSI, 150lb. 316 S.S.

Supply voltage 85 - 264 VAC (2 wire) - Direct Load Switching

POINT LEVEL DETECTION - VIBRATING TUNING FORK ORDERING INFORMATION

Supply voltage 20 - 60 VDC / 20 - 264 VAC / 1 relay SPDT 250 VAC - 5A max.Supply voltage 20 - 60 VDC

2" Tri-Clamp

3/4" Thread

Type of threadBSP

Hallar / Tefzel

EnclosureGlass filled nylon

Insertion length

NPT

Specifications

Process Connection

Other - Specify

Supply voltage 20 - 60 VDC 3 wire <PLC>

1" Thread1 1/2" Tri-Clamp

Hygienic Fitting with Coupling (See Note)

Other - Specify

L=3 1/8" (80mm) - Standard

Not a thread

NoneOther - Specify

Aluminum die cast

Coating

Electrical ConnectionCable gland with 1/2"NPT conduit entryM12 connector1/2" NPT conduit entry

Sitron-USA, Inc.PO Box 7000

New York, NY 10128Tel: (516) 935-8001 / Fax:(516) 935-6001

e-mail: [email protected]: www.sitron.com