Shape optimization of an echography robot...For the shape optimization, easy to program free shape...

Transcript of Shape optimization of an echography robot...For the shape optimization, easy to program free shape...

Shape optimization of an echography robotSylvain Miossec, PRISME Lab., Univ. of Orléanssylvain.miossec@univ‐orleans.fr

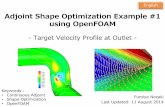

IntroductionThe considered echography robot Fig.1 manipulates an echography probe controlled remotely by an operator. During its operation, the robot is placed on the patient and held by an assistant. Therefore, robot must be light enough to be held without fatigue. At the same time, deformation of the robot must be limited in order to obtain a good precision.Robot architecture is based on a parallel structure with pantographs that has good kinematic properties but that gave a too heavy system. That's why we investigate here the shape optimization of the structure to lighten it while maintaining a minimum stiffness for precision of the probe positioning. In this first study, only most challenging articulated pantographs are shape optimized.

ChallengeFor a thorough optimization of the structure, one would consider many dynamic motions representative of the real use of the structure. For a first optimization to be tractable, optimization is restricted to a static approximation in the most representative configurations of the robot, and with a maximum possible force applied on patient of 30N. The challenge is then to simulate and optimize the shape of:• Several links together• Attached with many joints constituting an hyperstatic system, see

Fig.2• For several configurations at the same time, see Fig.3

SolutionsTo obtain a limited computation time, problem is further simplified by representing the different configurations under a vertical contact force by the center configuration under several orientations of the contact force. Structure is then modeled in Optistruct by linear elasticity approximation with joints represented by degrees‐of‐freedom between links.To avoid a complex and heavy model of contact, joints are modeled with rigid elements at the contact surface of each link. A difficulty was to represent revolute joints degrees‐of‐freedom around arbitrary directions with Multi‐Point Constraints (MPC). However, when properly oriented, all revolute joints of the structure in the reference configuration are aligned with x, y and z absolute axis. It was then possible to use rigid elements with corresponding free degree‐of‐freedom.

Results and BenefitsOptimized structure Fig.4 and 5 is obtained after about 3min of computation and reduces weight by about 28% (for same compliance), for a model with about 6000 elements and 32000 optimization variables. Optistruct with HyperMesh and HyperViewallows fast development and computation for a complex shape optimization problem.

Fig.1 Echography robot Fig.2 Kinematics of the robot

Fig.4 Superposition of initial and optimized shapes

Fig.5 Superposition of undeformed and deformed structure (x50) with Von Mises stress

PerspectivesSeveral simplifications were performed. Next improvements using Optistruct will be:• Add non considered parts of the structure in the shape

optimization• Use of the ESL method to couple multi‐body dynamics with

shape optimization, in order to optimize for several configurations of the robot

• Perform a topology optimization of the parts• Consider the dynamics of the robot on several reference

motions• Allow the change of position of the joints center

For the shape optimization, easy to program free shape optimization was used. Planar constraints were added to preserve support surface of bolts, especially for joints.Criterion considered for the optimization is the mass, while maximum compliance constraints were set to obtain a maximum displacement of 1mm for the 30N load.

Fig.3 Example configurations of the echography robot