Seal #1 Seal #2 Seal #3 Seal #4 Seal #5 Seal #6 Intermission Seal #7

Seal Installation Divyam Engineers

-

Upload

parmar-chandresh -

Category

Documents

-

view

221 -

download

0

description

Transcript of Seal Installation Divyam Engineers

DIVYAM ENGINEERS-BARODA

MECHANOCAL SEAL INSTALLATION

[A] Equipment Parameters:

For satisfactory seal performance, equipment parameters should be as under.

Radial movement of shaft (run out / deflection) shall be less than 0.08 mm.

Axial movement of shaft (end play) shall be less than 0.26 mm.

Stuffing box face squareness (face run out) shall be less than 0.05 mm.

Stuffing box bore concentricity (with respect to shaft) shall be less than 0.13 mm.

Stuffing box shall be free of burrs and sharp edges.

Shaft / sleeve shall be free of burrs and sharp edges.

Please check manufacturer’s drawing /instruction for above parameters.

[B] Installation Instructions:

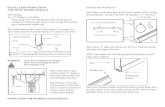

A conventional (component) seal is one where each part of the seal must be assembled on the equipment

individually. This requires considerable skill and significant time as compared to installation of a cartridge seal.

During installation of a mechanical seal take care of following.

• Assemble seal parts in a clean environment.

• Do not use hammer for assembly as seal faces are delicate and may crack / break.

• Check that seal parts, gland and stuffing box are free from burrs, sharp edged and deep scratches / damage.

• Check surface finish at elastomer area to be as per manufacturer’s recommendation.

• Check that set screws on either the rotary unit or the drive collar of the seal assembly are free in the threads.

• Confirm hardness of shaft / sleeve to be such that after tightening set screws, rotating assembly does not get

loose (if set screws are tightened against a hard surface, they will fail to hold assembly in desired position during

operation). Alternatively, use hardened set screws.

• It is a good practice to check fitting of shaft sleeve, rotary assembly and gland without O-Rings to ensure that

are fitting freely before assembling them with O-Rings.

• Use correct size O-Rings at all places.

• Do not use used O-Rings and gaskets.

• Never use "glued together" O-Ring for any "dynamic" application. A hard spot will be created that will interfere

with the movement of the O-Ring.

Continue on Page-2-

PAGE-02-

• Lubricate shaft and secondary seal (O-Rings / bellows) as per manufacturer’s recommendation. If assembling is

difficult, apply water or soap water as lubrication on shaft / sleeve. Rubber bellow seals should be lubricated with

Vaseline. Don’t apply silicon grease on them. EPR (Ethylene Propylene Rubber) elastomers should not be

lubricated with petroleum based oil. For EPR material use silicon grease.

• Check that all O-Rings are protruding out of respective groove provided on mating part.

• Install seal at its correct operating length as per manufacturer’s drawing.

• After assembly of rotating head, check for free movement of seal ring by compressing and releasing the rotary

head.

• Check direction of helix of coil for single spring seal. Helix should be R.H. for C.W. rotation and L.H. for C.C.W.

rotation when looking at seal face.

• Gland bolts or nuts should be tightened only enough to effect a gasket seal at the stuffing box face. This can be

achieved by initial finger tightening and further tightening with ½ to ¾ turns. Over tightening could result in distortion

of seal faces.

• Cartridge type seal assemblies are provided with axial location plates that hold the assembly together before

installation in the equipment. Make sure that the axial location plates are moved out of the grooves provided on the

shaft sleeve after their fitting.

• When seal assembly is complete, connect all piping, check that all environmental controls have been connected,

and all unused holes in the stuffing box / gland are plugged.

[C] Start-up Procedure:

Take care of following before starting equipment and during its operation for the first time after installation of

mechanical seal.

• Equipment should be aligned with the driver as per manufacturer’s recommendations.

• Check the shaft for free movement. Manually rotate the shaft several turns. If shaft binds due to any reason,

investigate and correct it.

• Activate all auxiliary systems like flush, quench, barrier lines and vent the stuffing box until all trapped air has

been released.

• Pump should have adequate NPSH (for its running without cavitations).

• Equipment should run without vibration.

• No noise should come from stuffing box.

Continue on Page-03-

PAGE-03-

• Excessive heat generation should not be there. This may be due to stationary parts contacting the rotating shaft

or rotating seal parts contacting the housing of the equipment.

• Examine the seal. Slight leakage should stop when the faces “wear in”.

If dynamic testing of a seal is to be carried out, it should be carried out at maximum stuffing box pressure. The seal

should be tested for at least 3 hours. Leakage should be less than specified in purchase order. If no leakage rate is

specified in purchase order, leakage at the rate of maximum 2 to 3 drops per minute is considered to be acceptable.

Causes of Seal Leakage

The operating life of a seal is complete when either face has worn entirely. If either face has completely worn, the

cause of failure is evident and no further inspection is required unless this occurred in a very short time. If both

faces are intact, seal parts shall be inspected. Major seal problems and possible causes are as under.

Seal Problems Possible Cause / Corrective Action

Seal spits and sputters

(“face popping”) in operation.

Seal fluid vapourizing at seal interfaces. This can be due to inadequate

cooling of seal faces or seal unbalance.

Seal drips steadily. This can happen if seal faces are not flat, distorted or damaged.

Distortion of gland plate due to over tightening.

Damage to secondary seal during installation.

Over aged O-Rings.

Spring failure.

Erosion / corrosion of seal parts.

Seal squeals (gives sound)

during operation

Inadequate liquid to lubricate seal faces.

Accumulation of carbon dust

outside the gland.

Inadequate liquid to lubricate seal faces.

Short seal life. Presence of abrasive in the fluid.

Misalignment of the equipment with its driver.

High vibration.