SB Conical Sand Atrion

-

Upload

monalinamares -

Category

Documents

-

view

234 -

download

1

description

Transcript of SB Conical Sand Atrion

S

ARa

b

a

ARRA

KACDS

1

i((tmahuM2

rbpTwia

s22

1h

Particuology 10 (2012) 592– 599

Contents lists available at SciVerse ScienceDirect

Particuology

j o ur nal homep ag e: www.elsev ier .com/ locate /par t ic

and attrition in conical spouted beds

ranzazu R. Fernández-Akarreguia, Jon Makibara, Isabel Alavaa, Luis Diaza, Fernando Cuevaa,oberto Aguadob, Gartzen Lopezb, Martin Olazarb,∗

Ikerlan-IK4, Juan de 4 la Cierva 1, Arabako Parke Teknologikoa, E-01510 Minao, Araba, SpainDepartment of Chemical Engineering, University of the Basque Country, P.O. Box 644, E48080 Bilbao, Spain

r t i c l e i n f o

rticle history:eceived 19 October 2011eceived in revised form 4 January 2012

a b s t r a c t

A study was carried out on the attrition in conical spouted beds using two sands with different propertiesfor several bed heights and gas flow rates. Furthermore, the influence of a draft tube was studied atambient and high temperatures. The main objective was to acquire knowledge on the attrition of sand

ccepted 20 February 2012

eywords:ttritiononical spouted bedraft tube

beds for biomass pyrolysis in a pilot plant provided with a conical spouted bed reactor. A first-orderkinetic equation is proposed for sand attrition in a conical spouted bed at room temperature. The predictedattrition rate constant depends exponentially on excess air velocity over that for minimum spouting. Boththe draft tube and temperature increase contribute to reduction of attrition.

© 2012 Chinese Society of Particuology and Institute of Process Engineering, Chinese Academy of

Oi(caBBoa

utpMg&tMtc1V

and attrition

. Introduction

Spouted beds have been proposed as an alternative to flu-dized beds for processes that call for efficient fluid–solid contactEpstein & Grace, 1997), especially for particles larger than 1 mmFreitas & Freire, 2001; Zhao, Li, Liu, Song, & Yao, 2008). An advan-age of spouted beds over fluidized beds is the well-defined cyclic

ovement of the particles, which facilitates contact between gasnd solid particles (Luo, Lim, Freitas, & Grace, 2004). In fact, bothigh solid circulation rate and efficient gas–solid contact favor these of spouted beds in many chemical processes (Azizi, Hosseini,oraveji, & Ahmadi, 2010; Vieira Neto, Duarte, Murata, & Barrozo,

008).In spouted beds, the fluid is introduced through a central nozzle

ather than uniformly through a distributor plate as in fluidizededs. The fluid enters the bed in the form of a jet and causes thearticles to circulate in a uniform way creating a central spout zone.he fluid and particles are in counter-current flow in the annulus,hich makes up the major portion of the spouted bed. Particle flow

s co-current with the fluid in the spout, where velocities are highnd residence time is short.

Nowadays, spouted beds are widely used in physical processes,

uch as drying (Altzibar et al., 2008; Berghel, Nilsson, & Renstrom,008; Markowski, Sobieski, Konopka, Tanska, & Bialobrzewski,007), coating and granulation (da Rosa & dos Santos Rocha, 2010;∗ Corresponding author. Tel.: +34 946392527; fax: +34 946393500.E-mail address: [email protected] (M. Olazar).

Hbw

mpt

674-2001/$ – see front matter © 2012 Chinese Society of Particuology and Institute of Process Ettp://dx.doi.org/10.1016/j.partic.2012.02.002

Sciences. Published by Elsevier B.V. All rights reserved.

liveira, Peixoto, & Freitas, 2005) and in chemical processes involv-ng combustion (Konduri, Altwicker, & Morgan, 1999), gasificationBelyaev, 2008; Spiegl, Sivena, Lorente, Paterson, & Milian, 2010),atalytic polymerization (Olazar, San Jose, Zabala, & Bilbao, 1994)nd pyrolysis of different solid wastes (Aguado, Olazar, Barona, &ilbao, 2000; Amutio et al., 2011; Elordi, Olazar, Lopez, Artetxe, &ilbao, 2011; Lopez, Olazar, Aguado, & Bilbao, 2010). An overviewf spouted bed reactors was carried out by Olazar, Alvarez, Aguado,nd San Jose (2003).

One of the challenges for scaling up the spouting regime is thenderstanding of the process controlling particle size reduction andhe determination of attrition kinetics, which will help to design arocess with high efficiency and reduced fine particle emission.oreover, the fines formed must be removed from the out-going

as stream, thereby increasing the processing cost (Stein, Seville, Parker, 1998). Although numerous papers address the attri-

ion in fluidized beds, few provide information on spouted beds.athur and Epstein (1974) devoted a brief chapter in their book

o this subject and, more recently, attrition in spouted beds wasonsidered for the processing of carbonaceous materials (Buczek,983; Wongvicha & Bhattacharya, 1994), calcite (Flamant, Chraibi,allbona, & Bertrand, 1990) and selected polymers (Al-Senawi,adi, Briens, & Chabagno, 2008). To our knowledge, no paper haseen published dealing with the attrition of spouted beds fittedith a draft tube.

The attrition process is commonly divided into two differentechanisms causing particle breakage, namely, the abrasion of the

article surface and the disintegration or fragmentation of the par-icle matrix (Boerefijn, Ghadiri, & Salatino, 2007, chap. 25; Lin &

ngineering, Chinese Academy of Sciences. Published by Elsevier B.V. All rights reserved.

A.R. Fernández-Akarregui et al. / Particuology 10 (2012) 592– 599 593

Nomenclature

DC diameter of the cylindrical section of the contactor(m)

Di diameter of the bed bottom (m)DT diameter of the draft tube (m)D0 diameter of the bed inlet (m)ds Sauter diameter (m)Ea attrition activation energy (m2/s2)HC height of the conical section of the contactor (m)Hf height of the fountain (m)HT total height of the contactor (m)Ka attrition rate constant in Lee’s equation (s−1)Kp dimensional constant in Gwyn’s equation (s−m)K0 frequency factor in an Arrhenius form (s−1)k0 kinetic constant in Eq. (4) (s−1)k1 kinetic constant in Eq. (4) (m2/s2)LH height of the draft tube entrainment zone (m)m exponent for time dependence on attrition in

Gwyn’s equation, dimensionlessP pressure (kg/(m s2))Mw molecular weight of air (kg/mol)Rt attrition rate (kg/s)t time (s)T temperature (K)umf minimum fluidization velocity (m/s)u0 inlet air velocity referred to the inlet diameter (m/s)(ums)0 minimum spouting velocity referred to the inlet

diameter (m/s)W weight of bed material (kg)W0 initial mass of particles in the bed (kg)We mass of particles in the bed at t time (kg)Wmin minimum weight of parent solids in the bed (kg)

Greek letters� cone angle (rad)�P pressure drop (kg/(m s2))

WaiteWt&cbt2p

iiWiictccb

Fb

ri

R

w(awdrtTe

W

wiadcp

K

At

&snlo

2

ey, 2005; Welt, Lee, & Krambeck, 1977). The factors that affectttrition dynamics include: (i) the properties of the bed material,.e., porosity, size, hardness, density, surface, cracks, shape and par-icle strength (Lee, Jiang, Keener, & Khang, 1993) and (ii) the reactornvironment, i.e., exposure time, particle size and velocity (Lin &ey, 2003, 2005; Shih, Chu, & Hwang, 2003) pressure system and

ype of enclosure (hard or soft surface), shear, temperature (Lin Wey, 2003, 2005; Arena, D’Amore, & Massimilla, 1983) and vis-osity and turbulence (Bemrose & Bridgwater, 1987). In fluidizededs, the jetting region is the most significant contributor to par-icle breakage (Boerefijn, Gudde, & Ghadiri, 2000; Boerefijn et al.,007) and in the case of spouted beds the same role is probablylayed by the spout region.

Many reports propose empirical correlations for attrition raten bubbling and circulating fluidized bed systems, and interest-ng reviews have been reported by Lee et al. (1993) and Lin and

ey (2005), but no correlation for spouted beds has been foundn the literature. This study addresses the kinetics of sand attritionn a conical spouted bed contactor under different hydrodynamiconditions. The kinetic equation corresponding to the experimen-al conditions studied has been obtained based on analogies with

ertain kinetic equations proposed for fluidized bed systems. Thelosest correlations are those by Gwyn (1969) and Lee et al. (1993),oth for fluidized beds. Gwyn (1969) studied silica sand attritionFc

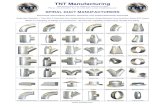

ig. 1. Schematic of the experimental setup for attrition tests in a conical spouteded contactor.

ate at room temperature and proposed a correlation of the follow-ng type:

t = Kpmtm−1W, (1)

ith m = 0.46 and Kp = 4.47 × 10−6–1.35 × 10−5 s−m. Lee et al.1993) investigated lime attrition in a circulating fluidized bedbsorber at 20–180 ◦C and found that the predominant mechanismas surface abrasion. According to these authors, lime attritionecreases as temperature is increased, due to changes in the mate-ial, whereas limestone attrition increases with temperature dueo the decrepitation resulting from increased internal pressure.he total weight of particles in the bed at time t, We, follows thequation:

e(t) = (W0 − Wmin)e−Kat + Wmin, (2)

here W0 (kg) is the weight of the bed at t = 0, Wmin is the min-mum weight for which the attrition is negligible and Ka is thettrition rate constant. These authors found that the constant Ka

epends exponentially on activation energy, temperature, superfi-ial air velocity and minimum fluidization velocity in the attritionrocess:

a = Koe−EaRTCs/PMWu0(u0−umf ). (3)

For lime attrition, the authors related a frequency factor in anrrhenius form, with Ko = 1.29 × 10−4 s−1, and calculated an attri-

ion activation energy, Ea = 3.38 × 10−3 kJ/kg.Other equations (Halder & Basu, 1992; Kono, 1981; Merrick

Highley, 1974; Wu, Baeyens, & Chu, 1999) are not suitable forpouted beds because they take into account phenomena that doot occur in these beds, such as the presence of bubbles, and those

ike the second-order model (Cook, Khang, Lee, & Keener, 1996) aref no direct use for the design of these types of beds.

. Experimental system and test procedure

The experimental set-up for sand attrition tests is shown inig. 1, including an air compressor, a mass flow meter and aontroller, a conical spouted bed contactor, a cyclone, a pressure

594 A.R. Fernández-Akarregui et al. / Particuology 10 (2012) 592– 599

Fa

sestifrp(o3(dgcbEAt(i

catrwPms

sdimfw

arstt

t

Fd

dstmfsbbrTae

tvvrvu

aaa2ThttLt

3

tmitfrtair velocity, which is due to the fact that the peak pressure drop is

ig. 2. Fractional size distribution of the two silica sands (A-GRS07, Sibelco Miner-ls), type I and type II.

ensor, a thermocouple and a data monitoring system. The attritionxperiments were carried out in two different plants, i.e., a conicalpouted bed contactor made of plexiglass and a non-porous draftube conical spouted bed reactor made of stainless steel. The latters the main component in a pilot plant unit designed and set upor continuously pyrolysing 25 kg/h of biomass. The experimentaluns in this reactor were conducted at both ambient and high tem-eratures. The dimensions of both contactors are exactly the sameFig. 1): the diameter of the upper section (DC) is 242 mm, the anglef the contactor is � = 32◦, the height of the conical section (HC) is30 mm and the total height (HT) is 1030 mm. The base diameterDi) is 52 mm and the inlet diameter (Do) is 15 mm when no internalevice is used, and 25 mm when a non-porous draft tube is used,iven that the use of this internal device improves bed stability and,onsequently, a greater inlet diameter may be used without insta-ility problems (Altzibar et al., 2008, 2009; Cunha, Santos, Ataide,pstein, & Barrozo, 2009; da Rosa & Freire, 2009; Olazar, Lopez,ltzibar, & Bilbao, 2011; Vieira Neto et al., 2008). The diameter of

he draft tube (DT) is 36 mm and the height of the entrainment zoneLH) is 80 mm. These dimensions of the draft tube were determinedn a previous paper (Makibar et al., 2011).

A stainless steel mesh (55 mesh size) placed at the base of theontactor supports the sand. Air (25 ◦C and 480 ◦C, 1 atm) was useds the spouting medium. The outlet air from the contactor enteredhe cyclone where the elutriated fines are collected. The air flowate was measured by a mass flow meter (Brooks, 5853S). Pressureas measured by a differential pressure transducer (RS 286-686).

ressure drop, temperature and air flow rate were continuouslyonitored and recorded by a Fluke NetDAQ Logger data acquisition

ystem.Attrition study was carried out using two types of commercial

ilica sand (called sands I and II) provided by Sibelco Minerals. Theensity of both sands is 2600 kg/m3 and their loose bed poros-

ty 0.46, as determined following the Brown and Richards (1970)ethod. The initial particle size distribution (before attrition tests)

or both types of sand is shown in Fig. 2 (determined by sieving),ith their Sauter average diameter being around 1.0 mm.

Experiments were carried out using two amounts of sand, 4.5nd 6 kg, which account for bed heights (Ho) of 24.5 and 27.8 cm,espectively. The height of the fountain (Hf) was visually mea-ured, whereas air velocities referred to the inlet diameter (u0),emperature and pressure drop (�P) were continuously recorded

hroughout the whole test.In experiments, air flow rate is gradually increased to a value 1.5imes higher than the minimum spouting gas flow rate and is then

mth

ig. 3. Pressure drop evolution with air velocity (6 kg of silica sand I, Do = 15 mm,S = 1.05 mm).

ecreased to the set spouting velocity. This air rises through thepouting bed, with the sand particles moving upwards in the foun-ain and falling down again onto the annulus where they continue

oving downwards until arriving at the spout, thus repeating theull cycle. The air supply is turned off at regular time intervals andand is taken out, weighed and put back into the contactor. At theeginning of the experiments, the measuring intervals are shorterecause the attrition process is more severe. When the weighteduction of the sand reaches a steady state, the test is concluded.he shape factor of bed particles is measured by optical microscopyt the beginning and end of each run, and the image analysis of finallutriated fines is also obtained by SEM microscopy.

Following the methodology described, attrition tests withouthe draft tube are carried out at room temperature using airelocities 1.16 and 1.35 times higher than the minimum spoutingelocity, (u0)ms, corresponding to the original bed. Thus, air flowates of 450 L/min and 574 L/min, corresponding to the spoutingelocities (per unit of inlet cross-sectional area) of 48–54 m/s aresed. Each experiment lasted 420 h.

In the experiments carried out with a draft tube, the velocitiesre 1.35 and 1.65 times higher than those for minimum spoutingt 25 and 480 ◦C, respectively. Thus, the flow rates used (measuredt ambient conditions) are 472 L/min for ambient temperature and10 L/min for 480 ◦C, and the runs are carried out using type II sand.he reduction in the gas flow rate required for the operation atigh temperatures is explained by the increase in gas viscosity and,herefore, by the increase in the momentum transfer from the gaso the solid, which facilitates the spouting phenomenon (Olazar,opez, Altzibar, Aguado, & Bilbao, 2009). In experiments with a draftube, each experiment lasted 248 h.

. Experimental results

The evolution of pressure drop with air velocity from the fixedo the spouted bed was analyzed in order to determine the mini-

um spouting velocity for the different systems studied. As shownn Fig. 3, at first, as air velocity is increased, pressure drop increaseso a peak value, at which, with further increasing air velocity, aountain is created and pressure drop decreases to a value thatemains approximately constant for a wide range of air veloci-ies. A highly pronounced hysteresis is noted upon reducing the

uch higher than the operating pressure drop and, furthermore,he velocity required to break up the bed and open the spout isigher than that corresponding to the peak pressure drop.

A.R. Fernández-Akarregui et al. / Particuology 10 (2012) 592– 599 595

Fa

dpata(tloaasAospa

3

abdvvnar(o

swocs(itob

Fv

ttdtaephiasw

atuiatot&the air inlet velocity, the smaller the Wmin. The values of Wmin forthe two sets carried out in this study are 5555 g and 5300 g for(u/ums)0 = 1.2 and 1.35, respectively. The higher air flow rate gave

ig. 4. Particle size distribution of sand I at the beginning and end of the tests usingir velocities of 1.2 and 1.35 times (u0)ms.

It is widely accepted that the predominant attrition mechanismuring fluidization is surface abrasion due to collisions betweenarent solids in the bed (Lee et al., 1993). Nevertheless, therere two different attrition mechanisms in a spouted bed: (i) par-icle impact attrition, which takes place in the fountain regionnd happens when particles collide against the vessel wall, andii) particle–particle surface abrasion, which takes place mainly inhe spout region. Particles collide with each other and against theayer of annulus particles constituting the spout wall. The extentf particle-wall impact attrition depends on total impact surfacerea, number of impact cycles, particle velocity, and the particlend vessel material (Chen, Jim Lim, & Grace, 2007). Particle–particleurface abrasion depends on particle velocity and particle material.ll these parameters change with time. This is due to the presencef fewer faults, flaws, or discontinuities affecting particles and tomaller particle size in the bed. Both mechanisms ensure that sandarticles undergo attrition, increasing the fractional weight of finesnd reducing the fractional weight of bigger particles.

.1. Effect of gas velocity

In order to study the effect of gas velocity on attrition, resultsre obtained at two operating velocities, both above the minimum,y using sand I. Fig. 4 shows the variation in the fractional sizeistribution at the beginning and end of the tests carried out at airelocities of 1.2 and 1.35 times higher than the minimum spoutingelocity. As observed, a reduction in the particle size of the sand isoted at the end of the tests. In fact, the Sauter diameters measuredt the end of the tests for these velocities are 0.90 mm and 0.94 mm,espectively. The higher Sauter diameter for the higher velocity1.35 times the minimum one) is explained by the higher amountf elutriated fines for the higher gas flow rate.

Knowledge on the attrition process of the bed material in conicalpouted bed reactors is essential because changes in the fractionaleight distribution involve changes in the hydrodynamic behavior

f the spouted bed reactors. Thus, a decrease in the average parti-le diameter throughout the run due to attrition causes minimumpouting velocity to decrease and, consequently, the operatingu/ums)0 ratio to increase when a constant air flow rate is usedn the run. Fig. 5 shows the evolution of (u0)ms and (u/ums)0 with

ime using an initial inlet air velocity of 1.35 times the minimumne which accounts for a velocity of 54 m/s. This effect has alreadyeen observed by Lin and Wey (2005) in fluidized beds. Fig. 5. Evolution of (u0)ms and (u/ums)0 with time, for sand I and an initial inlet airelocity of 1.35 times (u0)ms.

Furthermore, the fountain height increases with the increase inhe small particle fraction by attrition. In fact, big particles tendo occupy radial positions near the annular–spout interface and soescribe shorter trajectories than the smaller ones. The smaller par-icles circulate mainly along the outer periphery of the annular zonend describe wider cycles. The fountain therefore acts as a high-fficiency distributor, which provides an interesting segregation ofarticles by diameter and/or density. Furthermore, as the fountaineight increases the particle-wall impact surface area and veloc-

ty also increase. In addition, the number of particles contained in given weight fraction is much higher when these particles aremall and, moreover, their ratio of surface area to volume is higher,hich increases the probability of collision.

Fig. 6 shows the experimental data of bed mass evolution for twoir inlet velocities. As observed, there is an exponential decrease inhe weight of solids in the bed throughout the run. Particles initiallyndergo rapid attrition, which then decreases exponentially, lead-

ng to a minimum weight value (Wmin) of steady state in whichttrition could be considered negligible. This seems to be due tohe fact that the irregular surface of the particles at the beginningf each experiment abrades easily, but the particles become hardero abrade when they are already rounded (Boerefijn et al., 2000; Lin

Wey, 2003). Wmin depends on air inlet velocity, so that the higher

ig. 6. Experimental data for bed weight evolution (sand I) at two air velocities.

596 A.R. Fernández-Akarregui et al. / Particuology 10 (2012) 592– 599

0 h sp

wctpv

oravepfb

3

am1imlti

rqepmq

bmsea

3

tbtsttIsa2rt2usAb

wo

Fig. 7. Microphotographs of (a) original sand I and (b) sand after 42

ay to more violent collisions between the particles and with theontactor surfaces. In all the experiments carried out in this work,he time to reach the minimum value was around 400 h, and it isroven that the attrition rate increases rapidly by increasing airelocity.

The rounding off and surface abrasion of silica sand werebserved under a microscope, as illustrated in Fig. 7, showing theough and irregular surface of the original sand I (Fig. 7(a)) and thebraded surface of the sand after 420 h of spouting with inlet airelocities of 48 and 54 m/s, respectively (Fig. 7(b) and (c)). The sharpdges gradually disappeared, and the surface became increasinglyolished with time due to collisions. The sizes of the fines elutriatedrom the spouted bed contactor and retained in the cyclone rangeetween 2 and 50 �m, as illustrated by SEM microscopy in Fig. 8.

.2. Effect of sand type

The effects of sand types, I and II, and gas velocities on attritionre shown in Fig. 9 by observing the evolution of bed weight. Theass loss is observed for sand type I operating with an air velocity

.2 times the minimum, and for sand type II operating with veloc-ties 1.16–1.26 times the minimum. As observed, the mass loss is

uch higher with sand II than with sand I, even operating withower gas velocities. In fact, when operation is carried out usinghe same (u/ums)0 ratio with both sands, the mass loss with sand IIs twice that observed with sand I.

The chemical compositions of both sands were analyzed by X-ay diffraction, to show the main component in both cases to beuartz (>99.5%), with feldspar as the main impurity. The differ-

nt behavior between the sands is due to their different texturalroperties, which were determined by means of a petrographicicroscopy: sand II is characterized by its sharp edges and, conse-uently, when it is subjected to impacts in the spouting operation,

Fig. 8. SEM image of fines elutriated from the spouted bed.

fbattl

Fv

outing, (u/ums)0 = 1.2; (c) sand after 420 h spouting, (u/ums)0 = 1.35.

reakage of these sharp edges causes faster and more significantass loss. Other authors (Lee et al., 1993; Lin & Wey, 2003, 2005)

tudying attrition in fluidized beds, also observed the importantffect of particle properties, such as porosity, size, shape, hardnessnd so on.

.3. Attrition in a contactor fitted with a draft tube

Operating with conical spouted beds has certain limitations forhe treatment of fine materials and a crucial parameter that hindersed stability in the scaling-up of the process is the ratio betweenhe inlet diameter and particle diameter. Thus, the inlet diameterhould be up to 20–30 times the average particle diameter in ordero achieve spouting status (Olazar et al., 2011). The use of a draftube is the usual solution to this problem (Swasdisevi et al., 2005).n fact, this internal device is the key for stable operation in large-cale spouted beds and allows increasing the spoutable bed heightnd reducing bed pressure drop (Altzibar et al., 2009; Luo et al.,004; Swasdisevi et al., 2004, 2005). Moreover, solid circulationate, particle cycle time, gas distribution and so on are governed byhe specifications of the draft tube (Altzibar et al., 2009; Cunha et al.,009; Ishikura, Nagashima, & Ide, 2003; Zhao, Yao, & Li, 2006). These of a draft tube allows increasing the versatility of the conicalpouted bed and improving the flexibility of the gas–solid contact.ccordingly, a conical spouted bed provided with a draft tube haseen developed for the biomass pyrolysis process.

Attrition in the conical spouted beds provided with a draft tubeas compared with that observed without it. Runs were carried

ut with a draft tube by using a higher velocity than the minimumor spouting in order to improve the less vigorous contact of theseeds without a tube. Thus, the (u/ums)0 ratio used is 1.35 at 25 ◦C

◦

nd 1.65 at 480 C. In spite of operating with a higher (u/ums)0 ratio,he fountain height observed at 480 ◦C (about 15 cm) is lower thanhat observed at 25 ◦C (around 20 cm). It is noteworthy that thisess vigorous contact at high temperatures reduces sand attrition.ig. 9. Comparison of sand mass loss for different types of sand and different gaselocities.

A.R. Fernández-Akarregui et al. / Particuology 10 (2012) 592– 599 597

Tiha(ftwiat2ftttpaa

iccf(tptvld(

witts(wpwtsat

Fig. 11. Bed weight evolution for sand I and air velocities of (a) (u/ums)0 = 1.2 and(

oaaezvoaaiod

4

ma

lr

Fig. 10. Effect of gas velocity and temperature on fountain height.

hus, at the end of the run (248 h), the sand mass loss at 25 ◦Cs 180 g, whereas it is only 115 g at 480 ◦C, even operating with aigher gas velocity. Certain authors observed the opposite oper-ting with fluidized beds, i.e., more attrition at high temperaturesBemrose & Bridgwater, 1987; Lin & Wey, 2003, 2005). This dif-erent behavior between spouted beds and fluidized beds at highemperatures is explained by the less vigorous gas–solid contacthen temperature is increased in the spouted beds. In order to

mprove knowledge on the spouting regime at high temperatures, study was conducted on the fountain height and gas–solid con-act behavior at different (u/ums)0 ratios and temperatures from5◦ to 500 ◦C. Fig. 10 shows the evolution of fountain height as aunction of temperature and (u/ums)0 ratio. As observed, the foun-ain height is reduced when operating at high temperatures andhis effect seems to be violated if operating over 400 ◦C. The reduc-ion in the fountain height is related to a change in the gas flowattern, i.e., a higher amount of gas crosses the bed through thennulus, which causes a reduction in the gas velocity in the spoutnd, consequently, in the acceleration of the particles in this region.

In addition to the lower fountain height at high temperatures,t is visually observed that solid movement is less vigorous and,onsequently, the solid circulation rate is lower. Both findingsause a reduction in the strength of particle collisions and there-ore in the attrition rate at high temperatures. Likewise, Shih et al.2003) related attrition in an internally circulating fluidized bedo the solid circulation rate. The lower attrition rate at high tem-eratures is related to the change in drag force from low to highemperatures. Increasing temperature leads to an increase in gasiscosity, whereas at the same time its density decreases. Since atow temperatures (i.e., well below 300 ◦C) increasing gas viscosity isominant in comparison with gas density, the drag force increasesSanaei et al., 2010).

Before comparing the results obtained at ambient temperatureith and without a draft tube, it should be mentioned that the con-

cal spouted bed without a draft tube is made of plexiglass, whereashe one with the draft tube is made of stainless steel. Consequentlyhe collisions between the sand and the contactor wall are moreevere in the latter case. Nevertheless, the mass loss with draft tubeand higher (u/ums)0 ratio) is less than a quarter of that observedithout a draft tube. This difference is due to the solid circulationattern when working with a draft tube. Thus, in the operationith a non-porous draft tube, the particles are incorporated into

he spout at the bottom of the contactor, whereas in a plain conicalpouted bed the incorporation of solids into the spout takes placet all heights throughout the spout. In the latter case, the particleshat are incorporated into the spout above the bottom collide with

rsoe

b) (u/ums)0 = 1.35. (Points: experimental data; lines: calculated.)

ther particles arising at a high velocity, thus causing severe break-ge due to the difference in their velocities. This situation is fullyvoided when working with a draft tube because all the particlesnter the spout at the bottom and their relative velocity is almostero. Moreover, in a spouted bed without a draft tube, there areiolent collisions between the particles in the spout and the layerf annulus particles constituting the spout wall. These collisionsre avoided by operating with a draft tube. These findings revealdditional advantages for operating with a draft tube because thenterest in reducing attrition is not only related to the avoidancef bed material loss but also to the cost of removing fine particlesownstream of the fluidized or spouted bed (Stein et al., 1998).

. Kinetics of sand attrition

Experimental data were fitted to different first-order kineticodels reported in the literature, specifically those by Gwyn (1969)

nd Lee et al. (1993).Gwyn’s equation is the most versatile model describing granu-

ar attrition and states that the elutriated weight fraction of sand atoom temperature is proportional to time under constant strainate conditions, Eq. (1). To estimate the weight changes of theand in the spouted bed using Lee’s formula, Eq. (2), the definition

f parameter Ka must be modified by assuming that it dependsxclusively on the excess air velocity over that corresponding to598 A.R. Fernández-Akarregui et al. / Particuology 10 (2012) 592– 599

Fb

mT

K

was

di

O

wan

iat(

tatttmb

Fu

bidp

cpnomsqb

5

etBritmsat

wmwmc

cip

wi

ig. 12. Bed weight evolution for sands I and II for different air velocities and initialed weights of (a) 6 kg and (b) 4.5 kg. (Points: experimental data; lines: calculated.)

inimum spouting velocity at the beginning of the run (u − ums)0.he empirical correlation proposed for Ka is:

a = k0e−k1/u(u−ums)0 , (4)

ith constants k0 and k1 depending on the contactor geometrynd various parameters related to the bed (solid density, porosity,phericity, particle mean diameter and bed height).

Scilab algorithms have been developed to fit the experimentalata to the above mentioned models. The objective function (OF)

s defined as:

F =∑m

i=1(Wcal − Wexp)2n +

∑mj=1(Wcal − Wexp)2

m

n + m, (5)

here Wcal and Wexp are the bed weights calculated with the modelnd the experimental values, respectively, and n and m are theumber of measurements in each one of the runs carried out.

In order to determine the model of best fit for the attrition kinet-cs in a conical spouted bed reactor, the data obtained for sand It different velocities were fitted to both models. Fig. 11 showshe results for two air velocities, 48 m/s (Fig. 11(a)) and 54 m/sFig. 11(b)).

By comparing the experimentally measured bed weights withhose calculated using the equations, it is clear that both modelsre acceptable for predicting attrition kinetics in spouted beds, buthe one based on that proposed by Lee et al. (1993) fits better the

rend for long time runs due to its exponential term. Consequently,he model developed by Lee et al. (1993) was fitted to the experi-ental results obtained for different sand types, gas velocities anded heights to compare experimental and calculated evolutions of

cati

ig. 13. Comparison of experimental data for bed weight with those calculatedsing Lee’s model.

ed weight as shown in Fig. 12(a) for initial bed weight of 6 kg, andn Fig. 12(b) for 4.5 kg, both showing how faithfully the model pre-icts the experimental evolution of bed weight, with the attritionarameters k0 = 6.77 × 10–3 h–1 and k1 = −0.068 (m2/s2).

Fig. 13 compares experimental data for bed weight with thosealculated using Lee’s model to show the adequacy of the modelroposed. Despite satisfactory prediction of the model it should beoted that, similar to other attrition models, it is highly dependentn the geometric factors determining the hydrodynamic perfor-ance in the contactor. Moreover, the physical properties of the

and also play a significant role on the attrition process. Conse-uently, the attrition parameters calculated in this paper shoulde extrapolated with care to other experimental conditions.

. Conclusions

Two attrition kinetic models proposed by Gwyn (1969) and Leet al. (1993) were fitted to experimental data obtained with twoypes of silica sand in a spouted bed contactor at room temperature.oth provide acceptable results but the second one predicts betteresults for long time runs due to the exponential term involvedn the equation. The attrition rate constant (Ka) depends exponen-ially on the excess of air velocity over that corresponding to the

inimum spouting velocity at zero time. The values of the con-tants k0 and k1 are 6.77 × 10–3 h–1 and −0.068 m2/s2, respectively,nd they depend on contactor geometry and bed material proper-ies.

As inlet air velocity is raised attrition rate increases until bedeight reaches a minimum value (Wmin) at steady state. Further-ore, the higher the inlet air velocity, the lower the final bedeight. Consequently, in order to maintain a given weight of bedaterial in the contactor, and therefore the height of the bed, a

ertain amount of material will have to be added.Particle properties play an important role in the attrition pro-

ess. Especially noteworthy is the effect of textural properties, thats, sand particles (type II) with sharp edges undergo more severearticle breakage than the more rounded.

A sharp reduction in attrition has been observed when operatingith a draft tube. The insertion of an internal device avoids the

ncorporation of particles into the spout at different heights and,onsequently, avoids violent impacts in this region. Furthermore,

ttrition decreases as temperature is increased, which is attributedo the less vigorous gas–solid contact and the resulting reductionn particle breakage.l. / Par

oFwo

A

EaC

R

A

A

A

A

A

A

A

B

B

B

B

B

B

B

C

C

C

d

d

E

E

F

F

G

H

I

K

K

L

L

L

L

L

M

M

MM

O

O

O

O

O

S

S

S

S

S

S

V

W

W

W

A.R. Fernández-Akarregui et a

Fountain height is another essential parameter in the designf spouted beds, as it determines the total height of the reactor.ountain height increases when small particles are handled andhen attrition increases the fraction of these particles in the bed

ver time.

cknowledgments

The authors would like to thank the Basque Government for theTORTEK Strategic Programme, the Provincial Council of Gipuzkoand the Spanish Ministry of Science and Education for the ProjectTQ2010-16133.

eferences

guado, R., Olazar, M., Barona, A., & Bilbao, J. (2000). Char-formation kinetics inthe pyrolysis of sawdust in a conical spouted bed reactor. Journal of ChemicalTechnology and Biotechnology, 75, 583–588.

l-Senawi, S., Hadi, B., Briens, C., & Chabagno, J. M. (2008). A comparison of thebreakage mechanisms for attrition of selected polymers in pneumatic transportand spouted beds. International Journal of Chemical Reactor Engineering, 6.

ltzibar, H., Lopez, G., Aguado, R., Alvarez, S., San Jose, M., & Olazar, M. (2009).Hydrodynamics of conical spouted beds using different types of internal devices.Chemical Engineering & Technology, 32, 463–469.

mutio, M., Lopez, G., Aguado, R., Artetxe, M., Bilbao, J., & Olazar, M. (2011). Effectof vacuum on lignocellulosic biomass flash pyrolysis in a conical spouted bedreactor. Energy and Fuels, 25, 3950–3960.

ltzibar, H., Lopez, G., Alvarez, S., Jose, M., Barona, A., & Olazar, M. (2008). A draft-tubeconical spouted bed for drying fine particles. Drying Technology, 26, 308–314.

rena, U., D’Amore, M., & Massimilla, L. (1983). Carbon attrition during the fluidizedbed combustion of a coal. AIChE Journal, 29, 40–49.

zizi, S., Hosseini, S. H., Moraveji, M., & Ahmadi, G. (2010). CFD modeling of a spoutedbed with a porous draft tube. Particuology, 8, 415–424.

elyaev, A. (2008). Gasification of low-grade fuels in a spouted bed for power gen-eration. Solid Fuel Chemistry, 42, 335–341.

emrose, C. R., & Bridgwater, J. (1987). A review of attrition and attrition test meth-ods. Powder Technology, 49, 97–126.

erghel, J., Nilsson, L., & Renstrom, R. (2008). Particle mixing and residence timewhen drying sawdust in a continuous spouted bed. Chemical Engineering andProcessing, 47, 1252–1257.

oerefijn, R., Ghadiri, M., & Salatino, P. (2007). Attrition in fluidised beds. In A.Salman, M. Ghadiri, & M. Hounslow (Eds.), Handbook of powder technology:Particle breakage (pp. 1019–1053). Amsterdam: Elsevier B.V.

oerefijn, R., Gudde, N. J., & Ghadiri, M. (2000). A review of attrition of fluid crackingcatalyst particles. Advanced Powder Technology, 11, 145–174.

rown, R. L., & Richards, J. C. (1970). Principles of powder mechanics. Oxford: Perga-mon.

uczek, B. (1983). Working of active-carbon by attrition in a spouted bed. PowderTechnology, 35, 113–114.

hen, Z., Jim Lim, C., & Grace, J. R. (2007). Study of limestone particle impact attrition.Chemical Engineering Science, 62, 867–877.

ook, J. L., Khang, S. J., Lee, S. K., & Keener, T. C. (1996). Attrition and changes inparticle size distribution of lime sorbents in a circulating fluidized bed absorber.Powder Technology, 89, 1–8.

unha, F. G., Santos, K. G., Ataide, C. H., Epstein, N., & Barrozo, M. A. S. (2009). Annattopowder production in a spouted bed: An experimental and CFD study. Industrial& Engineering Chemistry Research, 48, 976–982.

a Rosa, C. A., & Freire, J. T. (2009). Fluid dynamics analysis of a draft-tube continu-ous spouted bed with particles bottom feed using CFD. Industrial & EngineeringChemistry Research, 48, 7813–7820.

a Rosa, G. S., & dos Santos Rocha, S. C. (2010). Effect of process conditions on particlegrowth for spouted bed coating of urea. Chemical Engineering and Processing:Process Intensification, 49, 836–842.

lordi, G., Olazar, M., Lopez, G., Artetxe, M., & Bilbao, J. (2011). Product yields andcompositions in the continuous pyrolysis of high-density polyethylene in aconical spouted bed reactor. Industrial & Engineering Chemistry Research, 50,6650–6659.

pstein, N., & Grace, J. R. (1997). Spouting of particulate solids. In M. E. Fayed,& L. Otten (Eds.), Handbook of powder science and technology. New York: VanNostrand-Reinhold.

lamant, G., Chraibi, M. A., Vallbona, G., & Bertrand, C. (1990). Decarbonation andattrition of calcite in a plasma spouted bed reactor. Journal de Physique, 51,

C527–C534.reitas, L. A. P., & Freire, J. T. (2001). Heat transfer in a draft tube spouted bed withbottom solids feed. Powder Technology, 114, 152–162.

wyn, J. E. (1969). On the particle size distribution function and the attrition ofcracking catalysts. AIChE Journal, 15, 35–39.

Z

Z

ticuology 10 (2012) 592– 599 599

alder, P. K., & Basu, P. (1992). Attrition of spherical electrode carbon particles dur-ing combustion in a turbulent fluidized bed. Chemical Engineering Science, 47,527–532.

shikura, T., Nagashima, H., & Ide, M. (2003). Hydrodynamics of a spouted bed witha porous draft tube containing a small amount of finer particles. Powder Tech-nology, 131, 56–65.

onduri, R. K., Altwicker, E. R., & Morgan, M. H. I. (1999). Design and scale-up of aspouted-bed combustor. Chemical Engineering Science, 54, 185–204.

ono, H. (1981). Attrition rates of relatively coarse solid particles in various typesof fluidised beds. AIChE Symposium Series, 77, 96–106.

ee, S. K., Jiang, X., Keener, T. C., & Khang, S. J. (1993). Attrition of lime sorbents duringfluidization in a circulating fluidized bed absorber. Industrial and EngineeringChemistry Research, 32, 2758–2766.

in, C. L, & Wey, M. Y. (2003). Effects of high temperature and combustion onfluidized material attrition in a fluidized bed. Korean Journal of Chemical Engi-neering, 20, 1123–1130.

in, C. L., & Wey, M. Y. (2005). Influence of hydrodynamic parameters on parti-cle attrition during fluidization at high temperature. Korean Journal of ChemicalEngineering, 22, 154–160.

opez, G., Olazar, M., Aguado, R., & Bilbao, J. (2010). Continuous pyrolysis of wastetyres in a conical spouted bed reactor. Fuel, 89, 1946–1952.

uo, B., Lim, C. J., Freitas, L. A. P., & Grace, J. R. (2004). Flow characteristics in aslot-rectangular spouted beds with draft plates. Canadian Journal of ChemicalEngineering, 82, 83–88.

akibar, J., Fernandez-Akarregi, A. R., Alava, I., Cueva, F., Lopez, G., & Olazar, M.(2011). Investigations on heat transfer and hydrodynamics under pyrolysisconditions of a pilot-plant draft tube conical spouted bed reactor. ChemicalEngineering and Processing: Process Intensification, 50, 790–798.

arkowski, M., Sobieski, W., Konopka, I., Tanska, M., & Bialobrzewski, I. (2007).Drying characteristics of barley grain dried in a spouted-bed and combined IR-convection dryers. Drying Technology, 25, 1621–1632.

athur, K. B., & Epstein, N. (1974). Spouted beds. New York: Academic Press.errick, D., & Highley, J. (1974). Particle size reduction and elutriation in a flu-

idized bed process. American Institution Chemical Engineering Symposium Series,70, 366–378.

lazar, M., Alvarez, S., Aguado, R., & San Jose, M. (2003). Spouted bed reactors.Chemical Engineering & Technology, 26, 845–852.

lazar, M., Lopez, G., Altzibar, H., Aguado, R., & Bilbao, J. (2009). Minimum spout-ing velocity under vacuum and high temperature in conical spouted beds. TheCanadian Journal of Chemical Engineering, 87, 541–546.

lazar, M., San Jose, M. J., Zabala, G., & Bilbao, J. (1994). A new reactor in jetspouted bed regime for catalytic polymerizations. Chemical Engineering Science,49, 4579–4588.

lazar, M., Lopez, G., Altzibar, H., & Bilbao, J. (2011). Modelling batch drying of sandin a draft-tube conical spouted bed. Chemical Engineering Research and Design,89, 2054–2062.

liveira, H. V. A., Peixoto, M. P. G., & Freitas, L. A. P. (2005). Study on the effi-ciency of hard gelatin capsules coating in a spouted bed. Drying Technology,23, 2039–2053.

anaei, S., Mostoufi, N., Radmanesh, R., Sotudeh-Gharebagh, R., Guy, C., & Chaouki, J.(2010). Hydrodynamic characteristics of gas–solid fluidization at high temper-ature. Canadian Journal of Chemical Engineering, 88, 1–11.

hih, H. H., Chu, C. Y., & Hwang, S. J. (2003). Solids circulation and attrition rates andgas bypassing in an internally circulating fluidized bed. Industrial and Engineer-ing Chemistry Research, 42, 5915–5923.

piegl, N., Sivena, A., Lorente, E., Paterson, N., & Milian, M. (2010). Investigation of theoxy-fuel gasification of coal in a laboratory-scale spouted-bed reactor: Reactormodifications and initial results. Energy & Fuels, 24, 5281–5288.

tein, M., Seville, J. P. K., & Parker, D. J. (1998). Attrition of porous glass particles ina fluidised bed. Powder Technology, 100, 242–250.

wasdisevi, T., Tanthapanichakoon, W., Charinpanitkul, T., Kawaguchi, T., Tanaka,T., & Tsuji, Y. (2004). Investigation of fluid and coarse-particle dynamicsin a two-dimensional spouted bed. Chemical Engineering & Technology, 27,971–981.

wasdisevi, T., Tanthapanichakoon, W., Charinpanitkul, T., Kawaguchi, T., Tanaka,T., & Tsuji, Y. (2005). Prediction of gas-particle dynamics and heat transfer in atwo-dimensional spouted bed. Advanced Powder Technology, 16, 275–293.

ieira Neto, J. L., Duarte, C. R., Murata, V. V., & Barrozo, M. A. S. (2008). Effect of adraft tube on the fluid dynamics of a spouted bed: Experimental and CFD studies.Drying Technology, 26, 299–307.

elt, J., Lee, W., & Krambeck, F. J. (1977). Catalyst attrition and deactivation in fluidcatalytic cracking system. Chemical Engineering Science, 32, 1211–1218.

ongvicha, P., & Bhattacharya, S. C. (1994). Attrition of lignite char in a spouted bedcombustor. International Journal of Energy Research, 18, 9–20.

u, S. Y., Baeyens, J., & Chu, C. Y. (1999). Effect of the grid-velocity on attrition ingas fluidized beds. The Canadian Journal of Chemical Engineering, 77, 738–744.

hao, X., Li, S., Liu, G., Song, Q., & Yao, Q. (2008). Flow patterns of solids in atwo-dimensional spouted bed with draft plates: PIV measurement and DEMsimulations. Powder Technology, 183, 79–87.

hao, X., Yao, Q., & Li, S. (2006). Effects of draft tubes on particle velocity profiles inspouted beds. Chemical Engineering & Technology, 29, 875–881.