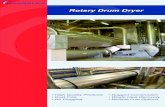

Rotary Drum Brochure

-

Upload

bkstevenson -

Category

Documents

-

view

27 -

download

1

description

Transcript of Rotary Drum Brochure

Ordering Information To order one of our standard rotary drums, or for more information about ACT services, including complete catalogs of ACT rotary drums, fluid beds and other process equipment, you may contact us by phone, fax, mail or e-mail.

APPLIED CHEMICAL TECHNOLOGYTM

The World Leader In Process Equipment Design.

Applied Chemical Technology, Inc.

4350 Helton Drive Florence, Alabama, USA 35630

Toll Free: 1-800-ACT-3217 Phone: 1-256-760-9600 Fax: 1-256-760-9638 e-mail: [email protected] Web sites: http://www.appliedchemical.com

http://www.thomasregister.comlappliedchemical

Applied Chemical Technology is a trademark of Applied Chemical Technology, Inc. ©2000 Applied Chemical Technology, Inc. 2S00-2-0SRD

APPLIED CHEMICAL TECHNOLOGYTM

The World Leader In Process Engineering.

•

Technical and

ACT offers complete engineering services to take your project from start to finish. Our engineering

and design team will evaluate your process, production and site requirements to develop the rotary

drum system that is right for you. Once fabrication is complete, your rotary drum undergoes rigorous

testing at our facilities. Our technicians will then install your rotary drum at any site you choose.

We'll also oversee your startup operations to ensure that your rotary drum works perfectly for your

process and production needs. We can also train your employees to operate your new equipment, either on site or at our complete pilot plant facilities. And should you wish to make later changes or

need other assistance, our engineering team is readily available to meet your needs.

ACT Engineering and Technical services include:

• Chemical, civil, mechanical, electrical and automation engineering

• Raw materials, process, product and site evaluation

• Custom research, development, engineering and design

• Lab and pilot plant testing

• Equipment testing at ACT

• Startup assistance

• Operator training

• Test production runs at ACT

• Complete technical support • Equipment and process modification

• Electrical design

• Instrument and automation design

ACT operates in accordance with the requirements of the ASME Boiler

and Pressure Vessel Code.

and Modifications At ACT we understand that . does not fit all That's why all of our rotary one Size . drums can be easily

ACT can also design custom internals for your existing drum, allowing modified to suit your specific needs.

you to improve your process efficiency or even convert your rum d for a new process. \Vhatever you need,

we can design and build it.

Your specialty rotary drum could include:

• Automated Controls • Custom Internals

• Screen Shell Sections - for material sizing

• Hoods • Breeches

-Dust seals

- Access doors

- Customized for your process

• Steam Jacketing

• Shell Access Doors - Allows servicing of intenals

• Flanged Shell

• Rubber Shell liners - Prevents material build up

• Shell Hammers

- Knocks product loose, prevents build up

• Variable Slope

• Bucket Discharge

• Slow Running / Fast Running Operation .

- Total range of speed available for all drum Slzes

• Skid Mounted

• Unitized or Separate Trunnions and Drive Bases

• Complete Drum Systems

- Full granulation systems

- Inert atmosphere systems

- Blowers

- Heaters

- Complete plants

• Multi-function Drum Design . I d - Heating, coating, drying, coo ing, screenmg, e . I tc in a sing e rum

- Batch or continuous process

• Aluminum or Specialty Metal Construction

Process

d ·d I for a wide range of applications, including: ACT rotary rums are 1 ea

• Granulating • Heating

- Agglomeration • Conditioning

- Reaction • Incinerating

- Spray Granulation • Milling

• Cooling • Mixing

• Drying • Impregnating

• Coating

Standard Rotary Drums

ACT can provide you with a variety of rotary drum models suitable for any application.

Many of our models include internals, heating and cooling units, or other built-in

featu res to save you space and money. Sizes of ou r standard models range from

counter-top laboratory rotary drums (capable of approximately 1 to 5 kg batches,

depending on material) to industrial-scale models with operating capcities up to 100

tons per hour and more. We also build complete process systems to handle every

aspect of your production needs.

ACT Standard Rotary Drums include the following:

• Shell thickness up to 1 112" • Carbon Steel or Stainless Steel Construction

• Drive System (will vary according to your application and preference)

- Helical

- Parallel

- Cycloidal

• Gear - High Horsepower

• Chain - Lower Horsepower

• Friction - Low cost

- Easily adjustable

• Axis • Pan • Riding Ring "Floating Tire"

- High heat expansion toleration

- Heat treated for hardness

- Reduces operating stresses

- ACT's exclusive ring design eliminates uneven wear

• Trunnions

- One piece forged steel construction

- Bearings rated for minimum 50,000 hours

- 1045 or 4140 heat treated carbon steel

(stainless steel and other materials available)

(friction trunnions are rubber or polyurethane)

- Adjustable alignment

- We provide on-site precision alignment for every drum we sell.

• Thrust Rollers

- Heavy Duty

- Adjustable for precision alignment

• Gear Box

- Soft starts available

- Fluid coupling

- Variable speed (mechanical/electrical)

- Programmable drives

- Speed sensing

- Reverse operation

• Optional Internals (will vary with your application)

- lifting flights

- Mixing flights

- Spiral flights

- Anti -slip flights

- Bed shaping flights

- Collection pans

- liquid / solid / slurry / gas distribution systems

- Reciprocating scraper bars

- Spray systems

- Heating / cooling systems

• Modular or complete system designs

• Easy operation and clean up

• Full compatibility with all ACT industrial equipment

ACT can design custom internals to meet any process needs, while assuring you

oj the most economical process operation.

Standard Rotary Drums

ACT can provide you with a variety of rotary drum models suitable for any application.

Many of our models include internals, heating and cooling units, or other built-in

featu res to save you space and money. Sizes of ou r standard models range from

counter-top laboratory rotary drums (capable of approximately 1 to 5 kg batches,

depending on material) to industrial-scale models with operating capcities up to 100

tons per hour and more. We also build complete process systems to handle every

aspect of your production needs.

ACT Standard Rotary Drums include the following:

• Shell thickness up to 1 112" • Carbon Steel or Stainless Steel Construction

• Drive System (will vary according to your application and preference)

- Helical

- Parallel

- Cycloidal

• Gear - High Horsepower

• Chain - Lower Horsepower

• Friction - Low cost

- Easily adjustable

• Axis • Pan • Riding Ring "Floating Tire"

- High heat expansion toleration

- Heat treated for hardness

- Reduces operating stresses

- ACT's exclusive ring design eliminates uneven wear

• Trunnions

- One piece forged steel construction

- Bearings rated for minimum 50,000 hours

- 1045 or 4140 heat treated carbon steel

(stainless steel and other materials available)

(friction trunnions are rubber or polyurethane)

- Adjustable alignment

- We provide on-site precision alignment for every drum we sell.

• Thrust Rollers

- Heavy Duty

- Adjustable for precision alignment

• Gear Box

- Soft starts available

- Fluid coupling

- Variable speed (mechanical/electrical)

- Programmable drives

- Speed sensing

- Reverse operation

• Optional Internals (will vary with your application)

- lifting flights

- Mixing flights

- Spiral flights

- Anti -slip flights

- Bed shaping flights

- Collection pans

- liquid / solid / slurry / gas distribution systems

- Reciprocating scraper bars

- Spray systems

- Heating / cooling systems

• Modular or complete system designs

• Easy operation and clean up

• Full compatibility with all ACT industrial equipment

ACT can design custom internals to meet any process needs, while assuring you

oj the most economical process operation.

and Modifications At ACT we understand that . does not fit all That's why all of our rotary one Size . drums can be easily

ACT can also design custom internals for your existing drum, allowing modified to suit your specific needs.

you to improve your process efficiency or even convert your rum d for a new process. \Vhatever you need,

we can design and build it.

Your specialty rotary drum could include:

• Automated Controls • Custom Internals

• Screen Shell Sections - for material sizing

• Hoods • Breeches

-Dust seals

- Access doors

- Customized for your process

• Steam Jacketing

• Shell Access Doors - Allows servicing of intenals

• Flanged Shell

• Rubber Shell liners - Prevents material build up

• Shell Hammers

- Knocks product loose, prevents build up

• Variable Slope

• Bucket Discharge

• Slow Running / Fast Running Operation .

- Total range of speed available for all drum Slzes

• Skid Mounted

• Unitized or Separate Trunnions and Drive Bases

• Complete Drum Systems

- Full granulation systems

- Inert atmosphere systems

- Blowers

- Heaters

- Complete plants

• Multi-function Drum Design . I d - Heating, coating, drying, coo ing, screenmg, e . I tc in a sing e rum

- Batch or continuous process

• Aluminum or Specialty Metal Construction

Process

d ·d I for a wide range of applications, including: ACT rotary rums are 1 ea

• Granulating • Heating

- Agglomeration • Conditioning

- Reaction • Incinerating

- Spray Granulation • Milling

• Cooling • Mixing

• Drying • Impregnating

• Coating

•

Technical and

ACT offers complete engineering services to take your project from start to finish. Our engineering

and design team will evaluate your process, production and site requirements to develop the rotary

drum system that is right for you. Once fabrication is complete, your rotary drum undergoes rigorous

testing at our facilities. Our technicians will then install your rotary drum at any site you choose.

We'll also oversee your startup operations to ensure that your rotary drum works perfectly for your

process and production needs. We can also train your employees to operate your new equipment, either on site or at our complete pilot plant facilities. And should you wish to make later changes or

need other assistance, our engineering team is readily available to meet your needs.

ACT Engineering and Technical services include:

• Chemical, civil, mechanical, electrical and automation engineering

• Raw materials, process, product and site evaluation

• Custom research, development, engineering and design

• Lab and pilot plant testing

• Equipment testing at ACT

• Startup assistance

• Operator training

• Test production runs at ACT

• Complete technical support • Equipment and process modification

• Electrical design

• Instrument and automation design

ACT operates in accordance with the requirements of the ASME Boiler

and Pressure Vessel Code.

Ordering Information To order one of our standard rotary drums, or for more information about ACT services, including complete catalogs of ACT rotary drums, fluid beds and other process equipment, you may contact us by phone, fax, mail or e-mail.

APPLIED CHEMICAL TECHNOLOGYTM

The World Leader In Process Equipment Design.

Applied Chemical Technology, Inc.

4350 Helton Drive Florence, Alabama, USA 35630

Toll Free: 1-800-ACT-3217 Phone: 1-256-760-9600 Fax: 1-256-760-9638 e-mail: [email protected] Web sites: http://www.appliedchemical.com

http://www.thomasregister.comlappliedchemical

Applied Chemical Technology is a trademark of Applied Chemical Technology, Inc. ©2000 Applied Chemical Technology, Inc. 2S00-2-0SRD

APPLIED CHEMICAL TECHNOLOGYTM

The World Leader In Process Engineering.