Retained Austenite in TRIP-Assisted Steels role of transformation plasticity China Steel.

-

date post

20-Dec-2015 -

Category

Documents

-

view

233 -

download

0

Transcript of Retained Austenite in TRIP-Assisted Steels role of transformation plasticity China Steel.

Retained Austenite in TRIP-Assisted

Steelsrole of transformation plasticity

China Steel

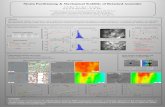

Shape deformations due to transformations

Fe-30.5Ni-0.32C wt%

Forsik, 2004

Invariant-plane strain

s

1

s

1

1

uniaxial dilatation

simple shear

general invariant-plane

strain

s=0.26

=0.03

Minimum requirement for martensitic transformation

• there must exist an invariant-line at interface

• i.e., one set of dislocations which can glide conservatively

• can be more than one invariant-line

body-centred cubic

cubic close-packed

(a)

BAIN STRAIN

(c) Body-centered

tetragonal austenite

(d) Body-centered

cubic martensite

a

a

a1

2

3 b3

b1 b2

(b)

[100]

[001]

o

aa'

b

b'

o b'

b

a,a'

(a)

(b)

Austenite Martensite (wrong shape)

Twinned Martensite

Slipped Martensite

Twin Boundary

Observed shape, wrong structure

RB

P

LATTICE -INVARIANT DEFORMATION

Correct macroscopic shape, correct structure

(a) (b) (c)

w

x

y

z

w

x

z

y x

w z

y

x

w z

y x

w z

y

P1 2

Bhadeshia & Edmonds, (1980)

Typical composition:

Fe-0.15C-1.5Si-1.5Mn wt%

polycrystalline

Bhadeshia & Edmonds, (1980)

b

Is the shear important in a polycrystalline sample?

How can we bias the microstructure?

By transforming under the influence of stress.

s

1

s

1

1

uniaxial dilatation

simple shear

general invariant-plane

strain

s=0.26

=0.03

50 m

polycrystalline austenite

Bhadeshia, 1982

What is the maximum tensile strain obtained from TRIP?

……in a fully austenitic sample which transforms completely into martensite.

sz3

z1

u v

Sakuma et al. (1991)

abso

rbed

ene

rgy

/ kJ

Yoshitake et al. (1996)

Retained Austenite in TRIP-Assisted

SteelsSlide 1Slide 1…..very small

contribution to elongation.

Bhadeshia & Edmonds, (1980)

Composite of soft and hard phase

Bhadeshia & Edmonds, (1980)

strain in soft phase

Str

ain

in h

ard

phas

e

Tomota (1976)

Bhadeshia & Edmonds, (1980)

low silicon high silicon

Jacques et al. (2001)

silicon causes scale

Summary

• Assistance from TRIP is less than 1.4% of total strain

• Emphasis could be shifted from retained austenite to studies of composite deformation

• Low silicon steels can perform well (Jacques)

Sherif et al. 2003

Sherif et al. 2003

Sherif et al. 2003

Sherif et al. 2003