The Redwood gazette. (Redwood Falls, Minn.), 1921-10-05, [p ].

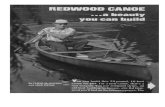

Redwood Canoe16 PSMar67

-

Upload

nongsamrong -

Category

Documents

-

view

222 -

download

0

Transcript of Redwood Canoe16 PSMar67

-

8/14/2019 Redwood Canoe16 PSMar67

1/6

-

8/14/2019 Redwood Canoe16 PSMar67

2/6

Make the building form and attach templatesto the crosspieces. Nail a strip down the cen-

ter to hold the stems and templates in position.

Redwood strips are tacked to the templates,and edge-glued. Drive brads through into the

templates before putting on fiberglass doth.

prototype canoe took about three weekendsto build. She's broad of beam and flatbot-tomed amidship. Two persons can sit sideby side in the center, with one person ateach end and plenty of room for gear.

This canoe is formed around plywoodtemplates using "-by-" redwood strips,glued edge to edge. You lay up the strips,remove the form, and the canoe is com-l f f b l d

and set them in place on the frame. Gluetwo pieces of white pine together for eachstem, and trace the lines from the full-sizedrawing on each. Bevel each piece to ac-cept the redwood side strips. Tie togetherthe stempieces and the templates with a"-square strip of wood.

Next, rip the longer straight-grain red-wood planks (see Materials List) into strips" id Y d b 70 f h

21

-

8/14/2019 Redwood Canoe16 PSMar67

3/6

nail each strip to the templates. Place thestrips so that the " width forms the thick-ness of the hull. Don't nail the strips to theendpieces yet.

A f t e r each strip is nailed in place put

beyond the stempieces. Glue them withresorcinol and nail them with " coppernails.

A little ingenuity is needed to clamp theends of the strips tight A large rubber band

Bevel strips so they meet in front of stem.A tight fit is not necessary, since the stems

are covered with two layers of cloth and resin.

Clamping jigs hold the stnps in place when youreach the point where twist gets bad. Scraps

from the beveled stem make good clamping pads.3 4

-

8/14/2019 Redwood Canoe16 PSMar67

4/6

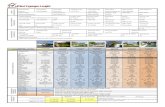

CHANGEFORM TO

BENCH FORWORKINGINSIDECANOE

RAG PADS

2" x 4" x 20"

2"x 8 x 24"

" REDWOODSTRIPS STAGGERED

AT KEEL

5

89

.625" x 1" x 5"ALUMINUM

CUT OFF EXCESSAFTERLEVELING

SEAT

COUNTERSINKNUT

4 NUTS

" DIA. x 6"BRASS ROD

THREADEDBOTH ENDS

WEBBING

SEAT" - 4RH SCREW

MATERIALS

" x .125" x 2"ALUMINUM

12"

15"

14"

18"18"

-

8/14/2019 Redwood Canoe16 PSMar67

5/6

1" SQUARES

STEMCUT FROM TWO

PIECES 1" x 12" x 22"PINE GLUEDTOGETHER

" SQ. STRlP(TEMPORARY)

MOLDFRAMES

PLYWOOD"

1"

2

3

4

1

24"2" x 4"s 18"

18"

18"

5

6

-

8/14/2019 Redwood Canoe16 PSMar67

6/6

Redwood Canoe You Can Build[Continued from page 173]

When all strips are in place, sand thehull and give the outside a coat of poly-ester or epoxy resin. When this has set,make a thin-point nail set and punch allnails in each strip through, into the form.

Cover the outside with glass cloth andanother coat of resin. Start at the centerand work the cloth toward each end. Afew staples hold it while you apply the resin.

Use inexpensive paintbrushes to applythe resin. Wear rubber gloves, and use asqueegee to work the resin through fiber-glass. A ft e r the firs t coat of resin, fit anextra strip of fiberglass at each end to over-lap about 2" on each side.

When the resin is set, sand the roughspots and apply the second coat. Two coatsof cloth and resin should be enough.

Removing the templates. After the out-side is finished, take out the screws thathold the, templates to the form, and care-fully remove the templates. To do this,push them toward the larger part of thehull. Turn the canoe right side up on thebuilding form to work on the inside.

Sand the inside and coat it with resin.Shape and attach the keel before glassing

and finishing the interior. The blueprintshows how to change the building form tohold the canoe at an angle; it makes work-ing inside easier.

Cover only half of the inside at a time.This lets you overlap the glass at the centerfor more strength. Before pu tt ing in thefull-length glass cloth, work some left-overpieces in at the stems.

You can cut 60" -wide cloth in half and staple the selvage about " over thecenter line so that the keel screws are cov-ered. Work it up the sides and towardeach end. A few staples may be neededalong the top edge until the resin is on;they may then be pulled out. One layer of resin and cloth is enough inside.

When the resin is set, trim off the excessglass cloth. Attach tho gunwales and in-wales with either screws or bolts,

Build and varnish the seats, breast plates,and yoke, and fasten them in place.

These plans let you build a 13' canoe,too. You build it the same way, but youeliminate templates 4 and 5, making tem-plate 6 the center of the hull. Nothing elseneed be changed.

![The Redwood gazette. (Redwood Falls, Minn.), 1921-10-05, [p ].](https://static.fdocuments.net/doc/165x107/61e75daafb034a33595cb385/the-redwood-gazette-redwood-falls-minn-1921-10-05-p-.jpg)

![The Redwood gazette. (Redwood Falls, Minn.), 1909-05-19, [p ].](https://static.fdocuments.net/doc/165x107/61f3066c4fb1c01f2e62eb08/the-redwood-gazette-redwood-falls-minn-1909-05-19-p-.jpg)