Recent Advances in Flow Chemistry. Asia Unique Modules Asia FLLEX: The Flow Liquid-Liquid Extraction...

-

Upload

millicent-murphy -

Category

Documents

-

view

218 -

download

0

Transcript of Recent Advances in Flow Chemistry. Asia Unique Modules Asia FLLEX: The Flow Liquid-Liquid Extraction...

Asia Unique Modules

Asia FLLEX: The Flow Liquid-Liquid Extraction module

• Continuous aqueous work-up

• Mixes organic and aqueous streams, allows time for diffusion

and then separate phases.

Asia Sampler and Diluter:

• Takes a sample, dilutes it before injecting onto an

HPLC/LCMS/UPLC.

• Dilution factors from 5 to 250.

• Compatible with the most popular analytical systems (Agilent,

Waters, etc...).

Asia Tube Cooler

• Reactor temperature: Ambient down to -68°C (dependent upon

cooling medium)

• Range of fluoropolymer, stainless steel and Hastelloy Asia Tube

Reactors can be cooled.

• Can either be used in standalone mode or can plug into an Asia

Heater to have the reaction temperature monitored and displayed

• Visible reactions: Reactions in Fluoropolymer tube reactors remain

visible due to a double glazing insulation and nitrogen purge

• Easy to use: Removable & easy to fill container for cooling medium

• Compact

• Launched in March 2014

• Syrris has developed a novel cooling system for ultra cold flow chemistry processes.

• The proprietary technology allows extremely cold flow reactions in a very compact unit,

powered only by mains power

New product launch

Asia Cryo Controller – Reactions as low as -100°C !

• Ultra cold flow processes: Cools tube reactors to -

70°C or microreactors to -100°C.

• Mains power only: No dry ice, liquid N2, running water

or circulator required for cooling!

• Compact: The module is just 16cm (6.3”) wide.

• Flexible: The module can cool a wide range of reactors

including glass or quartz microreactors (62.5μl or 250μl)

and fluoropolymer or stainless steel tube reactors (4ml

and 16ml).

• Clear reaction view: Clear insulation and a nitrogen

purge ensure the reaction can be viewed even at ultra

low temperatures.

• Easy automation: The Asia Cryo Controller can

connect to the Asia Manager PC Software

Asia Cryo Controller – As low as -100°C !

• Microreactor temperature control

• Glass or quartz

• Ambient to -100-100°C°C

• Tube reactor temperature control

• Fluoropolymer , Stainless Steel or Hastelloy

• Ambient to -70-70°C°C

Quick and easy swap

Why use Electrochemistry?

• Electrochemistry enables:

• Unique activation of reagents enabling selectivity and transformations not possible by

other techniques

• A reduction in the quantities of toxic and hazardous oxidising/reducing reagents used.

• Ideal for creating reactive intermediates

• Ideal for multi-step synthesis

• Rapid oxidations and reductions (even up to 6 electron oxidation)

• Oxidative synthesis of drug metabolites

• Electrochemistry is a surface phenomenon

• High surface areas to volume ratios are required

• A small gap between the electrodes lowers the requirement for additives/electrolytes

• Electrochemistry and Flow Chemistry are a perfect marriage !!

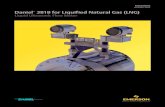

FLUX Control Module

Cell and holder

Asia FLUX control module

• Syrris is developing a flow electrochemistry system known as the FLUX module

• It will become part of the Asia product family

• The FLUX module controls the current or the voltage applied to the electrodes, locates the cell on the front of the module

• Can work in constant Voltage or constant Current mode

Control module

Working electrode

Counter electrode

Electrical connector

Gasket with channels (serpentine flow path)

Temperature control module

Electrochemistry Flow Cell

Electrodes are located on here

• The flow cell consists of pairs of

electrodes separated by a gasket.

• Cell can be divided to isolate

anode from cathode.

• Cell volume 225l.

• Electrode materials include SS, Pt,

C, Mg, Cu.

TEMPO-mediated electrooxidation of primary and secondary alcohols in a microfluidic electrolytic cell

• The University of Southampton oxidised 15 different alcohols to the corresponding aldehyde/ketone

• The reaction used a catalyst that could be electrochemically regenerated, allowing greener

chemistry

R1 R2

OH

R1 R2

O

1 2

TEMPO (30 mol %), anode (20 mA)

t-BuOH-HCO3-/CO3

2- buffer (1:1),

pH 11.5, 25 °C

N

O

N

O

N

OH

3

4

5

R1 R2

OH

R1 R2

O

1

2

Anode

(-e-)

Anode

(-e-)

J. T. Hill-Cousins, J. Kuleshova, R. A Green et al, ChemSusChem, 2012, 5, 326-331

Benzylic Oxidation of Tolyl Substrates

• AbbVie2 and Burnham Inst, FL1, US have been investigating a number of different applications in FLUX

• Anodic oxidations

• Fluorinations, Aryl Couplings, Reductive cyclisations and oxidative metabolite synthesis.

• First reaction was oxidation of p-methoxytoluene compounds

• Reaction is well researched on an industrial scale

• Achieved both 4e- and 6e- oxidation (6e- oxidation of p-methoxytoluene was yielded 62%)

• Methoxylation of o-Anisole to the four- and six- electron products has never been seen in the

electrochemical literature

G. P. Roth1, R. Stalder1, T. R. Long1, D. R. Sauer2 , S. W. Djuric2 J Flow Chem, 2013 , Vol 3, 2, pp 34-40

Benzylic Oxidation of Tolyl Substrates: Batch vs. Flow

• Compared flow results with the same reaction in batch

• The problem with over-oxidation seen in the batch process is overcome as new starting materials

are constantly flowing over the electrodes.

• Avoids oxidising already reacted substrates

• Very high degree of reproducibility, <3% variation in product formation and an ability to vary product

ratios (dependant upon electron equivalents)

Preparative Microfluidic Electrosynthesis of Drug Metabolites

• The Sanford-Burnham Medical Research Institute, Florida have researched the use of flow

electrochemistry to synthesise drug metabolites

• Electrochemistry can been used to simulate CYP450 oxidation

• However, this has been almost exclusively confined to the analytical scale

• In this paper, metabolites of several commercial drugs were synthesised at rates of up to 100mg/hr

using flow electrochemistry

R. Stalder and G. P. Roth, dx.doi.org/10.1021/ml400316p ACS Med. Chem. Lett., Accepted Oct 1st 2013

Preparative Microfluidic Electrosynthesis of Drug Metabolites

• The research aimed to synthesise oxidation products of the following drugs using flow

electrochemistry (using the Asia Flux Module):

• Diclofenac (DCF)

• Tolbutamide (TBM)

• Primidone (PMD)

• Albendazole (ABZ)

• Chlorpromazine (CPZ)

• A broad range of oxidative chemistry was targeted: aliphatic oxidation, aromatic hydroxylation, S-

oxidation, N-oxidation, or dehydrogenation.

R. Stalder and G. P. Roth, dx.doi.org/10.1021/ml400316p ACS Med. Chem. Lett., Accepted Oct 1st 2013

Preparative Microfluidic Electrosynthesis of Diclofenac Metabolites

• Initially, Diclofenac (DCF, an anti-inflammatory) was selected as the substrate

• Electrosynthesis of Phase I Metabolite of Diclofenac (DCF-5-OH) was synthesised in 46% yield (vs

25% batch process

• Sodium bisulfite used as electrolyte

• The 4 and 6 Glutathione Phase II Adducts (DCF-GS) were also both successfully synthesised in a 2

step continuous flow process via the Quinone Imine (DCF-5-QI)

glutathione

Preparative Microfluidic Electrosynthesis of Drug Metabolites

• After the success of Diclofenac, metabolites of four other commercial drugs were synthesised using

flow electrochemistry:

• Tolbutamide (TBM) (20%)

• Primidone (PMD)

• Albendazole (ABZ)

• Chlorpromazine (CPZ)

Preparative Microfluidic Electrosynthesis of Drug Metabolites – Conclusion

• Simulation of the in vivo metabolism of drugs have been demonstrated using a continuous-flow

electrochemical cell.

• Aromatic hydroxylation, alkyl oxidation, sulfoxidation, quinone imine formation, and glutathione

conjugation were achieved on a 10 to 100 mg scale of pure isolated metabolites per hour

• For any specific compound, the product selectivity of electrochemical oxidation is controlled by the

most redox-active sites on the molecule.

R. Stalder and G. P. Roth, dx.doi.org/10.1021/ml400316p ACS Med. Chem. Lett., Accepted Oct 1st 2013

Preparative Microfluidic Electrosynthesis of Drug Metabolites

• Electrosynthesis is not intended to replace analytical biosynthetic techniques

• CYP450 Oxidation mechanism very different to Electrochemical mechanism

• However, flow electrosynthesis can:

• Achieve a reaction output higher than that of typical electroanalytical techniques by

several orders of magnitude

• Enable complete structural elucidation by NMR

• Considerably reduces route development time and synthesis time to

metabolites

• Enables further bioassays and study of the toxicity of potential drug

candidates

• Rapid synthesis of new potential drug candidates and analogues

R. Stalder and G. P. Roth, dx.doi.org/10.1021/ml400316p ACS Med. Chem. Lett., Accepted Oct 1st 2013

Conclusions

• Flow chemistry is an exciting and growing area of research, coupling with other

techniques.

• Flow electrochemistry shows key benefits

• Syrris are developing an ‘out-of-the-box’ solution for enabling laboratory scale

electrochemistry to be carried out.

• FLUX module to be launched in 2014

• Syrris are currently working with a number of academics across the globe to further

the knowledge and use of flow electrochemical strategies.

Conclusion

• Many more exciting modules and systems to come soon

• Dedicated continuous nanoparticle systems

• Dedicated droplet nanoparticle/reactor systems

• Including Telos scale up system

• Up 300,000 droplets per second !!

• For all latest news, visit www.syrris.com

• Please visit www.syrris.com/applications to see more chemistry from our

customers