Railway Strategies Issue 105 Final Edition

Click here to load reader

-

Upload

schofield-publishing-ltd -

Category

Documents

-

view

295 -

download

46

description

Transcript of Railway Strategies Issue 105 Final Edition

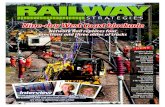

RAILWAYS T R A T E G I E Szzzzzzzzzzzzzzzzzzzzz

Issue 105 Final

The North West Electrification Programme is leading the way for

progressive electrification

F o r S E N I o r r A I L M A N A G E M E N T

Electrification contracts

announced

Dealing with Dawlish

Network Rail signs up to CP5

Record passenger growth continues

Civs frameworks awarded

ORR to review ticketing market

FutureRailway FutureRailway

launches structures & gate-line competitions

NEWS

See Page 22

FOCUS ON

l Electrificationl Plant & Equipment

l Depots & Maintenance

Interview : Rob Wallis talks about TRL’s innovative research

RS Live 2014 Preview page 4

Preview page 74

www.railwaystrategies.co.uk 1

ChairmanAndrew Schofield

Managing DirectorMike Tulloch

Editor Martin Collier

Managing EditorLibbie Hammond

Art EditorJon Mee

Advertisement DesignerJamie Elvin

Profile EditorLibbie Hammond

Advertisement SalesDave King

Head of Research

Philip Monument

Editorial ResearchersKeith Hope

Karl Riseborough Gavin Watson

Alex Merritt

AdministrationTracy Chynoweth

No part of this publication can be reproduced, stored in a retrieval system or transmitted in any form or by any means

(electronic, mechanical, photocopying, recording or other) without prior written permission being obtained from the publisher.

While every care has been taken to ensure the accuracy of the editorial content, the publishers cannot be held responsible for

any errors or omissions. Views expressed by the contributors are not necessarily those of the editor or the publisher.

Published by

Schofield Publishing Cringleford Business Centre,

Intwood Road, Cringleford, Norwich NR4 6AU

Email: [email protected]

Tel: 01603 274 130Fax: 01603 274 131

Little did I realise when I wrote the editorial for the previous issue of Railway

Strategies that the overwhelmingly dominant subject would remain the

same this time around: the weather. The hoped-for respite did eventually

materialize as February wore on but not before the rail infrastructure had

taken an unprecedented battering, remaining seriously compromised in a number

of areas – notably Dawlish. Damage recovery will set the agenda for weeks and

months, inevitably impacting on efforts to make a seamless transition between

Control Periods 4 and 5 in April. Locations such as Datchet and Maidenhead

amply demonstrate that water and electricity are not good bedfellows, with

the loss of traction and signalling power, respectively, as a consequence of

groundwater flooding. Inevitably the debate over the continued use of third-rail

traction power supply will resurface; if it isn’t leaves or snow and ice it’s water that

brings trains to a halt. There is good news, however, in that contracts have now

been announced to electrify a further 2000 track miles of the network in the North

West by means of overhead catenary. Just the wind to worry about then!

Stop PressNetwork Rail has announced that the Great Western Main Line through Dawlish will re-open on Friday 4th April, two weeks ahead of Easter.

Looking ahead to the spring, the Railway Strategies Live! conference will be

taking place again. As last year, the venue is the Royal Geographical Society in

London and a fascinating programme is being assembled – further details appear

within this issue.

So save the date: 15th May 2014

From the Editorzzzzzzzzzzzzzzz zzHave your details changed? Are you reading someone else’s copy of Railway Strategies?Please email: [email protected] to amend your details or request a regular copy

Issue 105 ISSN 1467-0395 Railway Strategies by email

Railway Strategies is also now available by email as a digital magazine. This exciting development is intended to complement the printed magazine, which we will continue to publish and distribute to qualifying individuals, whilst also giving added value to our advertisers through a more widespread circulation. To secure your continued supply of Railway Strategies in either digital or hard copy format, please contact our subscriptions manager Iain Kidd ([email protected]).

Elemental forces – continued!

Netw

ork

Rail

40

FeaturesExpert voice – Rob Wallis 6Libbie Hammond

Future-proofing the UK rail network 34Dan Rodgers

London Bridge transformation – Chris Drabble 40Gay Sutton

The future of urban mobility 44Arthur D. Little and the UITP

ProfilesLowery 17Tracksure 48Craig & Derricott 53Angel Trains 64Percy Lane Products 66NuSteel Structures 70Trackwork Moll 82Stadtwerke Bonn 88GB Railfreight 90Oleo International 93Odlewnie Polskie 97Trans Data Management 101 Arbil Rail 104PMA 106Kier 109

48

64

6

zzzzzzzzzzzzzzzzzzzzzzzzzContents

RS Live 2014 Preview 4

INFRARAIL Preview page 74

News

Focus on... Depots & Maintanence

Best practice in bearing lubrication 80

Malcolm Watson & Tony Synnott

Industry News 9Contracts 30

Rail Alliance 37Stations 38

Integrated Transport 47Products & Services 52

Research 56Rolling Stock 61

Health & Safety 100Conferences & Exhibitions 112IMechE Training Courses 112

58

22

61

zzzzzzzzzzzzzzzzzzzzzzzzzContents www.railwaystrategies.co.uk

14

Focus on... Electrification

Powering ahead – Jon Clee 22Gay Sutton

Modelling the Great Western electrification 26

Power is nothing without Protection & Control 28

Richard Jones

Helping 3.5 million London commuters get to work 32

Mark Beswick

Focus on... Plant & Equipment

Pumping concrete at Dawlish 58

Earthworks use long-reach solutions 59

Sound advice 60Andy Heatherington

zzzz

zzzz

zzzz

zzzz

zzzz

zz Network Rail to use Railway Strategies Live 2014 to launch its new Product Acceptance

process for the first time in an open forum. Conference to offer visitors access to Terence Watson,

Chairman of the newly created RSG

l The Supply Chain of the Futurel Finding the Right Route to Market

Royal Geographical Society (with IBG) 1 Kensington Gore, London SW7 2AR

Thursday May 15th 2014

Network Rail

Hosted in association with

RAILWAYS T R A T E G I E Szzzzzzzzzzzzzzzzzzzz

FOR SENIOR RAIL MANAGEMENT

2014Live

stop press

Gold Sponsor Silver Sponsor

Terence Watson – CEO, Alstom Transport UK & Ireland, Chair of the RSGDavid Clarke - Director, FutureRailway Enabling Innovation Team,

FutureRailway, hosted by RSSBJim Carter - Head of Procurement, Network Rail

James Lewis - Technology Introduction Manager, Network Rail Richard Holland - UK MD, TBM Consulting Group

Rob Wallis - Chief Executive, TRLMartyn Chymera - Former Chairman, Young Rail Professionals

Chris Rolison - Founder, Comply Serve

SPEAKERS

For further details of the event, email Mark Cawston: [email protected], for delegate enquiries, email Maxine Quinton: [email protected], telephone: 01603 274130 and ask for Mark or Maxine,

or visit: http://www.railwaystrategies.co.uk/eventbooking.php?id=574

Railway Strategies Live 2014 will deliver a conference that is designed to be a useful and memorable learning experience for all delegates, and valuable resource for sponsors and exhibitors. With extensive

prospects for networking it will be a unique opportunity to meet the people you need to in order to drive your business forward. The conference is already attracting interest from former delegates, sponsors and

exhibitors keen to secure repeat attendance. There are a number of sponsorship/exhibiting opportunities available, which will enable forward-thinking

businesses to expose their services and skill sets to an audience of delegates who are ready to embrace

innovation and bring state-of-the art technologies and approaches to the UK railway sector.

zzzz

zzzz

zzzz

zzzz

zzzz

zzThe Eighth Annual Conference from Railway Strategies (in association with the Rail Alliance) is being held at the

Royal Geographical Society (www.rgs.org) London, Thursday May 15th 2014

For further details of the event, email Mark Cawston: [email protected] for delegate enquiries, email Maxine Quinton: [email protected]

or telephone: 01603 274130 and ask for Mark or Maxine, or visit:

http://www.railwaystrategies.co.uk/eventbooking.php?id=574

www.railwaystrategies.co.uk 5

l Working in very close affiliation with the Rail Alliance and its members, Railway Strategies Live 2014 will deliver a conference that is going to cover the sort of topics that really matter to those in the rail supply chain. Following the results of a recent Rail Alliance research report, Railway Strategies Live is going to take a look at how the rail sector can make better use of the innovative capabilities of the SME in the supply chain. It will discuss why the Route to

Market is so very difficult and complex, and try to identify what is being done to put this right.

But not only is it going to put the spotlight on the small to medium enterprise (SME), but it is also going to offer the chance to hear how Terence Watson, the first ever chairman of the newly formed Rail Supply Group (RSG)

plans to create a more innovative and capable UK supply chain that has a clearer understanding of government policies and investment plans.

The conference will give visitors access to the Chairman of the RSG - their voices will help to shape the railway of the future!

ALSO AT THE EVENT - the launch of a very exciting new process from Network RailAnother factor that makes Railway Strategies Live a must-attend event is the news that Network Rail will be using

the conference to launch its new Product Acceptance process for the first time in an open forum. Jim Carter, Head of Procurement will discuss the merger of the two divisions at Network Rail, the Contracts/Procurement operation

and the National Delivery Service, into the new National Supply Chain headed up by Nick Ellis, who will be the Managing Director of the new operation.

In addition to the above, speakers from a range of blue-chip organisations have now been confirmed for Railway Strategies Live 2014. The confirmed speaker list is as follows:

Terence Watson, Chair of RSG + UK Country President & Managing Director, Alstom Transport UK & Ireland

David Clarke, Director, FutureRailway Enabling Innovation Team, FutureRailway, hosted by RSSBJim Carter, Head of Procurement, Network Rail

James Lewis, Technology Introduction Manager, Network RailRichard Holland, UK MD, TBM Consulting Group

Rob Wallis, Chief Executive, TRLMartyn Chymera, Former Chairman, Young Rail Professionals

Chris Rolison - Founder, Comply Serve

SPONSORED BY TBM CONSULTING GROUP

EIGHT SPEAKERS NOW CONFIRMED, INCLUDING JIM CARTER,

HEAD OF PROCUREMENT FOR NETWORK RAIL

MEET AND QUESTION THE FIRST EVER CHAIRMAN OF THE RSG, TERENCE WATSON, UK COUNTRY PRESIDENT & MANAGING DIRECTOR,

ALSTOM TRANSPORT UK & IRELAND

T RL, the Transport Research Laboratory, is an internationally

recognised centre of excellence, which provides world-class

research, consultancy, product testing and software tools

covering all aspects of transport. Rob Wallis joined TRL in

July 2013 as CEO, and he brings 30 years of professional services,

business services & ICT leadership experience, including five years at the

British Standards Institution (BSI) and almost two decades at EDS and

Logica leading transport-focused businesses. He started his career at

the Civil Aviation Authority.

He explained that he was drawn to the role because it offered him an

interesting balance: “I have worked in both the public and private sectors,

and now at TRL, with its set-up as a non-profit distributing Foundation, it

presents a very interesting challenge between the two – especially given its

strong scientific and academic capabilities. It also offers me the chance to

leverage my experience in transport, logistics, supply chain and

automotive sectors,” he said.

“The other attraction is where TRL is strategically in its journey.

6 www.railwaystrategies.co.uk

zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

There is an enormous depth of history at TRL – it was created in 1933

as part of the British Government, and it is well-known around the

world for its research and innovation in road transportation. But today

our reach is far broader than that, with lots of innovative, thought

leading projects in road, rail, cycling and pedestrian modes.

“The company was privatised in 1996 and today has 330 employees,

and almost 1000 clients using TRL’s products and services in 140

countries internationally. When we were privatised the vast majority of

our income came from the UK public sector, whereas today we have

diversified substantially and now our income comes from a global

customer base and less than 40 per cent is UK public sector oriented.

“We are now very strong in surface transport modes, and our

strategy is to continue focusing on our strengths in vehicle, road

and rail safety, infrastructure asset management and journey-time

optimisation. In particular, we are continuing to invest in the newer

areas of low carbon vehicle technologies, automated vehicles, satellites

and remote sensing, big data and de-carbonising transport.

INTERVIEW I Rob Wallis

ExpertLibbie Hammond talks to

Rob WaLLis, the new CEo of TRL, about an

organisation whose services vary from innovative

transport infrastructure and vehicle safety

research to investigating the psychology of cyclists

Rob Wallis

voice

Who we were and who we are now is quite different and I saw this

as a chance to join an organisation with enormous brand strength,

credibility and heritage, and take it into the future.”

Rail sector

A major priority at TRL is to take the experience it has gained from its

specialist research into road transport and apply it to the rail sector,

bringing transferable technologies and new ways of thinking into what

some regard as a somewhat traditional and introspective market.

“Due to the range of expertise we have within the company, TRL is very

good at looking at areas from a different perspective,” confirmed Rob. “A

perfect example of this is linear asset management. We have a lot of

experience in this area on the roads, and we believe it is very applicable to

rail and some of our projects and research have proved that.”

Rob highlighted an example: “While the rail sector has sophisticated

ways of monitoring the surface condition of tracks and associated rail

pathways, in the road sector TRL has led a number of innovations around

assessing surface condition and also measuring what is called

‘deflection’ – measuring movements beneath the road surface as an

indication of strength and quality – and rail companies are now looking

more closely at these kinds of innovations too. It would mean rail

companies have a much better insight into the rail asset condition, and

this is a major indicator for any kind of asset maintenance investment,”

explained Rob.

“Asset management is one of the big cost drivers in operating road

and rail networks, and we’re also constantly looking at innovative ways

of understanding the conditions of assets such as bridges, tunnels

and retaining walls using technology. TRL has designed and built

some of its own specialist products, and also researched and

evaluated innovative monitoring methods such as unmanned aerial

vehicles that can hover and get images of different assets around the

country, removing the need for physical inspections.”

Helping to find solutions to the challenges faced by rail operators is

really where TRL can add value: “I see rail operators having a big

challenge around driving down the operational costs of the rail

network, supported by the need to improve capacity and journey time

reliability. This has to be linked with trying to decarbonise as much as

possible and make rail travel an environmentally sound public service,”

he said. “In fact, the decarbonising of transportation in general and

specifically the perceived shift from road to rail is high on TRL’s

agenda,” he added.

One of the approaches adopted by TRL for projects is working in

partnership with commercial businesses. “So we – as an innovation

partner – are sitting behind a number of the major asset renewal and

asset enhancement programmes that are already underway and being

procured through Network Rail into the industry,” Rob said.

“Furthermore, in the research area we have a strategic partnership

with RSSB and with other organisations in Europe. We are also acting

as Technical Advisors to the DfT on a number of rail franchise direct

awards and competitions.”

TRL has very strong links with major universities and academic

organisations in the UK and internationally, participating in collaborative

research projects, as well as having PhD students on staff.

Additionally, as an Affiliated Research Centre to the Open University,

suitably qualified TRL staff can supervise PhD students. The

organisation has a big focus on competency and expertise

development that benefits staff, the organisation and industry.

Safety remains at the core of TRL’s research and consultancy work,

not only for road and rail travellers but also for pedestrians and

trackside workers: “We have undertaken innovation work in the road

arena on motorway lane closures and how you manage the safety

dimensions to workers and road users and a lot of that is transferable

into rail and hazardous working environments,” Rob highlighted.

“There is already a lot of maturity in how rail manages possessions

from a safety perspective, but there are different experiences from

road that can be applied and further added to the safety regime.”

www.railwaystrategies.co.uk 7

zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

Who we were and who we are now is quite different and I saw this as a chance to join an organisation with enormous brand strength, credibility and heritage, and take it into the future‘‘

8 www.railwaystrategies.co.uk

zzzzzzzzzzzzzzzz

TRL’s testing laboratories also have a lot to offer in the area of rail

vehicle crashworthiness and occupant safety: “This includes crash

impact testing,” said Rob, “where for example we work with the train

and component manufacturers to assess the crashworthiness of seats,

tables and cab configurations against latest industry standards.”

This is the physical side, but TRL is also looking at the human aspect

to safety, and as a result it has a whole team of human factor scientists

researching the psychology of driver behaviour in road and rail domains.

Rob gives an example of where this crosses over into another research

area where TRL is active – autonomous vehicles: “If you consider a

vehicle that requires no input from a driver while in automatic pilot mode

but at some point the driver has to retake control, the few seconds after

automation is disabled is perhaps the most unsafe moment in terms of

a driver’s situation awareness. Drivers may be more likely to be involved

in a collision in those few seconds due to the need to reacclimatise to

being in control.”

These safety studies also tie into TRL’s expertise in accident

investigation, where it has software tools and capabilities to monitor

and understand accidents. “We’ve done that work with the rail and

road industry in the UK, and we are transferring that knowledge and

expertise into markets such as the Middle East and India at the

moment, perhaps some of the more challenging markets for crashes

and accident investigations,” said Rob. “We are also collecting a lot of

factual statistics on accidents around the UK on behalf of the

Department for Transport (DfT) so they can start to understand trends

that can influence policy decisions.”

Next Rob identified ‘big data’ as an area that is rising up the agenda.

“There is an enormous amount of data being created and collated by

the rail industry. With suitable analysis and management, we can

generate information to improve the way the rail network runs,” said

Rob. “So for example, rolling stock is becoming more sophisticated,

providing more data to the operator. By analysing that data, the

operator can learn more about passenger behaviours while they are in

transit, as well as improve trackside communications.”

Passenger analysis can also be useful in the design of rolling stock

layouts, especially given the need to increase rail capacity in a safe

manner. “This can cover areas like the layout of the carriages,” said

Rob. “It also ties into the whole issue of multimodal transport and the

INTERVIEW I Rob Wallis

movement of passengers from car parks, through stations and onto

trains, and on a wider basis this also includes pedestrians and cyclists.

When it comes to cycling especially, we are doing some interesting work

on how the rail network can support this mode of transport in a sensible

multimodal way.”

TRL is working closely with Transport for London on a number of

cycling initiatives to improve cyclist safety on the roads in London. “I think

the link with rail becomes increasingly important, especially in considering

the rail/pedestrian/cyclist interactions at stations,” said Rob. “These are

much more intricately linked than we give them credit for. If you consider

the cycle-hire scheme in London with the bike racks right outside the

stations, it’s very clear that people are increasingly using this sustainable

travel approach.

“Much of TRL’s work is in understanding the psychological behaviour of

pedestrians and cyclists who do not behave in the same controlled way

as car drivers for example, when they approach an interface. If a car

goes into a railway station car park, the driver normally follows certain

accepted rules and behaviours. There is much more variation in the ways

in which a cyclist or pedestrian may choose to access a station. We’re

trying to understand that variation so that we can make cycling safer, and

the movement of people more efficient.”

As if the list of services from TRL wasn’t already incredibly

comprehensive, Rob added that he is keen to expand the engineering

and assurance offering of the organisation. “In our laboratories we’re

constantly creating pieces of technology to solve problems, but we are

also frequently being asked to evaluate other people’s technology and

give some assurance or certification that TRL has approved it. This is an

increasingly important area because it links back to my experiences in

product and systems certification and I am looking at ways to increase

TRL’s role as a trusted, independent assurance organisation for products

and services from industry.”

He concluded: “The vision of TRL is to continue to build on its role at

the forefront of creating the future of transport, using our independent,

research-based innovation and thought leadership to bring value to

industry. Our aim is to strengthen our position in the UK as our home

market, while continuing to expand our international activities, sharing

knowledge and expertise with government and industry stakeholders

around the world.” zz

www.railwaystrategies.co.uk 9

Netw

ork

Rail

Netw

ork

Rail

Network Rail commits to CP5l The Office of Rail Regulation (ORR) has confirmed that

Network Rail has committed to deliver plans for a safer, higher

performing and more efficient railway between 2014 and

2019 (CP5).

As part of the multi-billion pound plan for Britain’s railways,

initially published in October 2013, Network Rail will bring

down the costs of running the railways by 20 per cent, while

delivering nine out of ten trains on time on regional, London

and South East and Scottish routes, and improved reliability

for long-distance passenger services. Network Rail will also

improve standards of infrastructure management, network

resilience, and safety for passengers and railway workers.

Over the next five years Network Rail will spend more than

£38 billion on maintaining, renewing and improving the rail

network, which includes the delivery of a programme of

enhancements worth more than £12 billion.

These are challenges for the whole rail industry, not just

Network Rail. Stretching targets and new incentives will get

the industry working closer together for the communities they

serve. Network Rail will publish its delivery plan for 2014-2019

in March.

To read ORR’s Final Determination and summary

overviews, visit: www.rail-reg.gov.uk/pr13/publications/

final-determination.php

zzzzzzzzzzzzzzzzzzz zzNEWS I Industry

Early arrivall Mark Carne, Network Rail’s new

chief executive took up his new role on

Monday 24th February, slightly earlier

than originally planned. Mr Carne joined

the company on 6th January and has

been spending time visiting Britain’s

railway, meeting staff, partners and

funders, customers and experiencing

projects. He has also seen at first

hand the impact on the network

and to passengers of the recent

extraordinary weather, including

several trips to Dawlish.

www.railimages.co.uk

Chancellor unveils the start of rail investment in the north of Englandl The Chancellor of the Exchequer George Osborne

MP marked the start of construction of a fourth platform

at Manchester Airport station on 7th February – the first

phase of a project which spans the north of England.

The £600 million Northern Hub project will provide

significant long-term benefits to passengers and help

stimulate economic growth in the region by providing

faster, more regular and reliable connections between

towns and cities.

Alongside Network Rail’s electrification programme,

more than £1 billion will be invested in the railway in the

north of England by 2019 – for more details visit:

www.networkrail.co.uk/northernhub.

The Chancellor examines work in progress at Manchester Airport

Record-breaking levels of growth continuel A statistical report published by the Office of Rail Regulation (ORR)

shows a record number of passenger journeys on Britain’s railways.

The ‘Passenger Rail Usage’ statistical release assesses rail passenger

numbers and revenue from 2002-03 to 31st December 2013. The

regulator’s report shows that rail usage in Britain has been steadily

increasing over the past decade.

ORR’s latest figures for 2013-14 Q3 (1st October-31st December) show:

l Passenger journeys in 2013-14 Q3 reached 402.8 million. This is the

highest number of franchised passenger journeys since records began

and a 4.5 per cent increase on the same quarter last year.

l Passengers on the network travelled 15.1 billion kilometres in 2013-14

Q3. This is an increase of 2.8 per cent compared to the same quarter

last year, and the highest number of passenger kilometres travelled since

records began.

l Total passenger revenue in 2013-14 Q3 was £2.08 billion, a

6.2 per cent increase on 2012-13 Q3. Continuing the trend, this was

the highest amount of revenue generated within any quarter since

records began.

The report identifies a number of possible factors behind recent

increases in rail usage such as the opening of new lines and stations,

additional train services and ticketing initiatives including special offers

and more competitive pricing.

Read the report in full at:

http://orr.gov.uk/__data/assets/pdf_file/0013/10651/passenger-

rail-usage-quality-report-2013-02-20-q3.pdf

10 www.railwaystrategies.co.uk

In early February, water levels in the River Thames

were at their highest for many years, bringing

disruption to certain routes in the area. Flooding

in the Datchet area and several other locations

meant that trains were not able to run between Staines

and Windsor & Eton Riverside stations.

Meanwhile, the line from Oxford to Didcot was

disrupted, but still running, with flooding at Hinksey.

Network Rail engineers removed sensitive equipment

from the line to allow for a swifter resolution when

water levels dropped. Rising groundwater also caused

problems with equipment in the Maidenhead area.

No way westFlooding on the Somerset Levels and a landslip at

Crewkerne meant there were no routes to the West

Country open to trains on the afternoon of Saturday

8th February. The route from Bridgewater was blocked

by the flooded River Parrett to the south of the town,

while the main line from Castle Cary was blocked by

flooding at Athelney.

The diversionary route via Yeovil was also blocked

by an embankment landslip at Crewkerne. The floods

were being blown into waves by the high winds in

the area, which were washing away the track ballast.

By Monday 10th February two of the three routes

from Exeter to London – via Athelney and Crewkerne

– had reopened, and trains were also able to run

from Taunton to Exeter following the completion of

engineering work at Whiteball Tunnel. The line through

Bridgwater, linking Taunton to Bristol, remained closed

with the flooding on the Somerset Levels.

Battle-ing the elementsThe line between Battle and Robertsbridge was

closed on 4th February for urgent repair work at two

landslip sites, Whatlington Viaduct, and Marley Farm.

The estimated construction time has been halved

through the decision to work 24 hours a day and it

was anticipated that the railway would re-open to

passenger services in the last week of February.

Once a temporary access road had been completed

at Whatlington, machinery was brought to the site,

including two massive piling rigs. These embedded

a 300 metre-long sheet steel wall in the ground to

provide a stable base on which to build the new

embankment.

The slip near Marley Farm was smaller in scope, but

still required a 60m length of steel piles to be installed

and 3000 tonnes of stone delivered.

Over the weekend of 8-9th February, Sussex

suffered a further landslip near Stonegate adding to

two slips that were already being repaired. zz

Weather reportThe rail

network continued

to take a battering

during the early part of

February. Here are just a few of the

stricken areas

zzzzzzzzzzzzzzzzzzzzz NEWS I Industry

Netw

ork

Rail

Netw

ork

Rail

Netw

ork

Rail

Netw

ork

Rail

The landslip at Stonegate

Netw

ork

Rail

Flooded signalling equipment at Maidenhead

The landslip near Crewkerne

Water covering the railway at Bridgewater – there are actually two tracks here

Water closed the railway at Datchet

Flooding at Bridgwater, with the railway running across

the centre of the picture

www.railwaystrategies.co.uk 11

Netw

ork

Rail

6 www.railwaystrategies.co.uk

Netw

ork

Rail

Civs frameworksl Network Rail has awarded framework agreements to cover its programme of

civil examinations and assessments for the next five years. All the agreements

are zero-sum with a workbank of £300 million over the course of the next funding

period – Control Period 5.

A single-supplier zero-value framework has been agreed with Amey to cover

civil examinations across the entire network, with the exception of the London

North Western route, which is delivering its examinations programme using in-

house teams.

Zero-value civil assessments frameworks have been agreed, to cover

each of Network Rail’s routes:

l Anglia – Aecom and Amey

l Kent – Amey

l London North Eastern and East Midlands – Aecom and Amey

l LNW – Aecom, SKM and Opus

l Scotland – Aecom

l Sussex, Wales, Wessex and Western – all WSP.

zzzzzzzzzzzzzzzzzzz zzNEWS I Industry

Improved Tube reliabilityl Latest performance figures from

Transport for London (TfL) show that

overall delays to Tube customers

continue to decline with a 13 per cent

reduction year-on-year.

Figures for Period 8 of 2013-14

(13th October to 9th November)

show that London Underground (LU)

operated more than 97 per cent of all

scheduled train services during the

four-week period, despite disruption

caused by the storm which hit the

south of England on 28th October.

There were 100.4 million passenger

journeys, which was an increase

of 3.4 per cent on the same period

last year. The continuing trend of

long-term improvement on the Tube

follows the success of the London

Underground Reliability Programme,

introduced in 2011.

FCC to carry onl The Government has agreed a deal

with First Capital Connect (FCC) to

continue running commuter services

for the next six months. The new

contract will cover services between

London, Bedford, Brighton and King’s

Lynn and will bridge the gap between

the current contract and the new

Thameslink, Southern, Great Northern

(TSGN) franchise which will start

operating in September 2014.

Direct rail link from the west to Heathrow l Network Rail has laid out its proposals, as tasked by the Government in summer

2012, for a new rail link from the Great Western main line to London Heathrow airport.

The future rail link, subject to planning permission, will allow passengers to travel from

Reading, via Slough, to Heathrow airport via a direct train service. Currently, passengers

wishing to access Heathrow by rail have to travel into London Paddington station

before changing to dedicated airport services.

Network Rail has met with MPs and other local stakeholders to discuss the detailed

plans – known as the Western Rail Access Programme – that would provide significant

economic benefits for the growing number of businesses in the Thames Valley, M4

corridor and south west England and south Wales.

Direct rail access to Heathrow from the west could deliver an increase in business

productivity, quicker journeys to the country’s busiest airports and a boost to

economic growth.

© T

rans

port

for L

ondo

n

In this latest phase of the Stafford Area

Improvements Programme, new

signalling will be installed in and around

Stafford station and a new freight loop

will be built in the area which will free space

for much-needed additional passenger

services on the West Coast main line.

A third phase of the project has

been proposed (which is subject to a

development consent order) which would

see the construction of a flyover at Norton

Bridge near Stafford which would untangle

the existing lines and remove the last major

bottle neck on the route.

When complete, the upgraded section of

line will be controlled by Network Rail’s rail

operating centre in Rugby, one of

12 national centres which will eventually

operate the entire rail network in Britain,

replacing more than 800 signal boxes and

signalling centres currently in use.

The signalling upgrade at Stafford

will include:

l The installation of foundations, cable

routes and new signals and gantries

l Installation of new signalling equipment,

power supplies and telecommunications

equipment

l Installation of new points and alterations

to the existing track layout

l Conversion of the existing postal ‘siding’

to a new goods loop for use by freight traffic

l Overhead line works

l Conversion of platforms 1,3,4,5 and 6 at

Stafford to bi-directional working (enabling

trains to run in either direction, which in turn

provides greater operational flexibility)

l Removal of two signal boxes from

Stafford

The majority of the work will take place

at weekends and overnight and the

improved signalling and line is due to be fully

operational by summer 2015.

Second phase of Stafford-Crewe upgrade gets underway

Work has started on the latest phase of a £250 million improvement project which will deliver greater capacity and improved reliability on one of the busiest railway lines in Europe

Stafford Area Improvements Programmel With unprecedented levels of passenger and freight growth on the rail network

and the West Coast main line being full to capacity within less than ten years, the

Staffordshire Area Improvements Programme seeks to remove a major bottleneck

through the Stafford area. Once complete, the £250 million programme will

facilitate the introduction of new timetables between 2015 and 2017 and help to

create the capacity to run:

l Two extra trains per hour (each direction) between London & the north west

of England

l One extra fast train per hour (each direction) between Manchester & Birmingham

l One extra freight train per hour (each direction) through Stafford

The programme will deliver this through the following three key projects:

l Phase 1 – Linespeed improvements between Crewe and Norton Bridge,

increasing the line speed on the ‘slow’ lines from 75mph to 100mph. Running from

January 2013 to April 2014, these works include modifications to the overhead

line equipment and installation of four new signals and will be delivered during

weekends and midweek nights, significantly reducing the impact to passengers

and lineside residents.

l Phase 2 – Stafford resignalling. The installation of a new freight loop and

the replacement of life expired signalling, telecoms and power supplies, with the

signalling control transferred from the existing Stafford No. 4 and No. 5 signal

boxes to Rugby, plus the installation of bi-directional signalling for platforms 1, 3,

4, 5 and 6 and an increase in the ‘slow’ line speeds (predominantly used by local

passenger/freight services) from 75mph to 100mph between Great Bridgeford

(near Norton Bridge) and Stafford. Running from spring 2014 to summer 2015,

the majority of these works will also be delivered during weekends and midweek

nights.

l Phase 3 – Proposed flyover at Norton Bridge. The proposed construction

of a grade-separated junction, including six miles of new 100mph railway, ten

new bridge structures and two bridge enhancements, four river diversions, major

environmental mitigation works, pipeline, road and footpath diversions and the

construction of temporary haul roads. As an infrastructure project of national

significance, the scheme is currently subject to a Development Consent Order,

which provides the relevant powers and permissions to enable successful delivery

of the programme. Upon the granting of the order, main works are scheduled to

run from spring 2014 to 2017, with key commissionings in 2016.

Staffordshire AllianceThe Stafford Area Improvements Programme is being delivered by the

Staffordshire Alliance – a partnership of Atkins, Laing O’Rourke, Network Rail

and VolkerRail, working as part of a new collaborative contract that will help to

transform the delivery of rail infrastructure projects in the UK.

12 www.railwaystrategies.co.uk

zzzzzzzzzzzzzzzzzzzzz NEWS I Industry

www.railwaystrategies.co.uk 13

Netw

ork

Rail

zzzzzzzzzzzzzzzzzzz zzNEWS I Industry

Ticketing market reviewl The Office of Rail Regulation (ORR) has launched

a review of the rail ticketing market to understand

whether arrangements for selling rail tickets

are encouraging innovation and competition to

the benefit of passengers.The review will focus

particularly on the industry arrangements and

practices with respect to the range and type of

ticket products that train companies sell, the sales

channels and the third-party market for ticket selling.

This year, the regulator will also oversee the

development of a code of practice on provision of

ticket retail information. The Code will provide clarity

on what information passengers can expect from

their train companies. This includes information

on the different types of fares, any restrictions

that apply, and key terms and conditions such as

compensation and refund rights.

Manchester - Liverpool improvement plansl Network Rail has submitted plans for a new section of railway near

Huyton station as part of the £600 million Northern Hub investment

to provide faster, more frequent services across the north of England.

Work is already underway to improve capacity between Manchester

and Liverpool to increase the number of tracks through Huyton and

Roby from two to four. Planning permission is required – through a

Transport and Works Act Order – to construct a new 240m section of

track which will allow additional non-stopping services to run on the

line without being held-up behind local stopping services and freight

trains. Subject to consent, work is expected to be complete by the

end of 2017. More information is available at

www.networkrail.co.uk/huytonroby.

European destination potential l Eurotunnel’s investment of €15 billion, 20 years ago

to construct the Channel Tunnel Fixed Link, created

a vital junction between Great Britain and continental

Europe which is now used by more than 20 million

people per year, of which ten million are on Eurostar

services. Beyond this remarkable success, Eurotunnel

has been convinced for some time that the opening

of new destinations by railway operators would

enable an increase in traffic via these new services.

Eurotunnel commissioned PWC to carry out a study

into these opportunities.

The conclusions from the study are very clear:

l The potential for ‘high speed’ traffic in 2020 is

14.2 million passengers per year

l Just four direct destinations represent 85 per cent

of the increase that would be created by new lines:

Geneva, Amsterdam, Frankfurt and Cologne

l The reduction in travel time is even more important

than price in relation to choice of ticket and has a

direct impact on the growth of market share in favour

of rail over air

l Due to the time required to build up traffic, the

volume captured can be even more important if the

service is created rapidly.

A summary of the study can be found on the

Group’s website at:

www.eurotunnelgroup.com/uk/the-channel-

tunnel/founding-documents/

© T

rans

port

for L

ondo

n

Punctual DLRl The Docklands Light Railway (DLR) has achieved its highest scores for

punctuality and performance in its 26-year history. The railway which is operated

on behalf of Transport for London (TfL) by Serco Docklands, ran 99.67 per cent

of its trains on time during the period 5th January to 1st February this year and

also operated 99.77 per cent of its scheduled services. The performance figures

consist of the departure score, which is a measure of how many trains ran, while

the reliability score calculates how many of those trains ran on time.

14 www.railwaystrategies.co.uk

Around 80m of sea wall was destroyed by

high tides and stormy seas at the beginning

of February, causing a significant stretch of

railway to collapse into the sea. The road

adjacent to the railway and several houses were also

significantly damaged, along with damage at Dawlish

station itself.

Network Rail mobilised a range of specialist

contractors, engineers and suppliers from across the

country to help with the work needed at Dawlish and

also took up the offer of discussions with the Ministry

of Defence to see if there was any help which could

be provided by armed forces personnel based in the

south-west.

Initial estimates were that it would take at least six

weeks to reopen the railway, but the immediate priority

was to shore up the damaged section using a concrete

spraying machine which was until recently being used

to refurbish Whiteball Tunnel in Somerset.

Dealing with the damage at Dawlish

The Dawlish diaryTuesday, 4th FebruaryWeather forecasts predict a major storm off the coast of

Devon and Cornwall. Network Rail marine buoys predict

‘black’ storm conditions, with six-metre waves. This is the

first ‘black’ conditions predicted since the system was

installed in 2007.

l 3.15pm – The line through Dawlish is closed to trains

and staff withdrawn to safe locations.

l Serious overtopping by waves is reported through the

evening.

l 9pm onwards, damage reports received concerning

both the railway and the adjoining land.

l 11pm-2.30am Inspections confirm extent of severe

damage.

Wednesday, 5th FebruaryEngineers were on site at first light but unable to inspect

Network Rail engineers have been working around the clock to repair the damage to the railway at Dawlish in Devon as Atlantic storm systems battered

the south-west of England during February

An aerial view of the damage at Dawlish

zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz NEWS I IndustryNe

twor

k Ra

il

www.railwaystrategies.co.uk 15

the line due to continuing storm conditions. Teams of

engineers, contractors and suppliers mobilised and head

to Dawlish. Work begins on site compound to store

machinery to shore up damage, including spray-concrete

equipment.

Friday 7th FebruaryEngineers have been working through the night to shore up

the seriously damaged section of sea wall before another

Atlantic storm system arrives on Saturday.

Work last night and into this morning saw the rails and

sleepers cut away from the hole and removed. That meant

it was then safe for staff to access the site and begin

removing debris. This was then used to help build an

access ramp so machinery could be brought onto site.

A concrete spraying machine, previously used to

refurbish Whiteball tunnel, began work later in the day to

build up a layer of material over the subsoil exposed by

the wall collapse. This is intended to be a sacrificial layer,

to absorb some of the force of the storm forecast for

tomorrow.

Work is ongoing to demolish the most damaged

platform at Dawlish station itself, prior to rebuilding.

Saturday 8th FebruaryNetwork Rail engineers have again been working though

the night to protect the most damaged section of sea wall.

Rail and concrete sleepers that once carried trains along

the sea wall have been cut away and placed across the

bottom of the damaged section. These are gradually being

reinforced with sprayed fast-drying concrete, which will

form a temporary barrier to take the brunt of the forecast

heavy seas. It is hoped this will absorb enough of the force

of the waves over the next few hours and days so that

the weakened sub-soil, which is very soft, will not erode

further. The most damaged platform at Dawlish station has

been demolished and will be rebuilt in the coming weeks.

Engineers are working in very difficult conditions with

work taking place on a six-hours on, six-hours off basis,

designed around the tidal patterns. Initial assessments are

that it will be at least six weeks to completion from when

work begins.

Monday 10th FebruaryWork to protect the damaged sea wall continues, with a

temporary breakwater erected from rubble-filled shipping

containers enabling the start of repairs to the main area

of damage. Further heavy storms are expected over the

coming weekend.

Wednesday 19th FebruaryFollowing the latest severe storms over the weekend of

14/15/16 February, Network Rail has updated its estimate

of the time it will take to restore the railway at Dawlish.

Work in progress to remove the suspended rails

zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

Work underway at Dawlish, showing the scrapped rails and the first spray of concrete

Netw

ork

Rail

Network Rail

station platform and clearing more debris throughout the

coastal route. To protect the site, 15 steel containers –

weighing around 70 tonnes each – have been installed as

a temporary breakwater and a scaffold bridge was also

built to reconnect services and signalling equipment.

Patrick Hallgate, route managing director, Network Rail

Western said: “We are all conscious of the importance of

this railway to the South West, its economy and the people

of Dawlish. They have been tremendous in supporting our

team and understanding of the challenges we face. We are

confident that we will have the railway back by mid-April

and if we can we will beat that date.”

Mark Hopwood, managing director First Great Western

welcomes Network Rail’s commitment to reopen the line

through Dawlish by mid April, he said: “This will allow

us to restore through train services linking London and

Exeter with Torbay, Plymouth and Cornwall. We appreciate

Network Rail’s efforts to work round the clock to get the

line reopen so we can resume services for customers as

soon as possible.

“Until the line reopens we are running train services

between Exeter and London and between Newton Abbot

and Penzance with bus services linking these to keep our

passengers moving.

“We will be ready to run services once Network Rail

completes the work and until then we will do everything we

can to minimise disruption to our customers’ journeys.” zz

To allow the public to witness the progress of the

restoration live, Network Rail has set up a video feed

for its restoration work on:

http://www.networkrail.co.uk/Dawlish/

It has now advised that the railway will be repaired by

mid-April and that it will be working night and day with

dedicated resources to accelerate this programme. The

most recent storm caused extensive, further damage,

increasing the scope of the repairs. However, the first

defences installed reduced the potential impact and helped

prevent further damage to the houses.

Significant additional damage on the evening of the

14th February has meant that the hole in the seawall is

30 per cent larger and also meant on that day only three

hours work was achieved. A day or two later, because

weather conditions were more moderate, Network Rail

achieved 20 hours production.

Work resumed immediately after the storm of the 14th

and engineers have since laid concrete foundation into

the main breach and the secondary breach at Dawlish

Warren. They have also started work on repairing the

16 www.railwaystrategies.co.uk

zzzzzzzzzzzzzzzzzzzzz NEWS I Industry

Netw

ork

Rail

The view of Dawlish on 10th February, with the breakwater made from shipping containers

Additional damage after 14th February at Dawlish

Netw

ork

Rail

zzzzzzzzzzzzzzzzzzzzzz Lowery Ltd

www.railwaystrategies.co.uk 17

With a list of clients that includes National

Grid, NTL, Thales and Seeboard by 2000,

Lowery Ltd took the strategic decision

to expand its railside activities in 2003

when it acquired its Principal Contractor’s

License (PCL) from Network Rail.

Celebrating its 60th anniversary in 2010,

the Addlestone headquartered company’s

core geographic area of activity is based

in the south and south east of England,

where it has additional offices to support

its ongoing major projects.

Focused on developing long-term

relationships with its customers since

its inception, Lowery Ltd has gained

repeat business from major firms with

its proven capabilities and performance.

With fully accredited, superior systems

in place, Lowery Ltd continually meets

T he principal operating firm within

the Lowery Group, Lowery Ltd

was established in August 1950

to initially work for British Rail,

the General Post Office (GPO) and its

major customer during this period, Pirelli

Cables. Through installing underground

supertension cables for the Central

Electricity Generating Board (CEGB)

during the 1950s and working in Belfast in

the 1960s, Lowery Ltd further developed

its relationship with Pirelli while also

extending its activities with British Rail,

CEGB and the GPO.

Securing major contracts with British

Telecom, Cable & Wireless and Network

Rail throughout the 1980s and 1990s,

Lowery Ltd had proven its capabilities as

a quality focused and highly efficient firm.

Following more than 60 years of

civil engineering, Lowery Ltd has

gained an excellent reputation for

quality and service

A superior service

18 www.railwaystrategies.co.uk

Aspin GroupThe Aspin Group’s expert and experienced

team works collaboratively with its clients,

providing a wide array of services to the

railway environment and across industry.

Aspin Group provides site investigation,

civil, structural and geotechnical design

consultancy, management, installation

and plant services to deliver all aspects of

substructure and superstructure installation

across the UK and beyond.

Aspin Consulting has specific skills and

knowledge to develop big-picture innovative

designs and solutions together with the

detail and minutiae necessary to deliver.

Aspin can provide the complete solution

from design through to delivery. Innovation,

technology and providing solutions are at the

heart of its service.

zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

its customer’s expectations by operating

in full compliance with all health, safety

and environmental legislation, while also

delivering the highest quality services.

By giving a high priority to compliance

and continual improvement in all areas of

activity, the company minimises downtime

and significantly lowers the likelihood of

incidents or accidents. All projects are

manned by a highly trained, efficient and

competent workforce and managed by a

capable and experienced management

team.

Boasting the civil engineering and

electrical skills required for the design,

build and commission of heavy voltage (HV)

and direct current (DC) cabling projects,

Lowery Ltd has been actively involved in

the Crossrail project, providing a reliable

service to long-term client Network Rail.

Acting as principal contractor for works

including installation of UTX, buried duct

and surface troughing, fibre and copper

cable terminations and jointing, cable

pulling and lift and shift of existing cables,

CSR board installation and cable laying in

confined spaces, Lowery Ltd has been an

active participant in the development of

Crossrail, which reached the halfway point

of its construction in January 2014.

On top of its involvement in the Crossrail

project, Lowery Ltd has been working as a

principal contractor for major projects and

Class 378 train at Norwood Junction on the East London Line, South stations

Anderton Concrete Anderton Concrete is the market leader in

the supply of cable troughing to the UK rail

industry. Anderton is the sole supplier to

Network Rail for standard cable troughing

(Certificate No. PA05/00318) and the

new revolutionary Anderlite Lightweight

Troughing System (Certificate No.

PA05/05810).

The Anderlite system has an identical

product profile to the traditional product

therefore, a transition from ‘system to

system’ is effortless.

Anderlite reduces the risk of manual

handling with a weight reduction of 30

per cent in relation to standard concrete.

Additionally, this reduction in weight affords

significant transport cost savings of up to

20 per cent, reducing the carbon footprint

for all its industry partners. Anderlite is up

to 50 per cent cheaper than alternative

light-weight systems.

www.railwaystrategies.co.uk 19

zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz Lowery Ltd zz

investments in south east territory (E&P)

HV feeder renewals. This is centred around

the supply, management, site works,

possession management, installation,

testing and commissioning of new high

voltage feeder and pilot cables

that replace life expired and oil

insulated cables at locations

based in the south east territory

of Network Rail’s infrastructure.

On top of this, the works include

the draining down of redundant

oil and recovery and disposal

of old cables following the

commissioning of each new

HV feeder and cable.

Link-up approved, Lowery

Ltd incorporates a wide

range of product codes

to support its scope

of operations, while the

company’s rail division is accredited by

BSI to BS EN ISO 9001:2008 Quality and

BS EN ISO 14001:2004 Environmental

standards. Furthermore, the firm holds a

PCL for line-side civil engineering works,

cable supply & laying and cable route

works from Network Rail and is a member

20 www.railwaystrategies.co.uk

of the British Safety Council. Working

directly for Network Rail and London

Underground, as well as a specialist

supplier with major rail contractors,

Lowery Ltd has an assurance team in

place to ensure complete compliance with

all London Underground and Network

Rail’s health and safety requirements.

As an established Principal Contractor

for London Underground’s electrical

enhancement projects, Lowery Ltd

has gained experience from delivering

successful solutions while working

on ETE, SUP and ATC contracts.

These projects include the design and

installation of a new 11kV feeder circuit to

the Old Dalby Test Track’s new switching

station, the design and installation of

DC Cable, upgraded for ‘S’ type rolling

stock in Wimbledon and DC ETE works at

Wembley Park Sidings.

With a long history of delivering civil

engineering solutions and an excellent

track record for delivering projects safely,

on time, on budget, Lowery Ltd guarantees

customer satisfaction with its commitment

to health, safety, quality and environment.

zz zzzzzzzzzzzzzzzzzzzzLowery Ltd

Furthermore, with a focus on continual

improvement and strong relationships

with major firms such as Network Rail

and London Underground, the company’s

reputation as one of the UK’s principle

contractors for rail power suppliers is sure

to continue growing in the future. zz

‘ International Transport Intermediaries Club (ITIC) is an

insurance association established in 1925, which insures

2000 different businesses throughout the world and is

recognised as the leading mutual provider of professional

indemnity insurance in its field. ITIC works closely with transport

professionals and their insurance brokers to provide specialist

guidance and advice on their risks in their working environment,

both in the United Kingdom and overseas.

ITIC has concluded that many insurers do not understand the

work that professionals in the rail industry undertake. Often, these

insurers do not analyse the work of the professional working

on a project and, as a result, your premiums are increased

unnecessarily.

ITIC’s insurance includes worldwide cover for bodily injury and

property damage as standard; this is of paramount importance

to those working in the rail industry and differentiates ITIC’s

insurance from many traditional underwriters who either exclude,

or expect you to pay an additional premium for this important

element of cover.

ITIC makes four recommendations to professionals working in

the rail industry:

1. Ask your current insurers or brokers if they understand

exactly what it is that you do. For example, if you are a signalling

systems design engineer, your direct involvement in the day to

day operational environment is limited. You design a signalling

system on a railway network, but you are not necessarily the party

who operates and maintains it. Your liability is substantially less

than the operator and, therefore, you require an insurance that is

adapted specifically to cover your liabilities if you make an error in

Rail professional opportunity

Are you a rail professional open to offers for new business? ITIC, a rail and transport sector specialist insurer, needs a network of rail specialists in the UK and overseas, to advise and consult on claims

the design of the system. However, the liabilities resulting from an error in

the use of the system you have designed fall under the

operator’s liability insurance programme.

2. Enquire about a longer term, non-contract specific, business-wide,

professional indemnity policy. It is more expensive to buy insurance for

each individual contract or tender than buying an annual policy that covers

all your work.

3. Ask your insurance broker or underwriter whether bodily injury or

property damage cover is included in your policy at no additional cost.

4. Ascertain whether your policy of insurance provides you with

worldwide cover. zz

To express an obligation-free interest please contact Roger Lewis, ITIC’s underwriting director: ITICTel: 020 7338 0150Email: [email protected]: www.itic-insure.com

zzzzzzzzzzzzzzzzzzzzzzz zzInsurance

www.railwaystrategies.co.uk 21

‘‘The service that we provide and the width of our professional indemnity insurance has resulted in a significant growth in the number of companies involved in the rail industry insuring with ITIC over recent years,” says Roger Lewis, ITIC’s underwriting director. “To help us support this growing rail portfolio we need a bigger network of consultants we can call upon to help with specific claims on a call by call basis.

22 www.railwaystrategies.co.uk

The year 2009 will be remembered for a paradigm

shift in strategic thinking for the national railway

network. With soaring costs, congestion and

overcrowding, Network Rail brought together an

industry-wide consultation to examine the feasibility of

doing something different. Until that point, Government

had not considered funding any further electrification of

the UK rail network. Indeed, the HLOS (High Level Output

Specification) announced in April 2009 made no allowance

for it. The consultation’s resulting Electrification Route

Utilisation Strategy was presented to Government, and the

industry’s case for electrification of the network accepted.

Things moved fast. In July and December 2009 the

Government announced funding for the first two phases

Powering ahead

of the North West Electrification Programme, a long-term

rolling programme to progressively electrify routes across

the North West, linking more and more destinations with

the already electrified West Coast Mainline. As a result,

operators will progressively be able to offer a greener,

more efficient, cost-effective and faster electric service

over wider distances. To date, five phases have been

announced and a further two are in the pipeline.

Blazing the way“When we set out on this programme only around

40 per cent of the national rail network was electrified,

which is low in comparison with the majority of Europe,”

explained Network Rail’s Senior Sponsor, Jon Clee. The

The North West Electrification Programme is leading the way for progressive electrification and modernisation of the UK railway network. With phase 1 delivered on time and under budget

and phase 2 due for completion at the end of the year, JON CLEE of Network Rail talks to Gay Sutton about the challenges, the triumphs and the continuous learning process

zz Electrification zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzNe

twor

k Ra

il

www.railwaystrategies.co.uk 23

Powering ahead

West Coast Mainline was one of the last to be electrified

in the North West. Largely completed in the 1960s,

electrification finally reached Glasgow in 1974.

There have been some minor electrification schemes

since the East Coast electrification in the mid 90s, but

NEW is the first significant new electrification to take place

since then in England, so Network Rail faced a number of

challenges for phase 1 of the project. “To overcome these

we have been developing our skills base, our linesmen and

electrical engineers,” Jon said. “And we’ve been building

a new supply chain to deliver this programme. The whole

exercise has been a continuous learning process.”

Before work could commence, Network Rail had to

identify and develop the next generation of technology

for delivering the preferred overhead power supply.

Once defined this could then be rolled out on all future

electrification programmes across the country. What

emerged from this collaborative innovation project is a

system called NR Series II, which draws on current best

practice in the industry throughout Europe and combines

that with Network Rail’s knowledge and experience

of managing and maintaining the existing systems

in the UK. “Simplistically, we identified that the more

components used in an overhead system, the more things

can potentially go wrong,” Jon explained. “So we have

reduced the number of components in a single track

cantilever from 32 in the traditional systems to 11 in

NR Series II.”

Taking this new technology out to Phase 1 of the North

West Electrification programme has been a steep learning

curve. The group’s engineers have learned a considerable

amount from these early installations and will be applying

this knowledge to improve delivery in subsequent

electrification projects around the UK.

Conquering Chat MossPhase 1 is a £60 million electrification of the line between

Castlefield Junction and Newton le Willows, and it

presented an interesting engineering challenge. “Phase 1

goes across Chat Moss which is essentially a peat bog,”

zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

Feeder station for power, Willow Park

Above: Feeder station for power, Parkside

Feeder station for power, Willow Park

Netw

ork

Rail

Netw

ork

Rail

zz Electrification zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

Jon explained. “When Stephenson originally built the

railway in 1829-30 he constructed a raft of bound heather,

branches topped with tar and timber to carry the railway.

So essentially, the line floats on the bog. The challenge for

us was to install the overhead lines, masts and wires in

such a way that we didn’t disturb Stephenson’s floating

railway tracks.”

The solution Network Rail devised was to install portals

rather than the usual cantilevers, and to make them wider

than usual so the legs would not interfere with the track.

The configuration of a leg on either side of the track and

a beam across the top makes the portal structure much

more stable than the cantilever. In the Chat Moss example,

the legs have also been bedded into piles driven down to

the bedrock beneath, so the risk of pressure being applied

to the floating rail bed is greatly reduced. In spite of these

complications, the phase was completed in December

2013 on time and under the allocated budget.

An enlightened approach to heritagePhase 2, meanwhile, is on schedule and due for

completion in December 2014. Projected to cost

£100 million, it consists of three elements. Liverpool

through Huyton to Newton Le Willows connects Liverpool

to the West Coast Mainline. Huyton to Wigan runs

northwards to the West Coast mainline. The final section is

Ordsall Lane to Manchester Victoria.

There have been two points of interest during this phase.

Firstly, the engineers encountered a number of uncharted

mine shafts that have had to be dealt with. Secondly,

the Liverpool to Manchester route passes through some

of the country’s most historic sites, raising the inevitable

heritage issues. “It passes Rainhill, for example, the site

of Stephenson’s Rocket locomotive trials in 1829. The

heritage issues on this line are fascinating.”

Many of the line’s stations, bridges and viaducts are

listed and have significant heritage value. “They will all

remain in operation, and we are working on them in a

sympathetic manner,” he insisted. “But we have worked

closely with English Heritage throughout, and they have

taken a pragmatic view. They do not see this as something

detrimental to the heritage of the route, but rather as

something that will enhance it and tell the story of how

the railway and railway technology has progressed. It has

been quite an enlightening approach.”

Major signalling workThe scheduled Phase 3 will electrify the branch from

the West Coast Mainline to Blackpool, but a number

of concerns about the age and condition of the line are

causing delays. Network Rail is currently consulting with

the operators and the Department for Transport to decide

whether work include upgrading the rails in order to deliver

a faster service. Even if the linespeed isn’t increased, the

opportunity to renew the signalling system has already

been agreed.

Usually an electrification project includes a programme

of immunisation on the signalling system to ensure the

25kV AC overhead power supply does not induce a

current in the signalling cables alongside the track. “On the

Blackpool line, which still uses the old semaphore signals,

we have established that strategically it would be more

cost effective in the long-term for us to replace the entire

signalling system with a modern one which will then be

controlled from the new Rail Operating Centre (ROC) being

built at Ashburys.”

As a result, it is likely that phases 4 and 5 will begin

before phase 3.

Next up – the first big tunnelsSo far, the North West Electrification programme hasn’t

included any major tunnel engineering, but that will change

in phase 4 which links Euxton Junction on the West

Coast Mainline just south of Preston, with Bolton and

Manchester Victoria. The 101m-long Chorley Tunnel is

a single-bore tunnel accommodating both up and down

Above:Wiring phase 1

of North West electrification

between Newton le Willows and Castlefield Jct

Track being lowered at Manchester Victoria over Christmas to accommodate the overhead wires under Cheetham Hill road bridge

Netw

ork

Rail

24 www.railwaystrategies.co.uk

zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

lines. The plan is to remove the existing track and replace

it with slab track which will not only lower the track bed

and make room for the overhead wires, but will also

make that challenging section of track easier to maintain.

Another piece of work for the Chorley Tunnel is to reinstate

the historic flying arches on the northern exit from the

tunnel, which had been removed a few years ago.

The second tunnel system on this section is at

Farnworth and comprises two bores, the larger of which

originally accommodated two tracks. “The smaller of the

two is currently an extremely tight fit for a diesel, which

effectively exits the tunnel as though it had been extruded

out of it,” Jon explained. “So we have a significant

challenge ahead of us to run two tracks through the

Farnworth tunnel and make room for the overhead wires

and pantograph.”

Rather than lower the track bed on the smaller tunnel,

which poses considerable risks, Network Rail has devised

a plan to widen the larger of the two tunnels so it can

accommodate both tracks with enough headroom for the

overhead wires.

A question of powerThe final element of the current North West Electrification

programme is phase 5 from Manchester Victoria to

Stalybridge. Working in conjunction with the Network Rail

team operating out of York, this is the North West’s section

of the Trans-Pennine route to Leeds. And Stalybridge has

been selected as the crossover point largely for its location

and accessibility for power supply. “Phases 1 and 2 of

the programme have been able to feed off the existing

power supplies,” Jon explained. “But to power subsequent

phases of electrification the National Grid is going to

provide us with a new grid supply point at Stalybridge by

2015, ready for completion of the section in 2016.” Once

this is done, the power feeding arrangements in the region

can be rationalised to better utilise the existing supplies,

and provide capacity for future phases of electrification.

“This is very much a continuously rolling programme,”

Jon pointed out, “and also links in with the Northern

Hub initiative improving the rail infrastructure around

Manchester.” Already, Government has announced its

interest in further electrification phases in the North West:

Oxenholme to Windermere and Wigan to Lostock, both to

be completed in conjuction with the existing phases.

The ongoing infill of electrification in the North West

will enable many services that had previously run diesel

services under the wire up the West Coast Mainline to

convert fully to electric traction. And in the long term, this

will result in an infrastructure capable of supporting longer,

faster and more frequent train services with significantly

lower running costs and higher capacity. “And no doubt

each individual route will have its individual challenges,

partly because of the nature of how the railways were built,

and partly because of the geography they serve,”

Jon concluded. zz

Above:Foundations being brought in place at Manchester Victoria over Christmas

First electrification train at Eccles on 8th December 2013

Foundations being prepared for phase 1 NW electrifcation

Netw

ork

Rail

Netw

ork

Rail

www.railwaystrategies.co.uk 25

26 www.railwaystrategies.co.uk

T he Great Western Electrification Programme

represents an investment of £1.5 billion that will

allow faster, quieter travel, with increased seating

capacity, and improved reliability on one of the

United Kingdom’s oldest and busiest railways. This

programme will enhance the railway line between London

and Oxford, Newbury, Bristol and Cardiff.

With a project of such scope, owner-operator Network

Rail needed a way to incorporate enormous amounts of

survey data with design models from multiple consultants,