PWR Vessel Examination - AREVA Nuclear Materials - AREVA...

Transcript of PWR Vessel Examination - AREVA Nuclear Materials - AREVA...

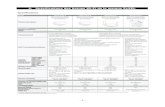

Field-proven manipulator designed for minimum vessel occupation time • Longesthistoryandexperienceformultiplereactorvesselconfigurations

• MostcompleterangeofPDIandglobal qualifications,includingnozzleinnerradius

• Recordexaminationtimeforseveralreactordesigns

Advanced underwater robot in compliance with global codes• Robustsix-axisroboticarmdesignedforaccurate positioningandheavypayloads

• RemoteheadchangeforvariousUTtransducer configurations:primary&auxiliarynozzles,shell weldsandskirt-occludedwelds

• On-boardcalibrationconfirmation

• Anchortovesselindependentofradial supports:nomoverequiredformaximum weldcoverage

• Flipjointtoallowrobotoperationaboveor belowbase

• ConventionalandPhased-ArrayUTcapability

• UTanalysiscompensationforwavysurfaces

Features and Benefits• Portableandcompactdesign

• Minimalon-sitehandlingwithpolarcraneand auxiliarybridge

• Adaptabletoalargerangeofvesseldesigns

• Dualmanipulationstoreducecriticalpathtime andfosterpredictableoutageschedules

• Limitedlaydownspacerequirementsand minimumutilitysupport

• Possibletotransportintoreactorbuildingvia personnelhatch

PWR Vessel ExaminationTWS Manipulator for Nozzle and Vessel UT Examination

AREVA NDE-Solutions

NozzleandVesselExaminationarerequiredforPre-Service(PSI)andperiodicIn-ServiceInspection(ISI).AREVATrans-WorldSystem(TWS)manipulatorisanadvancedunderwaterrobotforUTexaminationincompliancewithawiderangeofglobalcodedemands.

The data and information contained herein are provided solely for illustration and informational purposes and create no legal obligations by AREVA. None of the information or data is intended by AREVA to be a representation or a warranty of any kind, expressed or implied, and AREVA assumes no liability for the use of or reliance on any information or data disclosed in this document. © 2013 AREVA Inc. All rights reserved.

For more information contact AREVA NDE-Solutions Regional Sales Manager [email protected]

U.S.:EddieIvinsOffice:+14348323781Cell:+14348413562

France:OlivierMoulinOffice:+33149784095Cell:+33628796555

Germany: FlorianSenneOffice:+49913190096766Cell:+4915114568545 7/13 ANP:U-360-V2-13-ENG

Proven technology to shorten PWR Vessel examination time

Advances in NDE and robot technology enable TWS to scan more rapidly and accurately

Kinematics optimized to reach deep into the nozzles

Flip joint to allow vessel weld examination with arm either above or below the base

Full access to radial supports and orange-peel welds without re-positioning base