Pub PDF 115

-

Upload

copperconcept -

Category

Documents

-

view

222 -

download

0

Transcript of Pub PDF 115

-

8/6/2019 Pub PDF 115

1/24

Architectural copper reviewMagazine for copper in the construction industry | 2004

p.3 Saaga in a Laplandish

environment

p.8 Beautiful building in a newsection of the city

p.13 Kungstrdgrden in

Stockholm

p.15 Construction on Svalbard

p.20 The Eesti Kunstimuuseum

project

stainless | copper | technology

-

8/6/2019 Pub PDF 115

2/24

Architectural copper review | 2004 / 2

This edition of Outokumpus Architectural Copper Review

shows the many ways copper can be used in house building.New creative ways to use copper have been developed thatbuild upon traditions dating back several hundred years.We are also happy to see how our new methods for patina-tion are being used. Patination is an area where we haveconducted research for many years and that has been cre-ated for the purpose of renovating existing buildings, but thatis also ideal for new construction where a patinated look is

desired from day one.

If you would like to know more about the subject, please go to our websitewww.outokumpu.com where you will find information about techniques,assembly methods, products and reference buildings. The editorial boardwould also like to get your comments and hear about new and excitingprojects.

Lennart Engstrm, Editor

Architectural copper review 2. edition, December 2004

Architectural copper review is published twice a year and has a circulation of 1.000 copies. Publisher isOutokumpu. The magazine is distributed to architects and professionals in the building construction industry inEurope.

Editor:Lennart Engstrm +46 21-198254,Address: Outokumpu Copper Products, Metallverk sgatan 5, 721 09 Vsters, Sverige, fax: +46 21-198704,[email protected]

Publisher:Lennart Engstrm, Outokumpu.

Editorial staff:Mogens Prstegaard Denmark telephone : +45 4323 7700 mogens.prastegaard@ tibnor.seDennis Wraamann Denmark telephone: +45 3956 5056 [email protected] Jan Erik Holler Norway telephone: +47 6755 4620 jan.erik.holler@ outokumpu.comHannele Numminen Finland telephone: +358 2626 6616 hannele.numminen @outokumpu.comHkan Svedman Sweden te lephone: +46 21-198250 goran.aldestrom@ outokumpu.com

Layout and technical production:Det Danske Idselskab, telephone.: +45 3956 5056

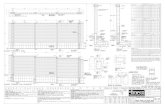

Front page picturNew office for the pension insuran

company Sampensio

Tuborghavnevej 1

2900 Hellerup, Denma

22

-

8/6/2019 Pub PDF 115

3/24

Architectural copper review | 200

Saaga in a Laplandishenvironment

Finnish Lapland with its rolling hills, soothing to the eye, is a popular and

multifaceted travel destination. Tourists from all over the world visit the

northern mountains, especially during winter and autumn when the

landscape is coloured by the russet autumn glow.

By Hannele Numminen, Finland

Ylls is one of Finlands best known

mountains and a popular ski resort. Ylls

became even more diverse in the spring

of 2003, when the new spa hotel Saaga

was built.

Laplands nature and copper

Several different facade materials were

used for Hotel Saaga. When planning for

buildings in Lapland, particular considera-

tion must be given to the demanding and

changing conditions. The material must

be suitable for both the heat of the sum-

mer and the biting cold of the winter. Ar-

chitect firm Arktes Oy in Uleborg was

commissioned to design a hotel that

33

-

8/6/2019 Pub PDF 115

4/24

Architectural copper review | 2004 / 2

gracefully blends in with the mountainous

landscape. The Nordic barren nature be-

came a magnificent framework for theproject.

As the weather conditions in Lapland are

unusually severe, the materials used must

be durable and have certain characteris-

tics. Over the course of the year the dif-

ference in temperatures can be as much

as 60 degrees! Because of this copper

was a suitable choice as one of the facade

materials. Copper is in a class of its own

when it comes to workability and durabil-

ity in all conditions.

A centre part in copper

In the centre of Hotel Saaga is the main

entrance to the hotels lobby and restau-

rants. In this part of the facade, pre-oxi-

dized, dark brown Nordic Brown copper

was used. The copper was assembled by

Napapiirin Yrityshallit from Rovaniemi.

To the building site, 1,100 square metres

of 1 x 700mm copper strips were deliv-

ered, which before assembly were divid-ed into different lengths. The strips were

then joined together by a simple vertical

seam, with consideration to the heat flow

in the copper. The seams were locked

with hidden cleats and then sealed with

oil. The assembly work itself, performed

during cold and snowy conditions, was

successful, even though the copper

smiths had to do the work wearing gloves

due to the freezing temperatures.

The beautiful and comfortable Hotel Saa-ga opened in March 2003 and has now

been in business for over a year and a

half. The hotel offers numerous facilities

in addition to regular hotel services and is

perfect for todays rushed people the

hotel is specialized in spiritual well-being

and physical revitalization. The hotel of-

fers 83 guestrooms, a spa and a large

number of rehabilitation services. Fur-

thermore, Saaga has a separate pool aresaunas and many possibilities for recrea-

tion.

The hotels exterior architecture and co

ours fit in nicely at the base of the moun

tain, where the landscape changes col-

ours with the season. And the natural

copper gracefully follows the colour

scheme of the surroundings.

Photographer:MikaelLinden

44

-

8/6/2019 Pub PDF 115

5/24

Architectural copper review | 200

The city hall building seen from the west, with the entrance to the left facing Stortorget. In the background Martenstorget and the Krogno building

dating from the 17th century.

Lunds city hall 40 years old By Per Qvarnstrm, architect, Sweden

After decades of discussions, investiga-tions and several architecture compe-titions for a new city hall building inLund, the municipality started theplanning in 1960 for the Stortorget ar-ea and the old city hall building. Cer-tain confusion existed due to the lackof an updated plan for this the oldestpart of Lund. Thus, as the hundreds ofconstruction plans for the building sitewere delivered in 1964, the architect

wrote on a note to the city represen-tatives: As I now hand over the build-ing plans for the city hall, I thank youfor giving me enough time to plan thisextraordinarily demanding work.Soon, the construction work was un-derway and after a few years the cityhall, stretching over an entire cityblock, was finished. As a child I of ten

peeked through a crack in the hoard-ing surrounding the building site. Atfirst it almost made me feel dizzy justto look down. Far down there in themud the archaeologist crawled aroundin small groups. Some of the itemsthey found are today exhibited at theMuseum of Cultural History in Lund.

Triangular block

When architect Klas Anshelm at the

end of his life alone with a small taperecorder described his projects, he didit with sharp direction in a single take.However, when it comes to the workwith Lunds city hall, Anshelm some-times returns to the subject with newcomments. The project was obviouslyexhausting but also of great personalsignificance to him. His descriptions

concern in particular the work withthe overall solution for the project.The answer was as simple as it wasbrilliant. The tall concert hall and thelower session hall for the city govern-ment council are placed freely in a tri-angular main building that in itself be-comes a small block. Around thebuilding, smaller, more intimate areasand defined office spaces are formed.There is also room for a bank, shops, a

foyer, a garage and much more. The in-terior becomes original and beautiful.

Simple materials

Brick, steel, concrete, glass and wood;these basic materials make up themain part of the building. But finelyscrubbed plaster and beautifully oxi-dized copper greatly influence the

55

-

8/6/2019 Pub PDF 115

6/24

Architectural copper review | 2004 / 2

overall impression of the building. Inparticular, the totally copper-clad, tallconcert halls sweeping shape can beseen from all directions in the neigh-bourhood. From certain angles moredominating, but the architect has clev-erly pulled back the big volume fromStortorget to make the city hall more

prominent from that viewpoint. A fineachievement by a tradesman whosereputation in the cultural preservationcircles of the time was not always con-sidered the best.

Copper will last

Verner Andersson, born 1938 and nowa retired metal sheet worker, tellsabout the metal work on Lunds cityhall: Well, it was work for two-three

men in periods during a couple ofyears. I was 27-28 years old andworked together with a man namedEkholm. He was a few years older. Weworked for Srenssons metal worksin Lund - this company no longer ex-ists. We did piecework, but we seldomhad vertical metal work of this magni-tude. The architect was stubborn. The

large window ledges would have toconnect directly to the brick. We toldhim there would be runoff that wouldturn the facade green, which hap-pened. Subsequently we had to addextra ledges at the upper levels lateron.

Besides this, after almost 40 yearspractically nothing has changed on the

exterior of the building that is other-wise rather difficult to maintain. Thewindow areas, almost all front doorsand the scrubbed plaster are original.No exterior building parts have beenadded. And the copper has only partlybeen supplemented or replaced, main-ly in connection with additional insula-tion of the horizontal concrete roofs.

Tore Gransson at Lunds municipalitis responsible for the maintenance anhe sees no need for metal repairs formany years to come. The municipalityalso knows that it has a very specialbuilding in its care.

The construction of Lunds city hall involved a big investment of the munici-pality. They decided to go through

with a proposal from one of the mostsought after architects in the countrywho with great enthusiasm performea demanding task. In return Lund re-ceived a representative building thatsince its inauguration has drawn con-siderable and justified international attention.

The concert halls copper-covered structure

has external vertical ventilation ducts. In thebackground Lunds cathedral can be seen.

Architect Klas Anshelm in front of the city hall

building in 1969. In the background the town

hall can be seen to the left.

City hall seen from Botulfsgrnden. The to

roof area and the concert halls technolog

platform can be reached through the gla

encased spiral staircas

The chestnut tree to the left is irrigated. In th

foreground a sculpture by Eduardo Chillid

Surrounding brick buildings are reflected in t

large window

66

-

8/6/2019 Pub PDF 115

7/24

Architectural copper review | 200

Sweden House is renovatedand gets new copper roof

Sweden House, situated in one of Stockholms most desirable office and

business areas on Hamngatan across from the department store NK, is

presently going through a complete renovation and expansion with an

additional floor.

By Lennart Engstrm, Sweden

Built in 1969, Sweden House was de-

signed by architect Sven Markelius,one of the great names of the 1920sclassicism and later also the functional-ism. The building was initially designedto house organizations for cultural re-lations. With its characteristic facadeit has become a cultural landmark inthe centre of the city. During the lastyear the building proprietor, Vasakro-nan, has carried out an extensive ren-ovation of the building with assistance

from architect firm Ahlsn Inredning-sarkitekter AB, which won the prestig-ious task of combining 1960s aesthet-ics with the most modern quality anddesign. Two entirely new floors withoffice space have been added. Here,

future tenants are offered first-class

offices with the best location at a well-known address! The new floors havefacades entirely clad in copper and anew roof of strip-covered copper.Sheet metal works Svenska Pltentre-prenader AB performed the 2,500square metres large copper coveringof the new floors. The metal work wasdone with a factory-oxidized NordicBrown copper sheet. The factory-oxi-dized dark surface of the copper is

achieved by letting the copper strippass through an oxidation line in themanufacturing process in the rollingmill. The oxide layer has the same col-our and texture as the naturally devel-oped oxide. Depending on the climate

and other external circumstances the

dark surface will, with time, shift togreen patina when exposed outside.Also the strip-covered roof areas aredone with factory-oxidized half-hardcopper. The facade is built up withhorizontal copper strips connectedwith an angled seam verge. The newdark-oxidized addition to SwedenHouse is in my opinion another goodexample of how copper successfullycan be combined with other building

materials and create bridges betweendifferent styles, and thus contribute toa harmonious architectural dialoguebetween the materials.

77

-

8/6/2019 Pub PDF 115

8/24

Architectural copper review | 2004 / 2

8

-

8/6/2019 Pub PDF 115

9/24

Architectural copper review | 200

A beautiful building in a new section of the city

We have earlier written in Architec-tural Copper Review about the con-struction of a new office for the pen-sion insurance company Sampension inTuborg Syd, a brand new section ofthe city north of Copenhagen. Thebuilding is now finished and constitutesthe work environment for more than300 employees. Sampension is one ofDenmarks largest pension insurancecompanies and handles mainly pensionmatters for the labour market. Thebuilding has therefore been given asolemn, but at the same time open,welcoming architectural language.

The building is made up of two bodies:one angled that carries a square tu-bular element. The angled body of thebuilding is covered with verdigris-green granite from Brazil, while thesquare tubular body to a large ex-tent gets its characteristics from thecopper cladding, which consists ofshutters that are alternately turned in-wards and outwards. This gives the

copper facade a sophisticated relieffeeling that contrasts nicely with manyof the neighbouring buildings, whichare characterized more by todaysfondness of glass facades.

Well thought-out sun shield

The copper shutters of the facade ofSampension can be turned so that theemployees get a free view. But theyare also perforated with small holes

that make it possible to look out evenwhen the shutters are turned down toshield from the sun. The shutters aremanufactured in factory-oxidized Nor-dic Brown and no less than 60 tons ofcopper were needed for the facade.Rich. Mller A/S manufactured thematerial and delivered the perforatedcassettes, while the actual facade cov-

ering was performed by Kai AndersenA/S.

The story-high cassettes will with timechange to a light green patina andthereby give the building a lighteroverall impression. It will be very in-teresting to see how this patina will

match the green granite on the otherpart of the building. Unfortunately, thiswill not happen for a few years, as thepatination takes longer today than itused to. There is not a lot of heavypolluting industry in Copenhagen thatwill help the patination.

9

-

8/6/2019 Pub PDF 115

10/24

Architectural copper review | 2004 / 2

Motor-driven work comfort

When looking at the solutions to Sam-pension's office building we find manyinteresting details that are worth men-

tioning. To remain with the copper,the shutters are motor-driven and ac-tivated by the employees pressing abutton. However, the buildings auto-matic system will turn all individualsettings back to zero at the end of theday, so that they are in their originalpositions when the employees come inthe next morning.

Kurt Norman Pedersen at Kai An-

dersen A/S tells us that all shutterframes are manufactured in stainlesssteel: The copper is extraordinarilycorrosion-aggressive towards steeland it is therefore necessary to usestainless steel in order for the con-struction to keep its high quality formany years to come.

Besides this, the motor-driven com-fort goes even further, with the instal-lation of a computerized mobile shelfsystem that employees can use by thetouch of a panel. Furthermore, aes-thetic considerations have been takennot only of the exterior, but also of

the interior. In the centre atrium theris a 27 metre tall light installation withfibre optic cables that attract atten-tion. The fibre optic creates a veil in

front of the meeting rooms and diversion with its changing colours, andgives off humidity through water droprunning along the fibres down into abasin at the bottom of the installationwhere the water is collected.

Proprietor:

SampensionArchitect:

3 x NielsenFacade:

Kai Andersen A/SMaterial:

Outokumpu Nordic Brown (Half hardManufacturing:

Rich. Mller A/SFacade covering:

Performed by Kai Andersen A/S

10

-

8/6/2019 Pub PDF 115

11/24

Architectural copper review | 200

Elegant combina-

tion of a city

building in brick

and the addition

characterized by

copper cladding.

Copper for a high schoolwith growing pains

In the heart of Roskilde is RoskildeCounty High School, situated rightnext to Roskilde Cathedral, whereDenmarks royalty are laid to rest.Roskilde was originally Denmarks gov-erning city and has an interesting his-tory, which gained a new dimensionwhen a Viking ship was found in thefiord in the early 1960s.

However, at Roskilde County HighSchool more contemporary problemsare occupying teachers and students.As more and more young people applyto the high school each year, the build-ing at Domkirkepladsen has becometoo crowded. With a prognosis ofmore than 700 students it is necessary

to expand, and this task was presentedto the countys permanent collabora-tion partner in this area: Skaarup &Jespersen in Hellerup.

Location, history, architecture andtodays demand on functionality shouldall be incorporated to an entity whenwe plan in such a sensitive area as cen-tral Roskilde says architect Hans Ap-pel at Skaarup & Jespersen who is incharge of the project. Initially, the en-tire discussion was about how to find

a site for the new building. This wasresolved by the possibility of buying aneighbouring house that could be torndown to give room.

Copper - a natural choice

When the necessary land area for thebuilding had been secured, the plan-ning and design work could begin. Ac-cording to Hans Appel it was a matterof course to use copper for the build-ing. This for two reasons: On onehand copper had already been used for

11

-

8/6/2019 Pub PDF 115

12/24

Architectural copper review | 2004 / 2

the original part of Roskilde CountyHigh School, on the other hand cop-per had been used for the twin towersof the historic Roskilde Cathedral,which borders to the high school.

Architect Hans Appel: With coppercovering on the new buildings towerand facades we draw a straight line tothe rest of the block and back to the

historical buildings surrounding us inthe centre of the city. Furthermore,this is a protected area, which contrib-utes to the tight limits for how muchwe will allow ourselves to do.Architect Lone Busk drew the firstlines for the project, after which HansAppel took over and brought it to thebidding stage, which was the projectsfirst objective. In Denmark, an archi-tect firm such as Skaarup & Jespersen,

that serves as proprietor advisor forRoskilde County, cannot itself contin-ue the project and carry it through.

Almost 1,100 additional

square metres

The total contract was won by ElindcoByggefirma A/S, and together with,among others, Henrik Srensen MAA

Architects they were commissioned todo the actual construction, but withHans Appel as the countys represent-ative at the work site. Today the build-ing is finished and in use. It houses sev-eral classrooms and project rooms,and even the teachers lounge hasfound space in the new building. Thishas at the same time created space fora larger dining-hall in the older part of

the building.

Towards Bondetinget the buildinglooks like a regular city building withplastered facades and a red tile roof,says Hans Appel. The building facingthe courtyard is built in finely struc-tured brick with extensive use of cop-per cladding. We have used approxi-mately five tons 0,75mm thick coppersheet and strips. Eckeroth/Gladsaxe

Tag & VVS did the sheet metal work incooperation with the full contractorElindco.

The result is worth seeing. The highschool did not only get more space forthe growing number of students. It al-so got an extension that in spite of itsmodern details and functions fits nice-

ly into the protected city centre. Andnot least, the use of copper has built bridge between the past and thepresent.

Architect:

Henrik Srensen MAAProprietor:

Roskilde AmtBuilding year:

2002Consulting:

Full consultingSheet metal works:

Eckeroth/Gladsaxe Tag & VVS

Approximately five tons of copper were

used to cover the tower, roof and

facades.

The extension has many nice details, for example this courtyard with the Cathedral in the backgroun

12

-

8/6/2019 Pub PDF 115

13/24

Architectural copper review | 200

Kungstrdgrden in Stockholmadorned with copper

By Lennart Engstrm, Sweden

The drainpipes are built into the exterior wall

In the centre of the city and in theheart of Stockholm is Kung-strdgrden, popularly called Kungsan.The park dates back to the 15th cen-tury, when the land was used for hor-

ticulture. Several centuries later thepark was turned into a beautiful ren-aissance garden. For the last hundredyears, the park that is surrounded by20 metre tall leafy lime tree avenueshas been a green oasis in the city.Here different activities take place allyear, from music festivals to Christmasmarkets, and during the last few years

also a restaurants day. During thesefestivities the entire park is often filledwith people.As a result there have been extensivestudies of the condition of the trees in

the park over the last few years. Stud-ies show that most trees were seri-ously rot- and fungus damaged. Therotting weakens the trees and increas-es the risk of falling branches thatcould injure visitors to the park. Afrequently visited park such as Kung-

13

-

8/6/2019 Pub PDF 115

14/24

Architectural copper review | 2004 / 2

san cannot risk injuries due to fallingbranches and because of this theStockholm department of streets andproperties decided to do a full renova-tion of the park. The old and diseasedlime trees will be replaced over athree-year period and the work will becarried out exactly according to the200 year old planting maps. In addi-tion, Sdergruppens ArkitektkontorAB was commissioned to draw theplans for four restaurant buildings inthe park. Architect Gabriel Herdevallcame up with a proposal where pavil-ions were placed along the east side ofthe park facing Kungstrdgrdsgatan.The pavilions serve as sound barriersagainst the street and large windowsopen up to the park and walkway. Thecharacteristic, curved pavilion roofswere made in copper. To use copperfor the pavilions was a natural choicein this part of Stockholm. In the blocksaround Kungsan with palace-like oldbuildings, there is a long tradition touse copper for roof covering. Many ofthe adjacent roofs have with time alsodeveloped the natural green patinathat is characteristic for copper.

When building on land dating backfrom the 15th century, great care hasto be taken in the detailed planning. Asfor the roof covering, an analysis ofhow rainwater from copper roofs af-fects the environment was made. In

this case, runoff from the roofs takesplace via drainpipes mounted in theexternal wall with connecting distribu-tion pipes to a sandstone bed for finalfiltration into the park ground. Withthe help of research results from,among others, the Royal TechnicalCollege in Stockholm, it is today possi-

ble to, with rather simple methods, es-timate the runoff from a copper sur-face and how the metal in the runoffreacts with the surroundings.The documented runoff from theroofs turned out to be within limits

and has no negative effect on the envronment. Cement and limestone arelong known to interact with rainwateand bind the copper ions during for-mation of the green mineral malachite

The first copper pavilion was built inthe spring of 2003 and another three

were built in 2004. The last pavilion isplanned for completion in spring 2005Hagalunds sheet metal works wascommissioned to install the copperroofs on the three pavilions built thisyear. The roofing is done with 0,6-mmcopper sheeting assembled in tradi-tional covering. Via a valley gutter therainwater is conveyed to the built-indrainpipes. The pale plastered facadesmeet the roof in a soft, slightly round

ed connection made of copper.

The copper sheets have been pre-joined together as a single unit to cover the entire length of th

roof by the sheet-metal workers, in order to simplify the assembly at the construction sit

View from Kungstrdgrdsgatan

1414

-

8/6/2019 Pub PDF 115

15/24

Architectural copper review | 200

Construction on Svalbardin harmony with the unique environment

By Lennart Engstrm, Sweden

In the previous issue of ArchitecturalCopper Review we described how thesheet metal workers prepared for the

building of the new 8,500 square me-tres research village outside Longyear-byen on Svalbard. The article showedsome of the problems of carrying outa demanding craft in extreme weatherconditions.Also planners and building proprietorsare facing various problems when plan-ning for such a large project as Sval-bard research village. For example, lay-ing foundations and putting down

pipes in areas with permafrost can beproblematic. Another very importantconsideration is to not disturb the nat-ural balance of the barren fauna on theisland. Here it is especially importantto analyse the choice of materials froman overall aspect and select materialsthat are environmentally friendly, as

Svalbard has a very limited and uniquefauna that must be preserved.Before the facade and roof materials

finally were selected, project leaderAstrid Reikvam at Stadsbygg, the build-ing proprietor, initiated at an earlystage an environmental analysis in or-der to minimize future environmentaleffects.Based on existing research findings itis possible to estimate the amount ofcopper that could be set free from thebuilding. An important parameter forthe calculations is the yearly precipita-

tion, which for Svalbard is relativelylow, only 120 mm/year. Other impor-tant factors are angles and aspect ofthe different bodies of the building.It turned out that very small amountsof copper were set free and these arebelieved to have no effect on the envi-ronment. With the answers from the

evaluation, Stadsbygg could make thedecision to cover the facades as wellas the roof with copper. Traditionally,

tar paper has been used for the hous-es on Svalbard and the roofs havebeen repaired and re-roofed withclose intervals. This type of roofing,however, could be less desirable froma maintenance aspect as well as en en-vironmental aspect.It is difficult to make a general classifi-cation of materials as good or bad. Re-ality is not black or white; all materialshave advantages and disadvantages.

Choices and recommendations mustbe based on an overall evaluation thatincludes all relevant aspects, includingevaluation of the alternatives.

1515

-

8/6/2019 Pub PDF 115

16/24

Architectural copper review | 2004 / 2

THE KALE IDOSCOPE

The lecture hall at Sveaplan HighSchool has been given a new roofof traditional copper covering.Oscar Jansson sheet metal work-shop has performed the roofing,and reports that the work wentalong well. The only problem was apeculiar theft, as some thieves onenight stole copper sheeting thathad just been mounted on the roofthe day before.The copper roof was installed withannealed copper sheeting.

The lecture hall at Sveaplan High School

is being renovated

Athen's train station

A new 5,000 m2 open shed made inpatinated copper now gives shelterfrom the rain to the waitingpassengers.

1616

-

8/6/2019 Pub PDF 115

17/24

Architectural copper review | 200

Prefabricated copper solutions

Dutch architect Erik van Egeraats

vision for Copenhagens harbour issix copper and glass towers onKryers Plads in Copenhagen, thetallest of them 55 metres.

Proposal for grandiose copper construction in Copenhagen

Elegant, beautiful andmaintenance freeProduced by E.J. VVS, Herning.

1717

-

8/6/2019 Pub PDF 115

18/24

Architectural copper review | 2004 / 2

When old

The stairways at the rear

of the building are covered

with prepatinated copper

and have large glass

surfaces that allow daylight

to pass through.

The folks at Askim Sparebank

were convinced, just by looking

over to the next street corner,

that their new building should be

covered by copper, and not zinc.

The result is a successful renova-

tion and extension, where prepat

nated copper creates a perfect

transition between old and new.

When those in charge of the renova-tion and extension of Askim Spare-bank began their planning, there weremany different suggestions. The taskfor stre Linje Arkitekter, the archi-tecture firm chosen for the job, was trenovate the existing building and de-sign a new building for the adjancent

corner lot and a block of apartmentsadjacent to the corner building.

It was decided that the new housewould be built in brick, like the exist-ing one, but there was some discus-sion on what surface material to use.Zinc was considered, but as zinc hadbeen used on the balconies of the

181818

-

8/6/2019 Pub PDF 115

19/24

Architectural copper review | 200

and new meet

The corner buildings glass front contrasts

nicely with the light, prepatinated copper that

characterizes the residential section of the

building along the side street.

The original building borders to the new

building with the glass facade in the corner.

building across the street, there wassome concern that too much zincwould give a lifeless impression, andthe architects therefore decided oncopper. Now they needed to deter-mine which type of copper to use.

Expressive surface with Nordic

Green PLUS

The building committee looked at sev-eral different types of prepatinatedcopper and decided on the NordicGreen PLUS method. An alternativemethod gave the material a bluishglow, but with Nordic Green PLUS,the natural patinated glow, structureand variation in the surface that wasaimed for appeared.

The result proves that the buildingcommittees decision was the rightone. Prepatinated copper frames thewindows facing the street. The cornerbuilding is characterized by large glasssurfaces, while the residential block onthe side street is entirely covered by

copper. The stairways at the rear ofthe building are covered with copperas well, broken up by large glass parti-tions that allow the daylight to passthrough.

Positive reactions from the cus-

tomers

The surface of the older building wasearlier aluminum that had been paintedgreen. Theres a noticable difference

today with the green patinated copper,which characterizes the entire block.A total of six tons of copper was deliv-

ered, and it was treated on site by Er-ling Freitag AS, who did the sheet met-al work. Thus, what was used was notfactory-patinated copper, but untreat-ed material that was brushed with theliquid immediately before the assem-bly. This gives a beautiful and varied

structure with life and movement ofthe colours.

Askim Sparebank is very different fromboth its zinc-covered neighbour acrossthe street and the old surface withpainted aluminum sheets. There havebeen many positive reactions, bothfrom customers and from people livingalong the street, and this naturallypleases the members of Askim Spare-

bank building committee, and inspiredthem to travel to Finland to visit thefactory that delivered the copper.

191919

-

8/6/2019 Pub PDF 115

20/24

Architectural copper review | 2004 / 2

The Eesti Kunstimuuseum

project moves forward

Illustration: Pekka Vapaavuo

By Pekka Vapaavuori, architect

The Eesti Kunstimuuseum project is

based on an international architecture

competition that was decided on April 1,

1994. First prize was given to bo-based

Finnish architect Pekka Vapaavuoris

proposal Circulos. The work started

immediately after the contest and in Jan-

uary of 1995 the revised outline plans ona scale of 1/200 were handed over. The

project was on hold for the following

years. In 1999 the continuous financing

was guaranteed and the actual planning

could be started. After a few delays a

building permit was granted in the sum-

mer of 2002. After extensive excavation

work the construction was started in

the fall of 2003. The building is planned

to be finished in September 2005 and

the museum will be inaugurated at the

end of that year.

The location of the museum on the

site and in the park environment

The site on the outskirts of the Kadri-orgi Park has two sides: At the base of

the twenty metre tall limestone preci-

pice, which is surrounded by a lush park

landscape, one is totally unaware of the

busy road 100 metre southwards. The

areas upper level opens up to an entire-

ly different view. The landscape is split in

half by Laagnaroad mountain gorge and

farther eastwards the large suburb of

Lasnamki can be seen, while the centr

of Tallinn with its towers can be seen tothe west.

The basis of the planning was to f it a

large building into the area and at the

same time keep the Kadriorgi Park as

unspoiled as possible. It was desirable t

preserve the old valuable trees and re-

serve the park mainly for pedestrians.

The light from the lighthouse in La-

snamki decided the buildings maximal

height. Because of these conditions the

building was lowered into the slope. Asthe building is partly placed below

ground level it gives an impression of be

ing smaller, and is not a threat to the

Kadriorgi Palaces predominate position

in the park. This solution also creates a

functional connection between the up-

per level and the park.

2020

-

8/6/2019 Pub PDF 115

21/24

Architectural copper review | 200

International website on copper in architecture

General solutions for the building

The building, which is partly surrounded

by a concrete wall circle, is well suited

for the needs of the museum. The circu-

lar wall defines the museums courtyard

in a natural and discreet way and meets

the security requirements without com-

pletely closing off the courtyard. The

wall also encloses an area of sculptures,

which serves as part of the park when

the museum is open. The busy traffic is

led to the museums basement via a 130

metre long tunnel, directly from Laag-

navgen.

Parking and the closest bus stops are lo-

cated at the upper part of the site. From

here the visitors are taken via a tunnel

for pedestrians through the sculpture

park to the museums front entrance.

On this level there is a ticket office,

shop and entrance to the exhibits. The

museums other entrance can be

reached via a ramp to the auditorium

lobby, from which visitors continue to

the main entrance foyer. Crossing bridg-

es dominate the tall entrance that di-

vides the museum into two parts. The

planners have sought simplicity and defi-

nition, especially in the galleries where

the goal has been anonymity to give

room for the art. The ascetic features of

the interior can also be seen in the ex-

ternal distinctly geometric shapes.

Nordic Green PLUS-copper on

the facade and inside

When selecting materials the architects

have sought clarity. Three different kinds

of facade materials were used. The

curved concrete wall has a surface of

limestone brick that connects the build-

ing to the surrounding limestone verge.

The northeast wall is mainly a double-

glazed facade. The special-made glass

diffracts and f ilters the light to suit the

museums exhibit halls. Horizontally

joined green-patinated copper sheeting

covers the part of the building contain-

ing the exhibition halls. There is totally

about 4,000 square metres of copper

covering on the exterior, the major part

Nordic Green PLUS-copper. The green-

patinated copper was in the picture even

at the contest stage in 1994, before Ou-

tokumpu had a finished product for pati-

nation, and pre-patinated copper surfac-

es could be found only on a few buildings

in central Europe. Patinated copper will

also be used in the interior of the build-

ing. The total area of the building is

23,900 m2 with a volume of 123,000 m3.

www.copperconcept.org

2121

-

8/6/2019 Pub PDF 115

22/24

Architectural copper review | 2004 / 2

Building renovation in Germanywith patinated copper

By Klaus Docter, Germany

On Bernadotte-Strasse 104-114 in Hamburg, just below the perhaps

better known Elbchaussee with its exclusive flats, there is a house that

was built during the fifties. The building proprietor wanted to add

another floor and commissioned architect firm Lbbert & Quibeldey

for the task. The result was a new floor and an entirely new roof shaped

like a wave with a slope of approximately seven degrees.

Detail of connection to skylig

After evaluation of different technicalsolutions for the roofing, the choicestood between a strip covering and atraditional covering of copper that fol-lowed the shape of the roof. Finally,the alternative with the strip coveringwas chosen, as in this particular case

this technique turned out to be themost beneficial both technically andeconomically. When it later alsoturned out to be possible to use fac-tory-patinated strips of the NordicGreen PLUS type, the last pieces ofthe puzzle fell into place. A sheet met-

2222

-

8/6/2019 Pub PDF 115

23/24

Architectural copper review | 200

The roofing is finished but the work still continues from the scaffolding on the facade.

View over the green roof landscape

al factory from Steinfurt was contractedto do the mounting of the new copperroof of approximately 1,700 square me-tres. The copper strips were pre-fabri-cated as much as possible at the

Rutkowski Metalldacheindeckungensheet metal shop before the materialwas transported to the constructionsite. With seam dressing, sizing and

curving already being performed at thesheet metal shop during favourableconditions, the assembly time at thebuilding site, normally the most costlystage, could in this case be consider-

ably shortened.The copper strips were delivered witha protecting plastic foil that preventsthe patina layer from being damaged

or scratched when worked on. The in-stallation at the site was done withtraditional tools and techniques. Theambitions and commitment of thesheet metal workers to perform high-

quality work is apparent in the niceimpression you get when walkingaround on the roof where all detailscan be closely examined.

2323

-

8/6/2019 Pub PDF 115

24/24

Architectural copper review | 2004 / 2

Faraday Housein London is renovated

By Lennart Engstrm, Sweden

Michael Faraday (1791-1867) was aBritish chemist and physicist who be-came one of sciences big innovativeexperimenters. He was best knownfor his groundbreaking experimentswith electricity and magnetism. It wasFaraday who in 1834 introduced theterm electrode.At his retirement he was allotted ahouse in Blackfriars near St. Pauls Ca-thedral, where he lived until his death1867. Today the building is owned andmaintained by British Telecom. An ex-tensive renovation of the entire build-ing is presently underway, and duringlast spring the roof was renovated.

Completely new roofing was donewith pre-patinated copper. The com-pany Marshott Non Ferrous Roofingwas contracted to do the strip cover-ing in copper. It was the first time thiscompany had performed roofing withpre-patinated copper of the NordicGreen PLUS type. We were a bit un-certain in the beginning, they said.We did not quite know then how thepre-patinated surface would be affect-

ed when worked on at the site. How-ever, we soon discovered that the patnated surface could stand all normalhandling and even mechanical treat-ment with seam sealing. When studying the roof from the street levelmost people probably believe that thebeautifully green-patinated copperroof has been there for several hun-dred years.

for more informationon copper products.

Visit our website Outokumpu.com