Properties of Filter Cake in Cake Filtration and Membrane ...Filtration is the operation of...

Transcript of Properties of Filter Cake in Cake Filtration and Membrane ...Filtration is the operation of...

KONA No.21 (2003) 19

1. Introduction

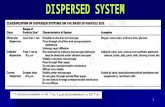

Filtration is the operation of separating a dispersedphase of solid particles from a f luid by means of a fil-ter medium which permits the passage of the f luidbut retains the particles. Filtration is probably one ofthe oldest unit operation. The old forms of filtrationby straining through porous materials were describedby the earliest Chinese writers. A gravity filter used ina chemical process industry was described in anEgyptian papyrus which has its origin in about thethird century A. D.

In recent years, many developments have increasedthe application of filtration. Filtration steps are re-quired in many important processes and in widelydivergent industries. The importance of filtrationtechniques has been emphasized by the increasedneed for protection of the environment and by theincreasingly critical need for larger supplies of en-ergy. Recently, membrane filtration of colloids hasbecome increasingly important in widely diversifiedfields.

The appropriate control of both the filtration rateand the rejection (or the transmission) of the par-ticles and/or the macromolecules in the filtrationprocess is of great interest in both industry and acad-emia. While there exist many factors inf luencing thefiltration behaviors [1], the underlying phenomenaare currently not well understood.

The filtration behaviors are strongly affected by theproperties of the filter cake formed by the accumula-tion of the particles and/or the macromolecules onthe surface of the filter medium or the membrane [2].Therefore, an understanding of the cake structurecan serve as a basis for clarifying the real mechanismof cake filtration and membrane filtration. In this arti-cle, role of filter cake in cake filtration and membranefiltration is overviewed.

2. Experimental Testing Procedures

It is extremely important from both theoretical andindustrial viewpoints to develop simple and precise fil-tration test methods. The most commonly used testsare classified into three groups: vacuum filtrationtests, pressure filtration tests, and compression-per-meability tests. Such overall filtration characteristicsas the average specific filtration resistance αav andthe average ratio m of wet to dry cake mass are mea-

Eiji IritaniDepartment of Chemical Engineering, Nagoya University*

Properties of Filter Cake in Cake Filtration and Membrane Filtration†

Abstract

Filtration of liquid suspensions is a widely practiced process in many industries. In recent years,membrane filtration of colloidal solutions has attracted a considerable amount of attention. Theappropriate control of both the filtration rate and the rejection (or the transmission) of the particlesand/or the macromolecules in the filtration process is of great interest in both industry and acade-mia. Such filtration behaviors are strongly affected by the properties of the filter cake formed by theaccumulation of the particles and/or the macromolecules on the surface of the filter medium or themembrane. This paper overviewed the author’s own contributions on the recent developments on thebehaviors of the filter cake in cake filtration and membrane filtration. The paper will mainly dealwith measurements and analysis of the internal structures of the filter cake, the role of the solutionenvironment in the properties of the filter cake, and filtration and fractionation mechanism of mix-tures.

* Furo-cho, Chikusa-ku, Nagoya 464-8603, JapanPhone: +81-52-789-3374, Fax: +81-52-789-5300E-mail: [email protected]

† Accepted: September 1, 2003

sured by conducting vacuum or pressure filtrationexperiments. In general, αav is calculated by usingboth the constant pressure filtration coefficient Kv

determined from the slope of the Ruth plots [3] andthe m-value. The value of m has almost invariablybeen determined by weighing the filter cake beforeand after the cake dries. However, visual determina-tion of the end of filtration often leads to erroneousvalues for m and also αav because of the indistinctinterface between the cake surface and the slurry.

The compression-permeability cell [4-6] is a devicein which a mechanical load is applied through a pis-ton to a cake resting on a filter medium. Both overallfiltration characteristics and internal structures of thefilter cake are analyzed on the basis of experimentaldata of the equilibrium porosity and the specific f lowresistance of the compressed cake in the compres-sion-permeability cell. However, this technique maybe rather tedious and time-consuming for industrialpractice.

A simple alternative procedure recently developeddepends on measurement of the capillary suctiontime (CST), utilizing the very small suction pressureapplied to the slurry by the capillary action of anabsorbent filter paper [7]. However, little attempt hasbeen made to determine filtration characteristics pre-cisely and easily under relatively high filtration pres-sure conditions.

A method has been developed for evaluating rigor-ously the properties of the filter cake, such as theaverage porosity εav and the average specific filtrationresistance αav [8]. It utilizes the sudden reduction infiltration area of the cake surface. The specially de-signed apparatus is schematically shown in Fig. 1.A close-fitting cylinder with an inner diameter D of 4cm is inserted in the cylindrical brass filter. Insertedcylinders having heights h of 5, 10 and 15 mm areused. A disk with a hole having a diameter Dh of 6mm is placed on top of the inserted cylinder, and thepart below this constitutes the filter chamber.

Filter cake steadily builds up on the filter mediumas soon as the filtration process starts. The surfacearea of the growing filter cake equals exactly the areaof the filter medium. At this first stage, on the as-sumption of negligible medium resistance, the recip-rocal filtration rate (dθ/dv) is represented by thewell-known Ruth equation for constant pressure filtra-tion in the form [3]

v (1)

where θ is the filtration time, v is the cumulative fil-

2Kv

dqdv

trate volume collected per unit effective medium area,and Kv is the Ruth coefficient of constant pressure fil-tration defined by

Kv (2)

where p is the applied filtration pressure, s is themass fraction of solids in the slurry, µ is the viscosityof the filtrate, and ρ is the density of the filtrate.

Once the filter cake builds up to the underside ofthe disk, the subsequent filter cake can form onlyinside the hole in the disk. Consequently, the filtra-tion area of the cake surface is reduced suddenly, andthe filtration rate decreases markedly in accord withthe decrease in formation rate of the filter cake. Afterthe filtrate volume v is beyond the critical volume vt atthe transition point, the reciprocal filtration rate(dθ/dv) vs. v deviates remarkably from the relationrepresented by Eq. (1).

From the value of vt, the average porosity εav of thefilter cake can be calculated using an overall mass bal-ance of dead-end filtration, to give

εav (3)

where ρs is the true density of solids. The ratio m ofwet to dry cake mass in Eq. (2) is related to the aver-age porosity εav of the filter cake by

rsh(1s)rsvt

rsh(1s)rsh

2p(1ms)mrsaav

20 KONA No.21 (2003)

Fig. 1 Schematic diagram of filtration apparatus having suddenreduction in its filtration area.

AIR PRESSURE INLETSLURRY INLET

SLURRY

CAKE SURFACE

DISK WITH HOLE

FILTER CAKE

FILTRATE

D h

Dh

INSERTED CYLINDER

FILTER PAPER &PERFORATED PLATE

m1 (4)

Thus, the average specific filtration resistance αav canbe evaluated accurately from Eqs. (1), (2), and (4) byusing the slope of the plot of dθ/dv against v and thevalue of m.

The values of m and αav obtained by this methodcan be predicted by using the compression-perme-ability cell data. On the basis of the compressiblecake filtration model [9, 10], the distributions of thelocal porosity ε and the local specific filtration resis-tance a and the apparent liquid velocity u relative tosolids in the filter cake can be estimated by using thecompression-permeability cell data in the form of eand a as functions of the local solid compressive pres-sure ps. Consequently, the values of m and aav can becalculated from Eqs. (5) and (6), respectively.

m1 (5)

aav0

1 d · (6)

where w is the net solid volume per unit medium arealying from the medium up to an arbitrary position inthe cake, w 0 is the net solid volume of the entire cakeper unit medium area, and u1 is the filtration velocity.The quantity pm is the pressure loss through the filtermedium, and can be neglected in this article.

In Fig. 2, the results obtained with the setup shownin Fig. 1 are plotted in the form of the reciprocal f lowrate (dq/dv) vs. the filtrate volume v per unit mediumarea. In the first stage of the operation, each curveyields a straight line in accordance with Eq. (1). Assoon as the cake builds up to the underside of thedisk with the hole, the value of dq/dv increases re-markably.

The value of m can be calculated from Eqs. (3) and(4) by using the values of the thickness h of the filterchamber and the filtrate volume vt at the transitionpoint determined from Fig. 2. In Fig. 3, m is plottedwith respect to the filtration pressure p. The value ofm decreases with pressure. The experimental resultsare fairly consistent with the calculations based on thecompression-permeability cell data. The discrepancyin the low-pressure region may be due to the inf lu-ence of sedimentation, which becomes important inthe case of small formation rate of the cake. For com-

ppm

0

ppm

aN1 dps

ww0

uu1

r0

1edw0N

w rs

0

1(1e)dw0N

w

reav

rs(1eav)

parison, the values of m determined by the conven-tional method of weighing the filter cake before andafter being dried are also included in the same figure.The values thus obtained are rather large comparedwith the calculations because of the indistinct inter-face between the cake surface and the slurry. InFig. 4, aav is plotted against pressure p. The resis-

KONA No.21 (2003) 21

6

5

4

3

2

1

00 0.5

v [cm]

dθ/d

v [s

/cm

]

1.0 1.5

103

KOREAN KAOLINs0.393h1 cm p98 kPa p196 p294 p392

TRANSITION POINT

Fig. 2 Relation between reciprocal filtration rate and filtrate vol-ume per unit medium area for various applied filtrationpressures.

0 100 200 300 400

1.7

1.6

1.5

1.4

p [kPa]

m [

]

KOREAN KAOLINs0.393

THIS METHODCONVENTIONAL METHODC-P CELL DATA

Fig. 3 Relation between ratio of wet to dry cake mass and filtra-tion pressure.

tance aav increases with pressure. The experimentalresults obtained by this method are fairly consistentwith the calculations, whereas the results obtainedby the conventional method show poor agreementbecause of incorrect values of m. It is demonstratedfrom the results of Figs. 3 and 4 that this method ismore accurate compared with the conventional one.

3. Compressible Cake Filtration Model

The compressible cake filtration model [9, 10] isused to evaluate such internal quantities as the solidconcentration, the compressive pressure acting onthe solids and the local specific filtration resistancewithin the filter cake exhibiting compressible behav-ior. The build-up of the filter cake increases thehydraulic resistance to f low, thereby reducing the fil-tration rate. Basically, the compressible cake filtrationmodel can evaluate the reduction of the filtration ratedue to the increase in the hydraulic resistance causedby the filter cake.

According to the compressible cake filtration mod-el, the filtration rate J (dv/dq) in dead-end filtrationwith negligible medium resistance compared with theresistance of the filter cake is represented by [3]

J (7)

where w0 is the net mass of deposited solids per uniteffective medium area. By accounting for the effectsof non-homogeneity and compressibility of the filtercake, the apparent solvent velocity Jω relative to solidsat an arbitrary position w in the filter cake can be

pmaavw

described by [11]

Jw · (8)

On the assumption that the solvent velocity Jω is con-stant throughout the entire cake, on the basis of Eqs.(7) and (8), one obtains [11]

1 (9)

a (10)

eeav 1 (11)

where w 0 (w0/rs) is the net solid volume of theentire filter cake per unit effective medium area, ande (e/(1e)) is the local void ratio. Therefore, if theaverage specific filtration resistance aav and the aver-age void ratio eav (eav/(1eav)) of the filter cake arerepresented as functions of the applied filtration pres-sure p, then the variations of the local solid compres-sive pressure ps, the local specific filtration resistancea and the local void ratio e with w can be evaluatedfrom Eqs. (9)(11). Thus, the variation of the massfraction c of the solid in the filter cake with the dis-tance x from the medium surface can be also calcu-lated from the result of e versus w.

For a practical standpoint, the following empiricalfunctions of ps may be convenient for simplified evalu-ations of filtration characteristic values [12, 13].

aa1psn (12)

eE0Cc ln ps (13)

where a1, n, E0, and Cc are the empirical constants.With the aid of Eqs. (12) and (13), Eqs. (9)(11) canbe written as [11]

1 (14)

aava1(1n)pn (15)

eavE0 Cc ln p (16)

On the basis of the model of solutions in which the

Cc

1n

11nw

w0

ps

p

NNd(ln p)d( ln eav)

1NNd(ln p)d( ln aav)

aav

1NNd(ln p)d( ln αav)

0

ps

aNdps

0

p

aNdps

ww0

∂ps

∂w1

mars

22 KONA No.21 (2003)

0 100 200 300 400

10

8

6

4

2

0

p [kPa]

α av [

cm/g

]

KOREAN KAOLINs0.393

THIS METHODCONVENTIONAL METHODC-P CELL DATA

1011

Fig. 4 Relation between average specific filtration resistance andapplied filtration pressure.

macromolecules appear as solid particles [14], it isassumed that the model which has been employed infiltration of particulate suspensions can be applied tothe f low of solvent through the filter cake in ultra-filtration of the solution. In Fig. 5, the average spe-cific filtration resistance aav and the average void ratioeav of the filter cake in protein ultrafiltration measuredwith a filter which has a sudden reduction in its filtra-tion area are plotted as functions of the filtration pres-sure p [15]. The macrosolute used in the experimentswas bovine serum albumin (BSA) with a molecularweight of 67,000 Da and with an isoelectric point of4.9. Increasing the filtration pressure causes a reduc-tion in the void ratio of the filter cake, leading to anincrease of the specific filtration resistance. It isapparent that eav around the isoelectric point (pH 4.9)is much smaller than that at pH 7.0. The two types ofplots show a linear relationship over the entire rangeof data in accordance with Eqs. (15) and (16), respec-tively. The parameters a1 and n in Eq. (12) can be cal-culated by fitting Eq. (15) to the logarithmic plot ofaav vs. p. The value of E0 and Cc in Eq. (13) can beobtained from a plot of eav vs. ln p in accordance withEq. (16), using the predetermined n value. The distri-butions of ps within the filter cake can be obtainedfrom Eq. (14). With the aid of Eq. (14), Eqs. (12) and(13) provide the distributions of a and e within the fil-ter cake, respectively.

The variations of the local solute compressive pres-sure ps and the local specific filtration resistance aacross the filter cake for different values of the filtrate

volume v calculated from Eqs. (14) and (12) are illus-trated in Figs. 6 and 7, respectively [16]. The dis-tance x from the membrane surface in the figuresmay be calculated from w by

· (17)ww0

1eav,w

1eav

xL

KONA No.21 (2003) 23

2

0

5

10

15

20

1015

4

6

8

2

4

1016

102101 1038642 8642

p [kPa]

α av [

m/k

g]

e av [

]

BSAs5103

, pH 4.9 , pH 7.0

Fig. 5 Effect of applied filtration pressure on average specific fil-tration resistance and average void ratio of filter cake fordifferent values of pH.

0 0.5 1.0 1.50

20

40

60

80

100

x [cm]

p s [

kPa]

BSAs5103

pH 7.0p98 kPa

v5 cm

v10 cm

v20 cm

Fig. 6 Distributions of local solute compressive pressure in filtercake for different filtrate volumes.

0 0.5 1.0 1.50

2

4

6

8

10

x [cm]

α [m

/kg]

BSAs5103

pH 7.0p98 kPa

v5 cm

v10 cm

v20 cm

1015

Fig. 7 Distributions of local specific filtration resistance in filtercake for different filtrate volumes.

where eav,ω is the average void ratio from the mem-brane surface to the distance w from the membrane.The thickness L of the protein filter cake is expressedbased on the material balance as

L v (18)

As shown in the figure, high specific filtration resis-tance can be obtained although the porosity in thecake is not so small [2, 17]. The figure obviouslydemonstrates that both ps and a decrease with thedistance x. As the filtrate volume v increases, ps and aincrease. The solute compressive pressure at the sur-face of the protein filter cake is essentially zero as nodrag on the solutes has developed. The frictional dragon each solute adds to the drag on the previoussolutes as the solvent passes frictionally along thesolutes in the compressible filter cake. Consequently,the net compressive pressure increases as the mem-brane surface is approached, resulting in the increas-ing resistance to f low. At the interface of the filtercake and the membrane, ps has risen to its maximumvalue and is equal to the applied filtration pressure pfor the negligible membrane resistance. Therefore,the protein filter cake tends to have a much morecompact structure at the membrane exhibiting a largeresistance to f low in comparison to a relatively loosecondition at the surface because the cake is com-pressible. In the compressible filter cake formed byultrafiltration of BSA solutions, it is demonstrated thata pronounced variation of characteristic values of thefilter cake can be seen. This is in agreement with theresults obtained for filtration of particulate suspen-sions [9, 18].

The local mass fraction c of the solute in the filtercake may be calculated from the local void ratio e inthe form

c (19)

Thus, the concentration distributions in the proteinfilter cake may be predicted from Eqs. (13), (14),(17)(19).

4. Analysis of Ultrafiltration Behaviors Basedon Ultracentrifugation Experiment

The f lux decline and the cake structure in ultra-filtration of protein solutions can be evaluated fromanalytical ultracentrifugation experiments [15, 19, 20].The experiments were performed in a Hitachi Model282 ultracentrifuge equipped with an optical system.

rs

rsre

rs(1eav)rs(1s)rseav

The rotor speed ranged from 45,000 to 60,000 min1.The distributions of the concentration, the concentra-tion gradient, and the refractive index gradient of thesolutions in a 1.5 mm double-sector centerpiece weremeasured over time using both the ultraviolet scan-ner absorption system and Schlieren optics. In thesedimentation velocity experiment, the sedimentationvelocity was determined from the displacement of thesedimentation boundary. In the high-speed sedimen-tation equilibrium experiment, the equilibrium thick-ness of the sediment of macromolecular solutes wasmeasured after equilibrium was reached at a constantrotor speed.

At relatively high solution concentrations, there isan analogy between the sedimentation of a macromol-ecule in a solvent and the permeation of a solventthrough the filter cake of macromolecules. The localspecific f low resistance a can be calculated as [15, 19]

a (20)

where ri is the radial distance of the sedimentationboundary from the center of rotation, W is the angu-lar velocity of the rotor, v0 is the sedimentation veloc-ity, and S is the sedimentation coefficient.

Thus, the relation between a and the volume frac-tion (1e) of the solute may be written as [15, 19, 21]

(1/a)1/4.65 1/4.65

1Ch(1e) (21)

where df is the average equivalent spherical diameterof solutes, Ch is the ratio of the volume of the hydrousprotein molecule to volume of anhydrous protein mol-ecule, and e is the porosity of the solution.

Figure 8 shows the permeability data obtained bymeasuring the sedimentation velocities for a numberof different solution concentrations. The plots are vir-tually linear as would be expected from Eq. (21). It isapparent that a around the isoelectric point is muchsmaller than that at pH 7 with the same solution con-centration. On the other hand, the average specific fil-tration resistance aav of the cake in the ultrafiltrationof BSA solutions reaches a definite maximum aroundthe isoelectric point [2]. In order to account for thisdiscrepancy, a high-speed sedimentation equilibriumexperiment was conducted.

If the local solute concentration of the cake formedin ultrafiltration is known, then the specific f low resis-tance a of the cake can be evaluated by using the per-meability data. Therefore, it is necessary to evaluatethe local solute concentration of the cake. We thusdetermined the compression data representing the

rsdf2

18Ch

rsrmrsS

(rsr)r iΩ2

mrsv0

24 KONA No.21 (2003)

relation between the local porosity e and the localsolute compressive pressure ps from high-speed sedi-mentation equilibrium experiments. If e is related tops by Eq. (22), the equilibrium thickness (Rrs) of thesediment is related to the centrifugal accelerationRW 2 by Eq. (23) [15, 19, 22].

1eEpsb pspsi (22)

Rrs (rsr)RΩ2b (23)

where R is the distance from the center of rotation tothe bottom of the sediment, rs is the distance from thecenter of rotation to the surface of the sediment, w 0 isthe net solute volume of the entire sediment per unitcross-sectional area, and E and b are the empiricalconstants. Below psi, e is assumed to be constant, andis equal to the porosity at pressure psi.

Figure 9 represents the logarithmic plot of theequilibrium thickness (Rrs) of the sediment againstthe centrifugal acceleration RW2. The plot shows alinear relationship in accordance with Eq. (23). It isinteresting to note that the sediment at the isoelectricpoint is much more compact than that at pH 7because the BSA molecule carries no net charge atthe isoelectric point. Therefore, it would be expectedthat in protein ultrafiltration a compact filter cakeforms around the isoelectric point. The relation be-tween e and ps can be determined from the plot in the

w 01b

E(1b)

figure using Eqs. (22) and (23). On the basis of theserelations, the variations of the filtration rate in ultra-filtration of protein solutions can be determined fromthe compressible cake filtration model [2, 9, 15].

In Fig. 10, the results of unstirred dead-end ultra-filtration are plotted in the form of the reciprocal fil-tration rate (dq/dv) versus the filtrate volume v perunit membrane area. The filtration rate around theisoelectric point is much smaller than that at pH 7.The solid lines indicate the theoretical predictionsbased on the compression-permeability data obtainedin analytical ultracentrifugation. The experimentaldata are in relatively good agreement with the theory,indicating that the compressible cake filtration modelaccurately describes the ultrafiltration behavior.

Figure 11 shows the variations of the mass fractionc of the solute across the cake calculated on the basisof the ultracentrifugation data. In the compressiblecake resistance model, the solutes deposited on themembrane are treated as the cake, and it is attributedto the hydraulic barrier. The cake tends to have amuch more compact structure at the membrane incomparison to a relatively loose condition at the sur-face because the cake is compressible. Of consid-erable practical interest is that this result is inagreement with that obtained for cake filtration of par-

KONA No.21 (2003) 25

0 0.1 0.2 0.35

7

8

9

11

12

1ε []

(1/α

)1/4.

65 [

(g/c

m)1/

4.65

]

6

10

BSA pH 5.1 Ω6283 rad/s pH 7.0 Ω5760 rad/s

104

Fig. 8 Relation between local specific f low resistance and poros-ity of solution.

106 2 3 42.4

3.0

3.2

3.4

3.8

4.0

RΩ2 [m·rad2/s2]

R

r s [

m]

2.6

2.8

3.6

BSA pH 5.1, s0.1 ω00.859 mm pH 7.0, s0.097 ω00.829 mm

103

Fig. 9 Relation between equilibrium thickness of sediment andcentrifugal acceleration.

ticulate suspensions [23]. A much more compact fil-ter cake exhibiting a large resistance to f low mayform around the isoelectric point than that whichforms at pH 7. Consequently, the filtration rate at theisoelectric point becomes lower than that at pH 7.

5. Measurement of Concentration Distributionin Filter Cake of Ultrafiltration

A variety of theoretical models describing the foul-ing phenomenon during ultrafiltration quantitativelyhave been developed: the gel polarization model [24-26]; the osmotic pressure model [27-29]; the bound-ary layer model [30, 31]; and the cake filtration model[32-34]. Although a significant amount of researchhas been conducted to better understand the dynam-ics of ultrafiltration, the real mechanism of separationremains incompletely understood.

The compressible cake filtration model has beenwidely used to describe filtration behaviors of particu-late suspensions [9]. Recently, some authors prefer touse the compressible cake filtration model to explainthe mechanism of ultrafiltration [2, 15, 35], and it hasthe potential for analyzing the membrane fouling dur-ing ultrafiltration. The filtration f lux rate during dead-end ultrafiltration of bovine serum albumin (BSA)solutions could be well evaluated by use of the ultra-centrifugation data on the basis of the compressiblecake filtration model [19]. The model regards a stag-nant filter cake on the membrane as the structuralassemblage of “particulate” solutes. In this model,highly resistant filter cake of excluded protein mole-cules accumulated in front of the membrane surfaceforms, and the filter cake acts as an additional hy-draulic resistance to f low in conjunction with thatprovided by the membrane, thereby reducing the fil-tration f lux rate. The model also takes the compress-ibility of the filter cake into account. Therefore, anunderstanding of the properties of the filter cakeformed by the accumulation of the protein moleculeson the membrane can serve as a basis for clarifyingthe real mechanism of ultrafiltration.

Several approaches have been developed for mea-suring the average value of the porosity in the filtercake formed on the membrane surface in ultrafiltra-tion of protein solutions. Nakao et al. [36] measuredthe gel concentration by scraping a thin layer ofdeposited material from the surface of a tubular mem-brane in ovalbumin ultrafiltration. Iritani et al. [2]used a batchwise filter device which had a suddenreduction in its filtration area to determine the aver-age porosity of the BSA cake. Also, in more recentwork by Nakakura et al. [35], the porosity was ob-tained from the measurement of the electric conduc-tivity within the filter cake during ultrafiltration ofBSA solutions. It is, however, crucial to measure theporosity distribution since the filter cake formed onthe membrane during ultrafiltration is extremely thin

26 KONA No.21 (2003)

0 0.5 1.0 1.50

v [cm]

1

2

3

5

dθ/d

v [s

/cm

]

4

BSAs6103

p98 kPa pH 5.1 pH 7.0 PREDICTED

104

Fig. 10 Evaluation of filtration rate based on ultracentrifugationdata.

0 0.5 1.0 1.50

x [mm]

0.1

0.2

0.3

c [

]

0.4

BSAs6103

p98 kPa pH 5.1 pH 7.0

θ12

θ6

θ12

θ6

θ2 h

CAKE SURFACE, θ2 h

Fig. 11 Evaluation of distributions of solute concentration in filtercake based on ultracentrifugation data.

in general.Relatively few investigators have measured concen-

tration distributions within the protein layer accumu-lated on the membrane during ultrafiltration. Vilker etal. [29] used an optical shadowgraph technique tomeasure the concentration gradient within the polar-ized layer on the membrane during unstirred dead-end ultrafiltration of BSA solutions. McDonogh et al.[37] reported the variation with time of concentrationin the polarized layer on the membrane during ul-trafiltration of BSA and Dextran Blue solutions usingthe electronic diode array microscope. Gowman andEthier [38] used an automated, laser-based refrac-tometric experimental technique for the measure-ment of concentration and concentration gradientin the concentration polarization layer during dead-end ultrafiltration of the biopolymer hyaluronan.Fernández-Torres et al. [39] obtained the evolution ofconcentration profiles during BSA ultrafiltration in anunstirred cell using the technique of holographicinterferometry. Their results demonstrated that a fil-ter cake was actually formed during BSA ultrafiltra-tion. Although these non-destructive methods havethe enormous advantage, they are technically com-plex and expensive.

A potential method has been explored for measur-ing the concentration distributions in the filter cakeusing the principle of the inclined ultrafiltration [40,41], where the membrane was inclined and a largeamount of filter cake was formed. The concentrationdistributions in the filter cake were measured afterdownward ultrafiltration was performed in the wakeof inclined ultrafiltration. This destructive method issimple, and inexpensive.

The f lowing behaviors of filter cake have beenobserved, as depicted in Fig. 12 schematically. It wasclarified that the filter cake formed mainly on thelower part of the membrane surface due to the effectof gravity during inclined ultrafiltration, as shown inFig. 12(a) [40]. The same phenomenon cannot beobserved in downward dead-end ultrafiltration. Oncedownward ultrafiltration was conducted after inclinedultrafiltration, the filter cake was spread over themembrane surface, as shown in Fig. 12(b) [41].

In Fig. 13, the f lux decline behaviors in various fil-tration modes are plotted in the form of the reciprocalfiltration rate 1/J (dq/dv) versus the cumulative fil-trate volume v collected per unit effective membranearea, which is well known as the Ruth plot [3] in theordinary cake filtration. For conventional downwarddead-end ultrafiltration (y0), the filtration rate de-clines gradually due to the build-up of a BSA cakeas filtration proceeds. The angle y represents theangle between the filtrate f low and the direction ofgravity. The plot is virtually linear throughout thecourse of filtration in accordance with the Ruth filtra-tion rate equation (1) [3] with negligible membraneresistance compared with the filter cake resistance.In contrast, in inclined ultrafiltration (yp/3 rad), thefiltration rate becomes remarkably high because thefiltrate passes through the upper part of the mem-brane which is less resistant. Furthermore, oncedownward ultrafiltration was conducted after inclinedultrafiltration, the filtration rate dramaticallydecreased because of the remarkable increase of thetotal filtration resistance. Surprisingly, the value of 1/Jin this case lies on the extension line in ordinarydownward ultrafiltration, as shown in the figure. This

KONA No.21 (2003) 27

Fig. 12 Schematic diagram of f lowing filter cake: (a) inclined ultrafiltration, and (b) downward ultrafiltration.

SOLUTION

(a) (b)

SOLUTION

FILTER CAKEFILTER CAKE

MEMBRANE

MEMBRANE

FILTRATE

FILTRATE

result supports that the structure of the filter cakeformed on the membrane such as the concentrationdistributions is almost the same between both opera-tions.

In Fig. 14, the mass fraction c of BSA on the mem-brane measured after changing the angle y from p/3rad to zero is plotted against distance x from the mem-

brane surface for the different values of the filtratevolume v collected until inclined ultrafiltration wasswitched to the downward mode. The profiles in thisfigure may be considered to be similar to those inordinary downward ultrafiltration, as expected fromthe results of f lux decline behaviors shown inFig. 13. The filter cake which was thicker than 1 cmwas formed at the filtrate volume of 20 cm. It is verydifficult to obtain such a thick cake as this from down-ward dead-end ultrafiltration. The solid lines on thefigure indicate the theoretical predictions based on acompressible cake filtration model. In the compress-ible cake filtration model, the concentration distri-butions of the solutes deposited on the membranetreated as the filter cake act as the hydraulic barrier.The pressure gradient on the liquid passing throughthe solute varies, and the porosity in the cake is notconstant [42]. The figure distinctly demonstrates thatthere exists a concentration distribution within the fil-ter cake formed on the membrane. The concentrationc has a maximum at the membrane surface (x0) anddecreases markedly with the increase of x, whichshows the same trend as that observed for the cakefiltration of particulate suspensions [9, 18]. It was ver-ified that the solutes forming the cake are compactand dry at the membrane whereas the surface layer isin a wet and soupy condition. It was also found thatthe thickness of the filter cake formed on the mem-brane increases as filtration proceeds.

6. Role of Solution Environment in Propertiesof Filter Cake

Cake filtration of suspensions of solid particles inaqueous solutions is frequently encountered in widelydiversified fields. In cake filtration, the nature of thecake formed upon the medium surface during filtra-tion will govern the filtration rate of the remainingsuspension. For fine particle suspensions, colloidalforces control the nature of the filter cake. Colloidalforces arise from interaction between the suspendedparticles. The two main colloidal forces are the attrac-tive van der Waals forces which originate from f luc-tuating dipoles as a result of the motions of outerelectrons on the interacting particles and the repul-sive electrostatic forces due to the presence of likecharges on the particles and a dielectric medium.Whilst for a given system the van der Waals forcesare essentially constant, the electrostatic forces willvary with the surface charge of the suspended parti-cles, which varies with the solution environment.Therefore, the filtration behaviors of the colloids are

28 KONA No.21 (2003)

0 0.5 1.0 1.50

0.1

0.2

0.3

0.4

0.5

x [cm]

c [

]

BSAs5103

pH 7.0p98 kPaψπ/3 rad → ψ0 v10 cm v20 cm PREDICTED

s5103

Fig. 14 Distribution of solute concentration in filter cake for dif-ferent filtrate volumes.

0 5 10 15 25200

v [cm]

2

4

6

8

1/J

[s/c

m]

BSAs5103

pH 7.0p98 kPa

ψ0ψπ/3 rad → ψ0 v10 cmψπ/3 rad → ψ0 v20 cm

105

Fig. 13 Relation between reciprocal filtration rate and filtrate vol-ume per unit membrane area in various filtration modes.

affected significantly by the solution properties, in-cluding pH and electrolyte strength. Considerablework has been published on the effects of the solutionenvironment on the filtration behaviors [43-52].

Figure 15 shows the average specific filtration re-sistance aav and the average porosity eav of the filtercake formed in particulate microfiltration at differentvalues of pH under otherwise identical filtration con-ditions [53]. The particles used in the experimentswas titanium dioxide of the rutile form with an origi-nal mean specific surface area size of 0.47 µm andwith an isoelectric point of 8.1. It should be noted thatthe resistance aav is a measure of the filtrability of thesuspensions. A larger aav causes a smaller filtrationrate. It can be seen that aav goes through a minimumaround the isoelectric point. Thus, the largest filtra-tion rate can be obtained when the particle carries nocharge. Tarleton and Wakeman [49] reported similarresults for crossf low microfiltration of anatase sus-pension. However, this result is in sharp contrast tothat obtained in protein ultrafiltration [2, 54]. It isclear that eav is much larger near the isoelectric pH.Since the titanium dioxide particles are hydrophobiccolloids, they are destabilized around the isoelectricpoint where the van der Waals attraction is more dom-inant. Consequently, the particles will tend to cometogether, i.e. to f locculate, and the very porous f locsare then formed. Thus, it is speculated that the filtercake formed from such porous f locs has often looseand wet structures. On the other hand, the filter cakebecomes compact and dry when the particle carries

the charge. Since the most loose filter cake formsaround the isoelectric pH, the filter cake is most per-meable. Thus aav is much smaller near the isoelectricpoint.

It is interesting to note that the results in proteinultrafiltration had a distinctly different behavior. Inprotein ultrafiltration of BSA solution, the filter cakeis in its most compact state around the isoelectricpoint [2, 54], as shown in Fig. 16. Since the BSA mol-ecules are hydrophilic colloids, their stability in thesolution would appear to be inf luenced not only bythe presence of a surface charge on the protein butalso by hydration of the surface layers of the protein.The BSA molecules, because of hydrated layers sur-rounding them, are not destabilized by such consider-ations as depression of the electrical double layer.Thus, the BSA molecules have water bound to themeven around the isoelectric point. The hydrophilicBSA molecules maintain a dispersed state in the solu-tion due to hydration of the surface layers of the pro-tein even around the isoelectric point. When a BSAmolecule acquires a charge, the filter cake becomesloose and wet due to electrostatic repulsion betweenthe charged BSA molecules. This contrasts to thecompact filter cake around the isoelectric point. Theaverage specific filtration resistance aav has a definitemaximum around the isoelectric point since a com-pact filter cake provides a large hydraulic f low resis-tance.

Charge effects are weakened in the presence ofsolids. In Fig. 17, the average porosity eav of the filter

KONA No.21 (2003) 29

2 4 6 8pH

10 120

2

4

6

8

10

12

α av [

m/k

g]

RUTILEs0.02cs0.2 mol/m3

p196 kPa

1012

0.5

0.6

0.7

ε av [

]

Fig. 15 Effect of pH on average specific filtration resistance andaverage porosity of filter cake formed in microfiltration oftitanium dioxide suspensions.

2 4 6 8pH

10 120

2

4

6

8

α av [

m/k

g]

BSAs6103

p98 kPa

1015

0.95

0.90

1.00

ε av [

]

Fig. 16 Effect of pH on average specific filtration resistance andaverage porosity of filter cake formed in ultrafiltration ofBSA solutions.

cake formed in particulate microfiltration is plottedagainst absolute values of zeta potentials. This figureshows a close relation between eav and the zeta poten-tial. It is surprising that the plots can be representedby a unique curve irrespective of the sign of the zetapotential. The cake porosity increases with decreas-ing zeta potential. The porosity remains constant inthe range of the zeta potential below ca. 20 mV. As thezeta potential decreases, the electrostatic repulsiondecreases and thus the porous f loc forms. Therefore,the average porosity of the filter cake increases. Therepulsive force that stems from the overlapping of theelectric double layers, depends on the presence orabsence of ionized salt in suspension. The repulsiveforce is less effective at higher ion concentrations andcannot counteract the van der Waals attraction, and sothe solution f locculates. Therefore, it is conceivablethat the filtration rate is markedly inf luenced not onlyby the solution pH but also by the solution ionicstrength. The result for the NaCl concentration of 200mol/m3 at pH 10.5 is shown in the figure. The magni-tude of the zeta potential decreased remarkably as aresult of the addition of NaCl compared with that forthe NaCl concentration of 0.2 mol/m3 at the same pH.The average porosity eav of the filter cake is aug-mented markedly by the addition of salt. This isbecause the addition of salt destabilizes the suspen-sion by reducing the double layer repulsion betweenrutile particles. It should be emphasized that the plotfor the NaCl concentration of 200 mol/m3 lies on theunique curve.

7. Properties of Filter Cake Composed of Mixtures

Especially when two types of particles which maybe membrane foulants in combination are present inthe feed f luid, the situation becomes more complex.The filtration behaviors can be strongly affected bythe nature of the interaction between the dissimilarcomponents.

The variations of the filtration rate with time andthe properties of the filter cake were examined formicrofiltration of binary mixtures of fine particles[55]. The average porosity in the filter cake of thebinary particulate mixtures was explained well by themixture packing model in which small particles fillthe voids between large particles. Further, the aver-age specific filtration resistance of the binary mix-tures was well evaluated on the basis of the additivelaw of the effective specific surface area. However, inmost of published works on filtration of binary partic-ulate mixtures [56, 57], the effects of the physico-chemical factors such as the pH and salt concentra-tion on the filtration performance have received littleor no attention.

Properties of a filter cake formed in dead-endmicrofiltration were examined using binary particu-late mixtures of titanium dioxide and silicon dioxidehaving the different values of the isoelectric point foreach material [58]. The original surface mean diame-ter of silicon dioxide is 0.92 µm. The silicon dioxideparticle has negative charge because it contains onlydissociable group of one type, the silanol groupsSiOH. In Fig. 18, the average specific filtration resis-tance aav and the average porosity eav of the filtercake at pH 4.5 are shown against the mixing ratio(st/s) of particles, where st is the mass fraction of tita-nium dioxide particles in the bulk suspension, andthe total mass fraction s of particles is kept constant.It is immediately obvious that aav tends to becomesmaller in a mixed system of two components in com-parison with a single component system. A smallerspecific filtration resistance was generally caused by alarger cake porosity. At this pH value, a titanium diox-ide has a positive electrical charge, whilst a silicondioxide is electronegative. For the single componentsuspension, the particles are likely to be well dis-persed by repulsive electrostatic forces, and formcakes of higher resistance during filtration. However,the particles in mixed suspension come together dueto heterocoagulation associated with a coulombicattractive force and the London-van der Waals force,and the very porous f locs are formed prior to deposi-

30 KONA No.21 (2003)

20 40 600|ζ | [mV]

0.5

0.6

0.7

RUTILEs0.02cs0.2 mol/m3

p196 kPa

pH 10.5cs200 mol/m3

pH 10.5cs0.2 mol/m3

ε av [

]

Fig. 17 Relation between average porosity of filter cake andabsolute value of zeta potential.

tion. Thus, the coagulated colloids form highly per-meable filter cakes, minimizing decreases in the fil-tration rate. For reference, the calculations based onthe additive law on the specific volume and the effec-tive specific surface area are shown as the dottedlines [56]. It is obvious that the effect of the surfacecharge of the particles on the cake properties shouldbe considered.

It is of significance to compare the results withthose obtained in dead-end ultrafiltration of the mixedprotein solutions. It was observed that the resultsobtained with protein ultrafiltration were in sharp con-trast to those with particulate microfiltration [17].The properties of the cake formed on the retentivemembranes in dead-end ultrafiltration of binary pro-tein mixtures have been studied by using a mixtureof the two proteins BSA and egg white lysozyme.The molecular weight and the isoelectric point oflysozyme are 14,300 Da and 11.0, respectively. InFig. 19, the properties of the filter cake at pH 6.9 areshown against the mixture ratio of the proteins,where sb is the mass fraction of BSA in the solution,and the total mass fraction s of solutes is kept con-stant. Of particular importance is the surprising resultthat the porosity eav shows a distinct minimum. In thecase of the single solute solutions, the average poros-ity is relatively large, since only an electrostatic repul-sive force acts between the solutes. In contrast, in themixed protein solutions, the BSA and lysozyme mole-cules are oppositely charged at pH 6.9. Therefore, the

average porosity of the cake decreases markedly byadding the other protein to the single protein solutionbecause of a higher attraction between solutes. Thedecrease of the porosity eav roughly corresponds tothe increase of the resistance aav. The resistanceshows a definite maximum at the mixing ratio ofabout 0.6 because the most compact cake forms atthat mixing ratio. Since the protein molecules arehydrophilic colloids, their stability in the solution isinf luenced not only by the presence of a surfacecharge on the protein but also by hydration of the sur-face layers of the protein. Even in the pH range wherethe two protein molecules have opposite electricalcharges, protein molecules are well dispersed in thesolution due to hydration of the protein. Conse-quently, the mixed protein cake becomes compactbecause of the attractive force associated with oppo-sitely charged solutes.

In microfiltration of binary particulate mixtures, theeffects of adding electrolyte on aav and eav at two dif-ferent pH values are shown in Fig. 20. The additionof salts leads to a decrease of the zeta potentialbecause of a less extensive electrical double layer. Itis observed that at pH 4.5 aav increases and eav

decreases slightly, but discernibly with the increaseof the salt concentration. The result is explained byassuming that the coulombic attractive force betweenthe particles decreases due to a decrease of the zetapotential, and as a result the effect of heterocoagula-tion is weakened. At pH 9.6, it is found that aav

KONA No.21 (2003) 31

0 0.2 0.4 0.6st/s []

0.8 1.00

2

4

6

8

10α a

v [m

/kg]

TiO2/SiO2s0.02, pH 4.5cs0.2 mol/m3, p196 kPa

1012

0.6

0.5

0.7

ε av [

]

Fig. 18 Effect of mixing ratio of particles on average specific fil-tration resistance and average porosity in microfiltrationof binary particulate mixtures at pH 4.5.

0 0.2 0.4 0.6sb/s []

0.8 1.00

2

4

6

8

10

α av [

m/k

g]

BSA/LYSOZYMEs6103

pH 6.9p98 kPa

1015

0.90

0.95

0.85

1.00

ε av [

]

Fig. 19 Effect of mixing ratio of proteins on average specific fil-tration resistance and average porosity in ultrafiltration ofbinary protein mixtures at pH 6.9.

decreases and eav increases markedly with increasingNaCl concentration. At this pH, the repulsive forcethat stems from the overlapping of the electric doublelayers, is reduced because of the charge-shieldingdue to the presence of salts, and consequently parti-cles tend to aggregate [59]. Thus, the cakes formedare more open and have a lower resistance to f low.

In Fig. 21, the profiles of the average specific fil-

tration resistance aav obtained in dead-end ultrafiltra-tion of titanium dioxide suspensions containing BSAmolecules using 10 kDa membranes are illustratedfor various pH values against the mass ratio (sb/s) ofBSA to the net colloids. At pH 4.2 and 5.1, the value ofaav increases with an increase of the mass fraction ofBSA. This is because the specific resistance aav ofBSA is significantly larger than that of titanium diox-ide. At pH 6.0, however, in the range of quite smallBSA fractions aav tends to become smaller than thatof the cake composed of titanium dioxide alone (sb/s0). The result is perhaps surprising when one con-siders the high specific resistance of BSA. At pH 6.0the positive charge of the titanium dioxide particle iscancelled by the adsorption of negatively chargedBSA molecules. The f locculation of titanium dioxidetherefore occurs due to a marked decrease of the zetapotential of the complex of titanium dioxide particlesand BSA molecules. This brings about the specificbehavior of aav at pH 6.0.

The average specific filtration resistance aav for dif-ferent concentrations of sodium chloride is plotted inFig. 22 against the mass ratio of BSA to the net col-loids. The value of aav decreases markedly by theaddition of an appropriate volume of sodium chlorideand BSA. This is due to charge-shielding of both par-ticles and proteins caused by the presence of thesalts, thus reducing the electrostatic repulsion be-tween titanium dioxide and BSA.

32 KONA No.21 (2003)

1016

1015

1014

1013

1012

1011

0 0.020.01sb/s []

α av [

m/k

g]

0.040.03 0.05 0.06

TiO2/BSAs0.01p98 kPa pH 4.2 pH 5.1 pH 6.0

Fig. 21 Effect of mixing ratio of proteins on average specific fil-tration resistance in ultrafiltration of particle/proteinmixtures.

1014

1013

1012

1011

1010

109

0 0.020.01sb/s []

α av [

m/k

g]

0.040.03 0.05

TiO2/BSAs0.01pH 4.2 cs0 cs300 mol/m3

Fig. 22 Effect of salt addition on average specific filtration resis-tance in ultrafiltration of particle/protein mixtures.

0 100cs [mol/m3]

2000

2

4

6

8

10

α av [

m/k

g]

TiO2/SiO2s0.02, st/s0.5p196 kPa

1012

0.6

0.5

0.7

ε av [

]

pH 4.5pH 9.6

Fig. 20 Effect of NaCl concentration on average specific filtrationresistance and average porosity.

8. Fractionation of Mixtures by Filtration

Solute/solute interaction plays an important role inboth the filtration rate and the solute rejection whentwo or more proteins are ultrafiltered [60-62]. It isgenerally accepted that solutes whose molecular di-mensions are clearly small enough to permeate themembrane are substantially retained by that samemembrane when larger solutes are present [63].

In Fig. 23, the solute rejection behavior followingultrafiltration of binary BSA/lysozyme mixtures con-taining equal amounts of each protein is shown in theform of the apparent rejection Robs,l of lysozyme ver-sus the cumulative filtrate volume v per unit effectivemembrane area collected in the filtration time q [64].Ultrafiltration experiments were carried out with theupward filtration mode, in which the filtrate f low wasopposite to the direction of gravity, using hydropho-bic, sorptive polysulfone membranes with a molecularweight cut off of 30,000 Da, making it essentiallyimpermeable to BSA, but permeable to lysozyme.Solution pH was adjusted to 7, which is pH betweenthe isoelectric points of both proteins, and the NaClconcentration cs was varied. The apparent rejectionRobs,l of lysozyme can be defined by

Robs,l1 (24)c l

s l

where cl and sl are the mass fractions of lysozyme inthe filtrate and bulk feed solution, respectively. Filtra-tion of binary protein mixtures with this membraneresulted in nearly complete retention of BSA, but thevariation in the lysozyme rejection with the filtratevolume. In the incipient stages of filtration, the mem-brane exhibits a high lysozyme rejection which maybe attributed to adsorption of the lysozyme solutes onthe hydrophobic surface of the membrane [65]. Therejection Robs,l is high during ultrafiltration in theabsence of NaCl (cs0). The BSA molecule is nega-tively charged at pH 7, while the lysozyme moleculehas a net positive charge at this pH value. The filtercake formed on the membrane surface consists of theadmixture of two proteins very well packed to form acompact layer because the coulombic, attractive forceassociated with oppositely charged solutes, resultingin high rejection of lysozyme. It can be seen that thelysozyme rejection decreases with the increase of theNaCl concentration. In the case of a charge-stabilizedcolloid such as protein, solute interactions depend onthe magnitude of the surface charge and/or on theextent of the electrical double layer, and this dependson the total electrolyte concentration. When salts areadded, this leads to a less extensive electrical doublelayer. Such charge-shielding between the protein mol-ecules resulting from the existence of salts wouldreduce electrostatic attraction between BSA andlysozyme molecules. Thus, the solute rejection at firstdeclines to a minimum value. However, as filtrationproceeds, the compressible filter cake of retainedBSA solutes provides a barrier to transport of thesmaller lysozyme solutes [66], and hence the rejec-tion of the lysozyme solutes rises dramatically.

In Fig. 24, the f lux behavior of the experimentdescribed in Fig. 23 is shown in the form of the reci-procal filtration rate (dq/dv) versus v. This plot is wellknown as the Ruth plot [3] in the cake filtration ofparticulate suspensions. In principle, the value ofdq/dv is directly proportional to the hydraulic resis-tance due to solute accumulation on or in the mem-brane. It would be expected that a rather dense, finelyporous filter cake of retained BSA/lysozyme mixturesforms on the membrane surface during the earlystages of filtration without added salt. Since thehydraulic resistance of this filter cake is remarkablylarge, the value of dq/dv rises rapidly to a near-asymptotic value with increasing filtrate volume.However, increase in the thickness of the filter cake issuppressed because the filter cake is exfoliated con-tinuously by the effect of gravity with the progress offiltration, similar to upward ultrafiltration of single

KONA No.21 (2003) 33

1.0

0.8

0.6

0.4

0.2

00 2 4

v [cm]

Rob

s,l [

]

6 8 10

cs0cs150 mol/m3

cs300cs600

BSA/LYSOZYMEsb5104, s l5104, pH 7p98 kPa, UPWARD

Fig. 23 Effect of salt addition on apparent lysozyme rejection atpH 7.

protein solutions [40, 54]. The filtration rate increasesmarkedly on addition of NaCl because of the forma-tion of a filter cake which is substantially free fromlysozyme molecules. However, as filtration proceeds,the filtration rate decreases gradually because thelysozyme molecules are trapped in the pores of the fil-ter cake.

In Fig. 25, the reciprocal filtration rate (dq/dv) inthe unstirred downward and upward, and the stirreddownward ultrafiltration of binary BSA/lysozymemixtures is shown as a function of v [67]. For theseexperiments, ultrafiltration membranes with very lowadsorptivity for proteins were used. Solution envi-ronment was set at pH 7 and the NaCl concentrationof 300 mol/m3 where electrostatic interactions be-tween BSA and lysozyme weakened comparativelyas implied from Figs. 23 and 24. For conventionalunstirred downward ultrafiltration, the plot is virtuallylinear throughout the course of filtration because ofthe continuous formation of the filter cake on themembrane in accordance with the compressible cakefiltration model [2, 9, 15]. For unstirred upward ultra-filtration, the f lux decline is suppressed, similar to theresult of Fig. 24. The increase in the shear stress act-ing on the membrane surface by stirring leads to thesuppression of the cake deposition, and consequentlythe marked increase in the filtration rate. Since the fil-

tration rate in upward ultrafiltration is slightly lowerthan that in stirred ultrafiltration with stirring of 5.2rad/s, an effect of gravity acting on the filter cake inupward ultrafiltration corresponds to that of very lowshear stress.

Figure 26 shows the lysozyme rejection behaviorof the experiment described in Fig. 25. The figureindicates that the lysozyme solutes pass almost com-pletely through the membrane in unstirred downward

34 KONA No.21 (2003)

2.5

2.0

1.5

1.0

0.5

00 2 4

v [cm]

dθ/d

v [s

/cm

]

6 8 10

103

BSA/LYSOZYMEsb5104

s l5104

pH 7cs300 mol/m3

p98 kPa

DOWNWARDUPWARDΩ5.2 rad/sΩ20.9Ω52.4Ω104.7

Fig. 25 Effect of hydrodynamics above membrane on filtrationrate.

1.0

0.8

0.6

0.4

0.2

00 2 4

v [cm]

Rob

s,l [

]

6 8 10

BSA/LYSOZYMEsb5104, s l5104

pH 7, cs300 mol/m3

p98 kPa DOWNWARD UPWARD Ω5.2 rad/s Ω20.9 Ω52.4 Ω104.7

Fig. 26 Effect of hydrodynamics above membrane on apparentlysozyme rejection.

6

5

4

3

2

1

00 2 4

v [cm]

dθ/d

v [s

/cm

]

6 8 10

103

cs0cs150 mol/m3

cs300cs600

BSA/LYSOZYMEsb5104

s l5104

pH 7p98 kPaUPWARD

Fig. 24 Effect of salt addition on filtration rate at pH 7.

ultrafiltration and are only a little retained by themembrane in upward ultrafiltration except that thehigh rejection appears in the incipient stages of filtra-tion. It has been reported that in single protein solu-tions the stirring resulted in increasing the soluterejection [63]. It should be emphasized that also inbinary protein mixtures the higher stirring speedcauses the higher rejection of the solutes. This isbecause the concentration of lysozyme near the mem-brane decreases with increasing shear stress actingon the membrane.

Figures 25 and 26 suggest that it is necessary tocontrol the hydrodynamics above the membrane inorder to obtain high lysozyme transmission simulta-neously with high filtration rate. While hard stirredultrafiltration, which produces the high filtration rateand solute rejection, is very effective for concentrat-ing protein solutions, it is not suitable for fractionationof binary protein mixtures. It can be concluded fromthe figures that unstirred upward or mildly stirredultrafiltration is more advantageous for the efficientfractionation of binary protein mixtures.

The effects of ultrasonic irradiation on the filtrationrate and lysozyme rejection in upward ultrafiltrationof binary BSA/lysozyme mixtures using the ultra-filtration membrane with very low adsorptivity forproteins at pH 7 and high salt concentration areshown in Fig. 27 [67]. The whole of the filter waskept immersed in the ultrasonic cleaning bath full ofwater during the course of filtration. The filter was setup so that the membrane surface was perpendicular

to the propagation direction of the ultrasonic wave.The oscillating frequency and the output power of theultrasonic irradiation were 25 kHz and 180 W, respec-tively. It is evident that the ultrasonic fields cancontribute to the remarkable improvement in thefiltration rate. As was shown in Figs. 25 and 26,although the observed filtration rate becomes high byincreasing the shear stress on the membrane, thetransmission of the lysozyme molecules becomesless. In contrast, of particular importance is the sur-prising observation that the ultrasonic irradiationdoes not lower the lysozyme transmission regardlessof involving a marked increase in the filtration rate.One possible explanation for this result is that ultra-sonic irradiation supplies vibrational energy to the fil-ter cake to keep the solutes partly suspended, andtherefore leaves more free channels for the filtratef low.

To clarify the effects of the ultrasonic irradiation,the lysozyme rejections observed in the cases wherethe filtration rates with and without ultrasonic irradia-tion are very similar are compared in Fig. 28. Thefigure shows that the filtration rate in the ultrasonicupward ultrafiltration irradiated under output powerof 180 W is substantially similar to that in downwardultrafiltration stirred with a rotational speed of 20.9rad/s without ultrasonic irradiation. However, it is ofimportance to note that there is a marked differencein the lysozyme rejection. The lysozyme transmissionin ultrasonic upward ultrafiltration is much higherthan that in stirred ultrafiltration. Therefore, it is

KONA No.21 (2003) 35

0 2 4 6v [cm]

8 100

0.5

1.0

1.5

2.0

dθ/d

v [s

/cm

]

BSA/LYSOZYMEsb5104, s l5104

pH 7, cs300 mol/m3

p98 kPa

103

0.4

0.2

0.6

0.8

0

1.0

Rob

s,l [

]

, UPWARD, UPWARD, ULTRASONIC

Fig. 27 Effect of ultrasonic irradiation on filtration rate and ap-parent lysozyme rejection.

0 2 4 6v [cm]

8 100

4

2

6

8

10

dθ/d

v [s

/cm

]

BSA/LYSOZYMEsb5104, s l5104

pH 7, cs300 mol/m3

p98 kPa

102

0.4

0.2

0.6

0.8

0

1.0

Rob

s,l [

]

, Ω20.9 rad/s, UPWARD, ULTRASONIC

Fig. 28 Comparison of apparent lysozyme rejection betweencases with and without ultrasonic irradiation in whichsimilar filtration rate are observed.

believed that the ultrasonic irradiation is quite effec-tive not only for concentration of proteins by ultra-filtration [68] but also for fractionation of the binaryprotein mixtures by ultrafiltration.

Conclusions

As was seen from this review, an understanding ofthe properties of the filter cake formed on the filtermedium or the membrane can serve as a basis forclarifying the real mechanism of cake filtration andmembrane filtration. In recent years, experimentaltesting procedures have been newly developed suchas filtration experiments in which a filter was sub-jected to a sudden reduction in its filtration area andultracentrifugation experiments. The compressiblecake filtration model which explicitly took the non-homogeneity and the compressibility of the filtercake into consideration was used to describe theproperties of the filter cake and the filtration behav-iors. In protein ultrafiltration, the validity of the com-pressible cake filtration model was verified by themeasurements of the concentration distributions inthe filter cake using the principle of inclined filtrationwhere a large amount of filter cake is formed. More-over, it was shown that the solution properties (in par-ticular, the solution pH and the electrolyte strength)play an important role in the filtration behaviors ofcolloids. The filtration behaviors of mixtures can bestrongly affected by the nature of the interaction be-tween the dissimilar components. Factors inf luencingfractionation behaviors by filtration were clarified.The author believes that many existing separationproblems would have been avoided by the applicationof available scientific data although the random na-ture of most particulate dispersions has resulted in adifficult process problem.

Acknowledgements

The author wishes to acknowledge the Ministry ofEducation, Culture, Sports, Science and Technology,Japan for the financial support and all university part-ners for the excellent cooperation.

Nomenclature

Cc empirical constant defined by Eq. (13)Ch ratio of volume of hydrous protein molecule

to volume of anhydrous protein moleculec local mass fraction of solid or solute in

filter cake

cl mass fraction of lysozyme in filtratecs NaCl concentration of solution (mol/m3)D inner diameter of inserted cylinder (m)Dh diameter of hole (m)df average equivalent spherical diameter of

solute (m)E empirical constant defined by Eq. (22) (Paβ)E0 empirical constant defined by Eq. (13)e local void ratioeav average void ratioeav,ω average void ratio from filter medium

surface to distance w from filter mediumh height of filter chamber (m)J filtration rate (m/s)Jω apparent solvent velocity relative to

solid at arbitrary position w (m/s)Kv Ruth coefficient of constant pressure

filtration defined by Eq. (2) (m2/s)L thickness of filter cake (m)m ratio of wet to dry cake massn empirical constant defined by Eq. (12)p applied filtration pressure (Pa)pm pressure loss through filter medium (Pa)ps local solid compressive pressure (Pa)psi pressure below which e remains constant (Pa)R distance from center of rotation to bottom

of sedimentation (m)Robs,l apparent rejection of lysozyme defined

by Eq. (24)ri radial distance of sedimentation boundary

from center of rotation (m)rs distance from center of rotation to surface

of sediment (m)S sedimentation coefficient (s/rad2)s mass fraction of solids in slurry, or mass

fraction of solutes in bulk feed solutionsb mass fraction of BSA in bulk feed solutionsl mass fraction of lysozyme in bulk feed solutionst mass fraction of titanium dioxide particles

in slurryu apparent liquid velocity relative to solid (m/s)u1 filtration rate (m/s)v cumulative filtrate volume collected per

unit effective medium area (m3/m2)vt cumulative filtrate volume collected per

unit effective medium area until cake surface reaches disk with hole (m3/m2)

v0 sedimentation velocity (m/s)w0 net mass of solid per unit effective

medium area (kg/m2)x distance from medium surface (m)α local specific filtration resistance (m/kg)

36 KONA No.21 (2003)

aav average specific filtration resistance (m/kg)a1 empirical constant defined by

Eq. (12) (mn1s2n/kgn1)b empirical constant defined by Eq. (22)e local porosityeav average porosityz zeta potential (V)q filtration time (s)m viscosity of filtrate (Pa・s)r density of filtrate (kg/m3)rs true density of solid (kg/m3)y angle between filtrate f low and direction

of gravity (rad)W angular velocity (rad/s)w net solid volume per unit medium area

lying from medium up to an arbitrary position in cake (m)

w 0 net solid volume of entire cake per unitmedium area (m)

References

1) Fane, A. G., “Ultrafiltration: Facrtors Inf luencing Fluxand Rejection,” Progress in Filtration and Separation,Wakeman, R. J. ed., Elsevier, Amsterdam, 4, 134 (1986).

2) Iritani, E., Nakatsuka, S., Aoki, H. and Murase, T.,“Effect of Solution Environment on Unstirred Dead-EndUltrafiltration Characteristics of Proteinaceous Solu-tions,” J. Chem. Eng. Japan, 24, 177 (1991).

3) Ruth, B. F., “Studies in Filtration. III. Derivation of Gen-eral Filtration Equations,” Ind. Eng. Chem., 27, 708-723(1935).

4) Grace, H. P., “Resistance and Compressibility of FilterCakes,” Chem. Eng. Progr., 49, 303-318 (1953).

5) Shirato, M., Aragaki, T., Mori, R. and Sawamoto, K.,“Predictions of Constant Pressure and Constant RateFiltration Based upon an Approximate Correction forSide Wall Friction in Compression Permeability CellData,” J. Chem. Eng. Japan, 1, 86-90 (1968).

6) Tiller, F. M., Haynes, S. and W-M. Lu, “The Role ofPorosity in Filtration: VII Effect of Side Wall Friction inCompression-Permeability Cells,” AIChE J., 18, 13-20(1972).

7) Gale, R. S., “Recent Research on Sludge Dewatering,”Filtr. & Sep., 8, 531-538 (1971).

8) Murase, T., Iritani, E., Cho, J. H., Nakanomori, S. andShirato, M., “Determination of Filtration Characteristicsdue to Sudden Reduction in Filtration Area of FilterCake Surface,” J. Chem. Eng. Japan, 20, 246-251 (1987).

9) Shirato, M., Sambuichi, M., Kato, H. and Aragaki, T.,“Internal Flow Mechanism in Filter Cakes,” AIChE J.,15, 405-409 (1969).

10) Shirato, M., Aragaki, T. and Iritani, E., “Analysis of Con-stant Pressure Filtration of Power-Law Non-NewtonianFluids,” J. Chem. Eng. Japan, 13, 61-66 (1980).

11) Murase, T., Iritani, E., Cho, J. H. and Shirato, M.,“Determination of Filtration Characteristics Based uponFiltration Tests under Step-up Pressure Conditions,” J.Chem. Eng. Japan, 22, 373-378 (1989).

12) Terzaghi, K. and Peck, R. B., “Soil Mechanics in Engi-neering Practice,” Wiley, New York, 65 (1948).

13) Tiller, F. M., “The Role of Porosity in Filtration. Part 2.Analytical Equations for Constant Rate Filtration,”Chem. Eng. Progr., 51, 282-290 (1955).

14) Tanford, C., “Physical Chemistry of Macromolecules,”Wiley, New York, 317 (1961).

15) Iritani, E., Hattori, K. and Murase, T., “Analysis of Dead-End Ultrafiltration Based on Ultracentrifugation Meth-od,” J. Membrane Sci., 81, 1-13 (1993).

16) Iritani, E., Mukai, Y. and Hagihara, E., “Measurementsand Evaluation of Concentration Distributions in FilterCake Formed in Dead-End Ultrafiltration of ProteinSolutions,” Chem. Eng. Sci., 57, 53-62 (2002).

17) Iritani, E., Mukai, Y. and Murase, T., “Properties of Fil-ter Cake in Dead-End Ultrafiltration of Binary ProteinMixtures with Retentive Membranes,” Trans. IChemE,Part A, Chem. Eng. Res. Des., 73, 551-558 (1995).

18) Tiller, F. M. and Cooper, H., “The Role of Porosity in Fil-tration. Part V. Porosity Variation in Filter Cakes,”AIChE J., 8, 445-449 (1962).

19) Iritani, E., Hattori, K. and Murase, T., “Evaluation ofDead-End Ultrafiltration Properties by Ultracentrifuga-tion Method,” J. Chem. Eng. Japan, 27, 357-362 (1994).

20) Iritani, E., Hattori, K., Akatsuka, S. and Murase, T.,“Sedimentation Behavior of Protein Solutions in Ultra-centrifugation Field,” J. Chem. Eng. Japan, 29, 352-358(1996).

21) Michaels, A. S. and Bolger, J. C., “Settling Rates andSedimentation Volumes of Flocculated Kaolin Suspen-sions,” Ind. Eng. Chem. Fundam., 1, 24-33 (1962).

22) Murase, T., Iwata, M., Adachi, T., Gmachowski, L. andShirato, M., “An Evaluation of Compression-Permeabil-ity Characteristic in the Intermediate ConcentrationRange by Use of Centrifugal and Constant-Rate Com-pression Techniques,” J. Chem. Eng. Japan, 22, 378-384(1989).

23) Shirato, M., Aragaki, T., Ichimura, K. and Ootsuji, N.,“Porosity Variation in Filter Cake under Constant-Pres-sure Filtration,” J. Chem. Eng. Japan, 4, 172-177 (1971).

24) Michaels, A. S., “New Separation Technique for theCPI,” Chem. Eng. Progr., 64, 31-43 (1968).

25) Porter, M. C., “Concentration Polarization with Mem-brane Ultrafiltration,” Ind. End. Chem., Prod. Res. Dev.,11, 234-248 (1972).

26) Trettin, D. R. and Doshi, M. R., “Ultrafiltration in anUnstirred Batch Cell,” Ind. End. Chem., Fundam., 19,189-194 (1980).

27) Kozinski, A. A. and Lightfoot, E. N., “Protein Ultrafiltra-tion: A General Example of Boundary Layer Filtration,”AIChE J., 18, 1030-1040 (1972).

28) Jonsson, G., “Boundary Layer Phenomena during Ultra-filtration of Dextran and Whey Protein Solutions,”Desalination, 51, 61-77 (1984).

KONA No.21 (2003) 37

29) Vilker, V. L., Colton, C. K. and Smith, K. A., “Concentra-tion Polarization in Protein Ultrafiltration,” AIChE J.,27, 632-645 (1981).

30) Wijmans, J. G., Nakao, S., van den Berg, J. W. A.,Troelstra, F. R. and Smolders, C. A., “HydrodynamicResistance of Concentration Polarization Boundary Lay-ers in Ultrafiltration,” J. Membrane Sci., 22, 117-135(1985).

31) van den Berg, G. B. and Smolders, C. A., “Flux Declinein Membrane Processes,” Filtr. & Sep., 25, 115-121(1988).

32) Reihanian, H., Robertson, C. R. and Michaels, A. S.,“Mechanism of Polarization and Fouling of Ultrafiltra-tion Membranes by Proteins,” J. Membrane Sci., 16,237-258 (1983).

33) Suki, A., Fane, A. G. and Fell, C. J. D., “Flux Decline inProtein Ultrafiltration,” J. Membrane Sci., 21, 269-283(1984).

34) Nakao, S., Wijmans, J. G. and Smolders, C. A., “Resis-tance to the Permeate Flux in Unstirred Ultrafiltrationof Dissolved Macromolecular Solutions,” J. MembraneSci., 26, 165-178 (1986).

35) Nakakura, H., Yamashita, A., Sambuichi, M. and Osasa,K., “Electrical Conductivity Measurement of Filter Cakein Dead-End Ultrafiltration of Protein Solution,” J.Chem. Eng. Japan, 30, 1020-1025 (1997).

36) Nakao, S., Nomura, T. and Kimura, S., “Characteristicsof Macromolecular Gel Layer Formed on UltrafiltrationTubular Membrane,” AIChE J., 25, 615-622 (1979).

37) McDonogh, R. M., Bauser, H., Stroh, N. andGrauschopf, U., “Experimental in situ Measurement ofConcentration Polarisation during Ultra- and Micro-fil-tration of Bovine Serum Albumin and Dextran BlueSolutions,” J. Membrane Sci., 104, 51-63 (1995).

38) Gowman, L. M. and Ethier, C. R., “Concentration andConcentration Gradient Measurements in an Ultrafiltra-tion Concentration Polarization Layer, Part I: A Laser-Based Refractometric Experimental Technique,” J.Membrane Sci., 131, 95-105 (1997).

39) Fernández-Torres, M. J., Ruiz-Beviá, F., Fernández-Sempere, J. and López-Leiva, M., “Visualization of theUF Polarized Layer by Holographic Interferometry,”AIChE J., 44, 1765-1776 (1998).

40) Iritani, E., Watanabe, T. and Murase, T., “Upward andInclined Ultrafiltration under Constant Pressure by Useof Dead-End Filter,” Kagaku Kogaku Ronbunshu, 17,206-209 (1991).

41) Zeng, W. P., Iritani, E. and Murase, T., “Dynamic Behav-ior of BSA Cake Layer Deposited on Membrane inDead-End Inclined Ultrafiltration,” Kagaku Kogaku Ron-bunshu, 24, 158-160 (1998).

42) Tiller, F. M., “The role of Porosity in Filtration, Numeri-cal Methods for Constant Rate and Constant PressureFiltration Based on Kozeny’s Law,” Chem. Eng. Progr.,49, 467-479 (1953).

43) Bacchin, P., Aimar, P. and Sanchez, V., “Model for Col-loidal Fouling of Membranes,” AIChE J., 41, 368-376(1995).

44) Bacchin, P., Aimar, P. and Sanchez, V., “Inf luence of Sur-face Interaction on Transfer during Colloid Ultrafiltra-tion,” J. Membrane Sci., 115, 49-63 (1996).

45) Kawalec-Pietrenko, B. and Ruszel-Lichodzijiewska, R.,“The Inf luence of Physico-Chemical and OperatingParameters on the Filtration of Precipitate of HydratedZr(IV) Oxide,” J. Chem. Tech. Biotechnol., 35A, 426-430(1985).

46) McDonogh, R. M., Fell, C. J. D. and Fane, A. G., “Sur-face Charge and Permeability in the Ultrafiltration ofNon-Flocculating Colloids,” J. Membrane Sci., 21, 285-294 (1984).

47) McDonogh, R. M., Welsch, K., Fane, A. G. and Fell, C. J.D., “Incorporation of the Cake Pressure Profiles in theCalculation of the Effect of Particle Charge on the Per-meability of Filter Cakes Obtained in the Filtration ofColloids and Particulates,” J. Membrane Sci., 72, 197-204 (1992).

48) Schultz, J., Papirer, E. and Nardin, M., “Physicochemi-cal Aspects of the Filtration of Aqueous Suspensions ofFibers and Cement. 4. Inf luence of the ζ Potential of theFibers on Filtration Efficiency,” Ind. Eng. Chem., Prod.Res. Dev., 22, 102-105 (1983).

49) Tarleton, E. S. and Wakeman, R. J., “UnderstandingFlux Decline in Crossf low Microfiltration: Prat II –Effects of Process Parameters,” Trans. IChemE, Part A,Chem. Eng. Res. Des., 72, 431-440 (1994).

50) Ueshima, K., Iizuka, H. and Higashitani, K., “OrderedStructure of Monodispersed Particles Filtered at Con-stant Pressure,” J. Chem. Eng. Japan, 24, 647-652 (1991).

51) Welsch, K., McDonogh, R. M., Fane, A. G. and Fell, C. J.D., “Calculation of Limiting Fluxes in the Ultrafiltrationof Colloids and Fine Particulates,” J. Membrane Sci., 99,229-239 (1995).

52) Willmer, S. A., Tarleton, E. S. and Holdich, R. G., “TheImportance of Cake Compressibility in Deadend Pres-sure Filtration,” Proc. 7th World Filtration Congress,Vol. I, p. 27-31, Hungarian Chemical Society, Budapest,Hungary (1996).

53) Iritani, E., Toyoda, Y. and Murase, T., “Effect of SolutionEnvironment on Dead-End Microfiltration Characteris-tics of Rutile Suspensions,” J. Chem. Eng. Japan, 30,614-619 (1997).

54) Iritani, E., Watanabe, T. and Murase, T., “Properties ofFilter Cake in Dead-End Upward Ultrafiltration,” J.Membrane Sci., 69, 87-97 (1992).

55) Iritani, E., Nagaoka, H. and Murase, T., “Filtration Char-acteristics and Cake Properties in Microfiltration ofBinary Mixtures of Fine Particles,” Kagaku KogakuRonbunshu, 22, 648-654 (1996).

56) Shirato, M., Sambuichi, M. and Okamura, S., “FiltrationBehavior of a Mixture of Two Slurries,” AIChE J., 9,599-605 (1963).

57) Abe, E., Hirosue, H. and N. Yamada, “A Method for Pre-dicting the Filtration Characteristics of Body Filtration,”J. Soc. Powder Technol. Japan, 32, 550-556 (1995).

58) Iritani, E., Mukai, Y. and Toyoda, Y., “Properties of a Fil-ter Cake Formed in Dead-End Microfiltration of Binary

38 KONA No.21 (2003)

Particulate Mixtures,” J. Chem. Eng. Japan, 35, 226-233(2002).

59) Chang, D. J., Hsu, F. C. and Hwang, S. J., “Steady StatePermeate Flux of Cross-Flow Microfiltration,” J. Mem-brane Sci., 98, 97-106 (1995).

60) Ingham, K. C., Busby, T. F., Sahlestrom, Y. and Castino,F., “Separation of Macromolecules by Ultrafiltration:Inf luence of Protein Adsorption, Protein-Protein Inter-actions, and Concentration Polarization,” Polymer Sci-ence and Technology, Ultrafiltration Membranes andApplications, Cooper, A. R. ed., Plenum Press, NewYork, 13, 141 (1980).

61) Rodgers, V. G. J. and Sparks, R. E., “Reduction of Mem-brane Fouling in the Ultrafiltration of Binary ProteinMixtures,” AIChE J., 37, 1517-1528 (1991).

62) Zhang, L. and Spencer, H. G., “Selective Separation ofProteins by Microfiltration with Formed-in-Place Mem-branes,” Desalination, 90, 137-146 (1993).

63) Nakatsuka, S. and Michaels, A, S., “Transport and Sepa-

ration of Proteins by Ultrafiltration through Sorptiveand Non-Sorptive Membranes,” J. Membrane Sci., 69,189-211 (1992).

64) Iritani, E., Mukai, Y. and Murase, T., “Upward Dead-EndUltrafiltration of Binary Protein Mixtures,” Sep. Sci.Technol., 30, 369-382 (1995).

65) Iritani, E., Tachi, S. and Murase, T., “Inf luence of Pro-tein Adsorption on Flow Resistance of MicrofiltrationMembrane,” Colloids Surfaces A: Physicochem. Eng.Aspects, 89, 15-22 (1994).

66) Iritani, E., Itano, Y. and Murase, T., “Dead-End InclinedUltrafiltration by Use of Dynamic Membranes,” KagakuKogaku Ronbunshu, 19, 536-539 (1993).

67) Mukai, Y., Iritani, E. and Murase, T., “FractionationCharacteristics of Binary Protein Mixtures by Ultra-filtration,” Sep. Sci. Technol., 33, 169-185 (1998).

68) Kokugan, T., Kaseno, T., Fujiwara, S. and Shimizu, M.,“Ultrasonic Effect on Ultrafiltration Properties ofCeramic Membrane,” Membrane, 20, 213-223 (1995).

KONA No.21 (2003) 39

Author’s short biography