Pro Line Platelet Agitator Service Manual

Transcript of Pro Line Platelet Agitator Service Manual

360391/C

Pro Line Platelet Agitator Service Manual

CountertopPF15-Pro PF48-Pro PF96-Pro

Document Updates The document is furnished for information use only, is subject to change without notice and should not be construed as a commitment by Helmer Scientific. Helmer Scientific assumes no responsibility or liability for any errors or inaccuracies that may appear in the informational content contained in this material. For the purpose of clarity, Helmer Scientific considers only the most recent revision of this document to be valid.

Notices and DisclaimersConfidential / Proprietary NoticesUse of any portion(s) of this document to copy, translate, disassemble or decompile, or create or attempt to create by reverse engineering or otherwise replicate the information from Helmer Scientific products is expressly prohibited.

Copyright and TrademarkHelmer®, i.Series®, AgiTrak™ and Rel.i™ are registered trademarks or trademarks of Helmer, Inc. in the United States of America. Copyright © 2021 Helmer, Inc. All other trademarks and registered trademarks are the property of their respective owners.Helmer, Inc., doing business as (DBA) Helmer Scientific and Helmer.

DisclaimerThis manual is intended as a guide to provide the operator with necessary instructions on the proper use and maintenance of certain Helmer Scientific products.Any failure to follow the instructions as described could result in impaired product function, injury to the operator or others, or void applicable product warranties. Helmer Scientific accepts no responsibility for liability resulting from improper use or maintenance of its products.The screenshots and component images appearing in this guide are provided for illustrative purposes only, and may vary slightly from the actual software screens and/or product components

Helmer Scientific14400 Bergen BoulevardNoblesville, IN 46060 USA

www.helmerinc.com Part No. 360391/ Rev C

Document HistoryRevision Date CO Supersession Revision DescriptionA 22 JUL 2019 14834 N/A Initial Release

B 19 MAY 2020 15444 B supersedes A

• Updated Location Requirements to include reference to Product Specifications.• Updated the use of caution symbols and statements throughout the document.• Added detail regarding agitator speed to Placement, Leveling and

Setup section.

C 08 SEP 2021 16200 C supersedes B

• Updated picture in Configure Platelet Agitator for Use in a Platelet Incubatorsection.

• Corrected part numbers for power cable, communication cables and white labelholders.

* Date submitted for Change Order review. Actual release date may vary.

Helmer Scientific Platelet Agitator Service Manual

360391/C ii

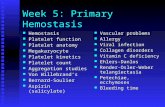

Contents1 About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31.2 Model Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31.3 Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31.4 Safety Symbols and Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31.5 Avoiding Injury . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41.6 Product Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Installation and Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62.1 Location Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62.2 Connect Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62.3 Mounting Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62.4 Placement Leveling and Setup (Stand-alone) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72.5 Configure Platelet Agitator for Use in a Platelet Incubator (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72.6 Storage Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82.7 External Monitoring Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92.8 Alarm Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113.1 Remove / Replace Trolley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113.2 Motion Alarm Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123.3 Test and Replace Motion Alarm Back-up Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123.4 Clean Agitator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134.1 General Operation Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134.2 Alarm Activation Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Appendix A: Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Appendix B: Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Helmer Scientific Platelet Agitator Service Manual

360391/C 3

1 About this Manual1.1 Intended AudienceThis manual provides information on how to use the platelet agitator Pro. It is intended for use by end users of the platelet agitator and authorized service technicians.

1.2 Model ReferenceThis manual covers all Pro Series platelet agitators which may be identified by size or model number.

1.3 Intended Use Note

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense.

Helmer platelet agitators are intended to provide controlled agitation required for the storage of platelet products.The devices are intended to be operated by personnel who have procedures in place for meeting FDA, AABB, EU or any other applicable regulations for the processing and storage of platelet products.

1.4 Safety Symbols and Precautions

Symbols and precautions found in this document

The following symbols are used in this manual to emphasize certain details for the user:

Task Indicates procedures which need to be followed.

Note Provides useful information regarding a procedure or operating technique when using Helmer Scientific products.

NOTICE Advises the user against initiating an action or creating a situation which could result in damage to equipment; personal injury is unlikely.

Symbols found on the units

The following symbols may be found on the agitator or agitator packaging:

Caution: Risk of damage to equipment or danger to operator

Refer to documentation

Helmer Scientific Platelet Agitator Service Manual

360391/C 4

1.5 Avoiding InjuryReview safety instructions before installing, using, or maintaining the equipment. ♦ Before moving unit, remove contents from the drawers. ♦ Do not open multiple drawers at the same time. ♦ Before moving unit, disconnect the DC power cord and secure the cord. ♦ When moving unit, use assistance from a second person. ♦ Never physically restrict any moving component. ♦ Avoid removing electrical service panels and access panels unless so instructed. ♦ Keep hands away from pinch points when agitation motion is enabled. ♦ Avoid sharp edges when working inside the electrical compartment. ♦ Ensure biological materials are stored at recommended temperatures determined by standards, literature, or good

laboratory practices. ♦ Proceed with caution when adding and removing samples from the platelet agitator. ♦ Use only manufacturer supplied power supply/cord when operating stand-alone or within incubator. ♦ Using the equipment in a manner not specified by Helmer Scientific may impair the protection provided by the equipment.. ♦ The platelet agitator is not considered to be a storage cabinet for flammable or hazardous materials. ♦ REQUIRED: Decontaminate parts prior to sending for service or repair. Contact Helmer or your distributor for

decontamination instructions and a Return Authorization Number.

Helmer Scientific Platelet Agitator Service Manual

360391/C 5

1.6 Product Labels Note

Service information varies depending on the model and power requirements.

This information appears on the product specification label, on the back of the platelet agitator.

C

A

B

Sample Product Specification label.

Label Description

A Model

B Serial number (SN)

C Power requirements

Helmer Scientific Platelet Agitator Service Manual

360391/C 6

2 Installation and Configuration2 .1 Location Requirements ♦ To ensure continuous operation of linearly shifting loads, the location surface must be level and adequately accommodate the

full weight of the agitator when loaded with product. ♦ Has a grounded outlet meeting the electrical requirements listed on the product specification label. ♦ Is clear of direct sunlight, high temperature sources, and heating and air conditioning vents. ♦ Minimum 0.5” (13 mm) behind. ♦ Minimum 0.75” (20 mm) on left and right sides. ♦ Meets specified limits for ambient temperature and relative humidity as stated in the Product Specification section of the Platelet

Storage Instructions for Use and Operation manual.

NoteAdd 1.5” (38 mm) to the width to accommodate the trolley frame when agitation motion is enabled.

2 .2 Connect Power SupplyThe platelet agitator may be used in a stand-alone configuration. A power supply with adaptable plugs is available for stand-alone use. Select and install the desired plug prior to attaching the power supply to the agitator. The power supply is not used when configured inside a Helmer Pro Series Platelet Incubator.

Configure and Attach Power Supply1. Remove the cover plate by using the thumb to push and hold the spring loaded locking key downward while sliding the plate forward. Retain the cover plate in secure location for future use.2. Select the desired plug and slide in place until it locks (a clicking sound will occur).Make sure the plug is firmly attached.3. Attach the power supply to the platelet agitator, and ensure the rotating lock is finger tight prior to plugging power supply into facility AC.

2.3 Mounting BracketsMounting brackets are included and may be installed for use inside the Pro series incubator or in stand-alone configuration.

Install Mounting Brackets1. Carefully place the agitator on its back on a solid surface allowing access to the bottom of the unit.2. Locate the two nutserts in the right or left side toward the front of the unit and align with the two holes in the mounting bracket.3. Hand thread the screws through each hole, and secure using a #2 Phillips screwdriver.4. Repeat steps 2 and 3 for the opposite side.5. Return the agitator to the upright position.6. Carefully place the agitator in the desired location aligning the hole in each bracket with the holes in the mounting surface. (If mounting inside a Pro series incubator, remove screws in the floor of the incubator prior to installing the agitator).

Helmer Scientific Platelet Agitator Service Manual

360391/C 7

2.4 Placement Leveling and Setup (Stand-alone)NOTICE• When lifting platelet agitator, lift using the ends of the base.• If the base is not accessible, lift using the ends of the trolley • To prevent damage, do not use trolley or trolley drawer to lift agitator.• The communication switch is fragile, do not use excessive force when changing the setting.

Notes• Leveling feet may crack or wear over time. Check leveling feet periodically and replace as needed.• For a setpoint of 72 CPM, rotate the arrow into the center of the green zone. The green zone represents an expanded 72 CPM area. Any point to the right of the green zone is a setpoint greater than 72 CPM.• Contact Helmer Technical Service for instructions regarding Agitator Speed Verification (T3I468).• For additional information regarding agitator setup, refer to the Platelet Agitator Pro Operation Manual.

1. Place platelet agitator on sturdy surface.2. Adjust leveling feet to ensure platelet agitator is level.3. Using a small flathead screwdriver, turn the communication switch to the X position. Ensure the arrow (shown in red for visibility in the picture) is pointing to the X.

2.5 Configure Platelet Agitator for Use in a Platelet Incubator (Optional)Pro Series platelet incubators may only be fitted with Pro Series platelet agitators. When installed in a Pro Series platelet incubator, the Pro Series platelet agitator can be monitored by the platelet incubator’s AgiTrak™ system. The AgiTrak™ system receives alarm information through a direct connection from the platelet agitator’s alarm system to the platelet incubator’s alarm system.

Platelet Agitator and Platelet Incubator Compatibility

NoteOnly Pro Series platelet incubators can monitor Pro Series platelet agitators.

Compatible Helmer Platelet Agitator Platelet Incubator

PF15-Pro PC100-Pro

PF48-Pro PC900-Pro

PF96-Pro PC1200-Pro

Install a Platelet Agitator in the Platelet Incubator

Notes• For additional instruction on configuring a platelet agitator in a platelet incubator, refer to the Platelet Incubator Pro Operation Manual.• Ensure data cable is carefully positioned to the right of the agitator to prevent damage caused by agitation motion.• The agitator communication switch is fragile, do not use excessive force when changing the setting. • To ensure continuous operation of linearly shifting loads, the location surface must adequately accommodate the full weight of the incubator with installed agitator when loaded with product. • Use only the manufacturer supplied coiled DC power cord when installing the Pro series agitator in a Pro series Incubator.• Ensure the incubator AC power and battery back-up power are switched OFF prior to connecting the agitator power cord to the incubator.• Installation of agitator anchor brackets is recommended when an installed agitator is set at a speed greater than 72 cycles per minute (CPM). Anchor brackets are included with the agitator.• The agitator motion alarm switch must be ON, and volume turned up to provide audible alarm backup in the event communication is lost between the agitator and incubator.

Helmer Scientific Platelet Agitator Service Manual

360391/C 8

PC900-Pro with PF48-Pro installed. Agitator communication switch

Helmer Pro Series platelet agitators can be installed inside Helmer Pro Series platelet incubators. The agitator can be connected to the incubator through a data cable. The connection allows the platelet incubator to monitor the platelet agitator motion, and to sound an alarm when agitation motion stops. Power is supplied to the agitator through the coiled DC power cable. Connect the data cable and DC power cable supplied with the incubator prior to placing the agitator inside the incubator. The power cable has a rotating locking feature on each end to ensure a secure connection. When installing the agitator inside the incubator, finger tighten each rotating lock. The agitator communication switch must be set to position 1 (shown in red for visibility in the picture above) for use in the incubator.

2.6 Storage ConfigurationDrawers can be removed or moved to adjust storage space as needed.

NOTICETo avoid injury and prevent damage to the agitator, ensure both left and right side drawer stop panels are fully installed prior to operating the agitator.

Remove and Replace Drawers1. Remove the thumb screws securing the drawer stop panels to the left and right sides of the agitator. (Note the orientation of each panel)2. Carefully pull each panel from the agitator and set panels and thumb screws aside.3. Slide the drawer(s) out and remove.4. Reinstall drawer(s) in desired location by aligning the outer edges of the drawer with the slots in the drawer guides and push inward.5. Reinstall both drawer stop panels in the same orientation as removed, and secure with thumb screws ensuring they are finger tight.

Install Label Holders (optional)1. Insert the tabs on the label holder into the slots on the drawer.2. Pivot the holder around the drawer handle and align the hole on the label holder with the corresponding hole on the drawer.3. Push thumb screw through the hole in the label holder and through the hole in the drawer to secure.

Agitator Power Connection

Thumb Screws

Helmer Scientific Platelet Agitator Service Manual

360391/C 9

2.7 External Monitoring DevicesThe agitator has two independent interfaces, each with spring loaded terminal pins for connecting external monitoring devices. These interfaces are located directly on the agitator control board which is located in the base of the agitator (The trolley must be removed to access these interfaces). One interface (J2) is a set of dry contacts with normally open or normally closed contacts depending upon connector terminals used. The other interface (J3) set provides a switched 9-15V, 100mA powered output.Requirements for your alarm system determine which alarm wires (user provided) must connect to specific connector terminals.

NoteWhen installed in a Pro series incubator, agitator alarms are communicated to the incubator.

J2 Dry Contact Remote Alarm InterfaceThe terminals on the J2 alarm interface have a maximum load capacity of 1 A at 33V (AC) RMS or 70V(DC). The dry contact remote alarm interface is a relay switch with three terminals.

♦ Common (COM) ♦ Normally Open (NO) ♦ Normally Closed (NC)

NOTICE• Terminals on J2 are dry contacts and do not supply voltage. The interface circuit is NO or NC depending upon connector terminals used. These connections are intended for use with an end user’s external alarm system(s) that interface to NO or NC dry contacts.• If an external power supply exceeding 33V (AC) RMS or 70V (DC) is connected to the (J2) remote alarm circuit, the remote alarm will not function properly; may be damaged; or may result in injury to the user.

J3 Agitator Powered Remote Alarm InterfaceThe terminals on the J3 alarm interface have a maximum supply capacity of 100 mA from 9-15V (DC). The agitator powered remote alarm interface has three terminals.

♦ Reference 9-15V ♦ Normally Open (NO) << In an alarm condition, 9-15V will be connected to this terminal ♦ Circuit Ground Reference (GND)

NOTICE• If any external power supply is connected to the J3 remote alarm circuit, the remote alarm or Agitator itself will not function properly; may be damaged; or may result in injury to the user.• The Agitator does not limit the output current thru J3 – it is required that the end user’s central alarm system(s) interface does not pull greater than 100 mA at 9-15V (DC).

Connect to Remote Alarm Interface (J2 or J3)1. Switch the ON/OFF switch OFF and disconnect the power cable from the power receptacle.2. Switch the motion alarm ON/OFF switch OFF.3. Remove the trolley to access the agitator board in the base of the agitator.4. Route alarm wires into the agitator base through the rear access hole in the base.5. On the alarm panel, locate the remote alarm terminals.6. Connect remote alarm wires to appropriate terminals, according to requirements for your alarm system.7. Use a cable tie to relieve strain on alarm wires (as necessary).8. Reinstall the trolley.9. Reconnect the power cable to power receptacle, and switch the ON/OFF switch ON.10. Switch the motion alarm ON/OFF switch ON.

Remote alarm interfaces.

Helmer Scientific Platelet Agitator Service Manual

360391/C 10

2.8 Alarm ReferenceIf an alarm condition is met, an alarm activates. Some alarms are visual only; others are visual and audible. Some Alarms are sent through the remote alarm interface. The table below indicates if an alarm is audible (A), visual (V), or sent through the remote alarm interface (R).

Notes• If the motion alarm switch is ON with no active alarms, the LED will be illuminated, solid red. • Alarm volume must be set to an audible level to receive an audible alarm.

Table 1. Alarm Reference

Alarm Alarm Type

Motion alarm A, R, V

Helmer Scientific Platelet Agitator Service Manual

360391/C 11

3 MaintenanceMaintenance tasks should be completed according to the schedule below.

Notes• These are recommended minimum requirements. Regulations for your organization or physical conditions at your organization may require maintenance items to be performed more frequently, or only by designated service personnel.• The Preventive Maintenance schedule provided below supersedes the schedule provided in the Platelet Agitator Pro Operation Manual.

Table 4. Preventive Maintenance Schedule

TaskFrequency

Annually As Needed

Test the motion alarm. ü

Check the 9V NiMH back-up battery for the motion alarm system after an extended power failure and change it if necessary, or change the battery if it has been in service for one year.

ü

Check moving parts for wear. Clean moving parts. ü

Replace moving parts if worn. ü

Clean the exterior of the platelet agitator. ü

Notes• During a power failure (when the motion alarm is enabled), the back-up battery provides power to the motion alarm. If the back-up battery is not functioning, the motion alarm will not be activated.• If the back-up battery does not provide power to the alarm system during the motion alarm test, replace the battery.• If battery has been in service for one year, replace battery.• Use only manufacturer specified rechargeable battery for replacement (9V NiMH battery with a capacity of ≥175 mAh).

3 .1 Remove / Replace TrolleyThe storage trolley must be removed when performing certain maintenance tasks.

Remove Trolley1. Switch the Motion Alarm ON/OFF switch OFF.2. Switch the Power ON/OFF switch OFF, and disconnect the power cable from the power receptacle.3. Remove the thumb screws securing the drawer stop panels to the left and right sides of the agitator trolley. (Note the orientation of each panel)4. Carefully pull each panel from the agitator and set panels and thumb screws aside.5. Slide the drawer(s) out and remove.6. Use a #2 Phillips screwdriver to loosen the four (4) center screws on the floor of the trolley. 7. Slide the screw heads to the opposite end of the slots.8. Lift the trolley straight up and set aside.

Install Trolley1. Carefully place the trolley on the base aligning the back and sides of the trolley with the back and sides of the base. Ensure the motor arm roller is placed within the trolley plastic guide block.2. Slide the four (4) center screw heads in the floor of the trolley to the opposite ends of the slots, and secure using a #2 Phillips screwdriver.3. Reinstall drawers in desired location by aligning the outer edges of the drawer with the slots in the drawer guides and push inward.4. Reinstall the drawer(s) stop panels in the same orientation as removed, and secure with thumb screws ensuring they are finger tight.5. Reconnect power cable to power receptacle and, switch the Power ON/OFF switch ON.6. Switch the Motion Alarm ON/OFF switch ON.

Helmer Scientific Platelet Agitator Service Manual

360391/C 12

3 .2 Motion Alarm TestTest the motion alarm to ensure it activates when the platelet agitator motion stops. The alarm may not activate immediately, depending on the motion alarm delay setting. If the alarm does not activate when it should, refer to Troubleshooting.

Notes• The motion alarm delay range is 10 - 600 seconds. When testing the alarm, be certain the set delay time has passed.• When the motion alarm is activated, the red LED on the motion alarm switch will flash.• The motion alarm is muted when the alarm volume is turned fully counterclockwise.

Test Motion Alarm1. Ensure the Alarm Volume is set to an audible level and the Alarm Delay is set to the minimum delay (as noted by red rotational arrows).2. Switch the Power ON/OFF switch OFF to stop agitation. When the alarm delay period elapses, the motion alarm will activate. 3. Switch the Power ON/OFF switch ON.

3.3 Test and Replace Motion Alarm Back-up BatteryThe motion alarm system is powered by DC power, backed up by a rechargeable 9V NiMH battery. The battery charges when the platelet agitator is connected to its external AC/DC power supply. In the event of a facility AC power failure, agitation would stop and the battery will power the motion alarm.

Test Motion Alarm Back-up Battery1. Ensure the Alarm Volume is set to an audible level and the Alarm Delay is set to the minimum delay. 2. Ensure the Motion Alarm ON/OFF switch is ON.3. Switch the Power ON/OFF switch OFF to stop agitation. When the alarm delay period elapses, the motion alarm will activate. If the motion alarm does not activate, replace the battery.4. Switch the Power ON/OFF switch ON.

To prevent personal injury or damage to the agitator, use only a 9V NiMH rechargeable battery.

Replace Motion Alarm Back-up Battery1. Switch the Motion Alarm ON/OFF switch OFF.2. Switch the Power ON/OFF switch OFF.3. Disconnect the DC power cord from the rear power jack.4. Remove the trolley to access the back-up battery in the base of the unit.5. Disconnect the battery from the terminals and remove.6. Insert the new battery and connect to the terminals ensuring the new battery is fully seated in the holder.7. Reinstall the trolley.8. Reconnect the DC power cord to the power receptacle.9. Switch the Power ON/OFF switch ON.10. Switch the Motion Alarm ON/OFF switch ON.

3 .4 Clean AgitatorClean exterior surfaces with a soft cotton cloth and non-abrasive liquid cleaner. Clean shelves and drawer surfaces with a soft brush. Disinfect using a mild disinfectant solution.

The interior base of the agitator may be cleaned using a clean compressed air cleaner to blow out any accumulated dust, or wiped out with a soft cotton cloth.

NoteHelmer recommends cleaning the interior base only when inspecting or replacing moving parts or battery.

Alarm Volume Alarm Delay

Helmer Scientific Platelet Agitator Service Manual

360391/C 13

4 TroubleshootingNOTICEReview all safety instructions prior to troubleshooting.

4.1 General Operation Problems

Problem Possible Cause Action

Agitator is inoperable Power switch is in OFF position. Switch power switch to ON.

The power cord is disconnected or loose.

Ensure cord is properly attached.

If the platelet agitator is installed in a Helmer incubator, the door switch has not been activated to allow agitation to resume.

Close the incubator door. Verify i.C3 AgiTrak screen door status is closed.

Agitation speed will not change.

Stand-alone agitator communication switch is not set to the (X) position

Verify agitator communication switch is set to the (X) position for stand-alone mode.

Agitation is noisy or rough. Trolley is not evenly loaded. Verify product drawers are evenly loaded.

Insufficient clearance around the trolley obstructing agitation.

Verify agitator has proper clearance, and no objects are preventing agitation.

One or more wheels are worn. Inspect the wheels. Replace if necessary.

Motor or gearbox is faulty. With the gearbox and motor exposed, turn on the power. If operation is noisy or jerky, replace the gearbox and motor.

Agitator is moving around on placement surface.

Placement surface is slick. Relocate agitator to non-slick surface.

Install mounting brackets (included in packaging) and attach to surface.

Agitation speed is set too high. Reduce agitation speed.

4.2 Alarm Activation Problems

Problem Possible Cause Action

Agitation has stopped, but the motion alarm is not active. Stand-alone, not in incubator.

The agitation alarm selector switch is in wrong position.

Verify agitator communication switch position is (X) for standalone mode.

Alarm delay period has not lapsed Check alarm delay setting.

The agitator motion alarm switch is OFF.

Turn the agitator motion alarm switch ON.

The alarm activates while the trolley is moving. (stand-alone)

The motion actuator and motion sensor are not aligned.

Ensure the actuator on the bottom of the trolley is aligned with the sensor on the base. Adjust the position if not aligned.

The motion sensor or actuator is faulty.

Check the connections for the actuator and the sensor. Replace the actuator or the sensor if faulty.

The Agitator Control Board is faulty. Replace the Agitator Control Board.

Alarm switch is blinking, but no audible alarm is active.

Alarm volume is muted. Rotate alarm volume clockwise to increase alarm volume.

Helmer Scientific Platelet Agitator Service Manual

360391/C 14

5 Parts

Label Description Model Part Number Label Description Part Number

A Power Switch - 120478 F Drawer Stop Panel -

B Top/Shelf 15 401752-1-067 G AC/DC Power Supply with Cord (stand alone) 120963

48 401751-1-067 H Agitation Speed Control Switch* -

96 401747-1-067 I Motion Alarm Volume Switch* -

C Drawer (white) 15 322731-1-069 J Motion Alarm Time Delay Switch* -

48 322749-1-069 K Agitator Communication Switch* -

96 322756-1-069 L Data Port (for use with Pro Series Incubator)* -

Drawer (stainless steel) 15 322759-1-000 M Communication Cable (* = PC100; ** = PC900, PC1200; included with Pro Series Incubator)

401773-1*

48 322758-1-000 120959**

96 322757-1-000 N Power Cable 120962

D Label Holder (white) - 402348-1 Not Shown

Base Leveling Foot (quantity varies based on model) 220698

E Motion Alarm Switch - - Base Leveling Foot Screw 230155

* H, I, J, K, L are part of the Agitator Control Board.

G

L

G

A

MKJIH

D

E

C

F

B

L

N

Helmer Scientific Platelet Agitator Service Manual

360391/C 15

Label Description Part Number Label Description Model Part Number

A Wheel (includes 4 wheels and brackets) 801031-1 E Motor 15/48 801057-1

B Actuator/Sensor 801035-1 96 801032-1

C 9V NiMH Rechargeable Back-up Battery 120232 F Crank Block - 801033-1

D Agitator Control Board 801036-1 Not Shown 2 Year Preventive Maintenance Kit - 800969-1

A

F

E

D

B

C

Helmer Scientific Platelet Agitator Service Manual

360391/C 16

Appendix A: Wiring Diagram

Helmer Scientific Platelet Agitator Service Manual

360391/C 17

Appendix B: WarrantyFor technical service needs, please contact Helmer at 800-743-5637 or www.helmerinc.com. Have the model and serial number available when calling.

Rapid ResolutionWhen a warranty issue arises it is our desire to respond quickly and appropriately. The service department at Helmer is there for you. Helmer will oversee the handling of your warranty service from start to finish. Therefore, Helmer must give advance authorization for all service calls and/or parts needs relating to a warranty issue. Any repeat service calls must also be authorized as well. This allows for proper diagnosis and action. Helmer will not be responsible for charges incurred for service calls made by third parties prior to authorization from Helmer. Helmer retains the right to replace any product in lieu of servicing it in the field.

PartsFor a period of two (2) years, Helmer will supply at no charge, including freight, any part that fails due to defects in material or workmanship under normal use, with the exception of expendable items. Batteries are expendable items. Inspection of defective parts by Helmer will be final in determining warranty status. Warranty procedures must be followed in all events.

LaborFor a period of one (1) year, Helmer will cover repair labor costs, provided that the product is returned to Helmer for warranty service. Alternatively, your facility’s staff may work with a Helmer technician to make repairs on site. Labor costs for repairs performed at a location other than Helmer, or for repairs made without the assistance of a Helmer technician, will be the responsibility of the end user.

Additional Warranty InformationThe time periods set forth above begin two weeks after the original date of shipment from Helmer. Warranty procedures set forth above must be followed in all events.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF. THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NO WARRANTIES OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE SHALL APPLY.THE LIABILITY, IF ANY, OF HELMER FOR DIRECT DAMAGES WHETHER ARISING FROM A BREACH OF ANY SALES AGREEMENT, BREACH OF WARRANTY, NEGLIGENCE, OR INDEMNITY, STRICT LIABILITY OR OTHER TORT, OR OTHERWISE WITH RESPECT TO THE GOODS OR ANY SERVICES IS LIMITED TO AN AMOUNT NOT TO EXCEED THE PRICE OF THE PARTICULAR GOODS OR SERVICES GIVING RISE TO THE LIABILITY. IN NO EVENT SHALL HELMER BE LIABLE FOR ANY INDIRECT, INCIDENTAL, CONSEQUENTIAL, OR SPECIAL DAMAGES, INCLUDING WITHOUT LIMITATION DAMAGES RELATED TO LOST REVENUES OR PROFITS, OR LOSS OF PRODUCTS.

This warranty does not cover damages caused in transit, during installation by accident, misuse, fire, flood, or acts of God. Further, this warranty will not be valid if Helmer determines that the failure was caused by a lack of performing recommended equipment maintenance (per Helmer manual) or by using the product in a manner other than for its intended use. Installation and calibration are not covered under this warranty agreement.

Outside of USA and CanadaConsult your local distributor for warranty information.

Helmer Scientific Platelet Agitator Service Manual

360391/C 18

Helmer Scientific14400 Bergen Boulevard, Noblesville, IN 46060 USA

Copyright © 2021 Helmer, Inc. 360391/C