Pressure actuation for dir ectional spool valvesdownloads.hawe.com/6/2/D6250-en.pdf · Pressure...

Transcript of Pressure actuation for dir ectional spool valvesdownloads.hawe.com/6/2/D6250-en.pdf · Pressure...

Pressure actuation for directional spool valves for pneumatic and hydraulic remote control

Suited for: Directional spool valves type SG and SP acc. to D 5650/1

Directional spool valve banks type SKP, SKH, and SKC acc. to D 7230

type SKS, SKV, and SKG acc. to D 5700++

D 6250Pressure actuation

November 1999-01

HAWE HYDRAULIK SESTREITFELDSTR. 25 • 81673 MÜNCHEN

2.1

© 1982 by HAWE Hydraulik

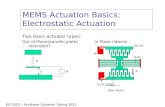

1. General1.1 Pressure actuation

Size 0 and 1 Size 2, 3, and 5 (4)

Size 2, 3, and 5 (4)

The pressure remote control of directional spool valves can be either pneu-

matically or hydraulically. The control medium is led via separate pilot

valves to the pressure actuator designed as a control cylinder. It corre-

sponds in its construction and function to a double-acting cylinder, whose

plunger is spring centered from both sides in its center stroke position

(neutral position). The plunger returns automatically to its neutral position

as soon as the control medium, which was fed to one of the control ports

before, gets depressurized. Therefore the pilot valves must vent both

control connections (pneumatic vers.) or connect them directly to the tank

(hydraulic vers.). A reversal stroke actuation is also available for valves with

two switching positions and a pneumatic actuation (not size 0 and 1),

where the compressed air has to be applied only briefly and the respective

shifting position is maintained via a detent. The internal parts of the

pressure actuations are identical for pneumatic and hydraulic actuations

for valves size 0 and 1 only, but different for size 2, 3, and 5(4) i.e. other

order codings.

The plunger of the actuation is mechanically linked to the valve spool. This

connection is located in the return cavity of the valve, with the shaft being

sealed to the actuation. Any pressure prevailing in the return line thus acts

on the cross section of the rod, generating a counter force to the return

force of the spring or to the holding power of the detent. Therefore the pres-

sure apparent in the return must not exceed the specified limits (see sect.

2.1), thus preventing uncontrollable switching movements. That is why the

standard version of this actuation must not be used at applications with

higher return pressure. Therefore is cannot be used for valve banks with

valves type SKH being connected in series. In case of higher return pres-

sures, a pressure-relieved version is available for type SG directional spool

valves, sizes 2 and 3, and for directional spool valve banks in SKP parallel

connection.

1.2 Actuation combination

There is a combination of pressure and manual actuation available for

directional spool valves size 2, 3, and 5(4). Here, the rod of the pressure

actuation is extended to the outside where it is connected to the hand lever

mechanism with the option for a contact switch (IP 65). It is intended for

applications where both modes are a must.

D 6250 page 2

2. Available versions, main data2.1 Pressure actuation

Actuation

Suitable for size

Design

Suitable for directional spool valve

Control plunger-# (mm)

Control volume approx. (cm3)

Permiss. pressure at return R (bar)

Installed position

Actuation

Design

Suitable for directional spool valve

Control plunger-# (mm)

Control volume approx. (cm3)

min.

max.

Permiss. pressure at return R (bar)

Installed position

Pneumatic / manual Hydraulic / manual

Single stroke 1) Double stroke Single stroke 1) Double stroke

3/2- and 3/3- and 3/2- and 3/3- and

4/2-way 4/3-way 4/2-way 4/3-way

30 30

7 7

5 12

10 20 2)

12 3) 12

Any

Pneumatic Hydraulic

0 and 1 2, 3 and 0 and 1 2, 3 and 2, 3, and 5 (4) 0 and 1 2, 3, and 0 and 1 2, 3,

5 (4) 5 (4) 5 (4) and 5 (4)

Single stroke 1) Double stroke Reversal stroke Single stroke 1) Double stroke

3/2- a. 4/2-way 3/3- and 4/3-way 3/2- and 4/2-way 3/2- and 4/2-way 3/3- and 4/3-way

20 30 20 30 30 20 30 20 30

1.6 7 1.6 7 7 1.6 7 1.6 7

5 5 5 5 5 5 12 5 12

10 10 10 10 10 10 20 2) 10 20 2)

10 12 3) 10 12 3) 12 3) 10 12 10 12

Any (ports 1 and 2 should direct upwards)

Any (ports 1 and 2 should direct

upwards)

Any

Co

din

gC

od

ing

Pressure relievedversion 4)

Control pressure

Valve switched completely

Control pressure (bar)

Valve switched completely

min.

max.

NE ND NU NE NM 5) 6) ND NM 5) 6)

NEH NDH NUH NEH NMH 5) 6) NDH NMH 5) 6)

--- NED --- NDD NUD --- --- --- ---

--- NEDH --- NDDH NUDH --- --- --- ---

0.3 0.5 (0.9) 0.3 0.5 (0.9) 0.5 (0.9) 0.3 0.5 0.3 0.5

Standard

Mass (weight) 8) approx. (kg)

Symbols

Standard version

with emergency

manual operation

2.2 Actuation combination (only size 2, 3, and 5 (4) !)

Preferred

installa-

tion mode

Installa-

tion mode

L 7)

Without

hand

lever

Without

hand

lever

Standard

with contact

switch

Standard

with contact

switch

Standard

with contact

switch

Standard

with contact

switch

KD

KDS

KD 1

KDS 1

KDL

KDSL

KDL 1

KDSL 1

KM

KMS

KM 1

KMS 1

KML

KMSL

KML 1

KMSL 1

1) Also for 3/3- and 4/3-way

valves if only switching

positions 0 and a are used;

(must be specified in the

order)

2) Over load capacity

max. 40 bar

3) 200 bar for pressure com-

pensated versions (NED,

NDD, and NUD)

4) Not available for size 5(4)

directional spool valves

acc. to D 5650 and D 7230

and SKS acc. to D 5700

5) In the case of 3/2- and 4/2-

way valves, port 2 non-

pressurized returned to the

tank (!)

6) See note in sect. 4.3 when

used for directional spool

valve type SKS...

7) Only with directional spool

valve banks

8) Figures in brackets for pres-

sure compensated version

9) Orifice in control port 1 and 2

is omitted with size 0 and 1

Important remarks on the installation of the actuation combination for 3/2- and 4/2-way valves

KD... and KM... The hand lever must be prevented from moving into switching position b; An external stop must be

customer furnished.

KD... A venting screw, order No. 6250 011, must be screwed into control port 2.

KM... A non-pressurized leakage drain must be provided from control port 2 back to the tank

External

stop

Masse (weight) approx. (kg) 0.9 0.9

9) 9) 9) 9) 9) 9)

With emergencymanual operation

With emergencymanual operation

D 6250 page 3

3. Unit dimensions3.1 Pressure actuation

All dimensions in mm, subject to change without notice !

Size 0 and 1

Size 2, 3, and 5 (4)

Base plates for pressure - relieved version

Directional spool valve SG (D 5650/1)

Directional spool valve SP (D 5650/1) and

SKP (D 7230)

3.2 Actuation combination3.2.1 Single valves

3.2.2 Directional spool valve banks

Both the consumer ports A and B of the mounted directional spool

valves and the control ports 1 and 2 point to the rear (away from the

observer) in standard assembly mode whereas towards the observer

in assembly mode L. A valve bank starts always with the initial valve

section or connecting block (inlet P) on the left and all subsequent

valve sections added to the right (independent of assembly mode).

1) Tapped plug (bleeder) for control connection 2 in type NE(H) and NU(H) and in double actuation KD, if provided for 3/2- and 4/2-way valves

(refer to remarks in section 2.2)

2) L = Any leakage oil may be drained off here (M6), not in NM or KM!

1)

1)

1)2)

2)

2)

Controlports 1 and 2 = G 1/8(BSPP)

Control ports

1 and 2

= G 1/4

(BSPP)Control

ports

1 and 2

= G 1/4

(BSPP)

Emergencymanual actuation(...H)

Emergency manualactuation (...H)

Standard assembly mode Assembly mode L

Contact switch

Cable glandPg 9

Hand levercan also bemountedhere

Mounting side for manifold mounting version

type SP 3(5)

Mounting side at directional spool valve type SP 1

Mounting side for manifold mounting version type SP 3(5)

ap

pro

x. 200

approx. 95

ap

pro

x. 40

D 6250 page 4

4. Appendix4.1 Reduction of the damping of the control cylinder (only size 2, 3, and 5 (4))

The pressure actuations feature orifices in the control pressure ports 1 and 2 (see symbols in sect. 2.2) as precaution to prevent

resonance vibration. These orifices may be removed to decrease the total resistance of the control circuit, if the flow resistance with

hydraulic actuations type NM or KM.... leeds to an excessively slow return movement into zero position (run-down). This might

occur with high viscosity of the fluid (in winter) or long, narrow control pipes, thus delaying response. Removal is accomplished by

punching the center of the nozzle gently to loosen it from the caulking, and subsequently removing it by means of a needle or piece

of wire.

A gentle punch bends the nozzle

inwardly and loosens it from the

caulking

A needle or wire is inserted then

into the needle bore to remove it.

It should be noted that the nozzles cannot be

refitted, when dampening becomes necessary

again.

Should run-down become too excessive, one

should first consider the possibility of changing

the oil or checking the possibility to increase

the diameter of the control pipe.

4.2 Contact switch for KDS... and KMS...

4.3 NM- and KM- actuation

Co. ELAN SEG 103 S, protection class IP 65

IP 00 (SEK 103/S/11) is possible upon request; pls. specify with

your order.

Guideline figures for electrical switch loading (, 1 x 106 cycles)Permanent current 10 A

Cut-off current 6 A for 230V AC (cos. ϕ 0.4)

5 A for 24V DC (π , 40 ms)

0.02 A for 110V DC (π , 40 ms)

The contact switch is not properly adjusted upon delivery of the

double actuation mounted on the directional spool valve. It must be

moved on the switch support and adjusted such that, in actuation

positions a-0-b, the desired contact is properly made (contact bridge

1-2 as the valve or 3-4 as the opener). The shifting cam is designed

such that the contact switch is depressed in the zero position.

for proportional directional spool valves type SKS

The installed spring assembly has been mated to the pressure

opposed valve spool area. Therefore any pressure applied to port 1

or 2 in the range of approx. 4...12 bar will lead to a proportional

response of the consumer flow with directional spool valves type

SKS. The response to the hydraulic actuation will start from 3 to 4 bar

enabling travel from neutral to start of consumer flow. Friction losses,

spring force tolerances, etc. result in a certain degree of divergence.

Thus the diagram on the right represents only a qualitative guideline.

Ro

ug

h g

uid

elin

e fo

r co

nsum

er

eff

ective f

low

Qco

nsum

in %

of

Qm

ax

as in p

am

phle

t D

5700

Co

ntr

ol p

ressure

(b

ar)

at

co

nnectio

n 1

or

2

Stroke (mm)

SKS-valve