Phase equilibria, phase diagrams and phase transformations: their thermodynamic basis

Phase Transformations

description

Transcript of Phase Transformations

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

Phase Transformations

Kinetics

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

Why study Phase Transformation ( in Metal)

Development of a set of desirable mechanical properties results from a phase transformation → heat treatment

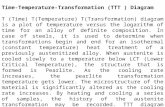

Time- Temperature dependencies of some phase transformation are conveniently represented on a modified phase diagrams

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

It is important to know how to use the diagram in order to design heat treatment that will yield room temperature mechanical properties

Eg. Tensile strength of an iron-carbide alloy of eutectoid composition (0.76%C) can be varied bet.~700MPa to 2000MPa depending on heat treatment employed

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

Phase transformations (change of the microstructure) can be divided into three categories:

Diffusion-dependent with no change in phase composition or number of phases present

Diffusion-dependent with changes in phase composition and/or number of phases (eg. Eutectoid transformations)

Diffusionless phase transformation – produces a metastable phase by cooperative small displacement of atoms in structure.

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

Phase transformations do not occur instantaneously

Hence need to consider the kinetics of the phase transformation

Diffusion-dependent phase transformations can be rather slow and the final structure often depend on the rate of cooling/heating.

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

Kinetics of Phase Transformations

Most phase transformations involve change in composition >> redistribution of atoms via diffusion is required.

The process involves :

Nucleation of new phase –formation of stable small particles (nuclei) of new phase. Nuclei are often formed at grain boundaries and other defects.

Growth of new phase

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

Plot of fraction reacted versus the logarithmic of time typical of many solid-state transformation in which temperature is held constant.

f = 1 – exp(-ktn) ……….Avrami equation

f = fraction transformation

t= time

k and n is a time-dependent constants for particular reaction.

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

Precipitation of a single-phase solid- nucleation

Precipitation within a homogeneous liquid matrix – homogeneous nucleation

The more common case is precipitation occuring at some structural imperfection such as foreign surface- heterogeneous nucleation

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

3

342

)(34 4 rrGG V

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

For solid –state trnasformations displaying kinetic behavior shown in Fig. fraction transformation y is afunction time t as follows:

Y = 1 – exp(-ktn) …. Eqn 8.1 Avrami Equation

k and n (0.5 -5)are time-dependent constants for a particular rxn.

By convention rate of transformation r is taken as the reciprocal of time required for the transformation to proceed halfway to completion, t0.5

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

r = 1/t0.5 …………..eqn 8.2

rate increases with temp. according to Arrhenius eqn, characteristic for thermally activated process

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

rate increases with temp. according to Arrhenius eqn, characteristic for thermally activated process

r= Aexp(-Q/kT) = A exp(-Q/RT) ………… 8.3

per atom per mole

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

Superheating and supercooling

Upon crossing a phase boundary on the composition-temperature phase diagram phase transformation towards equilibrium state is induced

But the transition to the equilibrium structure takes time and transformation is delayed.

During cooling, transformation occur at temperatures less than predicted by phase diagram: supercooling

During heating, transformation occur at temperatures greater than predicted by phase diagram: superheating

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

Degree of supercooling/super heating increases with rate of cooling/heating

Meta stable states can be formed as a result of fast temperature change. Microstructure is strongly affected by cooling rate

We will consider the effect of time on phase transformation using iron-carbon alloy as an example

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

The S-shaped curves are shifted to a longer times at higher T indicating transformation is dominated by nucleation and not by diffusion

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

Euctectoid temp. indicated by the horizontal line

(Referring to earlier diagram)

→austenite is stable for all times

The austenite to pearlite transformation will only occur if alloy supercooled to below the eutectoid temp.

The required will depend on the temp.

From eqn 8.2 transformation rate at some particular temp inversely propnl. To the time required for rxn proceed 50% completion.

Eg. Temp just below eutectoid 105 s , while at 540oC ~ 3 s

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

This rate –temp behavior contradict eqn 8.3 → rate increases with increasing temperature

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

The above Fig. is isothermal transformation diagram or commonly known as TTT diagram – temperature,time, and transformation.

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

This Fig shows the progress of transformation that can be traceby a group of curves showing different percentages of completion

Using the industrially important eutectoid transformation in steels as an eg.

2 types of transformation:

1. Diffusional transformation in solid – eutectoid transformation

2. Diffusionless (martensitic) transformations

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

1. Diffusional transformation in solid – eutectoid transformation

Involve a change of structure due to the long range migration of atoms

Fig 8-7 shows TTT diagram of eutectoid stell (Fe with 0.77 wt%C

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

Fig 8-7

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

The most important new info provided in Fig 8-7 –pearlite is not the only microstructure that can develop from cooling of austenite

For certain temp. bainite rather than pearlite is formed

Base p.d eutecticand eutectoid structures are generally fine - grained

• But for slow cooling near the eutectoid temp-coarse pearlite

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

Reason: low nucleation rates and high diffusion rates near eutectoid temp lead to relatively coarse structure

Fine pearlite formed at low temperature bcos transformation is diffusion control.

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

Bainite Formation

Pearlite formation – from eutectoid temp (727oC) down to about 400oC

Below 400oC, ferrite and cementite form as extremely fine needles in microstructure known as bainite

Eventhough various morphologies develop over the range of temperatures- all have the same phase composition and relative amount of each phase.

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

A slow cooling path that leads to coarse pearlite formation is superimposed on the TTT diagram for eutectoid steel. This type of thermal history was assumed,in general, throughout previous lectures

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

The microstructure of bainite involves extremely fine needles of -Fe and Fe3C, in contrast to the lamellar structure of pearlite. (From Metals Handbook,8th Ed., Vol. 7: Atlas of Microstructures, American Society for Metals, Metals Park, Ohio, 1972.)

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

The interpretation of TTT diagrams requires consideration of the thermal history ìpath.î For example, coarse pearlite, once formed, remains stable upon cooling. The finer-grain structures are less stable because of the energy associated with the grain boundary area. (By contrast, phase diagrams represent equilibrium and identify stable phases independent of the path used to reach a given state point.)

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

2. Diffusionless (martensitic) transformations

Fig 8-11

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

Diffusionless (martensitic) transformations

Fig 8-11 shows ver different process occur at lower temp. – below 250oC

Two horizontal lines are added mto represent the occurrence of a diffusionless process known as martensitic transformation

This is a generic term referring to a broad family of diffusionless transformation in metals an non-metals alike.

Common eg. trsnfmtn in eutectoid steel – product from the quenched austenite – martensite

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

Quenching austenite rapidly enough bypassing the pearlite knee (~550oC) – suppress diffusional transformation

The austenite increasingly become unstable with decreasing

At about 215oC the austenite transform spontaneously to martensite (~1% of the austenite)

Instead of diffusional migration of C to form α and Fe3C , there is sudden reorientation of C and Fe from fcc SS of γ-Fe to bct SS – which is martensite

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

In (a),the bct unit cell is shown relative to the fcc lattice by the h100i axes. In (b), the bct unit cell is shown before (left) and after (right) the transformation. The open circles represent iron atoms. The solid circle represents an interstitially dissolved carbon atom.

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

Complex crystal structure,and supersaturated conc. Of carbon atoms in martensite lead to a characteristically brittle nature

The start of martensitic transformation - line Ms

If quenching below this line austenite increasingly become unstable and more will transfrom to martensite.

Various stages of martensitic transformation in Fig 8-11

- 46oC transformation complete.

16/7/02 EBB512 –Phase Equilibria and Phase Diagrams

The End