Phase Diagrams, Solid Solutions, Phase Transformations...Phase diagram Indicate phases as a function...

Transcript of Phase Diagrams, Solid Solutions, Phase Transformations...Phase diagram Indicate phases as a function...

-

Phase Diagrams, Solid Solutions, Phase

Strengthening, Phase Transformations

-

2

• Components: The elements or compounds that are mixed initially (Al and Cu).• Phases: A phase is a homogenous, physically distinct and mechanically separable

portion of the material with a given chemical composition and structure ( and ).

(darker phase)

(lighter phase)

Components and Phases

Aluminum-CopperAlloy

-

Solid solution A solution that contains two or more types of atoms or ions that are dispersed uniformly throughout the material

Solute The impurities that may occupy regular lattice sites in the crystal or interstitial sites

Alloys A material made from multiple elements that exhibits properties of a metallic material

Stainless steels Alloys that usually contain iron (Fe), carbon (C), chromium (Cr), nickel (Ni), and some other elements

Single-phase alloy An alloy consisting of one phase

Multiple-phase alloy An alloy that consists of two or more phases

-

© 2011 Cengage Learning Engineering. All Rights Reserved. 10 - 4

Figure 10.2

Chapter 10: Solid Solutions and Phase Equilibrium

-

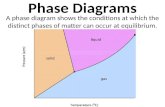

Phase Equilibria: Solubility Limit• Solution – solid, liquid, or gas solutions, single phase• Mixture – more than one phase

Question: What is the solubility limit for sugar in water at 20°C?

Answer: 65 wt% sugar. At 20°C, if C < 65 wt% sugar: syrup At 20°C, if C > 65 wt% sugar: syrup + sugar

65

• Solubility Limit: Maximum concentration for which only a single phase solution exists.

Sugar/Water Phase Diagram

Sug

ar

Tem

pera

ture

(°C

)0 20 40 60 80 100

C = Composition (wt% sugar)

L (liquid solution

i.e., syrup)

Solubility Limit L

(liquid) +

S

(solid sugar)20

40

60

80

100

Wat

er

-

6

Equilibrium

• A system is at equilibrium if its free energy is at a minimum, given a specified combination of temperature, pressure and composition.

• The (macroscopic) characteristics of the system do not change with time — the system is stable.

• A change in T, P or C for the system will result in an increase in the free energy and possible changes to another state whereby the free energy is lowered.

-

© 2011 Cengage Learning Engineering. All Rights Reserved.10 - 8

Conditions for Unlimited Solid Solubility

Hume-Rothery rules Size factor – The atoms or ions must be of similar size, with no more

than a 15% difference in atomic radius, in order to minimize the lattice strain.

Crystal structure – The materials must have the same crystal structure.

Valence – The ions must have the same valence. Electronegativity – The atoms must have approximately the same

electronegativity.

Chapter 10: Solid Solutions and Phase Equilibrium

-

© 2011 Cengage Learning Engineering. All Rights Reserved.10 - 10

Figure 10.3

Chapter 10: Solid Solutions and Phase Equilibrium

-

© 2011 Cengage Learning Engineering. All Rights Reserved.10 - 11

Solubility and Solid Solutions

Polymeric systems Copolymer: A polymer that is formed by combining two or more

different types of monomers, usually with the idea of blending the properties affiliated with individual polymers.

For example, acrylonitrile (A), butadiene (B), and styrene (S) monomers can be made to react to form a copolymer known as ABS.

Chapter 10: Solid Solutions and Phase Equilibrium

-

© 2011 Cengage Learning Engineering. All Rights Reserved.10 - 12

Solid-Solution Strengthening

Solid-solution strengthening Increasing the strength of a metallic material

via the formation of a solid solution.

Chapter 10: Solid Solutions and Phase Equilibrium

-

© 2011 Cengage Learning Engineering. All Rights Reserved.10 - 13

Figure 10.8

Chapter 10: Solid Solutions and Phase Equilibrium

-

© 2011 Cengage Learning Engineering. All Rights Reserved.10 - 14

Isomorphous Phase Diagrams

Phase diagram Indicate phases as a function of Temp., Comp. and Pressure

(under equilibrium condition) Binary phase diagram

A phase diagram for a system with two components. Isomorphous phase diagram

A phase diagram in which the components display unlimited solid solubility.

Chapter 10: Solid Solutions and Phase Equilibrium

-

© 2011 Cengage Learning Engineering. All Rights Reserved.10 - 15

Figure 10.9

Chapter 10: Solid Solutions and Phase Equilibrium

-

16

• Rule 1: If we know T and Co, then we know: --how many phases and which phases are present.

• Examples:

wt% Ni20 40 60 80 1000100 0

110 0

120 0

130 0

140 0

150 0

160 0T(°C)

L (liquid)

(FCC solid

solution)L +

liquidu

s

solidu

s

A(1100,60)

B(1

250,

35)

Cu-Niphase

diagram

A(1100, 60): 1 phase:

B(1250, 35): 2 phases: L +

Determination of phase(s) present

Melting points: Cu = 1085°C, Ni = 1453 °C

Solidus - Temperature where alloy is completely solid. Above this line, liquefaction begins.Liquidus - Temperature where alloy is completely liquid. Below this line, solidification begins.

-

17

• Rule 2: If we know T and Co, then we know: --the composition of each phase.

• Examples:

wt% Ni20

1200

1300

T(°C)

L (liquid)

(solid)L +

liquidus

solidus

30 40 50

TA A

DTD

TBB

tie line

L +

433532CoCL C

Cu-Ni system

Phase Diagrams: composition of phases

At TA = 1320°C: Only Liquid (L) present CL = C0

( = 35 wt% Ni)

At TB = 1250°C: Both and L present

At TD = 1190°C: Only Solid () present C = C0 ( = 35 wt% Ni)

CL = C liquidus ( = 32 wt% Ni) C = C solidus ( = 43 wt% Ni)

-

18

• Rule 3: If we know T and Co, then we know: --the amount of each phase (given in wt%).

Cu-Ni system

• Examples:

At T B: Both and L

At T A: Only Liquid (L) WL = 100wt%, W = 0

At T D: Only Solid ( ) WL = 0, W = 100wt%

Co = 35wt%Ni

wt% Ni

20

1200

1300

T(°C)

L (liquid)

(solid)

L +

liquidus

solidus

30 40 50

TA A

DTD

TBB

tie line

L +

433532CoCL C

R S

Phase Diagrams: weight fractions of phases

WL S

R S

W R

R S

RR S

SR S

WL C CoC CL

= 27wt %R

R S W

Co CLC CL

SR S

WL C CoC CL

WL S

R S

W R

R S

43 3543 32

73wt %

-

© 2011 Cengage Learning Engineering. All Rights Reserved.10 - 19

Figure 10.15

Chapter 10: Solid Solutions and Phase Equilibrium

-

© 2011 Cengage Learning Engineering. All Rights Reserved.10 - 20

Figure 10.16

Chapter 10: Solid Solutions and Phase Equilibrium

-

© 2011 Cengage Learning Engineering. All Rights Reserved.10 - 21

Figure 10.17

Chapter 10: Solid Solutions and Phase Equilibrium

-

22

Importance of Phase Diagrams

• There is a strong correlation between microstructure and mechanical properties, and the development of alloy microstructure is related to the characteristics of its phase diagram.

• Phase diagrams provide valuable information about melting, casting, crystallization and other phenomena.

-

23

Microstructure

• In metal alloys, microstructure is characterized by the number of phases, their proportions, and the way they are arranged.

• The microstructure depends on: – Alloying elements– Concentration– Heat treatment (temperature, time, rate of

cooling)

-

24

Eutectic• A eutectic or eutectic mixture is a mixture of two or

more phases at a composition that has the lowest melting point.

• It is where the phases simultaneously crystallize from molten solution.

• The proper ratios of phases to obtain a eutectic is identified by the eutectic point on a binary phase diagram.

• The term comes from the Greek 'eutektos', meaning 'easily melted.‘

-

25

•The phase diagram displays a simple binary system composed of two components, A and B, which has a eutectic point.

•The phase diagram plots relative concentrations of A and B along the X-axis, and temperature along the Y-axis. The eutectic point is the point where the liquid phase borders directly on the solid α + β phase; it represents the minimum melting temperature of any possible A B alloy.

•The temperature that corresponds to this point is known as the eutectic temperature.•Not all binary system alloys have a eutectic point: those that form a solid solution at all

concentrations, such as the gold-silver system, have no eutectic. An alloy system that has a eutectic is often referred to as a eutectic system, or eutectic alloy.

•Solid products of a eutectic transformation can often be identified by their lamellar structure, as opposed to the dendritic structures commonly seen in non-eutectic solidification.

-

26

2 componentshas a special compositionwith a min. melting T.

Binary-Eutectic Systems

• 3 single phase regions (L, , )

• Limited solubility: : mostly Cu : mostly Ag

• TE : No liquid below TE: Composition at temperature TE

• CE

Cu-Ag system

L (liquid)

L + L+

C , wt% Ag20 40 60 80 1000

200

1200T(°C)

400

600

800

1000

CE

TE 8.0 71.9 91.2779°C

cooling

heating

• Eutectic reactionL(CE) (CE) + (CE)

Ag) wt%1.29( Ag) wt%.08( Ag) wt%9.71( L

-

c10f08Pb-Sn Phase Diagram

Liquidus

SolidusSolidus

Solidus

Solvus Solvus

-

28

Lamellar Eutectic StructureA 2-phase microstructure

resulting from the solidification of a liquid having the eutectic composition where the phases exist as a lamellae that alternate with one another.

Formation of eutectic layered microstructure in the Pb-Sn system during solidification at the eutectic composition. Compositions of α and β phases are very different. Solidification involves redistribution of Pb and Sn atoms by atomic diffusion.

Pb-rich

Sn-rich

-

29

Pb-Sn Microstructures

The dark layers are Pb-rich α phase, the light layers are the Sn-rich β phase.

-

30

Iron-Carbon System• Pure iron when heated experiences 2

changes in crystal structure before it melts.

• At room temperature the stable form, ferrite ( iron) has a BCC crystal structure.

• Ferrite experiences a polymorphic transformation to FCC austenite ( iron) at 912 ˚C (1674 ˚F).

• At 1394˚C (2541˚F) austenite reverts back to BCC phase ferrite and melts at 1538 ˚C (2800 ˚F).

• Iron carbide (cementite or Fe3C) an intermediate compound is formed at 6.7 wt% C.

• Typically, all steels and cast irons have carbon contents less than 6.7 wt% C.

• Carbon is an interstitial impurity in iron and forms a solid solution with the phases

-

c10f28Iron-Carbon System

-

Though carbon is present in relatively low concentrations, it significantly influences the mechanical properties of ferrite: (a) α ferrite, (b) austenite.

c10f29ab

-

4 Solid Phases

-

34

Iron-Carbon (Fe-C) Phase Diagram

• 2 important points

- Eutectoid (B):

+Fe3C

- Eutectic (A):

L ↔ + Fe3C

Fe 3

C (

cem

entit

e)

1600

1400

1200

1000

800

600

4000 1 2 3 4 5 6 6.7

L

(austenite)

+L

+Fe3C

+Fe3C

+

(Fe) C, wt% C

1148°C

T(°C)

727°C = Teutectoid

4.30

Result: Pearlite = alternating layers of and Fe3C phases,

not a separate phase.

120 m 0.76

B

AL+Fe3C

Fe3C (cementite-hard) (ferrite-soft)

↔

-

c10f30Pearlite Eutectoid reaction:

↔ + Fe3C

Austenite – 0.76 wt% CFerrite - 0.022 wt% CCementite - 6.70 wt% C

Redistribution of carbon by diffusion

-

36

Slide 1Components and PhasesSlide 3Slide 4Phase Equilibria: Solubility LimitEquilibriumSlide 7Slide 8Slide 9Slide 10Slide 11Slide 12Slide 13Slide 14Slide 15Determination of phase(s) presentPhase Diagrams: composition of phasesPhase Diagrams: weight fractions of phasesSlide 19Slide 20Slide 21Importance of Phase DiagramsMicrostructureEutecticSlide 25Binary-Eutectic Systemsc10f08Lamellar Eutectic StructurePb-Sn MicrostructuresIron-Carbon Systemc10f28c10f29ab4 Solid PhasesIron-Carbon (Fe-C) Phase Diagramc10f30Slide 36