Paul welander cryogenic rf characterization of sc materials at slac with cu and nb-coated cavities

-

Upload

thinfilmsworkshop -

Category

Science

-

view

153 -

download

4

Transcript of Paul welander cryogenic rf characterization of sc materials at slac with cu and nb-coated cavities

Cryogenic RF Characterization of Superconducting Materials at SLAC with Cu and Nb-Coated Cavities

Paul B. Welander, Matt Franzi, Jiquan Guo*, Sami Tantawi

SLAC National Accelerator Laboratory, Menlo Park, CA 94025

6 October 2014

* now at JLab

2TFSRF 2014 – P. Welander – [email protected]

Outline

• Motivation

• Review of Previous Work at SLAC

• New Cryostat and New Cavity

• Initial Measurements on Bulk Nb

• Thin Film Growth at Stanford

3TFSRF 2014 – P. Welander – [email protected]

The Takeaway

• Cryogenic RF testing underway again at SLAC

• New cryostat dedicated to SRF materials evaluation

• Two cavities (Cu & Nb) for sample characterization

- Hquench up to 360 mT, Rs with sub-nΩ resolution

• Low-power Q vs. T takes less than 24 hrs.

• We’re eager to test your samples!

TFSRF 2014 – P. Welander – [email protected]

Motivation

Test bed for SRF materials

• Characterize a variety of samples, bulk and thin-film

• Magnetic quenching field measurements up to high fields- Possibly higher than Nb’s 170-180 mT

• Quick testing cycles with small (easy to coat) samples

• Able to explore higher Tc materials (e.g. MgB2, A15s)

• Surface resistance characterization (no longer Cu-limited)

Non-superconducting materials

• RRR of copper in different forms

• Other materials, such as complex oxides

TFSRF 2014 – P. Welander – [email protected]

System Capabilities

• Characterize surface impedance by measuring the quality factor, Q0, of a cavity at 11.4 GHz, down to 4 K

• Capable of low power (PNA) and high power (Klystron) measurements

• Compact design thanks to X-band design (5.5” diameter)• Interchangeable flat cavity bottom, fits 2” diameter samples

up to 0.25” thick.• Cavity design maximizes H-field and minimizes E-field on

the sample surface

• Can achieve Hpeak ~ 360 mT with 50 MW Klystron running 1.6 µs flat pulses and Qe ~ 3.2e5, Q0 ~ 3.2e5

• New Nb-coated cavity designed for Qe ~ 3.2e7, Q0 ~ 3.2e7

6TFSRF 2014 – P. Welander – [email protected]

Cryomech Pulse-Tube Cryocooler

Our cavity cryostat utilizes a Cryomech cryorefrigerator.

• Two-stage pulse-tube operation• Base temperature of 2.8 K with

cooling power of 1.5 W at 4.2 K

In our system, the practical base temperature is about 3.6 K.

One shortcoming of this model is the motor vibrations large fluctuations in resonant peak

• Solved in new cryostat by using remote motor version

TFSRF 2014 – P. Welander – [email protected]

Cu Cavity Design

High-Q hemispheric cavity under a TE013-like mode

• Zero E-field on sample

• Maximize H-field on the sample,

Hpeak on bottom is 2.5 times of

peak on dome

• Maximize loss on the sample,

36% of cavity total

• No radial current on bottom

Copper cavity body• No temperature transition or

quenching

• Higher surface impedance

• Coupling sensitive to iris radius

HFSS modeling of high-Q Cu cavity under TE013-like mode

SampleR = 0.95”

H E

TFSRF 2014 – P. Welander – [email protected]

Cu Cavity Design

HFSS modeling of high-Q Cu cavity under TE013-like mode

SampleR = 0.95”

H E

f0 = 11.40 GHzQtotal = 1.60e5

Gtotal = 1289 ΩGCu = 1967 ΩGsample = 3742 Ω

1𝑄0

=𝑅𝑡𝑜𝑡𝑎𝑙

𝐺𝑡𝑜𝑡𝑎𝑙

¿(𝛼𝐶𝑢𝑅𝐶𝑢+𝛼𝑠𝑎𝑚𝑝𝑙𝑒𝑅𝑠𝑎𝑚𝑝𝑙𝑒)

𝐺𝑡𝑜𝑡𝑎𝑙

𝛼𝑠𝑎𝑚𝑝𝑙𝑒=𝐺𝑡𝑜𝑡𝑎𝑙/𝐺𝑠𝑎𝑚𝑝𝑙𝑒=0.345𝛼𝐶𝑢=𝐺𝑡𝑜𝑡𝑎𝑙 /𝐺𝐶𝑢=0.655

9TFSRF 2014 – P. Welander – [email protected]

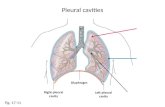

Cavity Cryostat Assembly – Model View

Cryocooler2nd Stage

SampleUnderTest

RF Feed

40 K Shield

DiodeTemp

Sensors

SamplePlate

Cavity Iris

TFSRF 2014 – P. Welander – [email protected]

Cavity Assembly

SampleUnderTest

SamplePlate Cavity Iris

RF Feed

40 K Shield

TFSRF 2014 – P. Welander – [email protected]

System Overview

Cryostat

Waveguide to Klystron/NWA

Measurement ports:Forward Power: 2 or 5Reflected power: 4 or 3Waveform measured by either a Peak Power Meter or a scope with mixersLow-power PNA measurement: 6, 7, or 3

1

2

3

4

Cavity

Klystron

10dB

45dB 45dB

5

6

55dB

7

Cryostat

Mode converter Bend

LoadSystem Diagram

TFSRF 2014 – P. Welander – [email protected]

5 104

1 105

1.5 105

2 105

2.5 105

0 50 100 150 200 250 300

SLAC Cu sampleLow power test result

Q0Q0

Temperature(K)

Measurement Results: Bulk Cu

This Cu reference sample is used to estimate the surface impedance, Rs, of the cavity body. It uses similar material as the body and underwent the same annealing process.

TFSRF 2014 – P. Welander – [email protected]

Measurement Results: Bulk Nb, low power test

FNAL bulk large grain Nb sample• Sample surface impedance is estimated from the measured Q0 of the

cavity with Nb sample and the measured copper surface impedance. • Without magnetic shielding, Rs is high. After adding a magnetic shielding

and 800 °C vacuum bake, surface impedance reduced by a factor of 3.

0

0.002

0.004

0.006

0.008

0.01

0.012

0.014

0 5 10 15 20 25 30

FNAL-Nb S15-1Estimated Rs

W/o shielding, before baking W/ shielding, before bakingW/ shielding, after baking

Rs

(Oh

m)

Temperature(K)

0

5 104

1 105

1.5 105

2 105

2.5 105

3 105

3.5 105

0 20 40 60 80 100

FNAL Nb S15-1measured Q

0

Before baking, w/o shieldingBefore baking, w/ shieldingAfter baking, w/ shielding

Q0

Temperature (K)

TFSRF 2014 – P. Welander – [email protected]

Measurement Results: Bulk Nb, high power test

FNAL bulk large grain Nb sample

• The residual resistivity causes pulse heating and degrades the quenching field.

• Without magnetic shielding and baking, the sample quench onset is ~ 65 mT and temp rises ~ 5 K.

• After shielding and baking, quenching onset is ~120 mT and temperature rises only ~ 3 K.1.1 105

1.2 105

1.3 105

1.4 105

1.5 105

1.6 105

1.7 105

1.8 105

0 20 40 60 80 100 120 140 160

FNAL Nb S15-1Q vs H, T=3K

w/ and w/o shielding/baking

Ql 04012010, no shielding, no bakingQl 09216010 with shielding, after baking

Qlo

ad

ed

Hpeak (mT)

TFSRF 2014 – P. Welander – [email protected]

Measurement results: 300nm MgB2 on Sapphire

0

5 104

1 105

1.5 105

2 105

2.5 105

3 105

3.5 105

4 105

0 5 10 15 20 25 30 35 40

300nm MgB2 thinfilm on SapphireQ vs T

H=10mT vs low power

Q0, H=10mTQ0, network analyzer

Q0

Temperature(K)

5 104

1 105

1.5 105

2 105

2.5 105

3 105

3.5 105

4 105

10 15 20 25 30

MgB2 thinfilm on SapphireQvsH

T=3K, 04082010

Q0Q0

Hpeak (mT)

300 nm MgB2 thin film on sapphire substrate, provided by LANL and deposited at STI.

TFSRF 2014 – P. Welander – [email protected]

Measurement results: MgB2/Al2O3/Nb

200 nm MgB2/300 nm Al2O3/Nb sample provided by LANL, Al2O3 coated at ANL, MgB2 coated at STI.

1 105

1.5 105

2 105

2.5 105

3 105

3.5 105

8 104

1 105

1.2 105

1.4 105

1.6 105

10 20 30 40 50 60 70

Q vs HMgB

2/Al

2O

3/Nb

T=3K, June 11, 2010

Q0

Qloaded

Q0

Qloa

ded

Hpeak (mT)

5 104

1 105

1.5 105

2 105

2.5 105

3 105

3.5 105

0 10 20 30 40 50

Q vs T for MgB2/Al

2O

3/Nb

Low power test(NWA) vs high power test(12mT)

Q0(NWA, 06112010)Q0(NWA, 06042010)Q0(H=12mT, 06102010)Q0(H=12mT, 06112010)

Q0

Temperature(K)

TFSRF 2014 – P. Welander – [email protected]

New Cryostat for Cavity Testing

• Recently completed assembly of a 2nd

cryostat dedicated to cavity testing.

• Improvements on old design: Remote-motor cryocooler – to reduce

cavity vibrations and fluctuations in

resonant frequency.

Increased pumping – to improve

cryostat base pressure (1e-9 torr vs.

1e-6 torr prior).

Improved thermal isolation – to

increase 4 K cooling power reserved

for cavity dissipation.

TFSRF 2014 – P. Welander – [email protected]

Sample SurfaceHemisphere Surface

f0 = 11.33 GHzQtotal = 1.59e7

Gtotal = 1389 ΩGNb = 2067 ΩGsample = 4233 Ω

Nb-Coated Cavity Design

1𝑄0

=𝑅𝑡𝑜𝑡𝑎𝑙

𝐺𝑡𝑜𝑡𝑎𝑙

¿(𝛼𝑁𝑏𝑅𝑁𝑏+𝛼𝑠𝑎𝑚𝑝𝑙𝑒𝑅𝑠𝑎𝑚𝑝𝑙𝑒)

𝐺𝑡𝑜𝑡𝑎𝑙

𝛼𝑠𝑎𝑚𝑝𝑙𝑒=𝐺𝑡𝑜𝑡𝑎𝑙/𝐺𝑠𝑎𝑚𝑝𝑙𝑒=0.328𝛼𝑁𝑏=𝐺𝑡𝑜𝑡𝑎𝑙 /𝐺𝑁𝑏=0.672

20TFSRF 2014 – P. Welander – [email protected]

Two Cavities

Coated w/ 5 μm Nb film at CERN (S. Calatroni)

21TFSRF 2014 – P. Welander – [email protected]

Single-Crystal Nb in Both Cavities

• Single-crystal bulk Nb from DESY

- Received January 2008- Baked in 2010, untreated since

• Cavity comparison shown- 2010 measurement in Cu

cavity after baking.- 2014 measurement in Nb

cavity after solvent cleaning.

• In Cu cavity, low-temperature Q0 is limited by Cu surface resistance.

105

106

107

108

Q0

141210864

Temperature (K)

S001-C1 in Both Cavities

Nb Cavity Cu Cavity

22TFSRF 2014 – P. Welander – [email protected]

4

6

0.1

2

4

6

1

2

4

6

10

2

Rs

(m

4 5 6 7 8 910

2 3

Temperature (K)

S001-C1 in Nb Cavity

Single-Crystal Nb in Nb Cavity

• Single-crystal bulk Nb from DESY

- Received January 2008- Baked in 2010, untreated since

• At 4.1 K and 11.42 GHz, Rs = 48 μΩ

- Assumes Rs,sample = Rs,cavity

- Standard deviation of 1%- Assuming f 2 and (T/Tc)4

dependence, Rs = 35 nΩ at 2.0 K and 1.3 GHz

TFSRF 2014 – P. Welander – [email protected]

Thin Film Deposition

• Collaborative effort with Mac Beasley

(Applied Physics) & Bruce Clemens

(Materials Science) at Stanford

• 3-target sputtering system being

utilized for deposition on 2” wafers.

• Elemental targets and nitrogen gas

used for reactive DC sputtering of

nitride films.

• Recently started thin-film growth

development with Nb films, followed

by NbN and NbTiN.Characterize materials using analysis tools at the Stanford Nano Center (e.g. XRD, XPS, TEM)

TFSRF 2014 – P. Welander – [email protected]

Cryogenic DC Characterization

• Utilizing cryogenic DC transport measurements to

optimize growth for maximum critical temp, Tc.

• Use Design of Experiments to model process

outcome (Tc) versus controllable process

parameters (e.g. gas flow, pressure, gun power)14

12

10

8

6

Mod

eled

Tc

(K)

14121086

Measured Tc (K)

Model Variables: - N2 Flow - Pressure - Gun Power

2 = 0.341

Quantum DesignPPMS

TFSRF 2014 – P. Welander – [email protected]

Summary

• Cryogenic RF testing underway again at SLAC

• New cryostat dedicated to SRF materials evaluation

• Working toward NbN and NbTiN film growth

• Two cavities (Cu & Nb) for sample characterization

- Hquench up to 360 mT, Rs with sub-nΩ resolution

• Low-power Q vs. T takes less than 24 hrs.

• Send us your samples!