Guide to Adopting Paint Systems for Galvanized Steel - Edition 2 May 201...

Paint Guide for GI Steel

Transcript of Paint Guide for GI Steel

-

7/24/2019 Paint Guide for GI Steel

1/12

PracticalGuide

for

Preparing

H

ot

Dip

Galvanized

Steelfor

P a i n

t i n g

Age of Galvanized Steel Cleaning Profiling

Newly Galvanized Steel No Yes

Partially Weathered Yes Yes

Galvanized Steel

Fully WeatheredYes No

Galvanized Steel

Maintenance Painting Yes No, if spot painting

of Duplex Systems Yes, if fully repainting

Quick Guide to Surface Preparation for

Painting Over Galvanized Steel

-

7/24/2019 Paint Guide for GI Steel

2/121

Practical Guide for Preparing

Hot-Dip Galvanized Steel for Painting

Successfully painting over hot-dip galvanized steel,

also known as a duplex system, does not have to be a

difficult or confusing job. Just like painting over

anything else, proper surface preparation is the key to

creating an effective bond between the paint and

galvanized su rface.

A galvanized coating is mostly made up of zinc.

Zinc is great at protecting the steel from corrosion, but

its very reactive. Almost immediately after galvanizing,

particles of zinc oxide and hydroxide form on top of the

zinc coating. These pa rticles, along with dirt and grease,

need to be properly removed from galvanized surfaces

in order to ensure the paint adheres to the galvanized

steel.

The following steps explain how to prepare the

galvanized surface to be painted successfully.

-

7/24/2019 Paint Guide for GI Steel

3/12

14 Steps for Good Surface Preparation

STEP 1 Know the Age of the

Galvanized Coating

Knowing the age of the galvanized steel ready to be

painted is important because age determines what type of

surface preparation should be done. Early on, zinc oxide

and hydroxide hinder the paints ability to adhere to the

galvanized coating. However, over the course of six to 24

months the zinc surface weathers and forms a thin,

dense film of mostly zinc carbonate called the zinc patina.

Once the patina has fully formed, the particulates no

longer interfere with paint adhesion.

Galvanized coatings can generally be grouped into

three categories: newly galvanized, partially weathered,

and fully weathered. The length of time a galvanized

coating takes to reach each age level depends on

environmental conditions, such as humidity, temperature,

wind, etc.

Newly galvanized steel has been-hot dip galvanized

within 48 hours typically has very little zinc oxide or

hydroxide on its surface. Most painting of newly

galvanized steel is done in a shop environment.

P a r t i a l l y

w e a t h e r e d

galvanized steel is

more difficult to

pinpoint. As a rule, a

partially weathered

coating is between

48 hours and two

years old. Generally,

this coating has

some zinc oxide,

hydroxide and carbonate film, but the full zinc patina is not

yet formed.

2

3

-

7/24/2019 Paint Guide for GI Steel

4/12

2

Fully weathered

galvanized steel is

generally older than two

years and has a fully

formed zinc patina.

STEP 2 Inspect the Galvanized

Coating

Chromate Testing

Sometimes galvanized steel is dipped in a chromate

bath immediately after galvanizing. The chromates can

greatly interfere with paint adhesion and must be removed

prior to painting. Although, some chromated galvanized

surfaces have a dull, flat gray finish, it can be difficult to

visually detect the use of chromates. If there is uncertainty

on whether the steel was chromate quenched, then the

galvanized surface needs to be tested for the presence of

chromates. This testing is fairly simple and is described in

ASTM B 201.

If chromates are found, the galvanized steel can either

be allowed to weather for approximately two years before

painting, or the chromates can be cleaned off using one

of the cleaning methods described in the next step.

4

5

-

7/24/2019 Paint Guide for GI Steel

5/12

Surface

Imperfections

Regardless of

the age of the

g a l v a n i z e d

coating, it

shouldnt have

s i g n i f i c a n t

bumpy spots,

sharp icicles,

high spots, or

extremely rough edges. This is important because

protrusions greater than the paints dry film thickness

(five -ten mils) interfere with adhesion and can cause

voids in the paint coating. To smooth out surface

blemishes, hand-file or power-sand the area. Be verycareful not to remove any more of the protective zinc

coating than absolutely necessary.

Touch-up and Repair

Check to see if there are any bare areas revealing

the underlying steel, such as drill holes or weld lines

and touch-up those areas. Large scratches and gouges

in the galvanized coating should also be repaired prior

to painting.

Complete the surface cleaning and profiling

appropriate for the age of the coating before repairing

the zinc coating. Then the damaged or bare areas

should be touch ed-up with

a product conforming to

ASTM A 780. These include

zinc-rich paints, or cold

galvanizing compounds. Be

sure the surface is even and

consistent after completing

touch-up.

If a touched-up surface

is to be powder coated, wait

24-48 hours before coating

in order to prevent blistering

of the powder coating.

6

7

-

7/24/2019 Paint Guide for GI Steel

6/12

8

9

3

Step 3 Clean the Galvanized Surface

The goal of su rface cleaning is to remove the

grease, dirt and oils from the galvanized surface in

order to promote paint adhesion.

If it is determined the galvanized surface needs to

be cleaned, any of the methods listed below can be

used. Remember, a cleaning solution is meant to clean

the zinc surface, not remove it. Some cleaners may

react poorly with certain paint systems. Be sure to

consult the paint manufacturer regarding specific

cleaning instructions.

Alkaline solutions in the pH range of 11-12, but

not greater than 13, (dilute sodium hydroxide,

trisodium phosphate or similar solutions) can be

sprayed at a temperature ideally between 140 F

and 185 F. If the solution is brushed on, use a

nylon bristle brush not copper or steel. After

cleaning, thoroughly rinse with hot water and allow

to dry completely.

Newly

Galvanized

Steel

No dirt or grease present.

Few zinc oxides and

hydroxides formed. No major

cleaning necessary.

Remove surface oxide and

hydroxide film, as well as dirt

and grime.

Requires minimal cleaning,

such as a warm water power

wash to remove contaminants

from the surface. Power wash

should not exceed 1450 psi.

Clean dirt and other surface

contaminates from previously

painted areas.

Maintenance

Painting of

Duplex

Systems

Partially

WeatheredGalvanized

Steel

Fully

Weathered

Galvanized

Steel

-

7/24/2019 Paint Guide for GI Steel

7/12

Solvent cleaning (mineral spirits, turpentine,

high-flash naphtha, or similar solvents) should be

used only if they can be applied with lint-free rags

or soft bristled nylon brushes. These rags and

b r u s h e s

must be

c h a n g e d

frequently to

avoid the re-

spreading of

contamnants.

A f t e r

c l e a n i n g ,

t h o r o u g h l y

rinse the

surface withhot water and

allow to dry

completely.

Ammonia cleaning, which should be used in a

solution of one to two percent ammonia, is

usually only used when ash residue from the

galvanizing process is present. Apply the ammonia

solution with a nylon brush. After cleaning,

thoroughly rinse the surface with hot water and

allow to dry completely.

1

1

Thorough

rinsing

ensures

that

leftoverresidue

from the

cleaning

solution

will not

interfere

with

paint

adhe-

sion.

-

7/24/2019 Paint Guide for GI Steel

8/12

4

Step 4 Surface Profiling

To promote paint adhesion, the profile of the

galvanized surface can be slightly etched. In order to

raise the surface profile, some of the zinc coating is

removed. Be very careful to remove as little zinc as

possible.

If the galvanized coating needs to be profiled, one

of the following methods can be used. When using a

chemical process, check with the paint manufacturer to

make su re it wont interfere with paint adhesion.

Sweep blastingis the most common way of profilinggalvanized steel. Particle size for a sweep blast of

galvanized steel should range between 200 and 500

microns (8-20 mils). Aluminum/ magnesium silicate can

be used to sweep blast, as can many types of natural

media like corn cobs, walnut shell, corundum,

limestone, and mineral sands with a Mohs hardness of

five or less. Conditions for sweep blasting are

recommended to be less than 50 percent humidity and

a minimum of 70 F. Consult SSPC Surface Preparation

Specification 7 for sweep blasting procedures.

1

1

Typically very smooth, will

benefit from profiling. Sweep

blasting while still warm (175-

390 degrees F) works well.

Benefits from some surfaceprofiling.

Fully formed zinc patina. The

profile is generally ideal. No

surface profiling is needed.

For spot repainting, no sur-

face profiling may be required.

For entire repainting, sweep

blasting may work best. Do

not remove too much zinc.

Newly

Galvanized

Steel

Maintenance

Painting of

DuplexSystems

PartiallyWeathered

Galvanized

Steel

Fully

Weathered

Galvanized

Steel

-

7/24/2019 Paint Guide for GI Steel

9/12

1

1

Penetrating sealers are two-part epoxy

systems, applied approximately two mils thick.

They have been used as a su rface treatment on

difficult to clean su rfaces. Follow manufacturers

directions and always use a topcoat.

Wash primers should be applied to the

galvanized surface at a thickness between 0.3 and

0.5 mils. Thickness above 0.5 mils causes

adhesion problems. Because of this, wash primers

are best applied in shop conditions. Follow

manufacturers directions for maximumperformance.

Acrylic passivation products should be applied

approximately 0.04 mils thick to a clean galvanized

surface. The coating should be completely dry

before painting.

Zinc phosphate treatments have been shown to

increase both paint adhesion and durability. They

can be applied by immersion, spray or soft bristle,

nylon brush. Only leave the treatment on the

galvanized steel between three and six minutes.

Follow this with a clean water rinse and let dry. Do

not use phosphate treatments in conjunction withzinc-rich paints.

-

7/24/2019 Paint Guide for GI Steel

10/12

Using Primers with Prepared Galvanized

Steel

After cleaning and profiling the galvanized su rface,

a primer coat is often used to help with paint adhesion.

Many types of paints react poorly when applied directly

on zinc coatings. Primers allow for the successful use

of many of

these paint

types. Zinc-

rich paints

have a great

track record

and can

often be

used as aprimer.

P r im ing

of galvanized

s u r f a c e s

should be done as soon as possible after cleaning and

profiling. Because the zinc coating continually reacts

with the environment, zinc oxides and hydroxides

begin to build-up right away. Always apply primers

according to the manufacturers directions and

specified paint system.

1

17

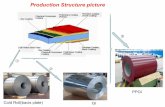

Duplex

System:

Hot dip

galvanized steel

Zinc-rich primer

Acrylic top coat

-

7/24/2019 Paint Guide for GI Steel

11/12

1

1

wears away, the steel will rust if the zinc isnt there to

protect it. If this is the case, then the duplex system

fails. To avoid this problem, be sure to use the correct

media for sweep blasting galvanized surfaces, and do

not blast in one area for too long.

Paint thickness When paint is not applied to

the manufacturers recommended thickness, the

duplex system can also fail. Too thin of a coating, and

the paint will wear away quickly. Too thick of a coating,

and the paint

may not cure

correctly and

cause adhe-

sion prob-

lems. Always

follow the

manufactur-

ers direc-

tions for

application.

Common Failure Problems

Most failures of

duplex systems can

be traced to three

things: poor surface

p r e p a r a t i o n ,

overblasting, orpaint thickness.

S u r f a c e

preparation

Taking the time to

correctly prepare the

surface strongly

contributes to a

good coating. The procedures in this booklet outline

proper surface preparation.

Overblasting When the galvanized coating is

overblasted, too much zinc is removed. Because the

zinc protects the steel from corrosion as the paint

-

7/24/2019 Paint Guide for GI Steel

12/12

When attention and

time are taken with surface

preparation, painting over

galvanized steel will create

beautiful results.

For more information

about hot dip galvanized

steel and its preparation for

painting, contact the

American Galvanizers

Association at

800.HOT.SPEC. For infor-

mation about paint selection and performance with

properly prepared hot dip galvanized steel, contact thepaint manufacturer.

1999 American Galvanizers AssociationThe material in this publication has been developed to provideaccurate and authoritative information about painting over hot-dipgalvanized steel after fabrication. This material provides generalinformation only and is not intended as a substitute for competent

professional examination and verification as to suitability andapplicability. The publication of the material herein is not intended asa representation or warranty on the part of the AGA. Anyone making

f thi i f ti ll li bilit i i f h

2

Tel: 720-554-0900

F ax: 720-554-0909

www.galvanizeit.org