North Carolina WOODTURNER - NC Woodturners Home Page · you started working wood, the lathe was not...

Transcript of North Carolina WOODTURNER - NC Woodturners Home Page · you started working wood, the lathe was not...

North Carolina WOODTURNER Journal of the North Carolina Woodturners Association

A Chapter of the American Association of Woodturners

Volume 9, Number 3 March, 1999

Jack Fruit Bowl By Kevin Bradley, Tryon, NC

2 March 1999

The President’s Message By Edgar Ingram

NORTH CAROLINA WOODTURNER Journal of the North Carolina Woodturners Association

Published Monthly by the

NORTH CAROLINA WOODTURNERS ASSOCIATION, INC Route 7, Box 137, Hendersonville, NC 28791

Editor: Bonner Guilford

1371 Perth Road, Troutman, NC 28166 (704) 332-2149 [email protected]

Contributing Editor: Mark Sakatos

OFFICERS

President: Edgar Ingram, Statesville (704) 876-4576 Vice President: Dean Amos, Sandy Ridge (336) 871-2916 Treasurer: George Wunker, Winston Salem (336) 768-9855 Secretary: Mary Bachand, Hendersonville (828) 890-4451 Programs: Dick Nielsen, Gastonia (704) 864-1742

BOARD OF DIRECTORS John Winslett, Tryon (Term exp. 1999) (828) 859-9863 Lee Holt, Swannanoa (Term exp. 1999) (828) 298-3403 Roy Fisher, Graham (Term exp. 1999) (336) 222-1714 Bill Young, Asheville (Term exp. 2000) (828) 254-0283 Jesse Wilkinson, Conover (Term exp. 2000) (828) 464-8519 Gary Johnson, Statesville (Term exp. 2000) (704) 873-4280 Craig Summerville, Charlotte (Term exp. 2001) (704) 847-2383 J.T. Barker, Hudson (Term exp. 2001) (828) 728-9406 Clyde Hall, High Point (Term exp. 2001) (336) 883-4474

PAST PRESIDENT Jack Stewart, Charlotte (704) 553-1819

I am confident you will agree that NCWA is an outstanding organization of woodturners. One of the things that makes this so is the willingness of the members to pitch in and help with whatever needs to be done. There are so many that I would not attempt to name them all for fear of leaving someone out. I want to say THANK YOU for all that you do to make NCWA great.

For those who do not know Frank Sudol and his work, you are in for a treat at our March meeting. He is a very down to earth person, easy to meet and one of the most outstanding turners today. I have seen his artistry and it is amazing. We may not du-plicate his work, but we can learn from his methods and techniques and apply them to our own work. This is one demonstration you do not want to miss. As usual our February gallery was out-standing but there is room for more. I intend to use my bully pulpit in this space to encourage everyone, and I do mean everyone, to bring your work and show it off. If you have a piece that did not turn out the way you wanted, bring it and ask someone how it can be improved. This is the way we learn and is what makes NCWA great. Time flies when you are having fun and before we know it, November will be here and it will be time for our mini-symposium at Mitchell Commu-nity College in Statesville. Jack Stewart is hard at work getting it organized. Mark your calendar now for the first week-end in November and plan to at-tend. See you Hickory at 10:00am on March 13. Good turning and BRING SOMETHING FOR THE

Edgar Ingram receiving the gavel from Jack Stewart

Treasurer’s Report Beginning Balance…………………………….……$ 4,324.57 Income………………………………… ……….…1,890.26 Expenses…………………………… ………….…..2,248.11 Balance as of January 3, 1999………………...……..$ 3,966.72

It is dues time. Send your check for $25, made out to NCWA, to me at Rt. 7 Box 137, Hendersonville, NC 28791. Dues must be paid by the March meeting if you are to be in-

cluded in the membership directory. Please let us know of any address changes or errors in our records as well.

The February gal-

Member News By Mary Bachand

Natural Edge Hollow Form By Clyde Hall

3 March 1999

lery brought in a lot of conversation pieces to say the least. All 35 turnings were well executed and made a beautiful table arrangement. We would like to thank all the participants, especially the newcomers to the gallery. Those 16 turners were as follows: Grant McRorie, Bill Paschall, Bill Jones, Roy Fisher, J.T. Barker, Don Olsen, Edgar Ingram, David Bowers, Cliff Reynolds, Pat

Campbell, Dean Amos, Tom Fitz, Clyde Hall, Harold Lineberger, John Hill, and Kevin Bradley.

February Challenge. The Challenge was to turn a piece made of composite materials (i.e. segmented turning). The winner was Clyde Hall with a beautiful segmented vase. Clyde will receive a $10 gift certificate for his efforts. March Challenge. Frank Sudol is well known for his thin wall hollow forms which can

be heavily incised with natural patterns. Our March challenge will be to turn an object of your choice and then take away some part of the object to leave a void, pattern, or profile. Surface carving or color can be used as well, so long as there is more than one hole in your hollow form or sculptural piece. This one will be judged on the artistic value of the incised/excised areas to the overall piece. Show off a little. Think outside the box. April Challenge. The footed vessel has been given a raw deal in the past. I think a turned piece with a well exe-cuted foot can give the turning a whole different look. So here is your chance to use your head to turn a foot. Since everyone’s feet look different, the “foot” in this Challenge will be given great leeway as well. Frank Sudol, internationally known turner and artist from Saskatchewon, Canada will be the demonstrator at our

March meeting. He will also conduct a four-day workshop on March 9-12 at the shop of member Ron Burleson in Bessemer City, NC. This is a great opportunity for up to six members to work directly with Frank in an intense learning experience. Up to three more applicants will be accepted on a first come basis. The cost will not exceed $400 per stu-dent. Call Dick Nielsen to reserve your place or for more information.

March 13, 1999 10:00am Ultra Thin Turning Frank Sudol ($25) April 10, 1999 10:00am Using Sorby Tools Keith Rowley May 8, 1999 10:00am Sculpture Stoney Lamar June 12, 1999 10:00am Turning Crotch Wood Todd Hoyer Sorby has informed us through Coleman and The Woodworking Shop that the April demonstrator will be Keith Rowley. Mr. Rowley is the Author of Woodturning, A Foundation Course which many of you know as a fine turn-ing reference. He is also widely known as a fine English woodturner. Be sure not to miss this one.

AAW Announcement East Meets West One feature of the 1999 AAW meeting in Tacoma is a joint exhibition of Japanese and Western woodturning. Fol-lowing the meeting, the exhibited pieces will be shipped to Japan for display at their national turning festival in Na-rugo, Japan. The 20-25 Western pieces will be selected through a juried process with submissions due by April 1, 1999. Each artist may submit three pieces for consideration in slide form. This is a chance to exhibit internationally and gain tremendous exposure for your work. Details and application forms are available from Mary Lacer at AAW or in the Winter issue of American Woodturner. At our last meeting, the membership of NCWA approved the sale of our Woodfast lathe and Delta bandsaw with the

proceeds going toward the purchase of the Oneway lathe from The Woodworking Shop. This will be accomplished with the following process. The board will establish a minimum desired price for each item. Members will have priority in the bidding process and may submit sealed bids to Jesse

Wilkerson. Bids will be opened by the Board at our March meeting. The highest bid above the minimum will be successful for each item. If no bid reaches the minimum, then the process will be opened to both members and non-members for the following month; bids will be then opened at the April meeting and the highest bid awarded. Woodfast lathe M408-5, 16” swing, 39” between centers, 1hp, 120volt, 5 speed. Includes faceplate, drive and tail centers, knockout, wrenches and toolrests. Current new price $2,895. Delta 14” bandsaw with stand, 1hp, 120volt and dropcord.

Gallery Notes By Dean Amos

Challenge Project By Dean Amos

Coming Events By Dick Nielsen

For Sale

4 March 1999

Don Olsen and the “Natural Edge Vase”

What inspires you to turn wood? Maybe you are an advanced home hobbyist who previously built beautiful and highly functional reproduction furniture? Perhaps you built jewelry boxes or a dovetail joint cradle for family and friends. Maybe you’ve constructed all of the above, yet your motivation came

from the quest for the almighty dollar. After all we all have to make a living. You are the professional. However you started working wood, the lathe was not likely the first, second or even the sixth power tool you acquired. The acquisition more likely occurred as an inevitable growth in experience while constructing a Windsor chair, country kitchen table or pencil post bed. Perhaps you became disenfranchised with the need for extensive planning and pre-cision involved in woodworking generally. You may have been searching for a way to express your love of wood in a more free form manner. Even so, you weren’t thinking about bowls, goblets, urns, vessels or boxes. You’d never considered keeping a chain saw in your vehicle “just in case” you spied a glorious burl or some other fine specimen of green wood. In fact, until you started coming to these meetings you’d never heard the word burl. And be honest, how many meetings did you attend before you mustered the courage to ask someone to tell you what green wood was?

But it happened. However you started out, you became drawn to woodturning. You probably own a lathe or are considering the imminent purchase of one. You’ve studied the available woodturning books and videos, or attended course at a folk arts school or community college. You’ve read the February 1999 Journal with increasing interest, in particular, the article graciously written by Don Olsen, by way of introducing his February demonstration Aspire to Inspire. Finally, you’ve made it to a meeting of the North Carolina Woodturners.

On behalf of the North Carolina Woodturners, I would like to thank Don for his preparation and execution of an informative and highly inspirational program. From the beginning of his slide show through his demonstration of special tools and techniques used to turn a natural edge vase, the attendees were treated to a fine example of what motivates one man to turn. In Don’s work we sense his appreciation of and continuing love affair with wood. Its color, its feel, its grain and figure, and the mystery that accompanies each journey into its depths, they are all part of what draws men and women to turn. I hope they moved and inspired you as well!

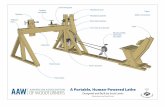

Don’s “Natural Edge Vase” In selecting his log, Don approximated the desired diameter and length of the finished piece to determine the blank’s dimension. He pays particular attention to the figure and contour of the top edge. Whether or not he envisions the bark remaining on the finished piece, he more often leaves the bark on during turning to help support the wood fibers at the edge. Between centers he prepares the bottom to be mounted on a faceplate. The workpiece is then remounted with the faceplate and the tailstock. It is then turned to a cylindrical shape, leaving 2-3 inches of bark at the top. He begins turning the outside, approximating the desired shape of the vase, and continuing to leave

the 2-3 inches of bark at the top. Then the top is turned, approxi-mating the distance inside of the top out to the widest edge of bark. As he removes material he leaves a support column of wood 1 to 1 ½” diameter in the center for tail-stock support. When he hollows into a deep vase he often utilizes a morse taper extender. Don fin-ishes turning the outside, remov-ing some of the bark to the desired outer diameter. Using a special ¼” machine tool bit that has a

flute ground with a Dremel tool, Don shapes the inside to a final wall thickness of about 1 to 1 ½”. Once the tailstock or support column are in the way he removes them. Hollowing depth should be monitored carefully, leaving sufficient buffer be-low the desired bottom depth to allow parting the piece clear of the mounting screws. He power-sands on the lathe at low r.p.m.’s. The bottom of the inside is sanded with a sanding drum on an extension arbor. The top of the inside

February Program Review By Mark Sakatos

Before

After

5 March 1999

is sanded using a Sioux “keyed type” 55-degree close quarter drill and interchangeable sanding disks. While the keyless versions are easier to change to varying diameter disks, the keyless mechanism adds 1 ¼” length from chuck to rear of head, rendering it more diffi-cult and dangerous to power sand the vessel’s inside. He takes great care when sanding the irregularly shaped natural edges. Safety is the primary factor, but the desire to achieve a crisp clean edge is important as well. A balanced stance and deliberate move-ments are crucial. Therefore, he sands from the vase body to the edge only, and is careful to avoid rounding over. Once sanding is completed, the workpiece is parted from the waste block and dried in one or two paper bags for a couple of weeks, or until it stops loos-ing weight. Don’s preferred finish is Watco. The special tools Don uses greatly enhance the safety and proficiency with which he hollows. They are truly something to see. The first has a boring bar that is ¾” diameter and 18” long. It holds a ¼” machine tool bit at varying angles or straight out. The bar is set 4 ½” into its 27” long wooden handle. The second tool also utilizes the same machine bit/handle configurations, but its boring bar is 7/8” diameter and 30” long. Finally, Don has a tool constructed of a 6’ long by 1 ½” square tube. The tube holds the ¾” boring bar previ-ously mentioned. It is used for deep hollowing. To aid in stability, Don uses two tool rests with this tool. The one nearest the workpiece has an upper containment bar. The rear toolrest supports the 35-lb. bar and is adjusted to maintain his desired angle of cut in the bottom left quadrant of the vase.

Beautiful work Don! While Sioux Tool Inc. and Milwaukee Electric Tool Corp. sell various models of the close quarter drill, each of their lines are

manufactured by Sioux. They are variable speed, reversible and come in varying speed ranges to accommodate your torque require-ments. The low r.p.m. models are perhaps more appropriate for our intended use. Milwaukee model #0375-6 and Sioux model #8000 have keyed 3/8” chucks and run from 0-1300 r.p.m. ; Milwaukee #0379-1 and Sioux model #8050 have keyed ½” chucks and run from 0-750 r.p.m.s; Milwaukee model #0380-1 and Sioux model #8030, have 3/8” screw drill with keyless chuck, 0-1500 r.p.m. ; Sioux model #8035 has a keyless 3/8” chuck that runs from 0-2500 r.p.m.

The heaviest snow fall of the year, to date, happened on Tuesday after-noon and night, February 23rd. It was reported that at some places in Gas-tonia, NC it was as much as one-half an inch deep! Caught in this set of circumstances, Uncle Buford elected to camp in front of a log fire in the privacy of his home. Others charged forth to Graham, NC for a visit in

the home and woodturning / woodworking shop of Roy and Pat Fisher. For those who have not located or visited 3267 Boywood, (one word, not two), Road, Graham, NC 27253, 1(336) 222-1714 or 222-8281, you should call ahead and get driving instructions. Otherwise you may drive around in Alamance County for a while. Take exit # 147 off I-40/I-85 onto NC highway # 87, south, toward Pittsboro, NC. Go about 4 miles, turn left onto Boywood Road. Go 1 mile and you are in front of the Fisher residence.

Hospitality in the Fisher home is first rate, even before a visit to the two-car garage shop which has never housed a motor vehicle. Roy has established his priorities involving car care vs. tool care. Vehicles come second. Roy has many turnings which Pat has marked “NFS”, (not for sale). There is a very interesting story that goes with most turned objects in the “Fisher Gallery”. They have also collected a number of turnings made by well-known turners they have met over the years.

Roy’s shop is as much a woodworking shop as a shop for woodturning. This is the result of his wide and varied interest in working with wood. However, the most used machine is his lathe

A VISITOR IN THE SHOP

6 March 1999

and the many jigs and fixtures he has made or has had made by his local machine shop friends. One jig of special note is a stabilizer he uses when turning platters. See pages 5 and 6 of Volume 9, Number 2 – North Carolina Woodturner, (February, 1999).

To give you an idea how much support Pat gives Roy in his woodturning pursuits, see page 2 of Volume 8, Number 9 -- North Carolina Woodturner, (September, 1998). He has purchased a mini-lathe for her to use as she also gets into the world of sawdust. There are no “His” and “Mine” signs on the lathes, YET!

Roy is a new member of the Board of Director of NCWA. He is also an active member of Triangle Wood-turners of NC. It is evident he is a productive person who is involved in the life of our Associations. Many thanks, Pat and Roy, for allowing us to get a little better acquainted and thank you for your hospitality.

the visitor (and uncle Buford, wherever you are) John C. Campbell Folk School has generously awarded NCWA with a ½ scholarship to be used during 1999. For those interested, please attend the March meeting and put your name in the hat. The lucky winner will be drawn during the raffle.

Nichols lathe with 37” swing and 24” between centers. 12 volt variable speed, foot switch, indexing, Oneway tailstock, massive steady rest (Sondy style) and many ac-cessories. $3200 complete. Also, Stronghold chuck with extra jaws, $250, Record

CL3 lathe with 12” swing and 48” between centers, heavy stand and accessories, $500. Other turning tools and pro-ject supplies are also available. Call Martin Stevens at 828-669-2846.

Jet variable speed lathe (model no. JWL 1236) 12 inch swing, 34 1/2" between centers, 3/4 hp., swivel head, all standard accessories. Like new, used approx. 100 hours. 600 lb. steel and wood topped base included. Price $350. Contact Gene Whitesides at 704-732-1753 between 4 and 9pm.

8/4 FAS Red Oak lumber, air dried, 6”-14” widths, 8’ long, $2.75/b.f. Call Dean Amos at 336-871-2916.

Arrowmont's 1999 Summer Wood Workshops

June 7-11, Betty Scarpino, WOODTURNING June 14-18, Todd Hoyer, WOOD AND ITS RELATIONSHIP TO THE TURNED VES- SEL June 14-18, Haley Smith, WOODTURNING SURFACE TREATMENT: TEXTURING THE TURNED FORM June 21-25, Michael Lee, WOODTURNING CARVED VESSELS June 21-25, Gary Rogowski, DOORS & DRAWERS IN SMALL CABINETS: IT'S WHAT'S INSIDE THAT COUNTS June 28-July 9, Kim Kelzer, SURFACE EMBELLISHMENT / FURNITURE ENHANCE MENT June 28-July 8, Stoney Lamar and Steve Loar, MULTI-AXIS TURNING AND ASSEMBLAGE July 12-16, Jean Francois Escoulen, THIN WOODTURNING AND MULTI-AXIS WORK July 19-30, John Jordan, WOODTURNING August 2-6, David Ellsworth, WOODTURNING August 2-6, Glenn Elvig, CHAIRS AND TABLES - LET'S GET STARTED August 9-13, Christian Burchard, WOODTURNING: THE SPHERE, ETC. Call Arrowmont for further details and registration information. 423-436-5860

Schools/Instruction

For Sale

7 March 1999

NCW GALLERY

GALLERY Clockwise from top left

Kevin Bradley Bill Paschall Cliff Reynolds Tom Fitz Edgar Ingram

Photos by George Wunker

8 March 1999

NCW GALLERY

Gallery Clockwise from top left

Bill Jones David Bowers J.T. Barker Dean Amos Joe Dobson

Photos by George Wunker