National Defense Defence nationale Maritime Engineering Journal · 2017-03-06 · •*•National...

Transcript of National Defense Defence nationale Maritime Engineering Journal · 2017-03-06 · •*•National...

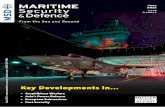

•*• National DefenseDefence nationale

MaritimeEngineeringJournalCANADA'S NAVAL TECHNICAL FORUM

CIMTHAl\lews inside!

June 1999

Photo ContestWinner!Leading Seaman GaryDrainville of Halifax, N.S.snapped this winning portraitof LS J.B.Y. Menard "puttingon a snort" for the last timebefore HMCS Ojibwa's finalsailpast in May 1998.(First Place $150)

Our photo contest brought in50 great photo submissions.Turn the page to see the restof the winning entries.

Also:• Converting TSRVs into Diving Tenders

• Forum: How important is the Divisional Systemto morale?

Canada

The Rest of ourPhoto ContestWinning Entries

"HMCS Edmonton" (Second Place $75)by CPO2 Ken Levert, HMCS Protecteur

"Medevac" (Third Place $25)by CPO2 Doug Morris

(Submitted by PO1 David Ross,CFB Borden)

"HMCS Calgary in Drydock"(Category: Equipment $25)by PO1 David Ross, CFB Borden

"HMCS Ontario"(Category: Ship/Vessel $25)

by Cmdre (ret.) W.J. Broughton, Ottawa

"Damage Control School Esquimalt"(Category: People $25)by MBdr Jon O'Connor, LFCA Headquarters

MARITIME ENGINEERING JOURNAL JUNE 1999 1

MaritimeEngineering JUNE 1999

Journal Vol. 18, No. 2 (Established 1982)

The Maritime Engineering Journal (ISSN 0713-0058) is an unofficial publication of the Maritime Engi-neers of the Canadian Forces, published three times a year by the Director General Maritime EquipmentProgram Management. Views expressed are those of the writers and do not necessarily reflect official opin-ion or policy. Mail can be sent to: The Editor, Maritime Engineering Journal, DMMS, NDHQ, MGenPearkes Building, 101 Colonel By Drive, Ottawa, Ontario Canada K1A 0K2. The editor reservesthe right to reject or edit any editorial material. While every effort is made to return artwork and photosin good condition, the Journal can assume no responsibility for this. Unless otherwise stated, Journal ar-ticles may be reprinted with proper credit. A courtesy copy of the reprinted article would be appreciated.

DEPARTMENTSGuest Editorial: A Change of the Watch

by Capt(N) Gerry Humby ...................................................................................2

Commodore’s Corner: Prefacilitated Contractsby Cmdre J.R. Sylvester ......................................................................................3

Letters ...................................................................................................................... 3

Forum:Engineering Recognition

by Cmdre (ret.) W.J. Broughton .....................................................................4

The Naval Divisional System and its FundamentalImportance to Morale in the Navyby Lt(N) Keith Coffen.....................................................................................5

FEATURESThe Canadian Navy’s Solution to

Simulation-based Command Team Trainingby LCdr Steven Yankowich .................................................................................7

Extended Work Period Management — Principles for Successby Irek J. Kotecki and David B. Jones ..............................................................14

Yard Diving Tenders — A Successful Vessel Conversion Projectby Ed Chan and Lt(N) Gaston Lamontagne .....................................................20

Greenspace:Protecting the Oceans in Future

by LCdr Mark Tinney ....................................................................................22HMCS Fredericton Joins the Solid Waste Management Fleet

by Sean Gill ...................................................................................................23

Ship Signature Reduction in the Canadian Navyby Mike Belcher and Ping. K. Kwok .................................................................24

Year 2000 Ship Readinessby LCdr Richard Gravel and Lt(N) Erick DeOliveira ......................................29

NEWS BRIEFS ...........................................................................................................31

CNTHA NEWS:Newsletter of the Canadian Naval TechnicalHistory Association ..........................................................................................Insert

Director GeneralMaritime Equipment Program ManagementCommodore J.R. Sylvester, CD

EditorCaptain(N) David Hurl, CDDirector of Maritime Management andSupport (DMMS)

Editorial AdviserBob WeaverDGMEPM Special Projects Officer

Production Editor / EnquiriesBrian McCulloughTel. (819) 997-9355 / Fax (819) 994-8709

Production Editing Services byBrightstar Communications,Kanata, Ontario

Technical EditorsLCdr Mark Tinney (Marine Systems)LCdr Marc Lapierre (Combat Systems)Simon Igici (Combat Systems)LCdr Chris Hargreaves (Naval Architecture)CPO1 G.T. Wall (NCMs) (819) 994-8806

Print Management Services byDirector General Public Affairs – CreativeServices

Translation Services byPublic Works and Goverment ServicesTranslation BureauMme. Josette Pelletier, Director

The Journal is available on the DGMEPMwebsite located on the DND DIN intranetat http://dgmepm.d-ndhq.dnd.ca/

MARITIME ENGINEERING JOURNAL JUNE 19992

Looking back, it seems quiteamazing to me that more than 37years have whizzed by, seem-

ingly at the speed of light, since I beganmy naval career as a mere teenage ordi-nary seaman at HMCS Cornwallis. Inthose salad days in what was then theRoyal Canadian Navy, when kit musters,boot polish and parade grounds were mydaily fare, it would have been quite im-possible to imagine that at the end of thisgreat adventure I would be a full navalcaptain, leading a huge and complex or-ganization such as Fleet MaintenanceFacility Cape Scott. I have been privi-leged to share the journey with some trulywonderful people — some of the finestpeople this country has ever produced —and it has been great fun, too (which iswhy, I suppose, the 37 years have passedso very quickly). I am happy and con-tented, and now that I am at this end ofmy career I can confidently report that themarvellous and extraordinary journey hasbeen worthwhile.

The navy I joined in 1961 was a smallerrepresentation of that which saw usthrough the Second World War, but thepeople who were training us had servedin the North Atlantic convoys, and werepassing on the fruits of their hard-wonexperiences. In those days most of thesailors in our ships still slept in ham-mocks, not bunks, and our pay washanded to us on top of our doffed caps.Technology (especially in the field ofelectronics) was a crawling infant, andeven though Sir Frank Whittle had pat-ented his gas turbine in 1930, the idea ofpropelling a warship with an airplane en-gine was still only in gestation. Over theyears I have witnessed enormous changein the navy, and as a sailor, engineer and

officer have even been instrumental inpart of it.

Some of the biggest changes havebeen cultural. As an AB sonarman“maintainer/operator” in the three-yearold HMCS Gatineau in 1962, the chancesof me seeing an officer in the course ofmy daily work were zero. Officers wouldonly be spoken to if they troubled to ad-dress you, and as a general rule theydidn’t. They were in the main unpleas-antly snobbish, and in some cases un-popular with the ship’s company — dis-tinctly un-Canadian. Clearly this had tochange, and of course it did — radically.By the time I was commissioned in 1973,the transition to the wardroom was verypleasant and easy because of the muchimproved social attitude.

The sixties brought many other signifi-cant changes to the navy. On boardHMCS Columbia in 1965, we were half-way across the Atlantic on our way tojoin our NATO cousins in the first Stand-ing Naval Force Atlantic squadron whenwe hoisted the new maple leaf ensign forthe first time. Unification of the Forcesfollowed, and as a navy we gradually dis-tanced ourselves from our Royal Navyroots. By the late sixties we were movingfrom vacuum tube technology to solid-state and digital electronics, and I was inthe thick of it with such uniquely Cana-dian development projects as hydrofoilVDS, ASROC, and AN/SQS-505 digitaldisplay sonar.

Throughout the 1970s and early 80smy career on the waterfront progressedfirst at sea and then ashore through UCSand ADLIPS, after which I went to Ottawato join the Canadian Patrol Frigate Projectin 1983. Dealing with the captains of in-

dustry was indeed an education. I fol-lowed this with a three-year stint asDMCS 2 (Surface and Air Weapons) dur-ing which time we were prime movers inNATO Sea Sparrow, and then it was backto the Coast in August of 1990, just intime for Op Friction. Shortly afterward, thepace began to get really exciting as ourlong-awaited new patrol frigates and mari-time coastal defence vessels started arriv-ing at a breathtaking rate. Not only that,but the navy began a major restructuringashore which saw my own organizationshrink from 2,200 people to 1,100 duringmy five-year tenure. Even more excitingtimes lie ahead as we anticipate the arrivalof the first two Victoria-class submarinesfrom the U.K. next year.

As I close out my own naval career,the message I would like to leave our jun-ior personnel is that your future can bejust as full of adventure, opportunity andenjoyable challenges as mine has been.But you must always remember that “yourattitude is the only difference between anordeal and an adventure.” In my estima-tion our navy has the finest calibre peo-ple, sound leadership, and a fleet ofworld-class warships.

The other day when someone askedme if I had any regrets, I hastily replied,“No.” On reflection, however, as I preparefor the change of the watch, I do haveone regret — that I cannot do it all again.

You have the watch!

[On behalf of the entire military andcivilian naval support community, we wishGerry Humby fair winds and a followingsea. You stood a good watch! — Editor]

Guest Editorial

A personal retrospective by Captain(N) Gerry Humby, CD

A Change of the Watch

The Journal welcomes unclassified submissions, in English or French. To avoid duplication of effort and to ensure suitabilityof subject matter, prospective contributors are strongly advised to contact The Editor, Maritime Engineering Journal, DMMS,National Defence Headquarters, Ottawa, Ontario, K1A 0K2, Tel. (819) 997-9355, before submitting material. Final selectionof articles for publication is made by the Journal’s editorial committee. Letters of any length are always welcome, but only signedcorrespondence will be considered for publication.

MARITIME ENGINEERING JOURNAL JUNE 1999 3

By Commodore J.R. Sylvester, CDDirector General Maritime Equipment Program Management

Commodore’s Corner

Letters

Iwas reading the Maritime Engin-eering Journal today and startedthinking about Cmdre Mack’s com-

ments about the fire on board HMASWestralia (Commodore’s Corner, Feb.1999 ). On reading the Westralia Board of

Inquiry report, I concluded that a) it wasthe best BOI report I’d ever seen, and b)there were a lot of great lessons in itabout engineering practice, and mistakesthat arise from making assumptions(pretty much what the commodore said).

HMAS Westralia Fire:Board of Inquiry report available on Internet

I think it would be a real service to theMar Eng community to publicize the re-port and its website: http://www.navy.gov.au/9_sites/o195/boi/report.htm —Sue Dickout, DMSS 2-4, Ottawa.

Last April’s MARLANT Techni-cal Support Seminar included alively debate on the subject of

prefacilitated contracts (PFCs), now thepreferred support method of the MaterielGroup. Two concerns were tabled: firstthat we, the technical community, are“contracting-out our bread and butter;”and, second, that PFCs represent alter-nate service delivery (ASD) without con-sultation or process.

On the first concern, we must acceptthat the world, industry and governmentpolicy have all changed. The Canadiangovernment “built” this country’s firstrailway, the St. Lawrence Seaway, and soon, but contrast this with the recent con-struction of PEI’s Confederation Bridgeand Ontario’s highway 407. The trend isclear: nowadays, if industry has the re-sources and expertise, industry should dothe work. Government should be as smallas possible, and should “steer, not row.”DND and the CF are no exception. Sinceour downsizing, we no longer have thehuman resources to do as much our-selves, which means we must continue tocontract-out work that is economicallyand effectively delivered by private in-dustry.

In-house we now focus on the “war-rior” aspects of the military role, and onthe “smart customer” activities — design

authority, planning, contract manage-ment, unique services, etc. — which haveto be done in-house. Of course, it wouldbe false economy and frustrating if ourcontract administration were to absorbmuch of the time saved, and this is whereprefacilitated contracts come in. By bun-dling contract work into larger packagesthan in the past (e.g. one PFC to coverhitherto separate contracts for R&O,TIES/FSR, spares, data warehousing, andso on), PFCs should reduce both theamount and cost of contract administra-tion.

The issue, therefore, is not with PFCphilosophy, but with the volume and typeof work to be included in a prefacilitatedcontract. A number of you have sug-gested that downsizing and future con-tracting-out will render us incapable ofbeing a smart customer, meaning that ex-perience in doing some work is a prereq-uisite to proper specification and analysisof contract deliverables. I fully agreethere is a limit beyond which we must notgo if we are to remain capable of offeringknowledgeable analysis and independentadvice to our navy and our government. Iam very conscious of this responsibilityand we will proceed with caution.

On the second issue — PFCs as alter-nate service delivery — it is not our in-tent to bypass the ASD policy if a PFC

affects work currently conducted in-house. In most cases, we are simply con-solidating R&O, supply arrangements,FSR support and documentation servicesthat have already been contracted to in-dustry, but in many separate vehicles.Where a PFC is to include work currentlydone in-house, consultation will takeplace. For incremental new equipment,and even ships like the MCDV, we haveutilized large omnibus support contractsfrom the outset because it made sense todo so as part of a new procurement.

With all of this in mind, I remind youthat the overall objective is to provide themaximum amount of support for everybudget dollar we receive. I simply will notrecommend to CMS or ADM(Mat) prefa-cilitated contracts, or any other contractsfor that matter, which do not achievevalue for money.

Prefacilitated Contracts —Navy is Proceeding with Caution

MARITIME ENGINEERING JOURNAL JUNE 19994

Forum

Icontinue to enjoy reading theMaritime Engineering Journaland appreciate being kept on the

mailing list. I was particularly interested inLt(N) M.D. Wood’s open letter in the Oc-tober 1998 issue. Engineering recognitionis, of course, a long-standing debate andperhaps your readers would be interestedin some personal recollections from whatis becoming the distant past!

Maritime engineers have come a longway since 1964. That was just two yearsafter I completed my naval architecturaldegrees at M.I.T. You can imagine myconsternation when the navy consideredestablishing a restricted duty list on therecommendation of the Tisdale Report,according to which any officer with a PGdegree would be too specialized to riseabove the rank of commander! I submit-ted my concerns and a rebuttal quotingthe M.I.T. calendar which specificallystated that the purpose of postgraduatestudies was to broaden (and deepen) thestudent. If integration had not comealong, the intended policy would have

I can now confirm, after consultingMacPherson’s “Ships of Canada’sNaval Forces” that it is definitely

not the Algerine-class minesweeper

gone into effect. And, on reflection, I amsure that I would not have stayed in thenavy for 37 years.

When I was sent on Course II of thenewly integrated Staff College in Torontoin 1967, I pursued my interest in the sta-tus of engineering within the service byselecting, “Dual-professionalism in theCanadian Armed Forces” as my majorpaper. Three particular groups were exam-ined. It is important for clarity to knowthat I applied the term “specialty/special-ist” to all officers (i.e. we are all officersfirst and then have a particular specialty).

I concluded that the first group, con-sisting of doctors, dentists, lawyers andchaplains, enjoyed a civilian view of theirdual-professionalism in the CF, which wasvalid considering they were almost com-pletely divorced from the prime warriorfunction of integrating available man-power and equipment into an effectivefighting system. Hence, the policies of thetime — particularly with respect to profes-sional pay for doctors —were considered

to be valid. Little has changed for themsince then, other than to put them on thethree-phase career employment scheme.

The second group I examined was airforce officers. At the time they receivedextra pay throughout the rank structureeven if they were flying a desk and onlyputting in minimum hours to maintaintheir flying qualification. (Needless to sayI took a dim view of this.) I concludedthat their dual-professionalism was dipo-lar, in that they received most of the ben-efits of both the civilian and warriorapproaches to dual-professionalism.Hence, I wrote, “Both pilots and naviga-tors must come under similar approachesto their professionalism as do engineers...flying pay must be eliminated except asa risk pay when on flying duty, and statusand career opportunities must be equal-ized between pilots and navigators andbetween aircrew and other specialists.” Ineffect, I was saying that their professionalobligation to be professional in the war-rior role was no different from the obliga-tion of engineers in theirs. As an aside, I

Francis in the Navy?

Ihave just been reading the Febru-ary 1999 edition of the Journal,and have noticed what I believe to

be an incorrectly captioned photo. In theHedgehog article on page 20, I think theship depicted is one of the ex-American“four-stackers” named after Canadiancities and rivers: HMC ships Niagara,Annapolis, Hamilton, etc. Definitely notFort Frances, which was an Algerine-class minesweeper.

I do enjoy the Journal very much. Isthere a chance of getting excess copiessent to the Warfare Centre? — LCdrDoug Thomas, Editor of Maritime War-fare Bulletin, etc., Halifax.

fied to look like a German vessel, rammedthe drydock gates at St. Nazaire, thus pre-cluding the use of the dock as an Atlanticdocking facility for German capital shipssuch as Tirpitz.

Given the evidence, I think it is safe topresume the ship in the photo is HMCSSt. Francis. Regards, — Pat Barnhouse,DSTM 3, Ottawa.

HMCS “Fort Francis” (sic) in the Hedge-hog article photo. It is definitely one ofthe Town-class destroyers, as evidencedby its very distinctive bridge superstruc-ture. The lower portion is the configura-tion as per the original build of theseships, and the upper portion is as modi-fied in Canada in WWII.

The Town class in RCN service num-bered eight (among them being HMCS“St.” Francis). These ships were a por-tion of the 50 ships transferred from theUnited States to the United Kingdom dur-ing the fall of 1940 in the “destroyers forbases” deal (Argentia, Bermuda, etc.) tohelp the RN close the gap in escort shipnumbers until sufficient corvettes (andlater, frigates) could be brought into serv-ice. Perhaps the most famous of these“four-stackers” was HMS Campbeltownwhich, loaded with explosives and modi-

[A good eye, gentlemen – the four-stackerHMCS St. Francis it is indeed! A case ofmistaken identity on the part of yourproduction editor. My apologies to Dr.Douglas, and also to the Directorate ofHistory and Heritage who had correctlyidentified the photo in the first place! —B. McC.]

Engineering RecognitionArticle by Cmdre W.J. Broughton (ret.)

Letters

MARITIME ENGINEERING JOURNAL JUNE 1999 5

drew attention to my discovery that navi-gators were even worse off than engi-neers in terms of rank status. Strengthfigures showed 73 percent as many navi-gators as pilots overall, but only 10 per-cent as many generals.

But what about engineers? First, I ar-gued against the then recent thinkingwithin the navy to train all officers (in-cluding engineers) for command at sea.For most, I said, it was “an unattainablemyth and an unnecessary requirement.Dual-professionalism of all specialistsmust be based on professional ability inonly one specialty, be it engineering orthe management of violence, coupledwith an underlying professionalism interms of motivation to the service.” As faras treatment was concerned, I noted thatengineers fell into two subgroups — “thetraditional military engineers and gunneryspecialists who had a consistent warriortreatment of their dual-professionalismbased on their long history and their inti-mate association and training for the con-duct of battle,” and “the variety of newengineers which have emerged in thetwentieth century...whose status, employ-ment and career opportunities failed to re-enforce either a warrior view or a civilianview. The result was considered to be aneutral view in that the new engineersderive few of the benefits and most of thedisadvantages of both the warrior andcivilian approaches to dual-professional-

Forumism.” Again you will notice that I calledthe warrior group a specialty, too, in aneffort to seek more parallel treatment inpersonnel policies. Such an approach, Istated, meant unprejudiced personnelpolicies, including the following for theengineering group in particular:

a. no extra pay;b. equal opportunity for promotion to

all billets not requiring a warrior expert;c. realistic job requirement specifica-

tions and posting opportunity, particu-larly with respect to opening up certaintraditional warrior billets which need notbe restricted to the warrior group (person-nel being an outstanding example);

d. promotion percentages in terms ofnumbers and time-in-rank on par with thewarrior group; and

e. staff training percentages on parwith the warrior group.

Although at the time I thought I was“whistling Dixie,” I think it is fair to saythat much was redressed, not that I hadanything to do with it. The navy in its wis-dom adopted a “Best Sailor” approach,largely due to the foresight of vice-admiralsJock Allan and Chuck Thomas, andCmdre Ray Ross. Flying pay was changed,although probably more for budgetaryreasons than for considerations of soundpersonnel policies, and “any” positionswere worked into the preferred manninglists of engineering classifications. I my-self enjoyed my five years in personnel

almost as much my time in engineering,and it certainly aided my career. I hardlysee “purple jobs” (we used to call them“green jobs”) as diluting one’s engineer-ing professionalism as Lt(N) Wood sug-gests. The question of extra pay willalways reappear, but I still believe MAREswould lose far more than they would gainby taking that route. The quid pro quowould undoubtedly be limitations on bothjob and promotion opportunities.

Finally, I see the question of profes-sional registration as a matter of personalchoice. In my experience we were alwaysencouraged to join appropriate profes-sional associations such as the Society ofNaval Architects and Marine Engineers,the Engineering Institute of Canada, theAssociation of Professional Engineers ofOntario, etc. Senior officers, military andcivilian, were always willing to endorseour qualifications. Lt(N) Wood’s letterbrought back many memories. It is goodto see junior officers taking their MARErole and their professionalism seriously,and being prepared to speak out on suchan important and personal topic.

Cmdre W.J. Broughton retired from thenavy as DGMEM in 1990.

Ihave chosen this moment to writean article for the Maritime Engi-neering Journal because the navy

has begun to encounter significant diffi-culty in retaining properly qualified andexperienced CSE technicians. As I under-stand it, last year there were 36 unplannedreleases of NE Techs and 13 unplannedreleases of NW Techs from the WestCoast alone. At the Eastern Region NavalTechnical Support Seminar held at the endof April, Cmdre Davidson and Cdr Bell ofDGNP presented a bleak outlook for alltechnical trades on both coasts, as man-ning shortages are expected to continuethroughout the next five to, possibly, ten

years. Manning problems are not uniqueto the combat systems MOCs, and workis needed virtually everywhere in thenavy to ensure these occupations do notbecome more critical than they alreadyare. Certainly, the recent pay raises andthe proposed cost of living allowance willhelp to resolve some of the problems, butthere is more to do than simply throwmoney at the problem.

It is my belief, confirmed to someextent by discussions with the sailors inHuron, that more important to our sailorsthan pay — is leadership. Our leadership,especially at the junior officer level, needs

to improve. The divisional system is a keyleadership tool, yet in my opinion it issuffering as a result of inattention fromthe officers who are supposed to lead it.

I will preface my remarks by sayingthat my views have been formed from arelatively short, four-year period of obser-vation, and it may be that many of youwho have the benefit of greater experi-ence will disagree with my point of view.So be it. My intent is less to convinceeveryone that the navy is in dire straitsthan it is to prompt discussion about thedivisional system among the officerscharged with its upkeep.

The Naval Divisional System and its FundamentalImportance to Morale in the NavyArticle by Lt(N) Keith Coffen

MARITIME ENGINEERING JOURNAL JUNE 19996

ForumThe Divisional System

I recently read a book by historianDavid Bercuson, entitled “SignificantIncident” [McClelland and Stewart, 1996].While his book focuses primarily on thearmy and its leadership challenges, some-thing he said struck me as appropriate tothe navy also:

Problems with family life, difficultieswith career management systems,complaints about poor equipment,and gripes about officers andNCOs…are a normal part of army life.When soldiers believe that theirleaders...care about them and appre-ciate their sacrifices, the complaintsmean little.

It is my view that the divisional systemis of paramount importance to the navybecause it is our demonstration of suchcare and appreciation. The purpose of thedivisional system is to foster loyalty tothe navy and to build the morale of oursailors by seeing to it that their concernsas individuals are met. In the absence of aproper measure of care applied to the wel-fare of our sailors, morale begins to de-grade. The ultimate manifestation of suchdegradation would be mutiny, like thosewhich prompted Admiral Mainguy to rec-ommend that the navy institute the cur-rent formalized system for the welfare ofour sailors. Today, however, it is muchmore likely that degraded morale will re-sult in sailors simply walking away fromthe navy, or taking on an “eight to four”attitude, both of which are essentiallywhat we are seeing. For those of us whowould blame that on the sailors, I offerthese words from Gen. Jacques Dextraze(CDS, 1972-77) who once said, “There areno bad soldiers — only bad officers.”

Reduced morale degrades our capabil-ity as a navy to accomplish any givenmission by robbing us of people, or byreducing the willingness of people towork to their full potential. Morale mustbe a fundamental concern for any leaderwith a mission to accomplish, and the di-visional system is the naval leader’s toolfor building morale.

As I see it, there are three key elementsto the proper application of the divisionalsystem:

a. Being available at all times to hearthe concerns of our sailors;

b. Allowing the sailors to speak, andlistening carefully to what they have tosay; and,

c. Acting in their best interest, regard-

less of the burden we assume by doing so.

I have observed officers fail to meetone or more of these general principlesregularly throughout my brief career. Weare busy people, and it often seems unde-sirable to take time out to deal with prob-lems that seem to have no immediateimport. We need to remember that failureto deal promptly and satisfactorily withsuch concerns will have a cost in terms ofthe regard our sailors hold for us. There isalways off-duty time to catch up on workthat may have shifted to the right as aresult of a divisional matter. Officersshould be prepared and expected tospend that time.

The proper application of the divisionalsystem is more important to us than anytechnical issue we might ever face. It has,however, been my observation that manydivisional officers have a tendency tohold the divisional system as a subordi-nate concern to “their real job,” which isviewed as strictly technical, or in the caseof our MARS brethren, strictly opera-tional. I think it should go without sayingthat no matter how good an engineer ortactician we may be individually, we runthe risk of being unable to accomplish ourmission by not demonstrating strongleadership. Strong leadership builds mo-rale and a genuine desire to accomplishthe mission in the hearts and minds of oursailors. There is more to leadership thansimple technical or operational skill. Cer-tainly to win the respect and trust of asailor, an officer must excel in his or herarea of expertise, but this is not enough.Officers must also concern themselveswith, and be very visibly seen to be con-cerning themselves with, the well-beingof the teams they lead, without whom themission would either not be accomplished,or would be accomplished at greater fiscalor human cost than necessary.

I have attended three of the so-called“junior officer” symposia, now, and whileeach meeting was more than three hourslong, not one minute of that time wasspent discussing issues that affect oursailors. Instead, we tended to focus in-ward on a steady stream of complaintsabout promotions, pay, and ORO or HODselection. I am as guilty as anyone else inthis matter, having rationalized that theforum was really for junior officer issuesand that it would not have been appropri-ate to raise other concerns. Lately, how-ever, I have begun to ask myself howoften, as junior officers, we get access to

DGNP or any other element of the Person-nel system. In reality, we have in thosemeetings an ideal forum in which to airsome of our concerns for our sailors. Wehave an obligation as officers to focusmore of our attention on our sailors andless on ourselves, whatever the perceivedpersonal costs may be. While the con-cerns are raised by and for junior officersduring these meetings do have validity, Iquestion whether the voices complainingmost loudly about promotions and so-called “deep” selection are in fact thosemost deserving of either promotion orselection. By complaining so loudly aboutour own problems, we demonstrate a cer-tain blindness to the basics of leadershipand our responsibilities as officers — ourships, our men, ourselves, isn’t it?

ConclusionThe divisional system is one of the

things makes the navy unique. It is notfound in private industry, and the reasonfor this, mutinies aside, is that the navy is(or is at least supposed to be) comprisedof better leaders than would be found inthe average private company. The divi-sional system is a formal demonstration ofour concern for our sailors and our com-mitment to their well-being. It is a guaran-tee that we will put their concerns aheadof our own. The divisional system, whenproperly applied, will win loyalty andbuild morale, which is of course what itwas designed to do.

Junior officers have a vital role to playin upholding the divisional system andusing it to serve the needs of their sailors,thereby setting a positive tone in the day-to-day working environment in the fleet.We are, in an era of scarce resources andincreasing workload, as pressed for timeas anyone, and it does indeed require agreat deal of effort to make time availableto every member of our division. The factremains, however, that this is our duty.Officers are officers not because of theireducation and training, so much as be-cause of their greater commitment to dutyand their ability to lead. We need to askourselves regularly whether or not we aredoing the best job we can for our sailors,and act according to the honest response.

Lt(N) Coffen was, until recently, theAssistant Combat Systems Engineer inHMCS Huron.

MARITIME ENGINEERING JOURNAL JUNE 1999 7

With the introduction of 12Halifax-class frigates intothe fleet, the Canadian na-

vy’s operational capability has undergonea significant revitalization. To fully realizethe potential of the technology employedby this class of ship, a comprehensiveand modern training system must be es-tablished. The core of an effective navaltraining system is command team training,and the Canadian navy’s OperationsRoom Team Trainer (ORTT) is designed tofulfill this critical role. This paper de-scribes the unique and cost-effective ap-proach through which the ORTT is beingdesigned and implemented.

BackgroundCanada’s Halifax-class frigates employ

a fully integrated combat systems archi-tecture in which all shipborne control,sensor, weapon and communication sys-tems are interfaced to the central com-mand and control system (CCS). The CCSis comprised of 22 AN/UYK-507 digitalcomputers, executing compiled CMS-2software in an SDX real-time operatingsystem environment. The computers aredeployed in a distributed configurationand networked together via a triple-redun-dant, four-channel serial data bus. Theintegrated system performs the functionsof navigation, target detection, acquisi-tion, tracking, classification, threat analy-sis and evaluation, localization andengagement. The system is capable ofautomatic threat response up to and in-cluding weapon firing.

The command information organization(CIO), or operations room team, is com-prised of 11 operator positions (includingthe bridge officer of the watch) which in-terface to the CCS through multifunctiondisplay consoles. The displays providethe principle operator-combat system in-terface and facilitate command of the ship,compilation of the tactical picture andcontrol of the ship’s sensors and weap-ons.

The ORTT is required to provide CIOteam training in command, control, com-munications and intelligence for anti-sub-

The Canadian Navy’s Solution toSimulation-based Command TeamTrainingArticle by LCdr Steven Yankowich

marine, anti-surface and anti-air warfareoperations in a realistically simulatedmultithreat, multiplatform time-stressedenvironment. It must present dynamicsimulations of tactical engagements toexercise the team in picture compilation,procedures, operations and the executionof tactics in a variety of simulated sce-narios which may occur during peace orwartime conditions. To satisfy the train-ing requirement, the ORTT must be capa-ble of providing simulated natural andtactical environments necessary to sup-port operator interaction with high-fidel-ity communication, sensor and weaponsystems (Fig. 1).

Simulation RequirementsThe ORTT must provide a realistic

training environment in which the full CIOteams for two independent Halifax-classships (herein referred to as “cubicles”),accessing a common scenario, performtheir individual and collective processesthrough interaction with simulation-driven equipment systems which accu-

rately reflect actual shipborne commandand control system functionality. Specificsystems requiring high-fidelity simulationinclude:

• Radar video — mode dependent ren-dering of contacts, coastline, chaff, jam-ming and environmental clutter;

• Interrogation Friend or Foe (IFF);• Link-11;• Weapon, electronic warfare (EW) and

acoustic systems interface and control;• Fire-control (FC) system interface and

control;• Navigation system interface and cu-

bicle simulated ship (ownship) control;• All operations room panels and dis-

plays;• Integrated internal/external communi-

cations system, including all transceivers;and

• Visual rendering of the simulated ex-ternal environment to the OOW, includingvisual display of contacts, coastline, seastate and other environmental conditions.

Fig. 1. Simulated Ship’s Tactical Environment

MARITIME ENGINEERING JOURNAL JUNE 19998

Trainer Control RequirementsTrainer control is required to support

scenario generation and execution, opera-tional environment simulation, and realtime monitoring of the CIO team perform-ance in each cubicle. Trainer control func-tionality is comprised of three roles:instructor, support station operator, andgamepiece operator.

Instructors must have the ability tomonitor the actions of all CIO members inboth cubicles, with any four positionsbeing monitored simultaneously. Instruc-tors will use this monitoring function tolisten in real-time on any communicationcircuit; view in real time the tactical pic-ture compiled at each CIO member sta-tion; and witness in real time eachmember’s interactions with panels anddisplays. In addition, instructors musthave the capability to dynamically inter-act with, control and change the scenario

being executed. Prior to a training exer-cise, instructors must be able to script ascenario, allocating roles, tasks andevent-dependent behaviour to selectedgamepieces.

Support station operators fulfill therole of the ships’ fire-control, electronicwarfare, acoustic warfare, and ship con-trol subteams. They must exchange infor-mation with the CIO team via the internalship communication nets, configure thesimulated weapon and sensor systems inaccordance with the direction of the CIOteam; and with the aid of semi-automaticdetection models, input track data to theappropriate cubicle CCS.

Gamepiece operators control themovements and actions of individualsimulated gamepieces. They must havethe capability to participate in externalcubicle communication nets and dynami-

cally interact with the cubicles’ CIO teamsas either a neutral, friendly or hostile ele-ment. Gamepieces not specifically control-led by gamepiece operators must behavein accordance with scripted, event-drivenbehaviour.

Debrief RequirementsSelected portions of monitored data

(both voice and visual) must, at the in-structor’s discretion, be recorded duringthe execution of a training session. At theconclusion of the training session, theinstructor must be able to compile andexecute an integrated debrief whereby allthe recorded data is played back in a for-mal instructional setting.

Scaleability/WAN RequirementsThe ORTT must be scaleable to in-

clude additional cubicles situated in dis-parate geographic locations. To expandbeyond intracubicle training, it must be

Fig. 2. ORTT Network Topology and System Architecture

MARITIME ENGINEERING JOURNAL JUNE 1999 9

compatible with other simulation systemsemploying the Distributed InteractiveSimulation (DIS) standard.

ORTT System DesignThe ORTT design incorporates a dis-

tributed network architecture and coresystem functionality largely consistentwith similar in-service trainers. This func-tionality is broken down into the follow-ing subsystems (Fig. 2):

• Cubicle simulation (trainee interface);• Link simulation;• Scenario generation and control

(SGC); and• Communication simulation.

In addition to the functional require-ments (scope), the ORTT design team wasconstrained by established parameters ofquality, cost and schedule performance.Although cubicle fidelity to the actualship system was the primary factor in thedetermination and selection of candidatesolutions, more design flexibility was allo-cated to the scenario generation and in-structor interface requirements. Eachdesign choice was ultimately evaluatedon the basis of the following criteria:

• Risk (technical, and schedule);• Cost;• Reliability, availability and maintain-

ability; and• Life-cycle support.

Commercial off-the-shelf (COTS) prod-uct-driven solutions, integrated in strictaccordance with the open architecturemethodology, were incorporated into theORTT system to the maximum extent pos-sible (as dictated by the requirements).This approach facilitated the implementa-tion of a standards-based system with aconfiguration of software and hardwarethat was flexible, accessible to a widerange of designers/developers, widelysupportable, and more cost-effective to

implement than military-standard compli-ant systems of similar complexity. Wher-ever possible, new software was devel-oped using POSIX-compliant C++ com-piled for execution in a Solaris environ-ment. Network and processing hardwarewere selected on the basis of cost, per-formance and proliferation in the commer-cial marketplace.

Network ArchitectureThe ORTT network topology (Fig. 2)

is based on an open and distributed ar-chitecture consisting of several intercon-nected local area networks (LANs). Thearchitecture incorporates the use of het-erogeneous platforms, layered communi-cation protocols, high traffic isolation anddistributed application software. In-creased flexibility and scaleability are fa-cilitated through the use of multiplerouting pathways and switching devicesequipped with virtual LAN capability.

The ORTT network consists of twoindependent Fiber Distributed Data Inter-face (FDDI) timed token rings of Ethernetswitches. This topology is symmetricalwith two FDDI backbone networks, eachsupporting the dedicated simulation ele-ments for one cubicle (e.g. DIS Gateway,panel system interface, communicationsystem interface) and distributing thecommon simulation elements (e.g. SGC,Link-11). The two dual-attach contrarotat-ing FDDI backbones provide redundancyand increase availability of the overallsystem. The FDDI 100-Mbps bandwidthis sufficient to handle the worst-casebackbone traffic congestion with enoughsurplus bandwidth to enable the additionof a third cubicle. Switched Ethernet pro-vides a mechanism to increase the effec-tive subsystem network bandwidth (sub-system to backbone) to 10 Mbps, whilemaintaining standard COTS adapter cardsin connected hosts. Furthermore, Switched

Ethernet provides the means to effec-tively regulate, monitor and manage LANoperation.

There are three backbone switches inthe ORTT architecture. In addition to pro-viding data filtering and routing capabili-ties between network segments, eachswitch provides two dual-attach FDDIports, six single-attach FDDI ports, and 38Ethernet ports. Each switch provides anintegral FDDI concentrator capability withsingle-attach FDDI connections to thebackbone for selected bandwidth criticalelements (e.g. DIS Gateway, Link-11 node).

Communication (network and/or trans-port layer) protocols for distributed appli-cations hosted across the FDDI andSwitched Ethernet networks are TCP/IP.Between applications, session layer mes-sage communication is achieved usingUNIX sockets for real-time critical applica-tions, and remote procedure calls for allother applications.

Network monitoring and ORTT systemconfiguration and maintenance are con-ducted through a trainer maintenance po-sition executing custom software hostedin a Solaris-based Sun Enterprise 2 stationinterfaced to the network via a SwitchedEthernet connection. Four Dual Ultra-SPARC fileservers, each interfaced to thenetwork via a dedicated FDDI connection,provide the means for file loading, saving,and backing-up the ORTT system toRAID-5 disk arrays.

Cubicle SimulationThe cubicle simulation subsystem pro-

vides the CIO team with the high-fidelityoperations room (Fig. 3) and bridge train-ing environments (Fig. 4). It is comprisedof the eight segments described below.Each segment is hosted in its own envi-ronment and interfaced to the other seg-ments via a switched Ethernet and/or anFDDI network connection.

Fig. 3. Halifax -class operations room Fig. 4. Bridge station (ORTT)

MARITIME ENGINEERING JOURNAL JUNE 199910

1. CCS Software and Hardware. Theheart of the Halifax-class ship is the inte-grated command and control system(CCS). The stringent fidelity requirements,coupled with the large quantity of un-known combinations and permutations ofoperator interactions occurring duringteam training, preclude the ready applica-tion of COTS simulation developmenttools to emulate this system. Conse-quently, it was decided that the best risk/cost solution was to retain the off-the-shelf CCS unmodified software as a fun-damental component of the cubicle simu-lation subsystem.

The unmodified CCS software necessi-tated using hardware which identicallyemulates that deployed in the ship. Therisk and cost associated with the emula-tion of the shipboard UYK-507 computersand serial data bus were substantiallyreduced by rebuilding the required CCShardware to commercial standards usingcommercial power supplies, chip sets,boards, interconnects and chassis. Theperformance and net saving of employingthis “commercialized” hardware was morethan 50 percent. Other CCS componentemulations, such as the trainee displayconsole, were completely redesigned andbuilt using commercially available toolsets and hardware solutions.

2. Trainee Display Console Emula-tion. The primary operator interface to theCCS is facilitated through a multifunctiondisplay console which supports the dis-play and control of all CCS functions aswell as the display of processed radarvideo. The in-service military-standarddisplay console satisfies the ORTT CCSI/O requirement, but the monitoring andradar video requirements render it difficultto integrate into the cubicle simulationsubsystem. Accordingly, a less expen-sive, wholly COTS derived solution wasimplemented.

To satisfy the human/machine inter-face (HMI) fidelity requirements, thetrainee display console emulation chassiswas built, using commercial standardsand products, to replicate the look andfeel of the Mil-Std display console. Agateway application hosted in a VME-mounted Power PC processing environ-ment and employing the VxWorks real-time operating system provides the bidi-rectional interface between the Naval Tac-tical Data System and the CCS. The gate-way is interfaced to a Solaris-based300-MHz, dual Pentium PC which hostsand executes the graphic generation andthe HMI control applications. All HMIevents, graphics and radar video are gen-erated using the X-Window Library sys-

tem. In each trainee display emulation, alocal X-server is used to detect HMIevents and generate graphic/video in re-sponse to X-requests transmitted from aclient. Since X-servers can be either localor remote, active or passive, this ap-proach enables remote instructor stationsto monitor trainee actions by recreating,using X-requests transmitted over thenetwork, the complete graphic/video pic-ture seen by a given trainee. All X-re-quests from all display emulation X-serv-ers are transmitted via a SwitchedEthernet connection across the ORTTnetwork, enabling any instructor to simul-taneously monitor any combination oftrainees.

3. Combat System Simulation (CSS).In addition to the 11 display consoles, theHalifax-class command and control sys-tem has 26 discrete interfaces to theweapons, sensor and operator panel sys-tems comprising the ship’s overall combatsystem. Providing a new high-fidelitysimulation for each of these interfaceswould have required substantial software

development and cost risk. Fortunately, aproven Halifax-class combat systemsimulation (CSS) software/hardware archi-tecture already exists. Used for CCS soft-ware support and lower level team/subteam training, the CSS architectureprovides functionality applicable to theORTT requirement:

• Proven functional I/O to CCS inter-faces;

• Models to support simulation of eachcombat system;

• User interface to control the simula-tion of the combat system equipment;and

• Management of a simulated targetdatabase.

The existing CSS software is compiledand executed in the same processing en-vironment as the operational commandand control system software. The sub-stantial modifications required to enablethe level of simulation and instructor con-trol specified for the ORTT could not beaccommodated within the constraints ofthis legacy environment. Consequently,

Fig. 5. ORTT main menu HMI

MARITIME ENGINEERING JOURNAL JUNE 1999 11

the off-the-shelf CSS software was modi-fied to enhance individual combat systemsimulation functionality and increase thetrack database capacity. Additional simu-lation and all CSS human/machine inter-face functionality were offloaded tocommercially developed software hostedin COTS processing environments distrib-uted across the ORTT network. The CSSand the CCS are interfaced to the rest ofthe ORTT system via a purpose-builtgateway developed and hosted in aCOTS environment and linked to theORTT network via a dedicated FDDI con-nection.

4. Panel System. The panel systememulates the required panels and con-soles used for team training. Panels areeither recreated virtually on a commercialPC, or rebuilt using commercial compo-nents with a micro-controller drivenEthernet interface to the ORTT system.The panel simulations accept input fromthe individual micro-controllers and theCCS (via the DIS Gateway). Depending onthe panel, responses to operator input areprocessed by either the modified CSS orthe new CCS interface simulations.

5. Support Station Simulations. Sup-port stations provide functionality to al-low the training staff to substitute forHalifax CIO members for whom there areno ORTT trainee positions. In the ORTT,support stations are required for ownshipmanoeuvring and control, fire-control/weapon system operation and control,sonar/torpedo system operation and con-trol, and electronic warfare sensor opera-tion and control. Support stations

incorporate semiautomated, system-spe-cific detection and information process-ing functionality that closely replicatesthe behaviour of the actual system. Cus-tom HMIs are used to ease the supportstation operator workload and facilitateefficient transfer of information to the CIOteams. Support station simulation soft-ware is hosted by a Pentium PC runningthe Solaris operating system, and is con-nected to the ORTT network via a dedi-cated Switched Ethernet connection.

6. Master Radar Video Simulation.The master radar video simulation syn-chronizes the associated video contact,land topography and environmental ef-fect databases, and generates the radarvideo picture for each operating mode ofeach of the three search radars. The videopicture generated by the various sensorsimulations is compiled in real-time andtransmitted in the form of X-requests via aSwitched Ethernet connection to eachtrainee display emulation and instructorstation. The processing environment is aSolaris-based multiprocessor SPARC En-terprise 4000 server (one per cubicle)shared with the SGC subsystem.

7. Officer of the Watch (OOW) VisualSimulation. The OOW visual simulationwas developed and implemented by athird party vendor. The system receivesDIS protocol data units (PDUs) from thecubicle simulation and SGC subsystemsvia a Switched Ethernet connection to theORTT system. Gamepiece-specific entitystate PDUs are converted to high-fidelitymodels and rendered in real-time on threehigh-resolution 67-inch BARCO rear-pro-

jection monitors. Land topography (con-sistent with the area of the world in whichthe game is situated), environmental ef-fects and a dynamic sea state are dis-played in conjunction with the gamepiecemodels. Each model is updated 30 timesper second, creating a realistic visual en-vironment.

Consistent with the open architecturedesign approach employing COTS tech-nology, the gamepiece model, dynamicsea-state model and land topography(coastline) visual simulations are createdusing Multigen OpenFlight databases.Real-time rendering software is OpenGLcompliant, with simulation extensions pro-vided by IRIS Performer and ParadigmVega. A Silicon Graphic’s ONYX II com-puter running IRIX 6.2 provides the hostenvironment.

8. DIS Gateway. The DIS Gateway isused to connect the cubicle simulationsubsystem to the other subsystems. Itreceives natural and tactical environmentinformation in DIS PDU format and trans-lates the data into intermodule messageswhich are used to populate and maintainthe CSS target database and to controlthe CSS simulations. Conversely, the DISGateway translates the intermodule mes-sages into DIS protocol data units for useby simulations external to the cubiclesimulation subsystem. It also providesintermodule message translation servicesfor non-DIS compliant intrasubsystemsimulations such as the panel system.Due to the large data throughput require-ment, the DIS Gateway is interfaced di-rectly to the ORTT system FDDI back-bone. The host processing environmentis a VME bus architecture with multiplePower PC processors running theVxWorks real-time operating system.

Scenario Generation and Control (SGC)The SGC subsystem provides the ca-

pability to define, script, execute and con-trol simulation scenarios containing bothcubicles and up to 300 simulated game-pieces. It is comprised of three distinctcomponents: a user interface for the sup-port station, gamepiece operator and in-structor station positions; a customizedversion of the COTS integrated softwaresystem Export Computer Generated Sur-face Forces; and services for real-timemonitoring, recording and debriefingtrainee performance in the simulation en-vironment.

Support Station, Gamepiece Operatorand Instructor Station Human/MachineInterface (HMI). The HMI pages for eachposition were designed by navy subjectmatter experts for efficient and intuitive

Fig. 6. ORTT trainer control

MARITIME ENGINEERING JOURNAL JUNE 199912

control of information dissemination(Fig. 5). Individual pages were built us-ing Motif widgets selected from a custom-ized UIM/X tool kit.

Each support station and gamepieceoperator position is configured with oneSolaris-based, 166-MHz Pentium PC andone 21-inch monitor. Each instructor sta-tion is configured with one Solaris-basedDual 300-MHz Pentium PC with a graphicscard driving four 17-inch monitors. Thisarchitecture enables the instructor to dy-namically configure and change the infor-mation displayed on each monitor. Usingthe previously described X-request tech-nique, the instructor is able to monitor upto four different trainee consoles at anygiven time.

Information from each ORTT subsys-tem is made available to the support sta-tion, gamepiece operator and instructorstations via a Switched Ethernet connec-tion. Consequently, all positions, depend-ing on the user’s access permission, maybe configured to enable real-time controlof the other ORTT subsystems. Undernormal operation, the instructor stationpositions are granted access to all HMIpages and functions, while the supportstation and gamepiece operator positionsare granted access to a subset of thesepages. This architecture provides flexibil-ity and redundancy to the ORTT trainercontrol organization (Fig. 6).

Export Computer Generated Forces(CGF). Export CGF is a COTS integratedsoftware system that configures and runsa synthetic tactical environment. It pro-vides the core functionality throughwhich the instructors create and control atactical scenario comprised of large num-bers of gamepieces. Definable physical,environmental and gamepiece behaviourmodels enable individual or groups ofgamepieces to function in a realistic man-

ner, independent ofoperator control.Predefinable scriptsand behavioural rulesets enhance the com-plexity and realism oflarge tactical sce-narios. Scenarios arecreated off-line withthe operator selectingand configuring thesensor, weapon andbehavioural character-istics of constituententities. This informa-tion is stored in a da-tabase where it is ex-tracted and used byhigh-fidelity simula-

tion models to run real-time tactical sce-narios. The effectiveness of these prede-fined scenarios can be validated off-lineat accelerated execution speed.

To satisfy the ORTT requirements, Ex-port CGF has been modified to incorpo-rate a custom HMI, as well as more entitymodels, scripting functionality and be-havioural rule sets. The software ishosted on two Solaris-based multiproces-sor SPARC Enterprise 4000 serversshared with the Master Radar Video Simu-lation. Connectivity to other ORTT sub-systems is achieved through thetransmission and receipt of DIS protocoldata units over the ORTT network via adedicated Fibre Distributed Data Interfaceconnection.

Monitoring, Recording and Debrief-ing. Through the custom HMI, instruc-tors can monitor and record the truesynthetic tactical picture, all trainee dis-play pictures, panel system interactions,and communication circuits. Eventswithin the recorded information can betagged during game execution for extrac-tion and playback during exercise debrief.All recorded information is stored overthe network. Prior to exercise debrief, aninstructor selects, extracts over the net-work, and compiles specific segments ofrecorded information for synchronizeddisplay (on one of three large-screenvisual projectors) and audio playback inthe ORTT Brief/Debrief theater (Fig. 7).

Link-11 SimulationThe Link-11 subsystem provides a tac-

tical data exchange radio link environmentto support each cubicle’s Link-11 opera-tions. It simulates Link-11 communicationbetween reporting and participating unitsto produce a consolidated tactical picture.A total of 14 gamepiece participatingunits, and two Halifax-class participatingunits are supported — any of which can

be designated as Net Control Ship. Theinstructors have the capability to dynami-cally create and change the Link-11 envi-ronment for each cubicle and gamepiece.Trainees interface with the simulationthrough the CCS and a high-fidelitymicrocontroller-based panel simulation.The simulation is comprised entirely ofnew development software hosted on aVME bus with SPARC processors run-ning the Solaris operating system andinterfaced directly to each cubicle CCS viaa direct point-to-point NTDS connection.A dedicated Switched Ethernet connec-tion is used to interface the simulationwith the rest of the ORTT system. Spe-cific synthetic tactical environment infor-mation (gamepiece identity, location,emitter information, etc.) is exchangedwith the SGC subsystem via the transmis-sion/receipt of DIS protocol data units.

Communications SimulationThe communications simulation sub-

system provides the internal and externalradio environment through which the cu-bicle CIO teams and the instructors com-municate. The entire communications en-vironment is simulated using a custom-ized COTS solution supplied by a third-party vendor. High-fidelity microcontrol-ler-based panel replicas are used tosimulate the actual shipboard communica-tions interface for each trainee position.Instructors interface to the systemthrough a customized HMI, and have theability to dynamically select and simulta-neously monitor/record up to four sepa-rate circuits. Radio frequency propaga-tion, communications range filtering andjamming effects are realistically modeledas part of the COTS simulation package.The communications simulation subsys-tem interfaces with the ORTT network viaa Switched Ethernet connection. Inter-gamepiece range and emitter status dataare exchanged with the cubicle simulationand SGC subsystems via the transmis-sion/receipt of DIS protocol data unitsover the network.

WAN ConnectivityConnectivity with other DIS-compliant

simulations is facilitated through a singleconnection to one of the FDDI/Ethernetswitches and a separate connection foreach of the communication simulation andLink-11 simulation subsystems. A routingtable provides appropriate field of viewfiltering for the ORTT and distributes DISdata to the appropriate simulation. Thecustomized COTS communication sub-system provides a separate interface forthe integration of external communicationcircuits into a WAN exercise. Similarly, theLink-11 simulation can be integrated into

Fig. 7. ORTT Brief/Debrief Theatre

MARITIME ENGINEERING JOURNAL JUNE 1999 13

Foruma WAN exercise through a dedicatedTADIL-A compliant interface.

Development and Integration StrategyThe ORTT development and integra-

tion strategy incorporates the incrementalbuild paradigm. This approach is basedon a structured design and developmentmethodology which enables design is-sues to be identified and corrected earlyin the development cycle. A necessaryprerequisite for the incremental build ap-proach is a firm validated requirementsspecification. In the ORTT this specifica-tion is comprised of two substantial docu-ments: the customer system specificationand the ORTT detailed design data pack-age. The system specification is a high-level text document enumerating 600specific requirements. Its focus is whatfunctionality the ORTT shall provide. Thedesign data package focuses on how theORTT system will provide the specifiedfunctionality. The system design is com-prised of eight computer software con-figuration items and five hardwareconfiguration items. The computer soft-ware configuration items are comprised ofcomprehensive software requirementspecifications developed using theRumbaugh Object-Oriented design ap-proach. The hardware configuration itemsprovide detailed hardware system prod-uct specifications.

In the ORTT adaptation of the incre-mental build paradigm, timing and execu-tion of the system development, test andintegration, qualification and deliverytasks are addressed based upon capabil-ity precedence and risk priorities. Using

the information provided by the systemspecification and the detailed design datapackage, the ORTT system is subdividedinto six manageable increments (builds)with each successive build adding func-tionality to the system as a whole. Eachbuild is defined by its functional traceabil-ity to the system specification, and is de-scribed with a statement of functionalobjectives which may be directly associ-ated with the ORTT high-level systemrequirements. In general, the ORTT incre-mental build approach achieves two ob-jectives. First, it mitigates risk by enablinghigh-risk system elements to be devel-oped early in the program cycle. Second,it compresses the project schedule byfacilitating and synchronizing parallel de-velopment and integration of systemcomponents.

Builds 1 and 2 provide the entire net-work and message communication infra-structure. Builds 3, 4 and 5 integrate theCOTS simulation applications and vendorsupplied subsystems. Build 6 is reservedfor the resolution of outstanding softwaredeficiency reports. At the time of writing,Build 4 has been successfully closed out,Build 5 is 10 percent complete and Build 6is scheduled for completion by summer1999. The Canadian navy expects finalacceptance of the ORTT in early 2000.

ConclusionThe Canadian navy’s Halifax-class

frigate Operations Room Team Trainercombines the integration of legacy soft-ware solutions with hardware emulationand developmental COTS-based solu-tions to create a cost-effective

multiplatform, multithreat high-fidelitysimulated command team training envi-ronment. Its powerful simulation applica-tions and scenario generation and controlsubsystem enable the creation and dy-namic interactive execution of realisticcomplex virtual exercises situated any-where in the world. Its open architectureand Distributed Interactive Simulationcompliance facilitate reduced life-cyclecosts and flexible expansion to incorpo-rate additional cubicle simulations and/orparticipation in a networked exercise com-prising other DIS-compliant simulations.

LCdr Yankowich is the former projectmanager for the ORTT and MPT projects.He is now on exchange with the RoyalNavy in England.

As a general rule, article submis-sions should not exceed 12 double-spaced pages of text. The preferredformat is MS Word, or WordPerfect, on3.5" diskette, accompanied by one copyof the typescript. The author’s name,title, address and telephone number

Submission Formats

Maritime Engineering Journal Objectives• To promote professionalism among

maritime engineers and technicians.

• To provide an open forum wheretopics of interest to the maritime engi-neering community can be presentedand discussed, even if they might becontroversial.

• To present practical maritime engi-neering articles.

• To present historical perspectives oncurrent programs, situations and events.

• To provide announcements of pro-grams concerning maritime engineeringpersonnel.

• To provide personnel news notcovered by official publications.

should appear on the first page. The lastpage should contain complete figure cap-tions for all photographs and illustra-tions accompanying the article.

Photos and other artwork should notbe incorporated with the typescript, butshould be protected and inserted loose

in the mailing envelope. If at all possi-ble, electronic photographs and draw-ings should be in TIFF or JPEG format.A photograph of the author would beappreciated.

MARITIME ENGINEERING JOURNAL JUNE 199914

When the scheduled refits forHMCS Athabaskan (DDH-282) and HMCS Iroquois

(DDH-280) had to be postponed until af-ter the ships returned from their 1999 de-ployment with NATO’s Standing NavalForce Atlantic, it was deemed prudent inthe interim to schedule shorter durationextended work periods (EWPs) to handleessential maintenance and implement cer-tain design configuration changes. TheEWPs were relatively brief (17 weeks), butvery intense, with configuration changebeing the predominant work. Both EWPswere highly successful, with all scheduledwork being completed on time and to asatisfactory quality standard. By review-ing the conduct of these two work peri-ods (Athabaskan’s in 1997; Iroquois’ in1998), certain common denominators canbe identified as critical success factors forEWP management. The same principlesand criteria would apply to any refit orother work period conducted in a commer-cial shipyard.

Normally, the EWP project is initiatedseveral months prior to the actual com-mencement of work and does not termi-nate until some time after completion ofwork on the ship. Although extended workperiods must be treated as stand-aloneprojects, each EWP should build upon thelessons learned from previous efforts —an especially important consideration inthe implementation of large configurationchanges throughout a ship class.

The overall success of the EWP de-pends on a series of linked activities, andon the actions and interactions of fourgroups: the project manager and his on-site team; the parent organization(NDHQ); the customer organization (for-mation/ship) and the contractor. Theproject manager can improve the probabil-ity of success through careful planningand execution of the project, and by beingmindful of certain critical success factors.This paper sets out some of these keyfactors.

EWP PreparationPlanning

The importance of EWP preparationcannot be overemphasized. The average

Extended Work Period Management —Principles for SuccessArticle by Irek J. Kotecki and David B. Jones

preparation time is approximately ninemonths, and many of the activities carriedout in this period will directly affect theconduct of the EWP. Any errors in judge-ment or failure to effectively carry outcertain tasks at this stage can jeopardizethe successful completion of the work inthe contract yard.

Preparation begins with the establish-ment of realistic milestones for the EWP.The milestones leading to contract awardand commencement of the EWP are iden-tified and initiated by the Dynamic Deliv-erable List letter, and should include thefollowing principal events and minimumrecommended lead times (longer in thecase of a refit):

• 36 weeks prior to EWP start – Main-tenance and Repair Specification List(MRSL) and configuration change speci-fication preparation commences; ship-board MRSL review meeting;

• 22 weeks prior – MRSL approval;• 20 weeks – MRSL distribution;

MRSL review and revision;• 17 weeks – Request for Proposal is-

sue;• 12 weeks – bidders conference;• 9 weeks – bid closing;• 6 weeks – contract award;• 3 weeks – Ship preparations

(destoring, deammunitioning, etc.); and• 0 weeks – EWP start

The project manager prepares and im-plements a detailed activities plan to meetthe set milestones.

Cost and DurationSeveral months before the Dynamic

Deliverable List letter is issued, theproject’s budget and duration must beestablished. The project manager esti-mates the level of effort required (workscope, duration and proposed schedule)based on the ship’s maintenance history,condition, the backlog of configurationchanges and the anticipated post-EWPdeployment of the ship, and seeks projectapproval from the Director General Mari-time Equipment Program Management inconjunction with the Director MaritimePolicy and Project Development and theformation. Once the work scope and dura-tion have been agreed upon and the cor-

responding project budget has been ap-proved, detail planning commences. Itshould be noted that the cost and dura-tion may vary depending on a contrac-tor’s geographical location and commer-cial market workload. It is important thatall factors be fully analyzed and that arealistic budget and schedule be estab-lished.

Critical Path and Risk ManagementA contracted work period has its criti-

cal risk areas. Properly assessing theseareas and developing risk managementstrategies to deal with them should beone of the most important activities of theproject manager during the preparationphase. The risk assessment must considersuch issues as:

• Is the proposed work achievable inthe specified time frame? Assume thatthe implementation schedule is based ona single shift, working weekdays.

• Will material be available? Considerthe assembly and delivery schedule forgovernment-supplied material, and theavailability of contractor-furnished mate-rial, long-lead items, substitute material,etc.

• What are the technical risk areas?Produce risk notes to identify potentialproblems and propose solutions.

• Does the on-site team fully appreci-ate the risk issues? This requires on-siteteam involvement in the preparations.

During implementation — be preparedfor the unexpected. Take a proactive ap-proach and work with the contractor toanticipate and resolve problems.

The On-site TeamThe composition and capability of the

on-site team is the most instrumental fac-tor in the success of the EWP. Duringimplementation, it is this team that man-ages the day-to-day EWP activities onbehalf of the project manager. Since theproject manager must have complete faithin the on-site team and trust their judge-ment, he must have the right to select keyteam members. Due to the complexity andintensity of the EWP, there is no time for alearning curve for the on-site team. To beeffective from day one, the core teammembers must have proven track records

MARITIME ENGINEERING JOURNAL JUNE 1999 15

in their field, know the ship and its sys-tems, and have engineering capabilities.The project manager can further stimulatethe probability of success by:

• developing the commitment andsense of mission from the start;

• generating an attitude of co-opera-tion and mutual respect and support; and

• having key team members participatein the decision-making and problem-solv-ing.

Specification ReviewAnother critical factor for a successful

EWP is the detailed review of specifica-tions and drawings for Maintenance andRepair Specification List (MRSL) work,and configuration change work by keymembers of the on-site team and by thelife-cycle material managers (LCMMs).This review serves several purposes inthat it:

• familiarizes the on-site team memberswith the work requirements;

• permits an assessment of areas whereone specification affects another, thuseliminating conflicts, contradictions andduplications;

• permits an understanding of the inter-connection of work items in the samework zone;

• permits identification of material defi-ciencies;

• provides time to incorporate neces-sary changes to a specification (includinglessons learned from a previous installa-tion); and

• permits comparison of the installationdrawings against the ship’s configuration,and identification of interference points orother areas of conflict.

Government-supplied MaterialWhen confronted with schedule con-

straints imposed by a short time frame andhighly labour-intensive work periods, it isvital that government-supplied material beorganized and available at the contractyard when work commences. Material isidentified in the configuration changespecification and drawings through theInventory and Bill of Material. From this, aConsolidated Material List (CML) is gen-erated and included with the specificationto combine like items such as cable or pip-ing in a single line item. Columns areadded to the CML so that the LCMM andsupply managers can indicate whether anitem is government- or contractor-sup-plied. Thus, the Consolidated Material Listbecomes the primary document for mate-rial procurement. However, because theCML items reflect the requirements ofmore than one drawing item, it is not pos-sible to determine the details of the item’send use without going back through the

Inventory and Bill of Material to thedrawing. This is an unwieldy processand is prone to errors.

When technical and logistics person-nel encountered problems identifyingand pre-staging government-suppliedmaterial for the Iroquois EWP in 1996,the on-site team generated a database inMicrosoft Access™ to correlate the draw-ings, the Inventory and Bill of Material,and the Consolidated Material List (Fig.1). The database proved to be invaluableas incoming material could now be read-ily identified by item, by the applicableconfiguration change, by drawingnumber and title, by drawing item numberand by the MRSL specification number.In other words, the end use of each itemwas identified.

There were more than 7000 line itemsof government- and contractor-furnishedmaterial in the database for both theAthabaskan EWP at Port Weller DryDocks in St. Catharines, Ont., and theIroquois EWP at Davie Industries inLevis, P.Q. To reinforce the spirit of co-operation, DND provided the contractorswith a copy of the integrated databasecreated by the on-site team. In bothcases, the contractors found the data-base to be an extremely useful and time-saving tool as it allowed them to combinethe procurement of like items required formore than one configuration change (e.g.cables, valves, etc.) rather than have toorder material separately for each con-figuration change. This resulted in sig-nificant economy of scale whenpurchasing.

At Davie Industries, the unexpectedprovision of the database by DNDshowed that the on-site team was sympa-thetic to the contractor’s procurementproblems, and went a long way towardestablishing a team approach to the con-duct of the EWP. What’s more, a soft-ware interface established between thematerial database and Davie’s procure-ment and inventory control system sim-plified and expedited the contractor’sprocurement and inventory control proc-esses. And since virtually all of the gov-ernment-supplied material was assembledprior to the commencement of the EWP,there were no schedule delays attributedto any late supply of material by the gov-ernment. Taken together, these factorsplayed a major part in the contractor’sability to deliver the required product onschedule.

Ship Preparation PlanA comprehensive and widely promul-

gated ship preparation plan is an impor-

Consolidated Material List(CML)

Inventory & Bill of Material(IBM)

IBM/CML Integrated Database

GSM Identification & Assembly

CFM Identification& Purchasing

GSM/CFM Receipt & InventoryManagement

Contractor’s Procurement& Inventory Mgmt Database

ConfigurationChange

Drawings

ConfigurationChange

SpecificationMRSL

Material

Fig. 1. Material Identification and Control

MARITIME ENGINEERING JOURNAL JUNE 199916

tant factor in the successful commence-ment of the EWP. The plan is prepared bythe EWP project manager, reviewed bythe responsible authority in the formationand by the ship’s commanding officer,and promulgated as a joint planningdocument. The plan sets out the respon-sibilities for the various players in theEWP, including the on-site team, and de-tails the ship preparation requirements.There are many potentially conflictingactivities that require co-ordination, suchas deammunitioning, removing radar an-tennas and weapons, defuelling the waterdisplaced fuel tanks, destoring, and start-ing the compartment turnover process.The successful commencement of theEWPs in both Athabaskan and Iroquoiswere the result of commendable effort bythe ship’s crew, the fleet maintenance fa-cility, formation personnel and the on-siteteam, guided overall by a jointly devel-oped, detailed plan.

EWP ImplementationSetting the Tone

As soon as possible after contractaward, a “kick-off” meeting should bearranged with the contractor. This meet-ing is extremely useful for a number ofreasons. First, it permits the key playersfrom the contractor’s staff to meet withthe contract officer from Public Worksand Government Services Canada(PWGSC), the DND project manager andkey members of the on-site team. An im-portant aspect of the meeting is to culti-vate a “team” approachso that the contractorcan be assured that thePWGSC/DND team un-derstands the pressuresfaced by the contractorand will deal fairly withissues faced by bothsides. The meeting alsosets the stage for thedelivery and turnover ofthe ship to the contractyard by dealing withsuch aspects as compart-ment turnover, berthing,jetty services, security,safety, defuelling anddestoring assistance.

The short durationand highly labour-inten-sive nature of the workperiod make it absolutelycrucial that the contrac-tor be able to ramp upresources very quicklyand begin meaningfulwork as soon as possibleafter the vessel has ar-

rived at the yard. This means that severalcritical activities first have to be com-pleted. For instance:

• The compartment turnover effortshould begin prior to the vessel’s transitto the contractor’s yard, continuethroughout the transit and be completedwithin two or three days after arrival.