Milcobel 2012 — 1 annual... · Milcobel 2012 — 1 ... Milcobel’s already strong position as...

Transcript of Milcobel 2012 — 1 annual... · Milcobel 2012 — 1 ... Milcobel’s already strong position as...

Milcobel 2012 —

1

Content Foreword 3

The Milcobel Group in 2012 5

Cooperative news 9

Key fi gures 2012 11

Industrial products and third-country export 13

Consumer cheese and butter 17

Consumer milk and functional drinks 19

Ice cream 21

Cheese packaging and distribution 23

Who is who in Milcobel 2012? 24

Financial report 25

Credits 45

Milcobel 2012 —

3

It is clear that Milcobel’s prices continue to be the main benchmark for milk prices in Belgium. From that standpoint, 2012 was an eventful year for us. Sharp increases in costs coupled with disappointing fodder crop yields in some regions put pressure on revenue at member companies. The uncertainty felt at large dairy farmer groups (non-cooperatives) stemming from a faltering commitment on the part of their buyers for long-term sales also led to unrest, which in turn had its effect on Milcobel.

The relatively weak prices that were set for milk in accordance with European standards at Milcobel and the other Belgian companies were cause for lively debate, both inside and outside our member structures. Our milk prices were under pressure in 2012, this due to both disappointing market trends for powder as well as a number of operational handicaps that are specifically related to the transitions that Milcobel is undergoing. In addition to this, more fundamental handicaps such as energy and wages - in comparison to neighbouring countries - are definitely playing an increasing role in the food sector.

Nevertheless, 2012 was still a “good” year in many areas:• In2012,wecelebratedthe20thanniversaryofOudBrugge.”Brugge”hasevolved intothepremiere

brand for the Belgian cheese palette. In a market segment for higher-quality cheeses that is otherwise feeling pressure, it is capturing an increasing market share and achieving net growth.

• ThenewcheesefactoryinMoorsledewasopenedinOctober.Heretheartisanalskillsofcheesemastersare combined with cutting-edge technology and automation in order to offer cheeses to “suit all tastes”. Expectations are very high. Belgian cheeses - with Brugge as the flagship cheese - are also gaining notoriety outside Belgium.

• ThroughitstakeoverofSherlockCheeseinNieuw-Vennep(nowDupontCheeseNL),ourcheeseserviceand distributor “DupontKaas” has evolved from its beginnings in Bruges into a genuine Beneluxorganisation. The entire domestic market is now indulged with the most specialised cheese palette in EuropefromlocationsinBruges,Nieuw-VennepandLiège.

• WorkcommencedontheexpansionofthemozzarellafactoryinLangemark.Thisexpansionwillensurethat the factory’s increased production capacity will be operational by early 2014. This will strengthen

Milcobel’s already strong position as the standard bearer for the use of mozzarella cheese in pizzatoppingsaswellasemergingsegmentssuchasmozzarellaslices.Thisinvestmentrepresentsthefinalcomponent of our cheese strategy: 60% of our members’ milk is destined for this type of production. We also managed to increase the valorisation of derived whey products in 2012.

• Powdercontinuestobeespeciallyimportantforthegroup,bothasaspecialisedingredientandasanutritional consumer product for international markets. In 2012 it was decided to expand the powder operations in Kallo, a plan which will involve new construction. The land surrounding the existing factory has been purchased, and the project study is now in its final phase.

• Inadifficultmarketformilkandmilkdrinks,Inzawassuccessfulatstayingafloat.Itdidthisbyenforcingstrict cost controls and by concentrating more on specialised drinks under the name brand of third parties,aswellasbyrepositioningitsownYogho!Yogho!,Choco!ChocoandInzabrands.

• Icecream,whichaccountsfor23%ofourturnoverandoccupiesalmost30%ofourworkforce,continuesto be an essential component of Milcobel’s business model. Activities which are further removed from dairy are intended to mitigate the volatility of milk prices, especially during downturns affecting the dairy market. In spite of a terrible summer and cutthroat competition, this is what Ysco did in 2012. Ysco held its ground and remained profitable in a European ice cream sector that is undergoing consolidation.

Togetherwithmanagement,Milcobel’sBoardofDirectorshasoutlinedplansforfurthergrowthusingourown resources. This approach is based on our belief that the best way for dairy farms in our operating area to thrive and be able to count on a long-term future is for them to be part of a cooperative dairy group managed from Belgium that guarantees market access for its members. The total commitment on the part of the Milcobel family to do this, even when times are tough, is illustrated by the strengthening of shareholders’ equity through retained earnings and the increase in capital contribution approved by the general assembly.

GuidoVeysChairmanoftheBoardofDirectors

Foreword

Milcobel 2012 —

5

The Milcobel Group again took a proactive stance in 2012, with important steps taken to further its growth in an effort to fulfi l the mission of the cooperative. This mission can be summed up in 4 points: • Asalesguaranteeforthemilkproducedbythememberdairyfarmers.• Therightmilkpriceforitsmemberdairyfarmersbasedonindustrialandcommercialactivitiesandapresenceinmultiple

markets with multiple products.• Asmuchinvolvementaspossibleonthepartofmemberdairyfarmers.• Together,putaninternationalfaceonBelgiumasadairycountry:“Belgiandairyproductsforyoutoenjoy”.

Milcobeltookthesestepsduringadifficultyearforthedairyindustry.Pricescollapsedformilkpowderandbutterinparticularandpricesforcheese,andespeciallymozzarella,weakenedaswell.Butthankstostrongdemand,thesepricesdidnotcollapseentirely, as has often been the case in the past when the dairy market is less than favourable. Because our cheese factory in Langemarkwasalreadyrunningat full capacity,however,wewereunableto take furtheradvantageof thisdemand.At the

same time we had to contend with the start-up costs of the newly renovated and expanded cheese factory in Moorslede. Valorisationbymeansofconsumptionmilkyieldedanaveragepriceformilk.Whenbearinginmindthatmilkpowder

is an important means by which the Milcobel Group valorises the milk of its members, this added up to a substandard year for the price of milk when compared to its European competitors. Nonetheless, there

are once again a number of noteworthy developments to report.

New strides in growth during 2012InJanuary,MilcobelmadeitsentryintotheDutchcheesedistributionsectorthrough

thetakeoverofSherlockCheeseinNieuw-Vennep.ThiscompanywasthenrenamedDupontCheeseNederlandafewmonthslater.WithKaasimportJanDupontin

Bruges and with Camal in Barchon, Milcobel is building a genuine Benelux operation for the distribution of its best cheeses, which can now be found

everywhere.

The cheese factory in Gierle ceased all operations in late April, at which point the new line in the cheese factory in Moorslede was

put into operation. On 6 October the new cheese factory in Moorslede was officially inaugurated by Chairman GuidoVeysandFlemishMinister-PresidentKrisPeeters.Thiswasfollowedthat afternoon by an open house for members and employees, and again on Sunday for the general public as part of the company open house. And the public arrived in large numbers: there were more than 10,000 visitors over the course of the weekend.

Meanwhile,constructionstartedonthenewmozzarellafactoryinLangemark,whichwill initially increaseproductioncapacity

from 25,000 tonnes to 45,000 tonnes, with the option to expand this to 70,000 tonnes in the future. Besides allowing Milcobel toprocesstheanticipatedincreaseinmembers’milkproduction,thesetwoinvestments(MoorsledeandLangemark)willalsofurther accelerate the shift from powder to cheese.

InzabuiltanewdivisioninSchoteninordertofulfilamajorco-packingcontractfortoddlergrowthmilksunderthebestpossibleconditions.IndoingthisInzaisimplementingoneofitsstrategicaxes.

The spring and summer of 2012 were anything but stimulating for the consumption of ice cream, yet Ysco still realised a slight rise in turnover thanks to a larger contract perimeter. This increase in turnover combined with the benefi ts from the streamlining efforts made in recent years meant that, even in a year with a poor summer, Ysco’s result was still a good one.

Finally, a large amount of research was carried out in Kallo. This was done in preparation for the decision on the best scenario for modernising the Kallo site so as to be able to produce milk powders and baby food under state-of-the-art conditions in the future.

Milk supply and processing stableIn 2012, the Milcobel Group processed only slightly more milk than it did the year before. Both the supply and third-party purchases were stable, while a bit more milk was sold. The group processed 2% less milk in its factories; in 2011, the total amount of milk processed was 1.058 billion litres.

Results of the subsidiariesTheindustrialproductsandthird-countryexportsdepartment(Belgomilk,Kemfoods)obtainedgoodresultswithmozzarella.Milk powder, however, brought down Milcobel’s average price for milk.

The consumer cheese and butter department (Belgomilk and Kempico) experienced a transitional year and yielded a weaker result. The transfer of production from the cheese factory in Gierle to that of Moorslede and the launch of the new line in Moorslede generated additional costs before production could be brought back up to speed. One positive development was that sales of Brugge Kaas cheeses again grew by multiple percentage points.

Belgomilk’sconsumerbutterwasalsoabletomaintainitspositiononthedomesticmarketthankstotheNazarethandDixmudabrands.

Asaspecialistinlong-lifeconsumptionmilkandmilkdrinks,2012provedtobeabetteryearforInza.Themarketforconsumptionmilklaggedlessbehindthoseofotherproducts.Comparedtotheyearbefore, Inzamanagedtovastly improveitsresultandalmost broke even, mainly through intensive cost savings and the initiation of new co-packing contracts.

Despitetheunfavourablesummer,Yscoachievedgoodresultsin2012.Theseresults,alongwiththepositivecontributiontheymade to the group’s overall results, can be attributed to better prices, well-functioning factories and more sales contracts, all of which combined to produce a slight increase in turnover in spite of the disappointing summer.

The Milcobel Group in 2012

— M

ilcob

el 2

012

6

Thanks to the takeover of SherlockCheese (now DupontCheese Nederland), theturnover of the cheese packaging and distribution department began to rise again. Kaasimport Jan Dupont was the only one to see its turnover fall, while Camal’sturnover increased. When one considers the investment in, and reorganisation of, DupontCheeseNederland,theoverallresultsmetexpectations.

Group resultsThe consolidated turnover of the Milcobel Group fell by a slight 0.5% to EUR 880 million. This drop was mainly a result of price declines.

The consolidated results of the group ended the year at EUR 3.7 million, compared to EUR 4.4 million for the previous year. The group’s cash flow amounts to EUR 24.6 million.

A dividend of 4% will be proposed at the general meeting. The remaining results will go to shoring up the group’s reserves.

Milk priceThe milk price paid fell by 9% as compared to 2011. With a fat content of 42.93 grams/litre and a protein content of 35.27 grams/litre, an average milk price of EUR 31.53 per 100 litres was paid.

If this is converted into the standard milk in Belgium (38 g fat and 33.5 g protein per litre), the average milk price for members amounted to EUR 29.14 per 100 litres, which is 9% less than in 2011.

InvestmentsMilcobel is maintaining its high investing rhythm. The group’s investments in tangi-ble fixed assets totalled EUR 35.9 million in 2012. Belgomilk accounted for 69% of this figure, which was devoted mainly to the cheese factories in Moorslede and the expansionofthemozzarellafactoryinLangemark.Inza’sshareofinvestmentswas8%,withYscoaccountingfor15%andDupontandCamal3%.

PersonnelMilcobel’s aim is to be a group in which every employee is convinced of the objectives of the Group in general and of those of his or her department in particular. In that way, each and every person will apply his or her talent with pleasure to achieve these objectives and will also be shown appreciation for their efforts. This is known as involvement by each and every person.

The group continued its policy of open communication and deliberation by way of appropriate official bodies, work groups and safety units. This is all with a view to a

good working atmosphere, health and safety at work and continued improvement in the quality of the work delivered and of the final products.

Corporate social responsibilityMilcobel places great emphasis on socially responsible entrepreneurship, which is characteristic of a cooperative enterprise. A social character and solidarity are ingrained in the origin and nature of cooperatives. It is therefore no surprise that Milcobel is concerned about social issues and human rights.

For Milcobel, sustainability means taking responsibility for - and providing sustainability to - the incomes of 3,000 dairy farmers and their families, the incomes of 1,800 employees and their families, a relationship with 100 or so buyers/customers that is based on trust, and contributing to the dairy consumption of millions of consumers.

The step towards other issues of socially responsible enterprise is small. Care for the environment is a question of sustainability of the enterprise, society and the environment in which it must prosper.

Belgomilk and Ysco participate in the West-Flanders Corporate Sustainability Charter through which work is being done to continually improve environmental, social and economic performance. Other branches of the Milcobel Group also follow this initiative.

Corporate sustainability is implemented by means of specific projects. Two examples of this include the visualisation of consumption trends for utilities in the workplace and the 45+ experience fund, which helps workers extend their working careers through the valorisation of experience and the avoidance of physical strain.

Milcobel cooperates in various projects and inter-professional deliberations on sustainable dairy farming.

ProspectsThe long-term prospects for dairy products remain good, especially at the global level. In particular, the increasing world population and rising purchasing power in developing countries are expected to raise dairy product consumption.

These favourable long-term prospects, however, do not change the fact that the markets remain volatile and that we may experience weaker years such as 2012 in the future.

But the prospects for 2013 are better. The market for dairy products began to improve in September 2012, when particularly strong improvements were recorded for the prices for milk powders and butter, and the imbalance in the market for the most part disappeared. Better prices have also been paid for consumption milk since November. The downside of this improvement is that it is basically a result of the diminished supply of milk. The diminished supply of milk in Europe is a result of the poor harvest season for fodder crops on dairy farms (lower quality grass silage and disappointingsilagemaizeyields).Highpricesforconcentratedfeedarealsoputtinga check on high milk production. The demand for milk remains quiet due to the on-going economic crisis, though we can probably expect to see prices remain steady or even improve into the new growing season if milk production lags in other parts of the world as well, particularly in New Zealand.

The factory in Moorslede is now capable of running at full capacity in order to keep up with the growth in sales of our branded cheeses. During 2013 Inza will beginwork on the new co-packing contract and Ysco has once again netted a nice portfolio ofcontractsfortheyear.DupontcontinuestoworkonbuildingfullcoverageoftheBeneluxmarket.Wehavetheprospectofahigh-performingmozzarellafactoryinLangemarkwhilethemostappropriatedecisionwillbemaderegardingthefutureof powder and baby food production in Kallo.

The Milcobel Group’s management and employees will therefore continue to develop a versatile and sustainable cooperative dairy group. Milcobel’s sustainability is the cornerstone of the sustainability of its members’ dairy farms and the sustainability of employment for its employees.

The group’s values are quality (a taste you can trust), service and flexibility (“customerthusiasm”), involvement on the part of members and employees, and respect for the environment.

Milcobel 2012 —

7

50%

50%

50%

7,07%

20%

Group structure

(1) as to asset mutation(2) not included

nv KaasimportJ. Dupont

cvba St. Marie

cvba Kempico

sa Camal

cvba MILCOBEL

nv Fassbel

geie Les From.des Flandres (2) nv Cheeseline

Prodinco

cvba Inza nv Ysco

sasu Ysco FrHolding

sasu Ysco France

bv Milcobel Ndl

sarl BMF Lait

nv BedrijvenparkWingene (2)

cvba Milcobel 3F

sa Héritage 1466 (1)

Members

cvba Belgomilk

cvba Zuivelindustrie Zandhoven (2)

bv Dupontcheese

NL

Milcobel 2012 —

9

Cooperative newsThroughout 2012, the cooperative member structures – following changes to their composition in 2011 – were heavily involved in Milcobel’s operations. At the board level of the 9 member circles a total of 21 board meetings were held. The Cooperative Board met 5 times.

An important topic covered in these meetings was the strategic development of the Milcobel Group, and the associated required increase in the shareholders’ equity of Milcobel and of the members’ capital in particular. A detailed explanation was also provided for the transitions which are underway in several divisions of the Group, as a result of which - and due also to difficult market conditions for a number of dairy products - Milcobel’s performance failed to meet expectations during 2012. This was communicated to all members via a special edition of the Milcobel Flash.

A members-only area was added to the Milcobel website last autumn. Members will be able to consult their individual delivery information and membership data in this members-only area, which will also allow for a greater amount of cooperative news to be disseminated more quickly. The members-only area of the Milcobel website will also become a tool for estimating the future milk deliveries of the members as accurately as possible in the post-milk-quota era.

The general assembly of 19 June 2012 approved an increase in members’ capital of EUR 1 per 100 litres, to be spread over 4 years. At the request of the member structures - and also because of the difficult dairy year - the Board of Directorsresolved not to move forward with this capital increase until 2013.

In order to arrive at a better estimate of the capacity needed to process members’ milk and to tailor investment planning accordingly, a survey was conducted of members that inquired into the future development plans of the member farms. The response to this survey was overwhelming, with more than 80% of those surveyed responding. Indications are that future increases in milk production stemming from the elimination of the milk quota will be achieved in large part by filling cow stalls that are already available. The combination of individual business development versus others ceasing activities points to a net increase in the milk supply of between 13% and 16% after the milk quota is dropped. As mentioned earlier, the members-only area of the Milcobel website will be used as a tool to make more accurate prognoses of both short-term and medium-term supply.

The following trends can be reported as regards the milk supply over the course of 2012:• Thenumberofmembersuppliersdecreasedfurther,from3,096in2011to2,993in

2012. This corresponds to a relatively low rate of decline of only 3.3%. The decline in membership has slowed down somewhat compared to 2011. Belgium as a whole saw the number of milk suppliers drop by more than 4% during 2012.

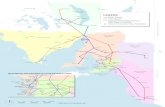

• The number of Dutch (81) and French (42) member suppliers remained fairlyconstant. The share of the overall volume of milk supplied came to 5.6% for the Netherlands and 2.6% for France.

• Milcobel also preserved the closed nature of the cooperative during 2012. Forbusiness and economic reasons, no new members will be accepted into the cooperative until further notice. Access to Milcobel will continue to be restricted to milk producers who are related to an existing Milcobel member or who take over a company of a Milcobel member. This measure safeguards the development potential of the existing member companies based on the commitment that Milcobel will not exert any control over production or manage supplies in any way whatsoever.

• Itisworthnotingthatthesupplyofmembers’milkin2012moreorlessstagnatedat a total volume of 1,114,948,082 litres. This represents an increase of only 1,135,459 litres, or 0.1%, over 2011. This stagnation is a clear reflection of the less favourableconditionsformilkproductionin2012:adverseclimate,poorgrazingseason, low fodder crop yields, high prices for concentrated feed and relatively low economic margins.

• The average volume of milk supplied by individual Milcobel members rose to372,519 litres, which is only a 3.5% increase over 2011.

The quality of the milk that was supplied continued to adhere to the previously attained high level of extra-quality during 2012 as well:• 98.1%ofthemilksuppliedmetthegermcountstandardofmax.of50,000/ml;• 94.4%ofthemilkhadasomaticcellcountbelow350,000/ml;• 85.8%ofthemilkmetthecountstandardforcolibacteriaofmax.of50/ml;• 99.7% of the supplied milk remained free of any demonstrable residues of

inhibitors.

Throughout all of 2012, 80.5% of the milk that was collected satisfied all of the additional quality standards maintained by Milcobel. As a result, this volume of milk wasawardedanadditionalqualitypremium.Proposalsformodifyingtheadditionalquality premium system were made several times during 2012. Simulation

calculations of these were submitted to the Cooperative Board. This means that, beginning on 1 June 2013, the switch will be made to a differentiated additional quality premium based on a revised germ count standard of 25,000/ml and a reduced somatic cell count standard of 300,000/ml. The coli bacteria count standard will remain unchanged at 50/ml.

The quality policy at the level of the milk supply continues to rest on the further remediation of a relatively small number of situations involving structural shortcomings. Intensified monitoring of the germ count appears to be a usable parameter for this policy. Since 1 November 2012, a special monitoring procedure has applied to suppliers in cases where a germ count of more than 100,000/ml is found. If no improvement is forthcoming, the collection of milk can be temporarily suspended.

Finally, Milcobel – as a major cooperative of dairy farmers – also continued its active participation in sectoral consultations throughout 2012. This participation occurred under the auspices of the Belgian Dairy Industry Confederation (BCZ/CBL),theGeneralAssociationofCooperativeDairies(AVCZ),andwithinthecontextof interprofessional consultations between the dairy industry and the agricultural organisations in Belgium. As such, Milcobel continues to play an important role within various consultative bodies regarding the future implementation of RFIDsampling, the development of sustainability criteria for dairy farms, adjustments to theDairyQualityAssurance(IKM/QFL)specificationsandtheimplementationoftheelementsoftheEUDairyPackage.

Within the frameworkof theDairyPackage,Milcobel submittedanapplication in2012 to be authorised as a producer organisation. This authorisation was obtained on 3 January 2013 and confirms that Milcobel, as a cooperative, is by nature a producer organisation.

And finally, Milcobel left no stone unturned – mainly by providing testimony – in its effort to contribute to the body of knowledge on the cooperative business model as part of the many initiatives that were taken on the occasion of the International Year of Cooperatives. More and more attention is being paid to the cooperative story, and more and more people are realising that a cooperative business model is synonymous with sustainable business and corporate social responsibility!

— M

ilcob

el 2

012

10

Milcobel-members

COOPERATIvE STRUCTURE

GROUP STRUCTURE

statutory general assembly

11 members of the board of directors

council of the cooperative5 delegates per member circle

milk collectionholding & coordination

& group servicesMilcobel cvba

Ice creamYsco nv

Ysco France SAS

Consumer cheese and butterBelgomilk cvba

Ste Marie Zuivel cvba

Industrial products and export third countries

Belgomilk cvba

Consumer milk and functional drinks

Inza cvba

Cheese packaging anddistribution

Kaasimport Jan Dupont nvCamal SA

DupontCheese NL B.V.

board of the member circle 9 regional member circles

Milcobel 2012 —

11

Key fi gures kEy fIGURES COLLECTION Of ThE MEMBERS 2012 2011 2010 Average number of suppliers 2,993 3,096 3,296 Quantity of milk supplied 1,114,948,082 1,113,812,623 1,098,473,243 Average fat content 42.93 42.56 43.00 Average protein content 35.27 35.12 35.24

Price paid for milk in millions of euro 351.57 386.18 358.07

Euro per litre 0.3153 0.3467 0.3260

kEy fIGURES MILk fLOW 2012 2 011 2010 Milk from members’ farms 1,114,948,082 1,113,812,623 1,098,473,243

Available total incl. third parties 1,131,898,100 1,131,500,576 1,116,910,726 Total sales 73,582,945 49,281,594 69,901,889 Available for transformation 1,058,315,155 1,082,218,982 1,047,008,837

kEy fIGURES MILCOBEL GROUP (IN ThOUSANdS Of EURO) 2012 2011 2010 Turnover 880,205 884,599 819,977

Investments fi xed assets 37,443 39,781 31,523 Result 3,683 4,399 6,028 Capital and reserves 113,011 106,894 101,885 Solvability % 27.5 26.7 28.0 Average number of employees 1,967 1,951 1,951

Milcobel 2012 —

13

Industrial products and exports to third countriesThe year 2012 was characterised by a high level of volatility on the dairy markets. An underlying cause of this was the milk supply, which was a determining factor in key market trends. The following events also had an impact on the market in 2012: the on-going economic slump in Europe, political indecisiveness in the US and the turmoil affecting a number of Arab and African countries (Syria, Mali, etc.).

On the supply side, strong growth in milk production in New Zealand, Europe and the U.S. gave rise to a milk surplus during the first half of 2012. This created downward pressure on market prices for dairy products. Full-fat milk powder, skimmed milk powder and butter all saw substantial price declines beginning early on in the year. These prices bottomed out around the month of May, at which point they found themselves at their lowest level since 2009.

The opposite effect manifested itself during the second half of the year by way of a milk shortage in the main production areas. It started in summer with a period of severe drought in the US, and was followed by a scarcity of milk on the European markets. This led to a recovery of market prices. Towards the end of the year, liquid dairy products - namely milk, milk concentrate and cream - experienced an unusu-ally active market.

New Zealand came to dominate the market for full-fat milk powder ever more em-phatically in 2012. The large quantities of extra milk produced in that country the previous season (2011-2012) found their way to the world market by way of the efficiently equipped New Zealand dairy factories, and did so primarily in the form of full-fat milk powder at unbeatable prices. Conversely, skimmed milk powder of EU origin proved to be genuinely competitive on the world market in 2012, which ensured steady demand for that product.

Milk powderEuropean exports of full-fat milk powder and derived products faced continued diffi-culty throughout 2012 due to significantly lower prices for these products from New Zealand. The demand for full-fat milk powder from the European food and beverage industrywassomewhaterratic.Drivenasitwasbyamilksurplus,themarketpricefor full-fat milk powder in Europe experienced a continual decline into the month of May.However,ithadreboundedbytheendoftheyearandevenclosedataslightlyhigher level than at the start of the year. The difference between the lowest and highestpriceatanypointduringtheyearwas21%.During2012,theaverageEuro-pean market price was 21% below the average in 2011.

Incolac (instant full-fat milk powder) continued to experience decent growth in its core markets in 2012. This was in spite of the adverse market conditions caused by operating at a pricing disadvantage to New Zealand in the area of instant full-fat milk powder, as well as the unfavourable economic conditions in some markets. Time and time again, the outstanding intrinsic quality of Incolac and its Belgian ori-gin have proved to be strong assets that work to the advantage of the Incolac brand. In 2012, Belgomilk expanded its cooperation with local co-packers in destination countries that package Incolac under licence.

The price of skimmed milk powder from the EU remained competitive on the world market in 2012. As a result, both the production of skimmed milk powder in Europe aswellasEUexportsremainedstrong.Drivenbythehighsupplyofmilk,themarketprice for skimmed milk powder experienced a continual decline into the month of May, but it rebounded by the end of the year and even closed at a slightly higher level than at the start of the year. The difference between the lowest and the highest price at any point during the year was 28%. The average European market price was 2% lower than the previous year.

In 2012, Belgomilk launched its popularly positioned Binco brand (based on skimmed milk powder with added vegetable oils). This nutritional, high-quality and popularly-priced brand concept received a positive initial response on many international markets. As a result, Belgomilk foresees good opportunities for the further growth of Binco.

Belgomilk’s sales of dairy ingredients to the food and beverage industry (chocolate industry, ice cream industry and baby food) continued to grow throughout 2012. New top European clients once again showed active interest in purchasing dairy ingredients from Belgomilk in 2012.

TheBelgomilkfactoryinLangemarkputanew,state-of-the-artpackag-ing machine for powder into operation in 2012 which allows the packaged milk powder to be gas flushed with a modified atmosphere.

The Belgomilk factory in Kallo made a series of modifications and im-provements to its packaging area for high-quality consumer packag-ing in 2012. This factory also opened a new laboratory in 2012. This laboratory is fully equipped to carry out quality controls on high-quality milk powder products.

ButterEarly on in 2012 European market prices for butter fell sharply and continued to decline into the month of May. At that point prices began a gradual recovery, and ended up closing the year at almost the same level as at the start of the year. The lowest price recorded in 2012 was 31% lower than the highest one recorded. The average European market price for butter was 24% lower than in 2011.

Mozzarella ThedemandforBelgomilkmozzarellaremainedstrongin2012andwasdrivenbyallofthemajorsaleschannels:pizzarestaurants(mozzarellausedasapizzatopping),thepizzaindustry,retailsalesandtheever-increasingdemandfromnewmarketsoutside Europe. Major sporting events in the summertime (such as European Cham-pionship football and the Olympic Games) also served to drive up demand. In spite of the volatility in the surrounding dairy market and the price pressure felt mainly from countries in Southern Europe, the price level remained relatively stable. The average price remained barely 2% under its 2011 level.

Thedemandforso-calledsingle-loaf(individuallypackaged,singleblock)mozza-rella appears strong, especially from new markets outside Europe. In 2012, Belgomilk sold this new packaging option in more than 50 countries.

The Belgomilk factory in Langemark commencedwork in 2012 on a major project to build a

new mozzarella factory. This new factory isintended to provide the additional capacity

that will be needed to meet the increase in demand for mozzarella expected in the yearsahead.

— M

ilcob

el 2

012

14

Whey productsWorldwide demand for whey products remained strong in 2012, especially from the sport food (WPC80), baby food (WPC35 and DWP) and clinical food marketsegments. The difference between the lowest and highest European price recorded for whey powder over the course of the year came to 26%. The European market price for whey powder rose 7% in 2012 compared to its 2011 level.

Baby foodWorldwide demand for high-quality baby food continued to grow sharply in 2012, driven notably by unusually strong demand from the Chinese market. As would be expected, sales of Belgomilk’s baby food, which is produced in cooperation with Fasska, continued to benefit from this increasing demand.

PeoplePeopleareimportanttoBelgomilk.Belgomilkstrivestoprovideallofitsemployeeswith a fascinating and varied work experience. Enthusiastic employees are afforded ample leeway and resources to grow their skills and expand Belgomilk’s business. Moreover, Belgomilk believes in collaboration within a strong team. Belgomilk is a solid employer that invests vigorously in people, markets and infrastructure.

In 2012, each and every one of our employees was invited to participate in a presen-tation and discussion concerning Belgomilk’s future plans and the results of the staff survey on employee satisfaction and engagement.

QualityBelgomilk’sLangemarkandKallo factoriesagainsuccessfullypassedBRC, IFSandACS quality audits in 2012. And once again, a large number of new and reputable clients audited Belgomilk’s factories as well. The quality requirements put forward by these authorities and clients are becoming more and more demanding. Belgomilk welcomes this challenge of continuously evaluating and improving its quality perceptions and quality systems. And in this context, when it comes to quality, food safety comes first. Belgomilk also pays a great deal of attention to the sensory aspects of its products: taste, aroma, instant and other functional aspects. Belgomilk’s goal is to consistently score higher on these points than its competitors.

Research and developmentBelgomilk is continually seeking to enhance its products with new characteristics that will serve to further distinguish these products from others on the market. This could include characteristics related to nutritional value and health, sensory aspects such as aroma and taste, or so-called functional characteristics, one example of whichistheelasticqualityofmozzarellaonapizza.

Corporate Social ResponsibilityBelgomilk consciously opts for CSR (Corporate Social Responsibility). In this connection, the Belgomilk factories in Langemark and Kallo are now bothoperating in accordance with a so-called CSR charter. This charter comprises the concrete initiatives undertaken by both sites in the areas of people (social), planet (environment) and profit (economic sustainability).

In 2012, Belgomilk’s Kallo plant put a CHP (Combined Heat and Power, orcogeneration) unit into operation.

Every precaution has been taken with the mozzarella project at Langemark tominimise the environmental impact of the new factory.

ProspectsIn the years ahead, Belgomilk is seeking to continue its growth in accordance with its two main pillars of business.

The first pillar relates to the development of brands for international consumer markets. This includes milk powders, toddler growth milk, baby food and other high-grade dairy products. Nutritional value and health play a key role here. The brand portfolio consists of Incolac (instant full-fat milk powder), Binco (popularly positioned milk powder) and baby food.

As a second pillar, Belgomilk concentrates on specialised ingredients for the food and beverage industry. Its focus here is primarily on European markets, but it is increasingly paying attention to markets outside Europe. To succeed, it is crucial to operate in a solution- and service-oriented way and to provide clients with technical support.Theproductsinquestionincludemozzarellacheeseastoppingforusebypizza restaurants and the pizza industry as well as (specialised) powder productsfor the food and beverage industry (chocolate industry, ice cream industry, bakery industry and baby food).

As such, Belgomilk’s business plan provides not only for the continued expansion of state-of-the-art production facilities, it also guarantees a range of products of the highest quality which are produced in the most efficient way possible.

Milcobel 2012 —

17

The cheese master plan of the Milcobel Group calls for an increasing amount of members’ milk to be processed into a wide range of cheese specialities in order to enhance the group’s product portfolio. Moreover, the goal is to process up to 25% of the current milk supply at the Moorslede site by 2020. In order to carry out the industrial component of the cheese plan, EUR 50 million was invested in the Moorslede factory during the 2008-2012 period.

In addition to being used to perform extensive renovations on existing plants and to make further progress in the area of quality and food safety assurance, these investments were also devoted to a significant expansion of capacity. On the one hand, this increase in capacity allowed the production of the Milcobel Group’s consumer cheeses to be concentrated. The production of consumer cheese, which had previously taken place at the Gierle factory, has been integrated into operations at Moorslede since May 2012. On the other hand, it also provides additional capacity with which to carry out the growth strategy.

A higher degree of automation and robotisation was sought as part of the renovation efforts and the new investments that were made, but care was also taken during the process design and implementation stages to fully preserve the specific characteristics of the cheese factory in Moorslede. The overall concept enables customised versions of a large assortment of cheeses to be produced. This flexibility is vital to supporting the product development of our cheese specialities as well as to fulfilling the growth strategy which is driven by product differentiation.

TheopenhousethatwasheldonthefirstweekendofOctober,alongwitharobustmediacampaignwhichincludedawell-receivedTVcommercial, resulted in a 15% increase in sales of Brugge Kaas in the final months of the year as compared to the same period in 2011.

Recent market research indicates that Brugge Kaas is now a member of the exclusive club of top brands in Belgium: two out of three Belgians are familiar with the Brugge Kaas brand. The thing that makes us most confident in the future is that we are the best at translating our name recognition into sales, which means that we have the highest fan score. Brugge Kaas consumers are loyal customers who also spread the word about our products.

The continual growth trajectory of Brugge Kaas over the last several years - at a time when so many name brands have taken a beating at the hand of store brands - has not gone unnoticed by retailers. Its distribution and visibility within the retail product range are continually improving. This means that the growth trajectory can and will continue to progress in the years to come as well.

Step by step, the position of the Belgian cheese category is being staked out within the overall range of cheeses at the international level. In the meantime, a large number of cooperation agreements have been finalised with local partners for the distribution and promotion of consumer cheeses produced at the factory in Moorslede. Our primary focus is on the traditional channels of cheese merchants and specialty stores that play a key role in the development of new cheese habits everywhere. In a number of countries, however, retailers have already been persuaded to start carrying Brugge Kaas specialties.

In addition to our own brands, our cooperation with Belgian retailers for their store brands constitutes an important development pole. This primarily involves the supply of pre-packaged cheese solutions that rely upon the cutting and packaging capabilities within the group,namelyKaasimportJanDupont.

Consumer cheese and butter

Milcobel 2012 —

19

Re-marque-able milkInzaistheMilcobelGroup’sconsumptionmilkdivision.Inza’sbusinessactivitiesare increasingly being oriented towards the production and commercialisation of functional drinks and the development of the product range under its own brands.

Research and development, targeted investments, a comprehensive quality policy supportedbyIFS,ACSandGMPcertificates,aswellasexperiencedanddedicatedemployees, guarantee a contemporary production system and a broad range of quality products.

Traditionally,Inzaiswellrepresentedinallimportantdistributionchannels,eitherwith products of its own brand, products of a third party with a premium brand, or with a private label. More than half of the total number of products is exported both in and outside Europe. Wholesale, wholesale dairy distribution and groups such as schools and industrial kitchens are the traditionally important customers. Inzaalsoworksintheout-of-homemarketsegment.

2012: a year of changeFollowing a few difficult years with respect to profit and margins for the consump-tionmilksectoringeneral,andforInzainparticular,apositivechangeoccurredin2012. Nonetheless, prices of consumption milk had declined considerably during thefirst6monthsoftheyear,whichmadeforadifficultfirsthalfof2012.Duringthe second half of the year, however, it became possible to raise sales prices. Better margins were achieved on average over the course of the year. These improvements in margin were partially facilitated by the lower price that was paid for milk on average during 2012 compared to 2011.

A major shift also occurred in the product range during 2012 towards more products with higher added value. This was a result of the continued development and growth of the specialised product range as well as the launching of the new Yogho!Yogho! range.

In addition to this, there was an increase in business activity compared to 2011. Volumeroseby4.5%andturnoverincreasedby3.5%.Togetherwithextensivecostsavings, this also contributed to the company’s improved profitability.

Investments in 2012 were devoted mainly to the expansion of infrastructure and processing equipment in order to further develop the specialised product range.

Prospects for 2013Continued positive change is expected for 2013. In line with the strategy that has been outlined, a further expansion of the specialised product range with higher added value is anticipated. The aim is therefore to minimise the influence of the highly volatile nature of the raw materials market as much as possible.

In order to be able to fully realise a significant expansion of the volume of products with higher added value, important investments in infrastructure and processing equipment are anticipated for 2013. This will also contribute to a boost in the overall level of quality, with the aim of complying with the specific requirements related to the production of baby food.

Because brands are also more immune to a volatile raw materials market, more effort will be devoted to the development of the Choco!Choco and Yogho!Yogho! brands in 2013. The necessary commercial and marketing activities will be organised to support this effort.

Special attention will continue to be paid to even more extensive cost savings and improvements in yield, both of which must contribute to the improved profitability of the company.

ChallengesHavingregardtomattersofscale,Inzaisobligedtoconstantlyexpandtheshareofproducts with higher added value and flexibly tap into market circumstances that are changing at an increasingly fast pace. In this context, the influence of relatively large price fluctuations on consumption milk is diminished under a private label.

As far as this is concerned, innovation through research and development, not only on new products but also on processes, takes centre stage. In addition, increasing attention will also be paid to the export of milk and milk drinks outside Europe, including China. In 2012, a substantial growth in exports was recorded compared to the previous year.

There are also on-going efforts to further expand partnerships with strategic partners for specialised products. This will be carried out within a sustainable development framework and for the benefit of all stakeholders. In 2013, it is once again expected that an important step will be taken in the right direction by significantly expanding these operations.

Consumption milk and functional drinks

— M

ilcob

el 2

012

20

A very late summerGiven the large number of new contracts it procured in the latter part of 2011, there were high hopes for Ysco in 2012. But unfortunately, in contrast to 2011, poor weather resulted in a very disappointing spring, and sales remained subpar through the first part of summer as well. This meant that, contrary to all expectations, Ysco ended June 2 million litres behind 2011. Fortunately, much of this lost ground was made up during the month of August, and the year ended with a net gain of 2.5 million litres, or almost 2% higher than 2011. Even turnover was almost 7% higher.

Ysco managed to maintain a steady volume on the French market, which at 23% remainsitsbiggest.ThesalesvolumeontheDutchmarket-Ysco’ssecondbiggest- again saw an increase, this time by 1.5 million litres to its highest level ever, and nowaccountsfor19%ofthetotalvolume.AlbertHeijninparticularexperiencedasensational growth in sales. Ysco’s sales in the United Kingdom also continued to improve in 2012.With a 13% share of total volume - driven mainly by Lidl - theUK is now Ysco’s third-largest market. In a collection of various smaller countries, Ysco’s volume grew by an impressive 3.5 million litres. This growth came primarily from Greece and Italy. The volume in the Belux region remained unchanged at 14 million litres, and as such remains Ysco’s fifth-largest market for volume with a share of 9%. Ysco again experienced a slight downturn in Scandinavia and Germany. These markets still account for a volume share of 9% and 8% respectively. In Spain, Ysco lost a great deal of volume for the fourth year running; its share has now shrunk to 6% of the total volume.

The private label share of the brand portfolio continued to rise for the 12th year running and now accounts for 90.5% of total volume. Co-packing – producing items under the brand of a different producer – rose to 2%, due mainly to the growth ofDaleFarm,basedinIreland.SalesofownYscobrandscontinuedtofallandnowamount to only 7.5% of the total volume. The main reasons for this are the private-label substitution of the Ysco brand by more and more clients and the continued growth of private labels on the European market. Figures also show that the retail segment accounts for 93% of total Ysco sales and that the food service share, though amounting to only 5% of the total volume, is holding steady.

Sales of cones,Ysco’s largest product group, dropped by 1 million litres. However,this product group still accounted for 34% of the total volume. Scoop ice cream saw the biggest increases in 2012, with a growth of almost 4 million litres. The main reason for this was the continued growth in sales of premium 900 ml tubs, with an additional 2 million tubs sold. The share of scoop ice cream in the total package now amounts to 33%. Sales of jumbos once again rose by one million litres and account for 20% of the total volume. The chocosticks product group fell for the third year in a row and now maintains a 6% share of volume. The volume share of cakes and cups remainedunchangedat3%and2%respectively.Despiteaweaksummer,salesofsorbet rose by a half million litres and captured a volume share of 1%.

Good results nonethelessDespiteanaltogethermediocresummerthatfailedtoproducetheexpectedgrowth in volume that had been budgeted, Ysco still managed to record very good results. This is remarkable considering the fact that Ysco operates in an extremely competitive market with overcapacity, and one in which many of its competitors find themselves in deep trouble. As a result, consolidations and closures have become commonplace in the ice cream market.

These good results can be attributed in part to extensive efforts on the part of Ysco in recent years to keep fixed costs to an absolute minimum, continually increase production efficiency and reduce logistical costs. In addition to this, utmost effort hasgoneintoincreasingmargins.Duringannualnegotiations,priceincreaseswerenegotiated for the majority of our clients. Moreover, prices for raw materials also remained within the anticipated budgets and production yields were very good at bothLangemarkandArgentan.

2013: strong momentum, continued growthMost annual contracts with the supermarket chains for 2013 were negotiated in the autumn of 2012. Ysco again succeeded in negotiating price increases for some of these new contracts, which should have a positive impact on results. In addition to this, a number of new contracts were again landed during these negotiations, which will likewise guarantee the volume for 2013. If this summer is normal weatherwise, further growth in volume is definitely possible.

Langemark’s production capacity for jumbos will be further expanded in 2013by investing in a new production line for bulk packaging. A smaller line for the production of a mini 200 ml version of the successful premium tub will also be set up.

All of the fundamentals needed to achieve good results are firmly in place, and the only major unknown is how prices for raw materials will evolve. If these prices remain within budget Ysco is practically assured to once again be in a position to achieve good results in 2013.terug een goed resultaat kunnen halen.

Ice cream

Milcobel 2012 —

23

Cheese packaging and distribution

The link between consumers and producers for the BENELUX!The strategic mission of cheese packaging and distribution (hereafter referred to as “Cheese Service”) has remained unchanged for years: to maintain a route-to-market to every point of sale where cheese is sold. The Cheese Service must be able to make direct or indirect deliveries anywhere, whether it’s to a specialty cheese shop, a traditional shop (butcher, delicatessen, market stall, etc.), a convenience store, a deli shop, a social and corporate event caterer, or a retail outlet.

Further to thetakeoverofDupontCheeseNL located inNieuw-Vennep(nearSchipholAirport), theinfrastructureneededtoachievethisontheDutchmarkethasbeeninplacesinceJanuary2012.Thismeans that, within the Benelux countries, a distribution service consisting of the three companies involved can be provided to both buyers (“customers”) and producers (“suppliers”) that covers the entire Benelux territory and is typified by a high level of service.

In late August, Milcobel took over the shares of local Bruges firm Vandenbroucke-Lemaître bvba(better known in Bruges under the trade name Keesbollekaas). As of 1 November, these cheese trade activitieshavebeensuccessfullyintegratedintoDupontBelgium’soperations.

The common denominator here is a“Passion for Cheese” in all respects, with a clear focus on thepremium segment. The product range is nevertheless differentiated and tailored to the needs of each channel, with a total focus on cheese. In this sense, there is a clear evolution towards a true specialist and supplier to other wholesalers/distributors (including meat products, dairy and the hospitality industry) and franchise formulas. This focus on cheese in all its forms (bulk and packaged) has led to a deep and wide range (1,000 types of cheese and more than 2,000 references) that can be delivered within 24 hours according to the “make to order” principle. To be able to realise this in daily practice, preferential relationships have been developed with a pool of suppliers consisting of more than 250 cheese producers, a number of whom are specialised in raw-milk cheese and/or AOC certification. In order to optimise the delivery route for these smaller producers, platforms (“grouping”) hasbeenoptedforinFrance,Italy,SwitzerlandandSpain.

For the companies in Belgium, the year 2012 ended up in line with expectations. In the Netherlands, there were a number of non-recurring expenditures following the acquisition that had a negative impact on results. The necessary corrective actions were taken to address this issue so that a future founded on a Benelux organisation can be faced with confidence.

Consolidation in the sector is proceeding unabated and the number of cheese wholesalers/distributors/packagersissteadilydeclining.Recently,cheesepackagerIDB(Belgium)andwholesalerZijerveld&Veldhuyzen(Netherlands)wereabsorbedbyRoyalFrieslandCampina.InnorthernFrance,wholesaler Prolaidis was incorporated into the national structure of France Frais. Competition willcontinue to grow in the years to come and even national borders will begin to dissolve.

WeremainverymuchconvincedthatastrongregionalpresenceconsistingofDupont innorthernBelgium,CamalinsouthernBelgiumandDupontCheeseinthe“Randstadregion”oftheNetherlandswill form the foundation of a customer proximity strategy, with the added asset of many years’ worth of expertise in cheese. To achieve this, the competence and dedication of our 300 passionate employees will be a critical factor. Our low rate of turnover is proof of this passion for cheese and at the same time serves as a guarantee that our competence in this area will be preserved within the organisation.

— M

ilcob

el 2

012

24

Board of directors

Veys Guido ChairmanGeelen Jean Deputy Chairman, Circle Limburg & BrabantWittevrongel Henri Circle Noord Oost-VlaanderenDesmet Christian Circle Zuid Oost-VlaanderenBruurs Jan Circle Noord-West AntwerpenVan Laer Luc Circle KempenlandCoens - De Roo Greet Circle ‘t Brugse OmmelandVermander Geert Circle WesthoekWallays Jan Circle Zuid West-VlaanderenD’haemer Kris French-speaking CirclePeeters Paul External director

audit committee

Wallays JanVeys GuidoGeelen JeanD’haemer KrisBruurs Jan

statutory auditors

PricewaterhouseCoopersRepresented by Lozie Filip

managing Board

Buggenhout Patric CEO Neirynck Geert CFOVan Gelder Luk Industrial products and third-country exportVan Hoe Luc Consumer cheese and butterMottar Jef Consumer milkHuyskens Patrick Cheese packaging and distributionVan Nieuwenborgh Bert Ice cream

Who is who in Milcobel 2012?

— M

ilcob

el 2

012

26

ASSETS

FIXED ASSETS

Intangible fi xed assets

Positive consolidation differences

Tangible fi xed assets Land and buildings Plant, machinery and equipment Furniture and vehicles Leasing and other similar rights Other tangible fi xed assets Assets under construction and advance payments

Financial fi xed assets Companies accounted for using the equity method Participating interests Other enterprises Participating interests and shares Amounts receivable

CURRENT ASSETS

Amounts receivable after more than one year Other amounts receivable

Stocks and contracts in progress Stocks Raw materials and consumables Finished goods Goods purchased for resale

Amounts receivable within one year Trade debtors Other investments and deposits

Cash at bank and in hand

Deferred charges and accrued income

TOTAL ASSETS

Codes PERIOD 2012 PERIOD 2011 in € in €

20/28 183,123,499 165,799,176

21 8,940,889 7,428,595

9920 2,341,110 1,721,961

22/27 170,684,773 155,451,881 22 42,303,853 37,632,450 23 104,233,367 82,209,020 24 6,547,884 5,610,726 25 1,895,778 2,801,951 26 180,097 204,542 27 15,523,794 26,993,192

28 1,156,727 1,196,739 9921 1,005,015 1,031,407 99211 1,005,015 1,031,407 284/8 151,712 165,332 284 2,790 2,790 285/8 148,922 162,542

29/58 227,432,834 234,332,644

29 2,112,720 2,207,685 291 2,112,720 2,207,685 3 95,150,196 96,264,916 30/36 95,150,196 96,264,916 30/31 18,039,256 17,756,789 33 64,357,729 66,828,762 34 12,753,211 11,679,365

40/41 126,112,249 133,183,303 40 114,806,998 122,387,400 41 11,305,251 10,795,903

54/58 1,572,085 1,735,362 490/1 2,485,584 941,378

20/58 410,556,333 400,131,820

A. annual accounts1. Consolidated balance sheet after appropriation

Milcobel 2012 —

27

Codes PERIOD 2012 PERIOD 2011 in € in €

10/15 113,011,230 106,894,698

10 30,500,382 28,289,249 100 31,707,895 29,799,817 101 1,207,513 1,510,568 11 32 32 9910 78,463,994 75,918,890 9912 2,731 2,731 15 4,044,091 2,683,796

9913 72,198 88,062

16 26,656,322 29,575,318

160/5 3,666,596 7,050,533 160 3,198,756 2,351,617 163/5 467,840 4,698,916 168 22,989,726 22,524,785

17/49 270,816,583 263,573,742

17 95,050,423 92,221,728 170/4 95,043,943 92,212,008 172 1,752,635 2,303,815 173 93,291,308 89,908,193 178/9 6,480 9,720

42/48 174,030,464 169,967,308 42 24,691,651 22,687,868 43 46,722,284 31,831,007 430/8 46,722,284 31,831,007 44 80,136,027 93,659,096 440/4 80,136,027 93,659,096 45 18,429,258 17,983,498 450/3 2,407,184 2,246,749 454/9 16,022,074 15,736,749 47/48 4,051,244 3,805,839

492/3 1,735,696 1,384,706

10/49 410,556,333 400,131,820

LIABILITIES

EQUITY

Capital Issued capital Uncalled capitalShare premium accountConsolidated reserves (+)(-)Translation differences (+)(-)Investment grants

MINORITY INTERESTS

PROVISIONS, DEFERRED TAXES AND LATENT TAXATION LIABILITIES

Provisions for liabilities and charges Pensions and similar obligations Other liabilities and chargesDeferred tax and latent taxation liabilities

AMOUNTS PAYABLE

Amounts payable after more than one year Financial debts Leasing and other similar obligations Credit institutions Other amounts payable

Amounts payable within one year Current portion of amounts payable after more than one year falling due within one year Financial debts Credit institutions Trade debts Suppliers Taxes, remuneration and social security Taxes Remuneration and social security Other amounts payable

Deferred charges and accrued income

TOTAL LIABILITIES

— M

ilcob

el 2

012

28

Operating income Turnover Increase (decrease) in stocks of fi nished goods, work and contracts in progress (+)(-) Other operating income

Operating charges Raw materials, consumables Purchases Increase (Decrease) in stocks (+)(-) Services and other goods Remuneration, social security costs and pensions Depreciation of and amounts written off formation expenses, intangible and tangible fi xed assets Amounts written down stocks, contracts in progress and trade debtors - Appropriations (write-backs) (+)(-) Provisions for risks and charges - Appropriations (+)(-) Other operating charges

OPERATING PROfIT (OPERATING LOSS) (+)(-)

Financial income Income from fi nancial fi xed assets Income from current assets Other fi nancial income

Financial charges Debt charges Amounts written down on positive consolidation differences Other fi nancial charges

PROfIT (LOSS) ON ORdINARy ACTIvITIES BEfORE TAXES (+)(-)

Extraordinary income Gain on disposal of fi xed assets Other extraordinary income

Extraordinary charges Amounts written down fi nancial fi xed assets Loss on disposal of fi xed assets Other extraordinary charges

PROfIT (LOSS) fOR ThE PERIOd BEfORE TAXES (+)(-)

Codes PERIOD 2012 PERIOD 2011 in € in €

70/74 891,574,105 901,236,898 70 880,204,950 884,599,138

71 -2,783,554 3,375,309 74 14,152,709 13,262,451

60/64 883,217,888 895,171,277 60 632,532,119 654,168,763 600/8 633,082,665 655,963,576 609 -550,546 -1,794,813 61 123,890,948 117,205,532 62 105,020,990 98,593,771

630 20,936,118 20,755,193 631/4 448,966 126,586 635/7 -3,382,941 905,426 640/8 3,771,688 3,416,006

9901 8,356,217 6,065,621 75 5,641,909 5,151,070 750 50,500 932,164 751 144,390 757,605 752/9 5,447,019 3,461,301

65 10,047,641 8,961,415 650 6,529,011 6,607,411 9961 687,823 426,429 652/9 2,830,809 1,927,575 9902 3,950,485 2,255,276

76 427,664 2,621,617 763 278,826 2,602,379 764/9 148,838 19,238

66 196,034 150,128 661 6 663 12,523 116,792 664/8 183,511 33,330

9903 4,182,115 4,726,765

2. Consolidated

income statement

Milcobel 2012 —

29

Codes PERIOD 2012 PERIOD 2011 in € in €

780 770,041 1,054,564

680 1,168,538 1,270,479

67/77 90,319 147,057 670/3 95,204 147,057

77 4,885

9904 3,693,299 4,363,793

9975 -26,392 32,318 99751 32,318 99651 26,392 9976 3,666,907 4,396,111

99761 -15,864 -2,740 99762 3,682,771 4,398,851

Transfer from postponed taxes and latent taxation liabilities

Transfer to postponed taxes and latent taxation liabilities

Income taxes (+)(-) Income taxes Adjustment of income taxes and write-back of tax provisions PROfIT (LOSS) fOR ThE PERIOd (+)(-)

Share in the result of the companies accountedfor using the equity method (+)(-) Profi ts Losses

CONSOLIdATEd PROfIT (LOSS) (+)(-)

Of which:Share of third parties (+)(-) Share of the group (+)(-)

— M

ilcob

el 2

012

30

NAME, full address of the REGISTERED OFFICE and for the enterprise governed by Belgian law,the COMPANY NUMBER

Method used(1)

Proportion ofcapital held

(2) (in %)

Change of percentageof capital held

(as compared tothe previous period)

B.M.F. Lait sarlRue de la Gare 3087 - 59299 Boeschepe - Frankrijk

I 100.00 0.00

Milcobel Nederland bvEverdenberg 15 - 4902 Oosterhout

I 100.00 0.00

Milcobel 3 F cvbaFabriekstraat 141 - 9120 Kallo (Beveren-Waas) - België - BE 0424.899.491

I 100.00 0.00

Cheeseline nvLieven Bauwensstraat 9 - 8200 Sint-Andries - België - BE 0441.187.078

I 100.00 0.00

Fassbel nvFabriekstraat 141 - 9120 Beveren-Waas - België - BE 0476.830.917

I 50.00 0.00

Kaasimport Dupont nvLieven Bauwensstraat 9 - 8200 Sint-Andries - België - BE 0405.109.216

I 100.00 0.00

Ysco nvFabriekstraat 141 - 9120 Beveren-Waas - België - BE 0472.336.451

I 100.00 0.00

Ysco France sasAvenue de la 2e DB 53 - 61208 Argentan - Cedex - Frankrijk

I 100.00 0.00

Ysco holding France sasuRue de la Gare 3087 - 5929 Boeschepe - Frankrijk

I 100.00 0.00

Belgomilk cvbaFabriekstraat 141 - 9120 Beveren-Waas - België - BE 0870.017.447

I 99.99 0.00

ZVF Inza cvbaWasserijstraat 5 - 2900 Schoten - België - BE 0428.890.547

I 100.00 0.00

Kempico cvbaMelkerijstraat 1 - 2275 Lille - België - BE 0431.515.287

Zuivelindustrie Zandhoven cvbaWasserijstraat 5 - 2900 Schoten - België - BE 0406.045.562

99.99 0.00

Camal nv Route de Légipont 12 - 4671 Barchon - België - BE 0412.859.912

I 100.00 0.00

I 99.74 0.00

1. LIST Of ThE CONSOLIdATEd SUBSIdIARy COMPANIES ANd COMPANIES INCLUdEd USING ThE EQUITy METhOd

3. Notes

on the consolidated

annual accounts

Milcobel 2012 —

31

NAME, full address of the REGISTERED OFFICE and for the enterprise governed by Belgian law,the COMPANY NUMBER

Method used(1)

Proportionof capital held

(2) (in %)

Change of percentageof capital held

(as compared tothe previous period)

Les Fromagers des Flandres GEIERue de Luxembourg 15 - 59059 Roubaix cédex 1 - Frankrijk

A 50.00 0.00

2. LIST Of SUBSIdIARy COMPANIES EXCLUSIvELy OR JOINTLy CONTROLLEd NOT INCLUdEd (pursuant to article 107 of the royal decree of 30 january 2001 in imple-mentation of company law) ANd ASSOCIATEd ENTERPRISES ACCOUNTEd fOR USING ThE EQUITy METhOd ( )

NAME, full address of the REGISTERED OFFICE and for the enterprise governed by Belgian law,the COMPANY NUMBER

Method used(1)

Proportion ofcapital held

(2) (in %)

Change of percentageof capital held

(as compared tothe previous period)

Bedrijvenpark Wingene nvOude Bruggestraat 13 - 8750 Wingene - België - BE 0461.014.769

7.77 0.00

Héritage 1466 nvRue de Charneux 32 - 4650 Herve - België - BE 0425.964.513

V4 20.00 0.00

St Marie cvbaBredabaan 522 - 2990 Wuustwezel - België - BE 0403.743.989

I 100.00 0.00

DupontCheese Nederland BVEscudoweg 1 - 2153 PC Nieuw-Vennep- Nederland - NL 800505177B01

I 100.00 100.00

(1) F Full consolidationE4 Joint subsidiary enterprise accounted for using the equity method where its activities cannot be closely integrated into the activities of the enterprise having the joint

control (article 134, second al. of the aforementioned Royal Decree).(2) Proportion of capital of those enterprises being held by the enterprises included in the consolidated accounts and persons acting in their own names but on behal of

these enterprises

(1) Reason for exclusion: A. Subsidiary company of minor importance.(2) Proportion of capital of those enterprises being held by both enterprises included in the consolidated accounts and persons acting in their own names but on behalf of

these enterprises.

— M

ilcob

el 2

012

32

Information and the criteria governing the application of full consolidation, proportional consolidation and the equity method as well as those cases in which these criteria are departed from, and justification for such departures (Decree of 30 january 2001 in implementation of Company Law).

The full consolidation method was applied to all companies which are controlled directly or indirectly by the consolidating company, by law or in fact, and to companies over which control is shared. These companies have been included in the consolidated annual accounts using the full consolidation method or the equity method, according to the degree of integration into Milcobel. The participations in affliated companies have been valued and included in the accounts using the equity method..

Disclosure of the criteria governing the valuation of the various items in the consolidated annual accounts, and in particular:

- the application and adjustments of depreciation, amounts written down and provisions for liabilities and charges, and revaluations (pursuant to article 165, VI.a. of the Royal Decree of 30 january 2001 in implementation of Company Law).

- the bases of translation applied to express in the consolidated accounts items which are, or originally were, expressed in a currency other than the currency in which the consolidated accounts are stated, and the translation in the consolidated accounts of the accounting statements of subsidiaries and associated companies governed by foreign law (by application of 165 VI.b of the aforementioned Royal Decree).

IIntangible fixed assets The establishment costs are depreciated on a straight-line basis at 20%.

Immateriële vaste activa The acquisitions and brought in intangible fixed assets are booked on the asset side of the balance sheet at their acquisition price or brought in value and are

depreciated on a straight-line basis in accordance with the following percentages: min. max. 1. Research and development costs 20 20 2. Concessions, patents, licences, brands, etc. 10 20 3. Goodwill 10 20 4. Advance payments 0 0

3. CONSOLIdATION CRITERIA ANd ChANGES IN ThE CONSOLIdATION SCOPE

4. SUMMARy Of vALUATION RULES ANd METhOdS Of CALCULATING Of dEfERREd TAXES

ASSETS

Milcobel 2012 —

33

Consolidation differencesThe consolidation differences represent the divergences between on the one hand the acquisition value and on the other the corresponding part of the equity capital on the date on which the shares have been acquired or a nearby date close to it.

Insofar as these differences originate from an over or under valuation of specific items on the asset or liabilities side, they will be allocated to it. The remaining difference is included in the consolidated accounts in the item “consolidation differences” on the asset or liabilities side of the balance sheet, depending on whether the acquisition value is higher or lower than the share in the (possibly recalculated) equity capital.

Activated consolidation differences are depreciated in a straight line over a five-year period. Additional or extraordinary depreciations are applied to these differences when, as a result of changes in economic circumstances, it is no longer justified to retain them at that particular value in the consolidated balance sheet.

Negative consolidation differences are booked to the liabilities side. They only benefit the consolidated profit & loss account to cover operational losses incurred for reasons existing at the time of the acquisition (overcapacity, staffing levels too high) and within a limited period of time. They are booked to code 9960 ‘Amounts written down on positive consolidation differences’.

Tangible fixed assets Tangible fixed assets are booked to the asset side of the balance sheet at their acquisition price (incl. additional costs) or their brought in value. Depreciations are booked according to the straight-line method (pro rata temporis) over the economic life. The depreciation percentages are as follows: min. max.1. Industrial, administrative and commercial buildings 3 102. Plant, machinery and equipment 5 253. Vehicles 10 254. Office equipment and furniture 10 335. Other tangible fixed assets 3 206. Assets under construction and advance payments 0 07. Leasing and similar rights: according to the category to which the asset belongs

Stocks- Raw materials: acquisition value according to weighted average price or lower market value on balance sheet date for solid and liquid dairy produce and for ice

cream activities- Consumables and goods purchased for resale::

• acquisitionvalueaccordingtoweightedaveragepriceorlowermarketvalueonbalancesheetdateforsolidandliquiddairyproduceandforicecreamactivities;

• acquisitionvalueaccordingtoFIFOmethodorlowermarketvalueonbalancesheetdateforliquiddairyproduce;• acquisitionvalueaccordingtotheweightedaverageprice,FIFOmethodorindividualisationofthepriceofeachcomponentforthecheese

distribution and this depending on the nature of the product. The acquisition value may not exceed the market value on the balance sheet date;- Finished goods: valuation at manufacture price or market value, if this is lower on the balance sheet date;

• Inadditiontothepurchasingcostofrawmaterials,consumergoodsandconsumables,themanufacturepriceincludesproductioncoststhataredirectlyaccountable to individual products or product groups.

Accounts receivable within one yearAccounts receivable are included at nominal value. Write downs are booked to these accounts receivable when their collectibility is in doubt.

— M

ilcob

el 2

012

34

IPLCestmentsShares and fixed income securities: acquisition value.Credit balances at financial institutions: nominal value.

Cash at bank and in hand

Valuation at nominal value.

Consolidated reservesThe group reserves include the reserves and results carried forward of the consolidated company, raised with the share of the group in the results, after deduction of dividends, of the full and proportionally consolidated companies and the companies to which the equity method has been applied.

IPLCestment grantsIPLCestment grants are valued at nominal value after deduction of deferred taxes.

Provisions for risks and costsThe Board of Directors decides, on the basis of a prudent evaluation, which provisions should be made to cover the cost of early retirement, major repairs and maintenance, settlement of claims, supplied guarantees, hedge risks and possible other risks and costs that are probable or certain on the balance sheet date, but the extent of which is not yet known.

Deferred tax and latent liabilitiesDeferred tax and latent liabilities are booked:- To the differences resulting from the application of the valuation rules of the Group with respect to the statutory valuation rules of the Group

companies,- To the temporary differences between accounting and tax results,- To the granted not yet depreciated iPLCestment grants and untaxed gains values included in the company’s equity capital.

Amounts payable after one year and within one yearAmounts payable are booked at their nominal value.

Deferred charges and accrued incomeRevenue and costs are allocated to the period to which they apply.

Foreign currencyForeign currency receivables and payables are valued at the exchange rate applicable on the balance sheet date. Negative exchange rate differences are booked in results. Positive exchange rate differences are booked to transitory accounts on the liabilities side.

LIABILITIES

Milcobel 2012 —

35

Detailed explanation on the methods applied in determining deferred taxesDeferred tax and latent liabilities are booked:- To the differences resulting from the application of the valuation rules of the Group with respect to the statutory valuation rules of the Group

companies,- To the temporary differences between accounting and tax results,- To the granted not yet depreciated iPLCestment grants and untaxed gains values included in the company’s equity capital.

Analysis of Heading 168 of the liabilities Future taxation (Pursuant to article 76 of the Royal Decree of 30 january 2001 in implementation of Company Law)Deferred taxe (Pursuant to article 129 of aforementioned Royal Decree)

fUTURE TAXATION ANd dEfERREd TAXES (code 168)

22,989,727220,405

22,769,322

CONCESSIONS, PATENTS,LICENCES, KNOWHOW, BRANDS AND SIMILAR

RIGHTS (code 211)

GOODWILL(code 212)

ADVANCE PAYMENTS (code 213)

RESEARCH ANDDEVELOPMENT

COSTS

10,017,628

8,78249,573

1,727,527219,993

11,924,357

4,737,085

1,191,50249,57425,498

5,904,511

6,019,846

7,652,847

7,652,847

6,868,038

211,603

7,079,641

573,206

1,363,244

2,680,501

-1,727,527

2,316,218

2,316,218

31,619

31,619

31,619

Acquisition value at the end of the previous period

Movements during the period Acquisitions, including produced fi xed assets Sales and disposals Transfers from one heading to another (+)/(-) Other movements (+)(-)

Acquisition value at the end of the period

Depreciation and amounts written down at the end of the previous period

Movements during the period Recorded Cancelled Other movements (+)(-)

depreciation and amounts written down at the end of the period

NET BOOk vALUE AT ThE ENd Of ThE PERIOd

5. STATEMENT Of INTANGIBLE fIXEd ASSETS

— M

ilcob

el 2

012

36

OTHER TANGIBLEFIXED ASSETS

(code 26)

LEASING ANDSIMILAR RIGHTS

(code 25)

ASSETS UNDER CONSTRUCTION AND ADVANCED PAYMENTS

(code 27)

749,290

116,483

632,807

544,749

24,444116,483

452,710

180,097

9,899,709

25,578

-5,330,000

4,595,287

7,097,758

715,060

-5,113,309

2,699,509

1,895,778

1,895,778

26,993,192

33,800,665286,873

-44,944,145-39,045

15,523,794

15,523,794

Acquisition value at the end of the previous period

Movements during the period Acquisitions, including produced fi xed assets Sales and disposals Transfers from one heading to another (+)/(-) Other movements (+)(-)

Acquisition value at the end of the period

Depreciation and amounts written down at the end of the previous period

Movements during the period Recorded Cancelled Transfers from one heading to another (+)/(-) Other movements (+)(-)

depreciation and amounts written down at the end of the period

NET BOOk vALUE AT ThE ENd Of ThE PERIOd

OF WICH:Plant, machinery and equipment

LAND ANDBUILDINGS(code 22)

PLANT, MACHINERY AND EQUIPMENT

(code 23)

75,704,123

414,500

7,288,191

83,406,814

38,071,672

3,020,060

11,229

41,102,961

42,303,853

289,984,256

1,284,62716,902,22341,265,261

345,150

315,977,071

207,775,236

14,621,38015,928,384

5,102,079173,394

211,743,705

104,233,366

Acquisition value at the end of the previous period

Movements during the period Acquisitions, including produced fi xed assets Sales and disposals Transfers from one heading to another (+)/(-) Other movements (+)(-)

Acquisition value at the end of the period

Depreciation and amounts written down at the end of the previous period

Movements during the period Recorded Cancelled Transfers from one heading to another (+)/(-) Other movements (+)(-)

depreciation and amounts written down at the end of the period

NET BOOk vALUE AT ThE ENd Of ThE PERIOd

6, STATEMENT Of TANGIBLE fIXEd ASSETS FURNITUREAND VEHICLES

(code 24)

20,770,814

398,4272,049,0091,720,693

260,884

21,101,809

15,160,088

1,152,0681,858,378

100,147

14,553,925

6,547,884

Milcobel 2012 —

37

ENTERPRISESACCOUNTED FOR

USING THE EQUITY METHOD (code 280)

AOTHERENTERPRISES

(code 282)

1,041,229

1,041,229

-9,821-26,393

-36,214

1,005,015

2,791

2,791

2,791

162,542

10,01023,630

148,922

PARTICIPATING INTERESTS

Acquisition value at the end of the period

Acquisition value at the end of the period

Movements in the capital and reserves of the enterprises at the end of the previous period (+)(-) Share in the result for the fi nancial period

Movements in the capital and reserves of the enterprises accounted for using the equity method

NET BOOK VALUE AT THE END OF THE PERIOD