MEYCO ME5 - bmssolutions.fr

Transcript of MEYCO ME5 - bmssolutions.fr

Extended range, rugged, spraying head equipped with optional directed working light

Large diameter concrete conveying system

Productivity heightened with improved pumping efficiency

Accuracy increased with improved boom operation

Safety ensured by under-dosage prevention and a fail safe conveying system

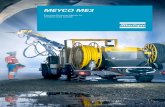

DEPENDABLE CONCRETE SPRAYINGACCURATE ECONOMICAL CONCRETE SPRAYER.

BETTER THAN EVER

2

Sturdy carrier with permanent electronic 4-wheel drive with ASS and TCS

Electric cable reel

Compacta+ sturdy telescopic boom load optimized design with retractable parking position and play free slide system

Constant flow high accuracy dosing system optimized for alkali free liquid accelerators

Control panel and Radio Remote control

2 x 1000 liter Containers for liquid accelerator

75 kW onboard compressor for optimal compaction of sprayed concrete.

Redundant and single point control panel for all functions and operation overview.

Complete machine function set controllable from standard Radio Remote Control.

ROPS/FOPS cabin with ergonomic drive by wire

3

+ WORLD CLASS SERVICEFlexiROC T35 and FlexiROC T40 are flexible and versa-tile tophammer drill rigs, developed and designed for high performance in demanding construction appli-cations. They are also a very efficient alternative for small and medi um size quarrying jobs. Even in tough terrain conditions, utilization of the rig is high, thanks to the long reach of the boom, FlexiROC T35 and FlexiROC T40 are flexible and versa-tile tophammer drill rigs, developed and designed for high performance in demanding

ATLAS COPCO SERVICE– IT’S NOT JUST ABOUTOUR PROMISES, IT’SABOUT DELIVERYWe offers several levels of service agreements tomeet the requirements of your operation and to secure your productivity. Our service agreements help you build a quality operation focused on proactive, planned maintenance to minimize unplanned downtime. We support maintenance with detailed parts information on every piece within our full inventory of components, accessories, and tools.

+ IMPROVED PRODUCTIVITY– Closed loop controlled constant flow liquid accelerator dosing system with

high accuracy– Flow meter for robust online measuring of a vast variety of accelerator types

– Meyco SE30 double piston pump with a super fast switchover resulting in constant concrete flow

– Single push button concept for intuitive and speedy operation

+ REFINED ACCURACY – Intuitive operator interface allows easy startup, operation and cleaning

– Customizable operator profiles speed up shift changes– Integrated diagnostics allows proactive maintenance and minimizes

downtime– Accelerator dosage with live adjustment provides flexibility

+ INCREASED SAFETY– Automatic pressure relief of blocked concrete lines

– Under dosage prevention– Hopper screen activated emergency stop

– Safe operator environment for tramming

MEYCO ME5PLUG AND SPRAYQUICK START UP FOR QUALITY CONCRETE SPRAYING.

4

= STANDARD = OPTION

CONCRETE SPRAYING PUMP

Meyco SE30 double piston pump with PRACTICAL constant flow for the full range from 6 m3/h up to 25 m3/h at 50 bar

Automatic reverse function for pressure relief

Manual central lubrication for pump unit

Feeding hopper 250 l at 1 320 mm height

Low profile feeding hopper 180 l at 1 160 mm height

Optimized screen for fibre reinforced concrete

Pump cylinder diameter 180 mm with 600 mm stroke

BOOM SYSTEMComnpacta+ spraying boom with slide system and proportional hydr. valves

Manual central lubrication for boom

Spraying head movement 135°/360°

Nozzle nutation (rotation) 8°

Max height 14.5 m (incl. 1.5 m spraying distance)

Max width 22.2 m (8 m each side incl. 1.5 m spraying distance)

Working lights LED 24 V, 6 x 50 W

2 working lights on turret, 1 working light on spraying head

Load match valves for higher safety

Retracted parking

3 metre parallel holding

Automatic parallel adjustment

DOSING SYSTEMFlow meter (system accuracy ± 2%)

Rotor/stator-pump max 24 l/min at 10 bar

Auto-stop for accelerator under dosage and dry run protection

CONTROL SYSTEM

PLC control system with touch screen

User profile machine parameter management and integrated diagnostics

Data logging for production data and system messages

Radio remote control with back-up cable, 20 m, with full function set

Control box stainless steel

Heater for control box and user panel

Sensor for concrete temperature in hopper

ELECTRICAL SYSTEMSupply Voltage 3 x 380-420/440-480

Frequency 50Hz/60Hz

Total installed power without compressor 60 kW

Total installed power with compressor 135 kW

Electric motor 55 kW

Cable size Buflex M 3x50+3G10, Cable for 60 kW without compressor

Cable size Buflex M 3x120+3G25, Cable for 135 kW with compressor

Recommended cable length is 80 m NOTE! Length is depending on cable type and voltage used

Cable reel with hydraulic drive

WATER SYSTEM

SPRAYING SYSTEMConveying and nozzle system diameter 100/80 mm

2 x 200 litre water tanks

Dual water pump 15 l/min at 12/200 bar for cleaning

Water hose reel with 15 m high pressure hose and spraying pistol

High pressure water pump 150 l/min at 80 bar for 20 kW low impact scaling

Hydraulic driven water hose reel with 100 m 1 1/4" hose

CARRIERDirect 4-wheel drive and steering +-25°, including front steering, 4-wheel steering, crab steering, ASS and TCS

Diesel engine Deutz 4 cylinder, TCD 3.6 74 kW, US EPA Tier 4F, EU Stage lV

Diesel engine Deutz 4 cylinder, TCD 3.6 74 kW US EPA Tier 3, EU Stage lllA downgrade

Power rating 74 kW at 2 300 rpm

Torque 388 Nm at 1 600 rpm

Hydrostatic power steering and transmission

Central joint oscillation ±15°

Rims/Tires 13.00/16.00 R20

Spare wheel

Open drivers cabin with protective roof, FOPS and ROPS, seat 90° sideways

Portable fire extinguisher

Fire suppression system Ansul/Fogmaker

Hydraulic front stabilizers 2x

Hydraulic rear stabilizers 2x

2 Circuit service brakes and SAHR emergency and parking brakes

Fuel tank 80 l

Electric system 24 V

Batteries 2 x 12 V, 70 Ah

Tramming lights 4 x 70 W

Brake lights

Horn and reverse alarm

Rearview and frontview camera

EAT (exhaust after treatment) system included with EPA Tier 4F, EU Stage lV

Lifting hooks on wheel hubs

Lifting kit

AIR SYSTEM

Rotary vane compressor 75 kW, 7 bar, 10.5 m3/min

Screw type compressor 75 KW, 7 bar, 10.5 m3/min

HYDRAULIC SYSTEMHydraulic tank 200 l

MISCELLANEOUSAccelerator tank 2 x 1 000 l

Heater and insulation for accelerator tank

Concrete release agent hand sprayer 5 l

Connection for external air supply

Toolbox

Automatic central lubrication system for boom, pump and carrier

Concrete release agent/pressurized form oil system 40 l tank including a hose reel

TRAMMING

Tramming speed on flat ground (rolling resistance 0.05) 18 km/h

Tramming speed on incline 1:8 7.8 km/h

Gradability at max load on good ground 30%

WEIGHT

Total weight without compressor 14 250 kg

Total weight 15 500 kg

DIMENSIONS

Width 2 200 mm

Height 2 920 mm

Length 11 500 mm

Ground clearance (with standard tires) 350 mm

TECHNICAL SPECIFICATIONS

5

0 m 1 m 2 m 3 m 4 m 5 m 6 m 7 m 8 m 9 m 10 m11 m12 m 13 m14 m

0 m 1 m 2 m 3 m 4 m 5 m 6 m 7 m 8 m 9 m 10 m11 m12 m 13 m14 m7 m

6 m

5 m

4 m

3 m

2 m

1 m

1 m

2 m

3 m

4 m

5 m

6 m

7 m

8 m

9 m

3 m

5.7 m

1.5

m

10 m

11 m

12 m

13 m

15 m

14m

15

13

13

14 m13 m12 m11 m10 m9 m8 m7 m6 m5 m4 m3 m2 m1 m0 m

14 m13 m12 m

12 m

11 m

10 m

10 m

11 m

12 m

9 m

8 m

7 m

6 m

5 m

4 m

3 m

11 m10 m9 m8 m7 m6 m5 m4 m3 m2 m1 m0 m

2 m

1 m

0 m

1 m

2 m

3 m

4 m

5 m

6 m

7 m

8 m

9 m

1.5

m

3 m

3 m

5.7 m

5.7 m

TECHNICAL SPECIFICATIONS

BOOM WORKING RANGE

Boom working range side view

Boom working range top view

6

1 32

0

2 200

0R8 110

R4

600

30%

0

5 100

8 650

11 500

15°15°1 32

0

2 60

0

2 92

0

350

Top view turning radius

Transport dimensions and gradability

DIMENSIONS

TECHNICAL SPECIFICATIONS

Rear View Front View Side inclination driving

7

COMMITTED TO SUSTAINABLE PRODUCTIVITY

We stand by our responsibilities towards our customers, towards the environment and the people around us. We make performance stand the test of time.This is what we call – Sustainable Productivity.

98

51 35

53 01c 2

016-0

6 Öre

bro, S

we

den

. Le

gal N

otice © C

opyrig

ht 2016

, Atlas C

op

co Ro

ck Drills A

B, Ö

reb

ro, Sw

ed

en. A

ny unau

tho

rized use o

r copyin

g of the contents o

r any part there

of is pro

hibite

d. Illustratio

ns an

d ph

otos m

ay show

eq

uipm

ent with o

ption

al extras. No w

arranty is mad

e reg

ardin

g spe

cifications o

r otherwise. S

pe

cifications an

d eq

uipm

ent are sub

ject to ch

ang

e with

ou

t notice. C

onsult yo

ur Atlas C

op

co Custo

mer

Center fo

r spe

cific inform

ation

.

www.atlascopco.com