Madras cements final report

-

date post

13-Sep-2014 -

Category

Education

-

view

6.009 -

download

3

description

Transcript of Madras cements final report

A STUDY ON THE WORKING CAPITAL MANAGEMENT OF

MADRAS CEMENTS LIMITED

Report submitted in partial fulfillment of the requirements

For the award of degree in

Master of Business Administration

Submitted by

Bala venkatachalam.s

Register no: 3511110836

Under the guidance of

DR.V.BALASUBRAMAIAN

Apr – May 2012

Page 1

Reg No – 3511110836

DECLARATION BY THE CANDIDATE

S.BALAVENKATACHALAM

Reg No – 3511110836

I MBA

SRM UNIVERSITY

CHENNAI

I hereby state that the report entitled, “A study on the working

capital management of Madras Cements Limited” was undertaken at

Madras Cements Limited (corporate head office) , R k salai,

Mylapore, Chennai, submitted to SRM UNIVERSITY, Chennai in

partial fulfillment of Master of Business Administration Degree is a

record of original work done by me and no part of this internship

report has been submitted for the award of any other Degree,

Diploma, Fellowship or other similar studies.

Page 2

ACKNOWLEDGEMENT

I put forth my heart and soul to thank The Almighty for being with me all

through my achievements, success and failures.

I express my sincere and whole hearted gratitude to the management of

Madras Cements Limited, Chennai for giving me a golden opportunity to

pursue a valuable project.

I extend my gratitude to Mr.Ramanarayanan (Manager-Accounts) for

guiding and helping me to solve all kinds of queries regarding the project

work. I would also like to thank him for his valuable suggestions and constant

encouragement at every step of my project work.

I sincerely thank Dr.jayashree suresh, SRM UNIVERSITY, for her

encouragement.

I extend my deep sense of gratitude to Dr.v.Balasubramanian, Faculty, and

SRM UNIVERSITY for providing support guidance and valuable ideas which

helped me to complete this project successfully.

Finally, I extend my heartfelt thanks to my friends and family members who

have been a source of inspiration and support throughout the project.

Page 3

EXECUTIVE SUMMARY

Madras Cements Ltd. is an India-based company that is principally engaged in the

manufacture of cement, ready mix concrete and dry mortar products. The

Company operates in two segments: cement and power generation from windmills.

The Company’s products include ordinary portland cement, portland pozzolana

cement and wind power. During the fiscal year ended March 31, 2011, the

Company’s cement production was 7.305 million tons; ready mix concrete division

had produced 59,589 cubic meters of concrete; dry mortar division had produced

27,156 tons of dry mortar, and wind farm division had generated 357200000

kilowatts hour.

The project entitled “Working Capital Management in Madras Cements Ltd”

deals in this segment. The term of study was kept limited to make the title true.

The purpose of the report is to get the in depth understanding of the process of

working capital management. With the growing Indian economy and the

government policies for infrastructure the demand for cement is increasing and

seeing this as an opportunity is under taking many new projects for expansion of

the production which are under implementation for increasing the capacity of the

plants. Working capital has been analyzed in two ways – overall study of the

working capital of Madras Cements Ltd and secondly, plant-wise working

capital of Madras cements ltd, since the company has fifteen plants in different

region and each plant has its own working capital.

The performance of the cement division of the company during the year was

satisfactory. During 2010-11 the cement production was 73.05 lacks tonnes,

compared to 80.26 lacks tonnes of the 2009-10.The clinker production at Alathiyur

and Jayanthipuram was lower at 34.96 in 2010-11 lacks tones as compared to

40.56 lacks tones the previous year of 2009-10 . The cement production at

Page 4

Alathiyur and Jayanthipuram was lower at 36.31 lack tones as compared to 47.9

lack tones during the previous year. The cement dispatches of Alathiyur and

Jayanthipuram units where 34.89 lack tones as compared to 47.5 lack tones during

last year.

During the 2010-11, the sale of cement was at 72.55 lack tonnes compared to 79.54

lacks tonnes the previous year of 2009-10.

The demand growth for the cement industry as a whole for the year of 2010-11 was

5%, compared to the growth of 11% for the previous year of 2009-10. The growth

percentage is the lowest in last several years.

The Southern Region witnessed a decline of 4% in 2010-11 compared to a growth

of 5% during the previous year of 2009-10. Within the Southern Region, the

States of Andhra Pradesh and Kerala, which are important market segments for the

Company, had witnessed negative growth. Lower infrastructure spending and

slow-down in the realty sector have contributed to this subdued growth. While

there has been a decline in the demand, the cement industry has seen a growth in

the capacity additions on All India basis and specifically in the Southern Region.

These factors have adversely affected the sales volume of the Company for the

year.

It has shown substantial decline in turnover, cash profit, profit before tax

and profit after tax. The total turnover of company has registered a decline of

4.61% in 2010-11 whereas operating profits for the year where lower by 27.10% in

2010-11 mainly on account of decrease in the volume of blended cement in the

overall cement sales, lower realisation and ineffective cost control.

The profit before tax was down by 43.97% at Rs.297.19 crores in 2010-11 as

against Rs.530.45 crores in the previous year of 2009-10. The profit after tax is

Page 5

210.98 crores in 2010-11 as against Rs. 353.68 crores in the previous year of

2009-10. EPS was 8.87 as against 14.86 in the previous year.

The objective of this project work is to focus on the working capital of the Madras

Cements Ltd and exploring its potential in the company. The project contain the

basic postulates of working capital, procedure of analysis of working capital, ratio

being used to define the working capital and the impact of working capital in the

company in case of excess or inadequacy. Also, the project contains analysis of

estimation of working capital requirement and the procedure to estimate working

capital requirement in manufacturing and trading concern and from the data

available it can be concluded that it holds a very strong position in the market.

Page 6

CONTENTS

CHAPTER PARTICULARS PAGE NO

1 INTRODUCTION

1.1 INTRODUCTION ABOUT THE STUDY

1.2 Need of working capital

1.3 Objective of the study

1.4 Scope and design of the study

1.5 Limitations

2 ORGANISATIONAL PROFILE

2.1.Company profile

2.2. Company history

3 INDUSTRY PROFILE

3.1.Cement industry in India

3.2. Cement industry

4 THEORITICAL FRAME WORK

5 DATA ANALYSIS AND INTERPRETATION

6 CONCLUSION

Page 7

INTRODUCTION

Chapter1

1.1 DEFINITION OF WORKING CAPITAL:

In the words of Prof.S.C.Kuchhal, “Working capital has to be, regarded as one of

the conditioning factors in the long run operations of a firm which is often inclined

to treat it as an issue of short run analysis and decision-making”. In the words of

Shubin, “Working capital is the amount of funds necessary to cover the cost of

operating the enterprise”. In the words of Genestenbug, “Circulating capital means

current assets of a company that are changed in the ordinary course of business

from one form to another as for example from cash to inventories, inventories to

receivables, receivables into cash.

CONCEPTS OF WORKING CAPITAL:-

There are two concepts of working capital:

1.Gross working capital

2.Net working capital.

In the broad sense, the term working capital refers to the gross working capital and

represents the amount of funds invested in current assets. Current assets are those

assets, which in the ordinary course of business can be converted into cash with in

a short period of normally one accounting year. In a narrow sense, the term

working capital refers to the net working capital. Net working capital is the excess

of current assets over current liabilities.

Working capital = Current assets – Current liabilities.

Page 8

Net working capital may be positive or negative. When the current assets exceed

the current liabilities the working capital is positive and the negative working

capital results when the current liabilities are more than the current assets. Current

liabilities are those liabilities

which are intended to be paid in the ordinary course of business within a short

period or normally one accounting year out of the current assets or the income of

the business. The gross working capital concept is financial or going concern

whereas net working capital is an accounting of working capital. These two

concepts of working capital are not exclusive; rather both have their own merits.

Gross concept is very suitable to the company form of organization where there is

divorce between ownership, management and control. The net concept of working

capital may be suitable only for proprietary form of organizations such as sole-

trader or partnership firms. However, it may be made clear that as per the general

practice net working capital is referred to simply as working capital

1.2 NEED FOR WORKING CAPITAL

The need for working capital to run the day-to-day business activities cannot be

overemphasized. We will hardly find a business firm which does not require any

amount of working capital. Indeed, firms differ in their requirements of the

working capital. We know that a firm should aim at maximizing the wealth of its

shareholders. In its endeavor to do, a firm should earn sufficiently return from its

operations. Earning a steady amount of profit requires successful sales activity.

The firm has to invest enough funds in current assets for generating sales. Current

assets are needed because sales do not convert into cash instantaneously. There is

always an operating cycle involved in the conversion of sales into cash.

Page 9

TYPES OF WORKING CAPITAL:

Working capital may be classified in two ways:

a. The basis of concept.

b. On the basis of time.

On the basis of concept, working capital can be further classified into:

a. Gross working capital.

b. Net working capital.

On the basis of time, working capital can be further classified

a. Permanent or Fixed working capital.

b. Temporary or variable working capital.

Gross working capital

Gross working capital is represented by the total sum of all current assets of an

organization. The gross working capital is also known as current capital or

circulating capital.

Net Working capital

Net working capital is the difference between the current liabilities. The concept of

net working capital helps the management to look forward the permanent sources

for financing the working capital. The working capital management has to examine

the proportion of the current assets, which has to be financed by permanent capital

or long term, borrowings.

Page 10

Permanent working capital.

Permanent working capital is that part of capital, which is permanently ,locked up

in the circulation of current assets and in keeping it’s moving. It can be classified

into:

i. Regular working capital and

ii. Reserve margin working capital.

Regular working capital

It is the minimum amount of liquid capital needed to keep up the circulation of

from cash to inventories to receivables and back again into cash.

Reserve margin working capital

It is the excess over the need for regular working capital that should be provided

for contingencies such as raising prices, business depressions, and strikes, fibers,

unexpected severe competition and special operations such as experiments with

products or with the method of distribution and the like which can be undertaken

only if sufficient funds are available.

Variable working capital

The variable working capital refers and denotes that the amount of funds over and

above the fixed working capital to take care of seasonal shifts etc. This variable

working capital also referred to as fluctuating or temporary working capital and

should be financed by short-term sources of funds.

The variable working capital changes with the volume of business. It maybe sub-

divided into:

I .Seasonal.

ii. Special working capital.

Page 11

The capital required to meet the seasonal needs of industry is termed as seasonal

working capital. On the other hand the special working capital is that part of the

variable working capital which is required for financing operations such as

inauguration of extensive marketing campaigns and carrying out special jobs and

similar other operations that are outside the usual business of buying, fabricating

and selling.

Excess Working Capital

There are problems associated with excess working capital. Firstly, more funds

would make the management complacent and it may invest this money in

unnecessary accumulation of inventory resulting in locking of investment. There is

another possibility that the firm may think of speculation inventory items in

quantities more than needed and these gains may not be realized due to price

fluctuations. The excess working capital also known as surfeit of working capital,

which promotes accumulation of inventories, permissive, credit policies and slack

collection procedures .Due to excess working capital, complacency develops and

management efficiency deteriorates

Inadequate Working Capital

If working capital is not adequate, the organization will come across certain

problems. The adverse effects of inadequate working capital are business failures,

reduction in profitability and consequent decline in return on investment (ROI).

The company will not be able to take advantage of full capacity utilization and the

growth that is desired cannot be achieved when enough funds are not available at

the right point of time. All the operating plans cannot be successfully implemented

when funds are in short supply. In adequate working capital can also lead to

temporary insolvency of a firm.

Page 12

FACTORS DETERMINING THE WORKING CAPITAL

REQUIREMENTS:

The working capital requirements of a concern depend upon a large number of

factors such as nature and size of business, the character of their operations, the

length of production cycles, the rate of stock turnover and the state of economic

situation.

1. Nature or character of business

The working capital requirements of a firm basically depend upon the nature of its

business. Public utility undertakings like electricity, water supply and railways

need very limited working capital because they offer cash sales only and supply

services, not products and as such no funds are tied up in inventories and

receivables

2. Size of business/scale of operations

The working capital requirements of a concern are directly influenced by the size

of its business which may be measured in terms of scale of operations. Greater the

size of a business unit, generally large will be the requirements of working capital.

3. Production policy

In certain industries the demand is subject to wide fluctuations due to seasonal

variations. The requirements of working capital, in such cases, demand upon the

production could be kept either steady by accumulating inventories during slack

periods with a view to meet high demand during the peak season or the production

could be curtailed during the slack season and increased during the peak season.

4. Manufacturing process/length of production cycle

Longer the process period of manufacture, larger is the amount of working capital

required. The longer the manufacturing time, the raw materials and other supplies

Page 13

have to be carried for a longer period in the process with progressive increment of

labor and service costs before the finished product is finally obtained

5. Seasonal variations

In certain industries raw material is not available throughout the year. They have to

buy raw materials in bulk during the season to ensure an uninterrupted flow and

process them during the entire year.

6. Credit policy

The credit policy of a concern in its dealings with debtors and creditors influence

considerably the requirements of working capital .a concern that purchases its

requirements on credit and sells its products/services on cash requires lesser

amount of working capital.

7. Business cycle

Business cycle refers to alternate expansion and contraction in general an

activity .In a period of i.e. when the business is prosperous there is a need for

larger amount of working capital due to increase in sales, rise in prices, optimistic

expansion of business, etc.

8. Working capital cycle

The working capital cycle starts with the purchase of raw materials and ends with

the realization of cash from the sale of finished products. This cycle involves

purchase of raw materials and stores. Its conversion into stocks of finished goods

through work -in-progress with progressive increment of labor and service costs,

conversions of finished stock into sales, debtors and receivables and ultimately

realization of cash and this cycle continues again from cash to purchase of raw

material and so on.

Page 14

9. Price level changes

Changes in the price level also affect the working capital requirements. Generally

the rising prices will require the firm to maintain larger amount of working capital,

as more funds will be required to maintain the same current assets. The effect of

rising prices may be different for different firms.

10. Other factors

Certain other factors such as operating efficiency, management ability,

irregularities of supply, import policy, asset structure, importance of labor ,banking

facilities, etc, also influence the requirements of working capital.

OBJECTIVES:

promote the growth of the cement interest

To promote the customer interest

To identify newer application of cement usage

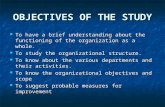

1.3 OBJECTIVES OF THE STUDY:

1. To Study working capital management in MADRAS CEMENTS Ltd.

2. To Examine an overview of working capital management.

3. To Analyze at the possible remedial measures to improve company’s working

capital performance in the near future.

4. To Evaluate the efficiency of the company in utilizing its Current Assets.

1.4 SCOPE OF THE STUDY

The scope of the study is limited only to MADRAS CEMNTS and is confined to 4

years i.e. 2005-06 to 2008-09 annual reports.

Page 15

DESIGN OF THE STUDY

METHODOLOGY

The present study is mainly about the working capital management of MADRAS

CEMENTS ltd. On the basis of the objectives of the study it was decided to use

ratio analysis and analysis of individual components of working capital as these are

universally accepted techniques for analyzing the short term liquidity position of

the firm. For the purpose of the analysis the following ratios have been used:

1 WORKING CAPITAL MANAGEMENT RATIOS

1. Working capital ratio/Current ratio.

2. Quick ratio/Acid test ratio.

3. Working capital turnover ratio.

4. Working capital performance ratio.

5. Current asset turnover ratio.

I. CASH MANAGEMENT

1. Cash turnover ratio.

II. INVENTORY MANAGEMENT

1. Raw materials turnover ratio.

2. Work in process turnover ratio.

3. Finished goods turnover ratio

DEBTORS MANGEMENT

1. Debtor’s turnover ratio.

Page 16

SOURCES:

The study is based on the analysis of data from the annual reports of MADRAS

CEMENTS Ltd. The data used in the present study are mainly of two types:

primary data and secondary data.

1. The primary data is collected through the discussions made with the officials of

MADRAS CEMENTS Ltd.

2.The secondary data is collected through the annual reports published by the

company and company website.

1.5 LIMITATIONS:

The present study limits itself to the study of working capital management. In the

present study the analysis is mainly based on secondary data given in the annual

reports published by MADRASCEMENTS Ltd. The limitations prevailing in the

secondary sources are self evident in the study. Despite their weakness, they

continue to be the only source for comparison of the results of the analysis. The

present study is carried taking this into consideration.

Page 17

COMPANY

PROFILE

Page 18

Chapter 3

3.1 COMPANY PROFILE

Company Overview:

Madras Cements Ltd is the flagship company of the Ramco Group, a

well-known business group of South India. It is headquartered at Chennai. The

main product of the company is Portland cement, manufactured in five state-of-the

art production facilities spread over South India, with a current total production

capacity of 10.49 MTPA. The company is the fifth largest cement producer in the

country. Ramco Group is the most popular cement brand in South India. The

company also produces Ready Mix Concrete and Dry Mortar products, and

operates one of the largest wind farms in the country.

Integrated Cement Plants

Ramasamy Raja Nagar, Virudhunagar, Tamil Nadu

Alathiyur, Ariyalur District, Tamil Nadu

Ariyalur, Govindapuram, Ariyalur District, Tamil Nadu

Jayanthipuram, Andhra Pradesh

Mathodu, Chitradurga District, Karnataka

Grinding Units

Uthiramerur, Kanchipuram District, Tamil Nadu

Valapady, Salem District, Tamil Nadu

Kolaghat, Purba Medinipur District, West Bengal

Page 19

Packing Terminals

Nagercoil Packing Unit, Kumarapuram, Aralvaimozhi, Kanyakumari

District, Tamil Nadu

Hyderabad Packing Plant, Pochampally Road, Malkapur, Nalgonda District,

Andhra Pradesh

State-of-the-Art Research Centre

Ramco Research Development Centre (RRDC), Chennai

MISSION

• To continuously improve productivity through quality, technology renewal and

customer focused operations.

• To position ourselves in the cement business as a pace setter and grow in the

same and related business.

• To seek green field locations for growth on the basis of developed synergies of

the existing operations.

•To continuously seek quality enhancement in product, processes and responses to

various stakeholders.

•To update management practices on a continuous basis and maintain a culture of

professional management.

• To conserve, protect and enhance quality of life for our employees and

community.

• To preserve the credence in our motto "our real resources are the human assets".

Page 20

CORE VALUES AND BENEFITS:

• Customers continued satisfaction and the sensitivity to their needs is our source

of strength and security. If there is no customer, there is no business We do not

look at productivity as a game in numbers. We try to learn from others, be

committed to quality and always stay ahead in terms of technology

RAMCO GROUP COMPANIES:

•Madras cements limited

•Ramco industries limited

•Raja palayam mills limited Rajapalam, Tamilnadu

•Sri Ramco spinning mills limited Rajapalam, Tamilnadu

•Sundaram spinning mills limited Rajapalam, Tamilnadu

•Sri Vishnu sankar limited Rajapalam , Tamilnadu

•Ramaraju surgical cotton mills limited

•Ramco systems limited

•Ramco lanka (pvt) limited

•Harini textiles

Some corporate responsibilities of Ramco group:

•Raja charity trust

•C. Rama Swamy Raja education charity trust

•P.A.C Rama Swamy Raja Poly technique

Page 21

•P.A Chinnaih Raja memorial higher secondary school

•P.A.C.R Ammani animal’s higher secondary school

•Chinnaih vidyalaya P.A.C.R Raju matriculation higher secondary school

•S.S.R vidhya mandir Plans are on to build a hospital in Rajapalam equipped with

the most advanced medical facilities. The primary aim of this hospital would be to

provide free medical to workers scheme society. In order to have impetus to

ecology development a senior horticulturist is being appointed his services will be

extended to the farmers of nearby villages to help them ingoing various fruit and

vegetation using hybrid varieties. We are going ahead shortly for massive a

forestation of ISO acres of our land located at the entrance of our factory premises.

Page 22

COMPANY

HISTORY

Page 23

3.2 COMPANY HISTORY

In 1950's, investment in Cement Industry was not attractive due to price controls

and the massive investments required. Only those entrepreneurs who were not

profit minded but cared for country's development came forward in investing in

Cement Industry. When Shri Manubai Shah, Central Minister for Industries in late

fifties came to Madras to meet the Industrialists, he called upon Shri P A

CRamasamy Raja and requested him to start a cement factory in TN . This was

readily accepted by Shri PACR and this marked the birth of "MadrasCements Ltd"

in 1961.On the night of September 3, 1962, while the whole city slept, PACR lay

on his bed in the Madras General Hospital, seriously ill. As all his near and dear

watched with tears in their eyes, PACR summoned his son Ramasubrahmaneya

Rajha, to his bedside. "There is no more hope", he whispered :"You should take

care of everything from now". My main concern is for Madras Cements. I have

taken a lot of money as shares from well wishers I have not paid them back any

dividends as yet. This has to be taken care of immediately ...."PACR's last wish

was dutifully fulfilled by the present chairman Shri.P.R.Ramasubrahmaneya Rajah.

Today Madras Cements Ltd is not only one of the most respected cement

companies in the country but also leads in giving the best return for the investors.

With a cement capacity of 10.49 millions tons per annum,(Mtpa) the company is

the sixth largest producer of cement in India. It is also one of the largest wind

energy producer in the country with a capacity of 45 MW. The first plant of MCL

at Ramasamy Raja Nagar, near Virudhunagar in Tamil Nadu commenced its

production in 1962 with a capacity of 200tonnes, using wet process. In 70's, the

plant switched over to more efficient dry process. A second kiln was also added to

bring the total capacity to 12 lakh ton per annum. The second venture of MCL is its

Jayanthipuram plant near Vijayawada in A.P set up in 1987 . The 16 lakh ton per

annum plant employs the latest state of art technology. The third venture of MCL

Page 24

is at Alathiyur in TN set up in 1997 and expanded by addition of another line in

2001. The 30 lakh ton per annum plant is the most modern plant in the country .In

2000 , MCL acquired Gokul Cements situated in Mathod in Karnataka whose

capacity is 600 TPD. Being a eco-friendly company, MCL set up the Ramco

Winfarm in 1993 at Muppandal TN. This was followed by windfarms in Poolavadi

near Coimbatore in 1995 and Oothumalai in 2005. The combined capacity of these

two put together is about 45 MW .In the year 1999, MCL commissioned the most

sophisticated Ready Mix Concrete Plant in Medavakkam in South Chennai. In

2002, a state-of-art Dry Mortar plant was commissioned near Sriperumpudur,

Tamilnadu which manufactures dry mortar, cement based putty and tile fix

compound.

Birth of the first Ramco Venture

His visited Britain and other European countries to see firsthand working of the

mills. There he had the chance to meet many business magnates .He returned to

India full of ideas .After returning to Rajapalayam, he put his plans into action. To

start they yarn mill, he found that he needed Rs.5 lakhs, which in 1936 was a huge

sum. It was considered a Herculean task to raise such a big capital .But the

determined Raja was not deterred. He decided to make the “shareholders”

Rajapalayam Mills Ltd.,

Thanks to his illustrious background and his own reputation, he got the required

capital ready, in next to no time. On September 05, 1938, the State Minister for

labor, V.V. Giri inaugurated the mill and Rajapalayam Mills Ltd commenced

operations. There was no looking back for Ramasamy Raja after this. The Mill was

a grand success .He followed up this with other successful ventures. He started

Rama Raju Surgical Cotton Mills along with his son-in-law Rama Raju.

Page 25

Madras Cements Ltd

At that time, Cement was not considered as a favorable venture due to price

controls. Shri.Manubai Shah, Central Minister for Industries called upon

Ramasamy Raja and appealed to him to start a cement factory. This was how

Madras Cements Ltd came into being in 1961.Ramasamy Raja needed one crore as

capital. The State Government for the first time in the history of India, invested

Rs.10 lakhs An indication of the total trust and implicit faith the Government had

in him. Concern for Shareholders and Workers Ramasamy Raja had the well being

of the people upper-most in his mind .He was very particular that the funds of his

share holders be utilized usefully. He showed high concern for his workers. The

famous trade unionist G Ramanujam once said :

"In the case of Ramasamy Raja's companies, the workers are always thinking of

the growth of the company, the Raja always has the well being of the workers and

their families uppermost in his mind"

AWARDS & ACHIEVEMENTS:-

AWARDS:

4 Leaves Award

Centre for Science and Environment

National Award for Energy Conservation

Confederation of Indian industry

Best Energy Efficient Unit

National Council for Cement and Building Materials

Page 26

Corporate Performance Award

Economic Times

Best Improvement in Energy Performance

International Congress on Chemistry of Cement

The Analyst Award

The Institute of Chartered Financial Analysts of India

Best all round Industrial performance

Federation of AP Chambers of Commerce & Industries

Visvesvariah Industrial Award

All India Manufacturers Organization

Business Excellence Award

Industrial Economist

Export Performance Award

CAPEXIL

State Safety Awards

Tamil Nadu & AP Governments

Good Industrial Relations Award

Tamil Nadu & AP Governments

Page 27

Technology Overview

Madras Cements Ltd is a trend-setter in adopting state-of-the-art technology for the

manufacture of Cement, Ready Mix Concrete and Dry Mortar Products. MCL is

the first to bring the following technologies in South India's cement industry.

• The FUZZY Logic Software System for process Controls

• Pre-calciner technology

• Most Modern Programmable Logic Controllers (PLC)

• Surface Mining Technology

• Vertical Mills for Cement Grinding

• Latest and highly effective ESPs and Bag filters

• Advanced X-Ray technology for Quality Control

JAYANTHIPURAM UNIT

In 1986 the company ventured into the second unit Jayanthipuram in

Andhrapradesh 75 kilometers from Vijayawada towards Hyderabad with a

investment of Rs 100 corers per manufacture of Rs 7.50 lakhs tones of cement

per annum. This plant was commissioned in 1986 six months ahead

of schedule plans Madras cements is a ramco group of most ambitious

diversification had. It is a profitable company today. Two were process plans were

setup in 1987with a capacity of 600 tones to produce Portland cements. In

the1970’s totals with over was made to the dry process of manufacture. The single

largest dry kiln in India at the time of establishment with a capacity of 1200 tones

was installed at ramaswamy rajanagar in Tamilnadu, for the first time in India,

over the years the plant has modified and updated with preclaciner technology.

Page 28

This has increased the capacity by 115% in 1993.Ramco group has setup its

second and India’s most technological advances cement unit which started its

production in 1987 Jayanthipuram Krishna district and Andhra Pradesh with

1.1 million tons per annum. This is the first factory in India to be totally

computerized.It’soneof the most sophist icate plants in India with ful l

computer control led special software of F.L smiths and fuzzy logical system

from Denmark for kiln control. This flagship company of Ramco producer of

market cements with brand Ramco. The ki ln was gradually upgraded from

2300 TPD in 1986, 1994 and to 3200 TPD in1995. During this period raw

material and coal mill were also upgraded from 220 to 240 TPH and 26 to 30 TPH

respectively.

Horizontali m p a c t c r u s h e r ( H I C ) , w a s i n s t a l l e d i n 1 9 9 5 i n

c e m e n t m i l l c i r c u i t t o increase the output from 125 TPH to 180 TPH

and the cement mill was optimized in 1996.with this the capaci ty has

been increased to 11 lakh tones per annum. The plant has electrostatic

precipitators(ESP)anddeductingbagh o u s e s t o e n s u r e c l e a n a n d

p o l l u t i o n f r e e e n v i r o n m e n t . M C L h a s a n uncompromising attitude

towards the prevention of anti-environmental pollution.

The above up gradation of kiln and other mills was carried out with and investment

of Rs 25 crores. 2004-2005 in this period they build one power grid. It carried out

with an investment of Rs 10 crores.

EXPANSION

Slag grinding unit Madras cements have always stayed in the forefront of the

industry. Special task forces within the company keep track of the latest

international development in cement technology and promote action toad opt the

state of art technology. India generates about 70 million tones of Fly ash and 10

Page 29

millions of slag annually. Disposal of Fly and slag problem to the environment.

Concern for the environment and ecology is percolating very fast into customer

awareness globally and there by a check on eco-hostile products is becoming an

imperative exercise. Both the central and state governments are strongly

propagating to use these products in cement manufacture .A working group has

been constituted by the government of Andhra Pradesh to study the generation and

disposal of Fly ash and BD slag. Based on the recommendations of the working

group the government of Andhrapradesh issued a GO instructing all government

departments for utilization of 100% Pozzolana/slag cement, with in a period of 5

years. In line with the policies of the government and our philosophy of using

otherwise no usable materials like Fly ash and slag to produce value added blended

cement and there by conserve limestone and other materials like coal etc, and also

to save energy apart from being eco-friendly and creating clean atmosphere by

reducing carbon dioxide mission proud of serving our nation by preserving

minerals and maintaining clean atmosphere for our future generations.

MCL is the first to bring the following technologies in South India's cement

industry.

1.The FUZZY Logic Software System for process Control

2.Pre-calciner technology

3.Most Modern Programmable Logic Controllers (PLC)

4.Surface Mining Technology

5.Vertical Mills for Cement Grinding

6.Latest and highly effective ESPs and Bag filters

7.Advanced X-Ray technology for Quality Control

ISO certification

Madras cements limited, Jayanthipuram unit also got ISO 9002certification in may,

1998.

Page 30

SALIENT FEATURES OF MADRAS CEMENTS LIMITED

JAYANTHIPURAM:

For the first time in India the very latest computerized control system are

introduced in the Jayanthipuram unit for efficient operation on energy

conservation. The silent features of Jayanthipuram plant is furnished below:

•A stacker re-claimer for pre blending and continuous flow silo for below

•Vertical roller mills for grinding raw material and coal

•Five stage per heater for their mail efficiency per calcinatory for efficiency use of

low grade coal

•A scanner connected to a computer for refractory monitoring

•X ray analyzer for quality control on line process computerized control for

consistent quality

•Fuzzy logical software for kiln control

Electro static precipitator at 5 strategic points for pollution control

•Belt bucket elevators for energy conservations

DEPARTMENTS IN MCL

The following are the departments in Madras Cements Ltd.

1.Personnel department

2.Accounts department

3.Mines

4.IT

5.Stores and Material department

6.Quality control lab

Page 31

7.Process department

8. Engineering departments

-Electrical and Mechanical department

-Civil and Power plant

-Instrumentation

9.Cement dispatch section

10.Security liaison

DETAILS OF EMPLOYEES

Sl no catagories No of

employees

1 officers 53

2 Officers prob with

grade

3

3 tarinee 7

4 Staff 70

5 Staff worker 2

6 Staff prob with

grade

7

7 trainee 1

8 Voucher staff 1

9 Voucher worker 4

10 workers 198

Page 32

INDUSTRY PROFILE

CEMENT INDUSTRY IN INDIA

The Cement industry in India has come a long way since 1914, when the first

cement plant was commissioned with a production level of 1000tons/ annum. The

first true Portland cement was manufactured in Calcutta presently called as

Kolkata. India is the second largest cement producer in the world. As cement is a

basic construction material with virtually no substitute, it is used worldwide for all

construction work. Thus the growth in the construction industry has a direct

relation with the production and consumption of cement.

India is the second largest cement producer in the world with a production level of

about 99 million tons (about 5% of world production ~2000 million tons). The

installed capacity is about 119 million tones and at an expected 10 % growth rate

the production is likely to grow to about158.5 million tons at the end of 2006-

2007.Over the years, the growth of the industry has been uneven. With

traditionally cement deficit regions covering the most of the major growth centers

of the country. Cement industry in India has made tremendous strides in

technological up gradation and assimilation of latest technology.

At present ninety three per cent of the total capacity in the industry is based on

modern and environment-friendly dry process technology and only seven per cent

of the capacity is based on old wet and semi-dry process technology. The major

Page 33

players of Indian cement industry are Madras cements, ACC, India cements,

Gujarat Ambuja, Ultratech, Grasim, JK group, Jaypee group, Century textiles,

Birla Corporation, Lafarge. There is tremendous scope for waste heat recovery in

cement plants and thereby reduction in emission level. Cement plants in the

country have mostly changed from the wet process to the energy efficient dry

process. In India, the cement factories are localized in the states of Tamil Nadu,

Madhya Pradesh, Gujarat, Bihar, Rajasthan, Karnataka and Andhra Pradesh.

Cement Industry

Cement industry is one of the important industries to country development in the

light of the main important basis for construction industry and also the important

indicator showing domestic economic growth. In the past, the domestic demand of

cement used to be up to 36 million tons. But, the severely negative effects from

economic crisis in 1997 have caused real estate and

construction industry subdued; the domestic demand of cement has shrunk and

been in oversupply atmosphere.

Until 2001–2003, the government has launched many economic actuating policies.

This has made real estate and construction industry recovered and the demand of

cement has been increasing gradually from 21 million tons in 2001 to 25 million

tons and 26.82 million tons in 2002 and 2003 respectively; and the price level is

higher in line with increase production cost.

Page 34

Cement Industry originated in India when the first plant commenced

production in 1914 at Porbandar, Gujarat. The industry has since been growing

at a steady pace, but in the initial stage ,particularly during the period before

Independence, the growth had been very slow. Since indigenous production was

not sufficient to meet the entire domestic demand, the Government had to control

its price and distribution statutorily. Large quantities of cement had to be imported

for meeting the deficit. The industry was partially decontrolled in 1982 and this

gave impetus to its pace of growth. Installed capacity increased to more than

double from 27 million tones in 1980-1981 to 62 million tones in 1989-1990.

The cement industry responded positively to liberalization policy and the

Government decontrolled the industry fully on 1st March 1989. From 1991

onwards cement industry got the status of a priority industry in schedule III of the

industry policy statement, which made it eligible for automatic approval for

foreign investment up to 51% and also for technical collaboration on normal terms

of payment of royalty.

DURING 2010-2011:

Growth in domestic cement demand is likely to remain strong, with the resumption

in the housing markets, regular government spending on the rural sector and

infrastructure spend accomplished by rise in the number of infrastructure projects

implemented by the private sector. Furthermore, it is expected that the industry

players will continue to increase their annual cement output in coming years and

India’s cement production will grow at a compound annual growth rate (CAGR) of

around 12 per cent during 2011-2012 - 2013-2014 to reach 303 Million Metric

Tons, according to Indian Cement Industry Forecast to 2012. Cement

Manufacturing Association (CMA) is targeting to achieve 550 MT capacities by

2020. A large number of overseas players are also expected to enter the industry in

Page 35

the coming years as 100 per cent FDI is permitted in the cement industry. Our

country is the second major cement producing country following the China having

a total capacity of around 230 MT (including mini plants). However, on account of

low per capita consumption of cement in the country (156 kgs/year as compared to

world average of 260 kgs) there is an enormous potential for growth of the

industry.

This chart represents the total cement production during(2009-

2010)

98.81

96.75

97.84

96

cement production cement despatches

The demand for cement mainly depends on the level of development and the rate

of growth of the economy. There are no close substitutes for cement and hence the

demand for cement is price inelastic. During the October – 2011, 14.78 MT were

produced and 14.38MT was consumed. For the FY 2011 – 2012 (Apr - Oct), MT

97.84 was consumed form the 98.91 MT produced. During the first half of the

year, there was marginally poor off take in cement demand due to passive

construction activity, which lead to excess supply, thus putting downward pressure

on realizations. This has been coupled with rise in input costs, especially prices of

coal and petroleum products. As a result, both the top line and bottom line have

been affected. This demand supply mismatch scenario is expected to prevail for

some time. Good agricultural income will support demand.

2010-11 2009-10

Page 36

ABOUT THE SECTOR:

Our country is the second major cement producing country following the

China; we have 137 large and 365 mini cement plants. Leading players in the

industry are Ultratech Cement, Gujarat Ambuja Cement Limited , JK Cements,

ACC Cement, Madras Cements etc. Cement is an adhesive that holds the concrete

together and is therefore vital for meeting economy’s needs of Housing &

accommodation and necessary infrastructure such as roads & bridges, schools,

hospitals etc. Hence, the cement is one of the fundamental elements for setting up

strong and healthy infrastructure of the country and plays an important role in

economic development and welfare of the nation.

Cement industry is being segmented regionally i.e. Northern, Central,

Western, Southern and Eastern. Cement, being a bulk item transporting it over

long distances can prove to be uneconomical as it attracts very high amount of

freight. Thus, it has resulted in cement being largely a regional play with the

industry divided into five main regions. As it is a freight intensive industry, the

segment is completely domestic driven and exports account for very negligible

percentage of the total cement off take.

Major players in Indian cement sector:-

Lafarge

Gujarat Ambuja Cement

Ultratech Cement

India Cements

Page 37

Century Cements

Jaypee Group

Madras Cements

Birla Corporation Limited

Jk cements

Dalmia cements

Chettinad cements

ANNUAL INSTALLED CAPACITY:

The Indian cement industry is highly fragmented with the top few accounting for

more than 50% of the industry capacity. The rest is distributed among the large

number of small players. The cement industry in India has come forward as the

second largest in the world, showing a total capacity of around 230 millions tones

MT (including mini plants).

This table represents the annual capacity of various cement comapies

Name of Cement Company

Annual

Installed

Capacity (MT)

Grasim Industries Ltd. 25.65

UltraTech Cement Ltd. 24.3

Jaiprakash Associates Ltd. 17.15

India Cements Ltd 14.05

Madras Cements Ltd. 10.49

Shree Cement Ltd. 12

Dalmia Cement 9

J.K. Cement Ltd. 8.42

Page 38

Chettinad Cement 8.2

Century Textiles & Ind 7.8

Lafarge India Pvt. Ltd. 7.55

Birla Corp. Ltd. 7.38

Kesoram Industries Ltd. 7.2

Penna Cement Ind 6.5

Binani Cement 6.25

Total capacity held by majors

(77% of the industry)

170.14

Others (23% of the industry) 51.68

Overview of the performance of the Cement Sector :-

The Indian cement Industry not only ranks second in the production of cement in

the world but also produces quality cement, which meets global standards.

However, the industry faces a number of constraints in terms of high cost of

power, high railway tariff; high incidence of state and central levies and duties;

lack of private and public investment in infrastructure projects; poor quality coal

and inadequate growth of related infrastructure like sea and rail transport, ports and

bulk terminals. In order to utilize excess capacity available with the cement

industry, the government has identified the following thrust areas for increasing

demand for cement.

Housing development programmers.

Promotion of concrete highways and roads.

Use of ready-mix concrete in large infrastructure projects.

Construction of concrete roads in rural areas under Prime Ministers Gram

Sadak Yojana.

Page 39

The types of cement in India have increased over the years with the advancement

in research, development, and technology. The Indian cement industry is

witnessing a boom as a result of which the production of different kinds of cement

in India has also increased. By a fair estimate, there are around 11 different types

of cement that are being produced in India. The production of all these cement

varieties is according to the specifications of the cement.

Some of the various types of cement produced in India are:

Clinker Cement

Ordinary Portland Cement

Portland Blast Furnace Slag Cement

Portland Pozzolana Cement

Rapid Hardening Portland Cement

Oil Well Cement

White Cement

Sulphate Resisting Portland Cement

In India, the different types of cement are manufactured using dry, semi-dry, and

wet processes. In the production of Clinker Cement, a lot of energy is required. It

is produced by using materials such as limestone, iron oxides, aluminum, and

silicon oxides. Among the different kinds of cement produced in India, Portland

Pozzolana Cement, Ordinary Portland Cement, and Portland Blast Furnace Slag

Cement are the most important because they account for around 99% of the total

cement production in India.

Page 40

THEORITICAL

FRAME WORK

Chapter 4

Page 41

Working capital management:

Working Capital is the firm’s holdings of current assets such as cash, receivables,

inventory & marketable securities. Every firm requires working capital for its day

to day transactions such as purchasing raw material, for meeting salaries, wages,

rents, rates, advertising etc.

Significance of Working Capital:

The world in which real firms function is not perfect. It is characterized by the

firms’ considerable uncertainty regarding the demand, market price, quality &

availability of its own products and those suppliers. While the firm has many

strategies available to address these circumstances, strategies that utilize

investment or financing with working capital accounts often offer a substantial

advantage over the techniques. The importance of working capital management is

reflected in the fact that financial managers spend a great deal of time in managing

current assets and current liabilities like

Arranging short term financing

Negotiating favorable credit terms

Controlling the movement of cash

Administrating accounts receivables

Monitoring investment in receivables.

Decisions concerning the above areas play a vital role in maximizing the overall

value of the firm. Once decisions concerning these areas are reached, the level of

working capital is also determined in active decision sense, but falls out as residual

from the decision just made.

The management of working capital plays an important role in maintaining the

financial health during the normal course of business. This critical role can be

Page 42

enunciated by examining the flow of resources through the firm. By far the major

flow is the working capital cycle.

This is the loop (previous page) which starts at the cash and the marketable

securities account, goes through the current account as direct labor and materials

which are purchased and use to produce inventory ,which in turn is sold and

generates accounts receivables, which are finally collected to replenish cash. The

major point to notice about this cycle is that the turnover or velocity of resources

through this is very high related to the other inflows and outflows of the cash

account. There are two concepts of working capital namely;

Gross Working Capital and Net Working Capital. Gross Working Capital, simply

called as working capital refers to the firm’s investment in current assets. Current

assets are the assets, which in ordinary course o business can be converted into

cash within an accounting year. Current assets include cash and bank balances,

short term loans and advances bills receivables, sundry debtors, inventory, prepaid

expenses, accrued incomes, money receivable ( within 12months).

The following are the few advantages of adequate working capital in the

business:

Cash Discount: Adequate working capital enables a firm to avail cash discount

facilities offered to it by the suppliers. The amount of cash discount reduces the

cost of purchase.

Goodwill: Adequate working capital enables a firm to make prompt payment.

Making prompt payment is a base to create and maintain goodwill.

Ability to face crisis: The provision of adequate working capital facilities to meet

situations of crisis and emergencies. It enables a business to with stand periods of

depression smoothly.

Page 43

Credit-Worthiness: It enables a firm to operate its business more efficiently

because there is not delay in getting loans from banks and other on easy and

favorable terms.

Regular supply of raw materials: It permits the carrying of inventories at a level

that would enable a business to serve satisfactory he needs of its customers. That is

it ensures regular supply of raw materials and continuous production.

Expansion of markets: A firm which has adequate working capital can create

favorable market condition i.e. purchasing its requirements in bulk when prices are

lower and holding its inventories for higher. Thus profits are increased .

Increased productivity.

Research programs.

High morale.

Problems of inadequate working capital:-

Firm may not be able to take advantage of profitable business opportunities.

Production facilities cannot be utilized fully.

Short-term liabilities cannot be paid because of non-availability of funds. Its low

liquidity may lead to low profitability. In the same way, low profitability results in

low liquidity.

It may not be able to take advantages of cash discounts. Credit worthiness of the

firm may be damaged because of lack of liquidity. Thus it may be lose its

reputation; thereafter a firm may not be able get credit facilities.

Working capital policy:

Working capital management policies have a great effect on firm’s profitability,

liquidity and its structural health. A finance manager should therefore, chalk out

Page 44

appropriate working capital policies in respect of each competent of working

capital so as to ensure high profitability, proper liquidity and sound structural

health of the organization.

In order to achieve this objective the financial manager has toper form basically

following two functions:

Estimating the amount of working capital.

Sources from which these funds have to be raised.

Operating Cycle:

Working capital is required because of the time gap between the sales and their

actual realization in cash. This time gap is technically terms as operating cycle of

the business.

In case manufacturing company, the operating cycle of time necessary to complete

the following cycle of event.

Conversion of cash into raw materials.

Conversion of raw materials into work in progress.

Conversion of work in progress into finished goods.

Conversion of finished goods into accounts receivables

Conversion of accounts receivables into cash.

This cycle is continuous phenomena. In case of “Trading Firm” the operating

cycle will include the length of time required to:

Cash into inventories.

Inventories into accounts receivables.

Accounts receivables into cash.

In case of “Financing Firm” the operating cycle includes the length of time taken

for 1 year.

Page 45

Conversion of cash debtors, and

Conversion of debtors into cash

IMPORTANT OR ADVANTAGES OF ADEQUATE WORKING

CAPITAL:

1. Solvency of the business: Adequate working capital helps in maintaining

solvency of the business by providing uninterrupted flow of production.

2. Goodwill: Sufficient working capital enables a business concern to make prompt

payments and helps in creating and maintaining goodwill.

3. Easy loans: A concern having adequate working capital, high solvency and good

credit standing can arrange from banks and other an easy and favorable terms.

4. Cash discount: Adequate we also enable a concern to avail cash discount on the

purchases and hence it reduces costs.

5. Regular supply of raw material: Sufficient working capital ensures regular

supply or raw material and continuous production.

6. Regular payment of salaries and wages and other day-to-day commitments:

A company which has ample working capital can make regular payment of

salaries, wages and other day-to-day commitments which raises the moral of its

employees increase their efficiency, reduces wastage’s and costs and enhance

production and profits.

7. Exploitation of favorable market condition: Only concern with adequate we can

exploit favorable market conditions such as purchasing its requirement in bulk

when the prices are lower and by holding its inventories for higher.

Page 46

8. Ability to face crisis: Adequate working capital enables a concern to face

business crisis in emergency such as depression because during such periods,

generally, there is much pressure on working capital.

9. Quick and regular return on investment: Every investor wants a quick and

regular return his investment sufficiency of working capital enables a concern to

pay quick and regular dividends to its investors as there may not be much pressure

to plough back profits. This gains the confidence to raise additional funds in the

future.

10. High morale: Adequacy of working capital creates an environment of security,

confidence, high morale and creates overall efficiency in a business.

EXCESS OR INADEQUATE WORKING CAPITAL

Every business concern should have adequate working capital run its business

operation. It should have neither redundant or excess working capital nor

inadequate nor shortage or working capital. Both excess as well as short working

capital positions are bad for any business. However, out of the two, it is the

inadequacy of working capital, which is more dangerous from the point of view of

the firm.

DISADVANTAGES OF REDUNDANT OR EXCESSIVE

WORKING CAPITAL

Excessive working capital means idle funds which earn no profits for the business

and hence the business cannot earn a proper rate of return on its investments.

When there is a redundant working capital, it may lead to un necessary purchasing

and accumulation of inventories causing more chances of theft, waste and loses.

Page 47

Excessive working capital implies excessive debtors and defective credit policy

which may cause higher incidence of bad debts. It may results into overall

inefficiency in the organization.

When there is excessive working capital, relation with banks and other financial

institution may not be maintained.

Due to low rate of return on investment, the value of share may also fall. The

redundant working capital gives rise to speculative transactions.

DISADVANTAGES OR DANGERS OF INADEQUATE

WORKING CAPITAL

A concern, which has inadequate working capital, cannot pay its short-term

liabilities in time. Thus it will lose its reputation and shall not be able toget good

credit facilities.

It cannot buy its requirements in bulk and cannot avail of discount, etc.It

becomes difficult for the firm to exploit favorable market condition andundertake

profitable projects due to lack of working capital.

The firm cannot pay day-to-day expenses of its operations and itscreates

inefficiencies, increases costs and reduces the profits of thebusiness.

It becomes impossible to utilize efficiently the fixed asset due to non-availability

of liquid funds .The rate of return on investment also falls withthe shortage of

working capital.

CHARACTERISTICS OF CURRENT ASSETS:

In the management of working capital, there are two characteristics of working

capital

(1) short life span

Page 48

(2) swift transformation into other asset forms.

Current assets have a short life span. Cash balances may be held idle for a week or

two, accounts receivable may have a life span of 30 to 120 days, and inventories

may be held for 30 to 100 days. The life span of current assets depends upon the

time required in the activities of procurement, production ,sales, and collection and

the degree of synchronization among them.

Each current asset is swiftly transformed into other asset forms cash is used for

acquiring raw materials ; raw materials are transformed into finished goods (this

transformation may involve several stages of work-in-progress);finished goods,

generally sold on credit are converted into sundry debtors, on realization, generate

cash.

The short life span of working capital components and their swift transformation

from one form into another has certain implications Decisions relating to working

capital management are repetitive and frequent.

The difference between profit and present value is insignificant. The close

interaction among working capital components implies that efficient management

of one component cannot be undertaken without simultaneous consideration of

other components

The investment in working capital is influenced by four key events in the

production and sales cycle of the firm

Purchase of raw materials

Payment of raw materials

Sale of finished goods

Collection of cash for sales Above diagram depicts these events on the cash flow

line. The firm begins with the purchase of raw materials which are paid for after a

delay which represents

Page 49

the accounts payable period. The length of operating cycle of a manufacturing firm

takes into account.

Inventor Conversion period (ICP)

Debtor Conversion period (DCP)

Payment Deferred Period (PDP)

The Inventory Conversion Period is the total time needed for producing and

selling the product .The firm converts the raw material in to finished goods and

then sells the same. The time lag between the purchase of raw materials and the

sale of finished goods is the inventory period.. Typically, it includes:

Raw Material Conversion Period (RMPC)

Work-in-Progress Conversion Period (WIPCP)

Finished Goods Conversion Period (FGCP)

The Debtor Conversion Period Is the time required to collect Outstanding amount

from customers. Customers pay their bills sometimes after the sales. The period

that elapses between the date of sales and the date of collection of receivables is

the accounts payable period or debtor’s period. The total of inventory conversion

period and debtor collection period is referred to as Gross Operating Cycle

(GOC).

The Payments Deferred Period is the length of time the firm is able to defer

payment on various resource purchases. The difference between the gross

operating cycle and payment-deferred period is Net Operating Cycle

(NOC).Symbolically,

ICP = RMCP + WIPCP + FGCP

GOC = ICP + DCP

NOC = GOC – PDP

Page 50

The duration of the cycle with reference to working capital is:

Longer the cycle ----- Higher the working capital

Shorter the cycle ----- Lower the working capital.

It is helpful to monitor the behavior of overall operating cycle and its individual

components. For this purpose, time-series analysis and cross-section analysis may

be done. In time-series analysis, the duration of the operating cycle and its

individual components is compared over a period of time for the same firm. In

cross-section analysis, the duration of the operating cycle and its individual

components is compared with that of other firms of a comparable nature.

Page 51

DATA

INTERPRETATION

&

ANALYSIS

CHAPTER 5

5.1 GROWTH RATE OF MADRAS CEMENTS LTD

Page 52

This chapter is allotted to analysis the growth of madras cements ltd .the analysis is

carried out of with following variables cost of equity, cost of debt, cost of

preference shares, retained earnings.

The variable selected to study the growth are

1. Fixed assets

2. Net current assets

3. Sales

4. Loan funds

5. Capital employed

5.1.1 FIXED ASSETS

Fixed asset, also called noncurrent assets, are assets that are expected to produce

benefits for more than one year. These assets may be tangible or intangible fixed

assets include items such as land, building, plant, machinery, furniture, and

computers. Intangible fixed assets include items such patent, copy right,

trademarks, and good will.

Tangible fixed assets are reported in the balance sheet at their net block

value, which is simply the gross value less accumulated depreciation represents the

allocation of the cost of a tangible fixed assets to various accounting periods that

benefits from its use. Likewise, intangible fixed assets are reports their net book

value, which is simply the gross value accounting period that benefits from its use.

The following table presents the data relating to the fixed assets

Years fixed assets (Rs in cr) Growth rate in %

Page 53

2006-2007 1258 100

2007-2008 2482 197

2008-2009 3635 289

2009-2010 4010 319

2010-2011 4489 357

Average growth rate 252

The following chart represents the data relating to the fixed assets

2006-2007 2007-2008 2008-2009 2009-2010 2010-20110

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

1258

2482

36354010

4489

fixed assets (Rs in cr)

fixed assets (Rs in cr)

INTERPRETATION

It is observed from the above chart that the Fixed Assets of MADRAS CEMENTS

Ltd. For past five years (2007-2011) have been increased continuously ,it shows

that Fixed Assets is properly used and maintain. The average company growth rate

of fixed assets increased at 252 %. So the company is performing well.

5.1.2 NET CURRENT ASSETS

Page 54

An indication of how much capital is being generated or used up by day to day

activities .It is also known as working capital or current capital., and it is calculated

by the following,

current assets minus current liabilities

CURRENT ASSETS

Current assets are cash and other assets expected to be converted to cash, sold, or

consumed either in a year or in the operating cycle. These assets are continually

turned over in the course of a business during normal business activity.

1. Cash and cash equivalents

It is the most liquid asset, which includes currency, deposit accounts and

negotiable instruments (e.g., money orders, cheque, and bank drafts).

2. Short term investments

Include securities bought and held for sale in the near future to generate

income on short term price differences (trading securities).

3. Receivables

Usually reported as net of allowance for uncollectable accounts

4. Inventory

Trading these assets is a normal business of a company. The inventory value

reported on the balance sheet is usually the historical cost or fair market value,

whichever is lower. This is known as the “lower of cost or market” rule.

Page 55

The following table presents the data relating to the Net Current Assets.

Years Net current assets

(Rs in cr)

growth rate in %

2006-2007 2202 100

2007-2008 3777 171

2008-2009 4734 215

2009-2010 5894 268

2010-2011 5088 231

Average growth rate 197

The following chart represents the data relating to Net Current Assets.

2006-2007 2007-2008 2008-2009 2009-2010 2010-20110

1000

2000

3000

4000

5000

6000

7000

2202

3777

4734

5894

5088

Net current assets (Rs in cr)

Net current assets (Rs in cr)

INTERPRETATION

It is observed from the above chart that the Net Current Assets of MADRAS

CEMENTS Ltd. has been increased continuously form 2007 to 2010 and it is

Page 56

slightly decreased in 2011, it shows that Net Current Assets is properly maintained.

The company average growth rate of Net Current assets decreased at 197%

5.1.6 NET SALES

A sale is the pinnacle activity involved in selling products or services in return for

money or other comparison. It is an act of completion of a commercial activity.

The “deal is closed”, means the customer has consented to the proposed product or

service by making full or partial payment (as in case of installments) to the seller.

A sale is completed by the seller, the owner of the goods. It starts with consent (or

agreement) to an acquisition or appropriation or request followed by the passing of

title (property or ownership) in the item and the application and due settlement of a

price, the obligation for which arises due to the sellers requirement to pass

ownership, being a price the seller is happy to part with ownership of or any claim

upon the item. The purchaser, though a party to the sale does not execute the sale,

only the seller does that. To be precise the sale completes prior to the payment and

gives rise to the obligation of payment. If the seller completes the first two above

stages (consent and passing ownership) of the sale prior to settlement of the price

the sale is still valid and gives rise to an obligation to pay.

The following table shows that data relating to the sales value.

Years Net sales (amt in cr) Growth rate in%

2006-2007 1567 100

Page 57

2007-2008 2005 127.9

2008-2009 2529 161.3

2009-2010 2807 179.1

2010-2011 2620 167.1

Average growth rate 147.08

The following chart shows that data relating to the net sales value.

2006-2007 2007-2008 2008-2009 2009-2010 2010-20110

500

1000

1500

2000

2500

3000

1567

2005

2529

28072620

Net sales (amt in cr)

Net sales (amt in cr)

INTERPRETATION1.43

It is observed from the above chart that the net sales of MADRAS

CEMENTS Ltd has been increased continuously form 2006 to 2007 and it is

decreased little in 2011. The Average Company Growth rate of sales increased at

147.08 %. So company is functioning in satisfactory level

5.1.7 LOAN FUNDS

Under certain circumstances and at the specific request of a borrower, the bank

may agree to the use of surplus loan amounts in the borrower’s loan account

Page 58

(commonly referred to as “surplus loan funds”) for purposes that are in accordance

with or even outside the broad objectives of the project, provided these funds are

not required to meet other needs of the project. The authority to approve

reallocation differs according to the purpose.

Surplus loan funds comprise those funds that are available (pr are expected to be

available) in the loan account of a borrower after arrangements for procurements of

all goods or services and payments for any other expenditures to cover any

contingencies), and it is clear that there will still be funds remaining.

The following table presents the data relating to the loan funds.

Years Loan funds(amt in cr) Growth rate in %

2006-2007 677 100

2007-2008 1635 241.50

2008-2009 2463 363.81

2009-2010 2566 379.02

2010-2011 2791 412.25

Average growth rate 299.316

The following chart shows that data relating to the loan funds.

Page 59

2006-2007 2007-2008 2008-2009 2009-2010 2010-20110

500

1000

1500

2000

2500

3000

677

1635

24632566

2791

Loan funds(amt in cr)

Loan funds(amt in cr)

INTERPRETATION

It is observed from the above table that the loan fund of MADRAS CEMENTS

Ltd. For past five years (2007-2011) has been increased continuously, it shows

that loan funds is properly used and maintained. The average company growth rate

is increased at 299.316%. So company is functioning in good level.

5.1.8 WORKING CAPITAL AS A % OF CAPITAL EMPLOYED

Capital employed has many definitions and is not easily analyzed. In general, it

represents the capital investment necessary for a business to function.

Consequently, it is not a measure of assets, but of capital investment: stock or

shares and long term liabilities. Capital employed can be defined as equity plus

loans which are subject to interest of one can say that it is total assets less non

bearing interest liabilities.

Capital employed can be defined as share holder’s funds (i.e. share capital and

reserves) plus creditors > 1 year (long – term liabilities) plus provisions for

liabilities and charges. This must equal total assets less current liabilities. Capital

employed is the value of the assets that contribute to a company’s ability to

generate revenue, i.e. their liquidity.

Page 60

The following table shows that the data relating capital employed.

Years Capital employed ( amt

in cr)

Growth rate In %

2006-2007 874 100

2007-2008 1936 221.51

2008-2009 2898 331.57

2009-2010 3113 356.17

2010-2011 3408 389.93

Average growth rate 279.836

The following chart shows that the data relating capital employed.

2006-2007 2007-2008 2008-2009 2009-2010 2010-20110

500

1000

1500

2000

2500

3000

3500

4000

874

1936

28983113

3408

Capital employed ( amt in cr)

Capital employed ( amt in cr)

INTERPRETATION

It is observed from the above table that the net capital employed of

MADRAS CEMENTS Ltd. For past five years(2007-2008) has been increased

Page 61

continuously .This shows that capital employed is properly used and maintained.

The average company growth rate of capital employed is increased at 256.72%. So

company is functioning in good level.

RATIO ANALYSIS

5.2 Ratios

Ratio Analysis is describing the significant relationship which exists between

various items of a balance sheet and a profit and loss account of a firm. As a

technique of financial analysis, accounting ratios measure the comparative

significance of the individual items of the income and position statements It is

possible to assess the profitability, solvency and efficiency of an enterprise through

the technique of ratio analysis.

1. Profitability: has the business made a good profit compared to its turnover?

2. Return Ratios: compared to its assets and capital employed, has the business

made a good profit?

3. Liquidity: does the business have enough money to pay its bills?

4. Asset Usage or Activity: how has the business used its fixed and current

assets?

5. Gearing: does the company have a lot of debt or is it financed mainly by

shares?

SHORT TERM LIQUIDITY MANAGEMENT

CURRENT RATIO:-

Page 62

The current ratio is a measure of a firm’s short-term solvency. It indicates the

availability of current assets in rupee for every one rupee of current liabilities. A

ratio of greater than one means that firm has more current assents than current

claims against them. A high ratio indicates high liquidity; while a low ratio

indicates a low liquidity. For manufacturing

CURRENT RATIO =

CURRENTS ASSETSCURRENT LIABILITIES

Table 1.1

CURRENT RATIO in Rs.

YEAER CURRENT ASSETS CURRENT LIABILITIES RATIO

2006-07 3149756052 1656267950 1.9

2007-08 3270733711 2286973441 1.43

2008-09 6147532582 3945088370 1.56

2009-10 7792358719 4015124569 1.94

2006-07 2007-08 2008-09 2009-100

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

Chart Title