Investigations in the compaction and sintering of large ceramic parts

Transcript of Investigations in the compaction and sintering of large ceramic parts

A

cptd©

K

1

i[cbtlcttiaccpdt

tmv

0d

Journal of Materials Processing Technology 190 (2007) 243–250

Investigations in the compaction and sintering of large ceramic parts

Peng Chen ∗, Gap-Yong Kim, Jun NiDepartment of Mechanical Engineering, University of Michigan, 1210 HH Dow Bldg., 2350 Hayward St,

Ann Arbor, MI 48109, USA

Received 11 September 2006; received in revised form 12 February 2007; accepted 22 February 2007

bstract

In this study, a large ceramic part was successfully compacted and sintered using uniaxial die compaction technique. The effects of die design,ompaction pressure, lubrication, sintering procedure and part orientation in the oven on the P/M part quality were investigated and the preferred

rocess conditions were discussed and concluded. The main quality issues encountered were cracking and distortion. A finite element model forhe powder compaction process was also developed and validated. Based on the model, the relationship between the cracking location and theensity distribution predicted from finite element analysis (FEA) was discussed. 2007 Elsevier B.V. All rights reserved.tfqicss[

c(maeatstds

eywords: Uniaxial die compaction; Sintering; Lubrication; Die design

. Introduction

Ceramics have become increasingly important in modernndustry due to their good mechanical and physical properties1]. Ceramic parts are generally produced by combination ofompaction and sintering. However, cracks and distortions haveeen recognized as the most significant concerns, and often limithe application of uniaxial die compaction technology to producearge-scale ceramic parts. Cracks in powder metallurgy (P/M)omponents primarily originate from the compaction prior tohe sintering. Although the cracks may not become evident untilhe sintering has occurred, the root cause is most likely the poornterparticle bonding obtained prior to the sintering [1–4]. Usu-lly, micro-cracks that are invisible during the compaction arearried over and enlarged during the sintering. Another commonhallenge in sintering is the dimensional control of the sinteredroducts. Warpage could occur as a result of green density gra-ient, friction drag (caused by the support material), gravity, andemperature gradient [4].

Uniaxial die compaction is the simplest form of consolida-

ion process that has been extensively used to densify powderaterials. One disadvantage of this technique, however, is theariation of the pressed density that can occur at different loca-

∗ Corresponding author. Tel.: +1 734 615 7445E-mail address: [email protected] (P. Chen).

sTwds

c

924-0136/$ – see front matter © 2007 Elsevier B.V. All rights reserved.oi:10.1016/j.jmatprotec.2007.02.039

ions of the parts. This density distribution mainly originatesrom particle–particle and die wall–particle friction, which causeuality issues such as cracking and warpage during the sinter-ng. Especially, when a large part size is considered, the poorontrol over the density uniformity of the green part becomesignificant and results in part failures. In general, the dimen-ions of the sintered compacts are in the range of 10–100 mm4].

The modeling methodology for powder compaction can belassified into three categories based on the length scale [5]:1) continuum models; (2) multi-particle models (discrete ele-ent models and particle dynamics models) [6–8]; and (3)

tomistic/molecular dynamics models [5,9]. Continuum mod-ls assume that a response of a powder packing is continuousnd similar to that of a solid material. Hence, they are attrac-ive in practical applications and have been employed in thistudy. There are two types of continuum models. The first ishe micromechanical model [10,11], which provides a way toerive macroscopic model parameters from information on amaller particle-level length scale. The micro-to-macro tran-ition is performed usually by homogenization techniques.he other is the empirical (phenomenological) model [12–14],hich is formulated using several ‘material’ functions that

escribe the response of a specific porous material to thetress.The objective of the study is to investigate the effects of pro-ess parameters to obtain a crack-free ring shaped part, which

244 P. Chen et al. / Journal of Materials Processing Technology 190 (2007) 243–250

mpac

hs

2

2

stcawitao

ss

aatmTw

raw

spacdtdtTbAp

ppitrfi

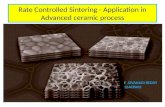

Fig. 1. (a) Instron 1136; (b) zirconia disk co

as a final dimension of 90 mm after uniaxial compaction andintering with minimum distortion.

. Experimental and simulation procedure

.1. Experimental setup and procedures

Two types of experimental setup have been designed and fabricated for thistudy. To acquire a final part dimension of 90 mm, green part dimensions needo be larger than 110 mm, which is rather large for a part made by uniaxialompaction. Since the final target part dimensions were larger than those oftypical ceramic powder compaction and sintering, a preliminary experimentas performed to compact a cylindrical part with a diameter of 46.4 mm to

nvestigate appropriate range of process parameters. Based on the results fromhis preliminary experiment, a die for the larger ring shaped part was designednd fabricated. The detailed experimental setup for the compaction and sinteringf both sizes are described below.

A commercial zirconia powder (YSZ, Inframat Advanced Materials, LLC)tabilized by 3 mol% Y2O3 was used for all the experiments conducted in thistudy. The particles have a mean particle size of 0.5 �m.

The setup for the preliminary experiment is shown in Fig. 1, which includespunch, a base plate, and a die. The components were made by precision milling

nd turning process from A2 tool steel. 50 g of zirconia powder was poured intohe assembled die/punch set. The setup was then placed in the Instron 1136aterial testing system for compaction, which had a single acting upper punch.he compaction process was achieved by a constant punch speed. The punchas held at the final position until the force stabilized and was released at a

ApiPh

Fig. 2. (a) Zirconia ring compaction die

tion die set; (c) section view of the tooling.

elatively slow speed. Finally, the base plate was replaced by an ejection ring,nd the green part was pushed out. The die wall was lubricated with mineral oil,hich was recommended by the powder vendor.

Based on the shrinkage ratios from the preliminary experiments, the dimen-ions of the die for the ring component was determined as shown in Fig. 2. Arevious attempt with a one-piece die design similar to the disk shaped parts shown in Fig. 1 but with a diameter of 114 mm resulted in green parts withracks due to excessive friction during ejection process, which caused a largeensity gradient in the green compact. Therefore, a split die design was adoptedo reduce the friction during ejection as shown in Fig. 2. The Container wasesigned, so it may be split into two halves to facilitate the ejection process. Thewo symmetric pieces were assembled by eight screws and two aligning pins.he core rod was designed to produce a ring shaped part, which was assembledy two screws and an aligning pin. All the tooling components were made from2 tool steel, which were heat treated to the hardness of HRC 55 and wererecision ground.

The experiment cycle requires assembly and disassembly of the die com-onents. First, the Dividable Container is assembled. Next, core rod and baselate are placed in the container, and then 380 g of zirconia powder is pourednto the container. The Punch is placed on top of the powder, which is guided byhe core rod and the container during the compaction. A constant punch speed isetained by Instron 1136 material testing system. After holding the punch at thenal position until the load is stabilized, it is released at a relatively lower speed.

fter the compaction, the Dividable Container is disassembled, and the baselate is detached from the core rod to eject the compact. Finally, the ejected parts sintered in an oven. Three sintering procedures (Fig. 3) were used in this study.rocedure II has a higher sintering temperature than Procedure I. Procedure IIIas a very slow heating speed than those of Procedure I and II.set; (b) section view of the tooling.

P. Chen et al. / Journal of Materials Processing Technology 190 (2007) 243–250 245

2

apppscatec(

wImaTtttriM

F

wsp

Table 1Material properties of zirconia powder [14]

Full density Initial density Particle size β α

6.08 (g/cm3) 1.885 (g/cm3) 0.53 �m (Nominal) 54.3◦ 0.03

E ν d R

206 GPa 0.31 1.53 MPa 0.835

dic

F

eeTpbcwnlTp

Fig. 3. Illustration of the sintering procedures.

.2. Material modeling for compaction simulation

In order to simulate the zirconia powder compaction process, a finite elementnalysis (FEA) model was developed utilizing the material property data fromrevious study in literature [14]. It is necessary to recognize the major physicalhenomena that occur during the compaction of ceramic particles. The com-action process can be divided into three main distinctive stages. In the earlytages of compaction, particles are rearranged (we will refer to this as stage 0ompaction). As compaction force is further exerted onto the powders, the rel-tive density (RD, which is defined as the ratio of the density of the compact tohe full density of the material) increases, and compaction is accommodated bylastic deformation of the particles (stage 1 compaction). At higher pressure, theompact structure will breakdown with a small amount of particle rearrangementstage 2 compaction).

In this study, we employed the modified Drucker–Prager/Cap (DPC) model,hich has been widely used in powder metallurgy and ceramic industry (Fig. 4).

t is a phenomenological model that has been adapted from soil mechanics. Theodel is attractive in compaction modeling because it contains features that

re in accordance with the physical response of particulate compacts [12,15].he DPC model at low hydrostatic pressure is a shear failure model, similar to

hose used in granular flow, which reflects the dependence of the strength onhe confining pressure. This enables the model to predict the strength in tensiono be smaller than the strength in compression, a concept which is common forocks, brittle materials, and pressed powder compacts. In its simplest form, its represented by a straight line in the p–q plane, which is also known as the

ohr–oulomb shear failure line, FS:

S(q, p) = q − d − p × tan(β) = 0 (1)

here d and β are cohesion and internal friction angle, respectively. If the stresstate is such that the corresponding Mises equivalent stress (q) and hydrostaticressure (p) result in a value of F(q, p) < 0, then the stress causes only elastic

Fig. 4. The Drucker–Prager/Cap (DPC) model [5].

isoKo

rAmm

3

3

3

w

Fig. 5. Densification behavior of the zirconia powder [14].

eformation. If the stress state is such that Eq. (1) is satisfied, the material failsn shearing. At high hydrostatic pressures, the yield surface is described by aap surface, Fc:

c(q, p) =√

(p − pa)2 +[

R × q

1 + α − α/cos(β)

]2

−R × (d + pa × tan(β) = 0 (2)

R is a material parameter that controls the shape of the cap. pa is anvolution parameter that represents the volumetric inelastic strain driven hard-ning/softening, which is related to hydrostatic compression yield stress (pb).he parameters pa and R may be obtained from compaction experiments. Thearameter α does not have a physical meaning, but ensures a smooth transitionetween the cap and the shear failure regions for numerical robustness. Typi-ally, a small value (α = 0.01–0.05) is used to avoid the situation of α = 0, whichill form a sharp corner at the intersection of Fc and FS. This may lead toumerical problems [16]. The geometric representation of the complete yieldocus is represented in the p–q plane as a limiting curve F(q, p, RD) = 0 in Fig. 4.his form is consistent with the DPC model implemented in the finite elementackage ABAQUS, which was used for this study.

The FEA results were compared with the medium size compaction exper-ments (Ø = 46.4 mm). The material properties used for the simulation areummarized in Table 1. These values were adopted from the experimental workf Kim et al. [14] (3 mol% Y2O3 stabilized zirconia powder, HSY-3.0, Daiichi-igenso Kagaku Kogyo Co. Ltd., Japan). Fig. 5 shows the densification behaviorf this powder.

Considering the geometric symmetry of the process, only an axisymmet-ic section of the compact was simulated using the commercial FEA software,BAQUS v6.5. The tooling was represented by rigid elements, whereas theaterial mesh for the powder consisted of an array of 4-node bilinear axisym-etric quadrilateral elements with reduced integration (CAX4R).

. Results and discussions

.1. Compaction of ceramic disk (Ø = 46.4 mm)

.1.1. Compaction results and discussionAs summarized in Table 2, different process parameter levels

ere investigated. The green part quality was evaluated in terms

246 P. Chen et al. / Journal of Materials Processing Technology 190 (2007) 243–250

Table 2Experimental conditions for the compaction (Ø 46.4 mm disk)

Case Pressure (MPa) Pressing speed (mm/s) Releasing speed (mm/s) Ejection speed (mm/s) Green Part

1 92.30 0.085 0.004 0.008 Horizontal crack2 134.5 0.042 0.021 Manual Horizontal crack3 118.7 0.042 0.008 Manual Horizontal crack

008008008

opptoitgcsh(

3

T

twttmalmAKhtt

4 65.93 0.042 0.5 (3 repeats) 65.93 0.042 0.6 (3 repeats) 52.74 0.042 0.

f the occurrence of cracks. It was found that the most importantrocess parameter was the compaction pressure. The effects ofressing, releasing and ejection speed on cracking were rela-ively small. As long as the compaction pressure was less thanr around 65.9 MPa, cracks did not occur. Typically, a cracks initiated by the existence of a sharp density gradient. Whenhe compaction force is reduced, the density gradient of thereen part also decreases correspondingly. Therefore, a smallerompression pressure helps to avoid cracks [2]. Fig. 6 shows auccessful and an unsuccessful case from the compaction: oneas a horizontal crack (case #2), and the other is free of crackcase #5).

.1.2. FEA results and discussionThe loading curve obtained from the experiment case #5 from

able 2 was compared with the loading curve from the simula-

Fig. 6. Compacted part: (a) Case #2; (b) Case #5.

pta

bassm

1

2.117 Crack free4.233 Crack free4.223 Crack free

ion as shown in Fig. 7. In general, the simulation results agreeell with the experiment. The underestimation of the load at

he initial loading stage is most likely due to the inaccuracy ofhe material modeling at low densities. As explained in [17], the

aterial parameters for DPC model at low densities are usu-lly not obtainable from the material testing experiment: theower the density, the more measurement noise in the experi-

ent. In addition, the powders used in the experiment (Inframatdvanced Materials, LLC) and simulation (Daiichi-Kigensoagaku Kogyo Co. Ltd.) were from different sources, which mayave contributed to the different loading characteristic, althoughhe powders were the same grade. The green part height fromhe simulation (11.866 mm) agreed well with that of the actualart (11.557 mm), and the final density of the green part fromhe simulation (2.554 g/cm3, at the top surface) also matched thectual part density (2.575 g/cm3).

Furthermore, the model was utilized to study the relationshipetween the density distribution and the crack formation. Thus,crack-free case (case #5) and a case with cracks (case #2) wereimulated. Fig. 8 shows the relative density distribution of theimulated parts after ejection. Following observations have beenade from Fig. 8.

. The highest density in a crack-free case (case #5) occurredat the upper corner of the compact, which agreed with thecommon practice in the sense that the upper corner of thepart experiences the highest compaction pressure [14]. On

Fig. 7. Loading curve comparison (Case #5).

P. Chen et al. / Journal of Materials Processing Technology 190 (2007) 243–250 247

2

F4

t

TZ

C

R

RRR

RR

R

R

R

R

R

R

Fig. 8. Density distribution after ejection: (a) Case #5; (b) Case #2.

the other hand, the highest density for the case #2 (whichhad cracks in the experiment) occurred below the uppersurface.

. Case #2 has a sharper density gradient near the upper cornerregion, and the corresponding relative density curves exhibit

a sharp distribution. This indicates a sudden change of densityin a localized area, while the relative density curves of case#5 are smoother and corresponds to a more uniform densitydistribution.stac

able 3irconia ring compaction experiment conditions

ase Pressure (MPa) Green part before ejection Luand

ing 1 40.49 Crack free Mi

ing 2 40.49 Crack free Miing 3 40.49 Crack free Waing 4 40.49 Crack free Alu

ing 5 40.49 Crack free Coing 6 28.92 Crack free Wa

lubing 7 57.84 Crack free Oil

(Luing 8 40.49 Crack free Oil

(Luing 9 52.05 Crack free Oil

(Luing 10 58.3 Crack free Oil

(Luing 11 63.62 Crack free Oil

(Luing 12 72.88 Crack free Oil

(Lu

ig. 9. Density distribution after ejection (ring compaction with a pressure of0.49 MPa).

The simulation results indicated the migration of the loca-ion of the highest density region of a compact from the top

urface to below the surface as the pressure was increased. Ashe pressure increased, cracks developed under the top surfaces shown in the actual part (Fig. 6a case #2). The location of therack corresponds to the highest density area in Fig. 8b. Whenbrication of the base plate surfacelower portion of core rod

Separation between the compactand the base plate

neral oil A blade was used for theseparation, which resulted in abad compact surface condition

neral oilxminum foil Easy separation, but the foil was

embedded into the compact,elimination of the foil resulted ina very bad compact surfacecondition and cracks, Fig. 9 a)

olube 5500 metalworking fluid Failed, crackster based graphite particlericant (Lubrodal F705 ALX)

Successful

based graphite particle lubricantbrodal Hykogeen Conc HI)

Successful, Fig. 9 b)

based graphite particle lubricantbrodal Hykogeen Conc HI)

Successful

based graphite particle lubricantbrodal Hykogeen Conc HI)

Successful

based graphite particle lubricantbrodal Hykogeen Conc HI)

Successful

based Graphite Particle lubricantbrodal Hykogeen Conc HI)

Successful

based graphite particle lubricantbrodal Hykogeen Conc HI)

Successful

2 rocessing Technology 190 (2007) 243–250

tgcrcais

3r

3

cipTceHpiTr

3

tsctoacsToatcw

dabsac((atittg

F(

3

cracks and distortions. Cracks are mostly due to the non-uniformdensity distribution induced from the compaction process andthe temperature gradient [4]. The distortions that are commonlyobserved in cylindrical parts are of a conical shape, which has

48 P. Chen et al. / Journal of Materials P

he high-density region is located on the top surface, a densityradient is created from top to bottom as indicated in Fig. 8,ase #5. In contrast, as the pressure increased, the high-densityegion shifted under the top surface, and the density gradient wasreated such that it caused tensile internal stress at the locations indicated in Fig. 8, case #2. It is speculated that the cracksnitiate from these highly dense regions to relieve the internaltress built up from the density gradient.

.2. Compaction and sintering of a large scale ceramicing (Ø = 114 mm)

.2.1. Compaction simulation results and analysisThe simulation tool was used to detect potential cracks that

an form in the ring shaped part prior to designing of an exper-mental setup. The resulting density distribution of the ejectedart at a compaction pressure of 40.49 MPa is shown in Fig. 9.he relative density distribution was smooth, and no potentialrack locations could be identified. This was proved later by thexperiment having the same condition (Case Ring 1 in Table 3).igher densities were found at the top surface where the movingunch contacted the powder. The density distribution at the ringnner perimeter is very close to that at the ring outer perimeter.he design change from the disk shape to the ring shape also

educed the required load due to the decreased contact area.

.2.2. Compaction experiment results and discussionPressing speed and releasing speed of the punch also affect

he crack formation of the compacted parts. A too high punchpeed will result in a higher density at the contacting surface sus-eptible to cracks. Also, a too high releasing speed will dischargehe internal pressure too quickly and lead to cracks. Thus, basedn the process parameters used in Section 3.1, and a few trial-nd-errors from both simulations and experiments with the newompaction die set, the pressing speed and releasing speed waselected to be 0.042 and 0.002 mm/s, respectively. As shown inable 3, the pressure for experiments was selected in the rangef values used in the simulation. The parts showed no cracksfter the compaction; however, a strong bond was formed athe interface of the powder compact-base plate and the powderompact-lower portion of the core rod. Hence, the green partsere frequently damaged during the separation process.In order to successfully detach the powder compact from the

ie, various lubrication and separation methods were evaluateds summarized in Table 3. Mineral oil, which was suggestedy the vendor, only seemed to be effective for smaller parts aseen in previous experiments. As the part size became largernd interface area increased for the ring shape part, all theompacts failed during ejection (Ring 1 and Ring 2). The waxRing 3), aluminum foil (Ring 4), and metal working lubricantRing 5) also failed to maintain the part intactness while ejectings shown in Fig. 10a. However, as demonstrated in cases Ring 6hrough Ring 12, the graphite particle based lubrication greatly

mproved the separation performance as shown in Fig. 10b. Forhe unsuccessful attempts, a mechanical press was used to ejecthe part, whereas the compact could be taken out by hands whenraphite lubrication was used.ig. 10. Green parts: (a) unsuccessful case (Ring 4); (b) successful caseRing 7).

.2.3. Sintering experiment results and analysisTwo biggest challenges encountered during the sintering are

Fig. 11. Schematic view of the part orientations in the oven.

P. Chen et al. / Journal of Materials Processing Technology 190 (2007) 243–250 249

Table 4Sintering experiment conditions and results

Case Compaction pressure (MPa) Sintering procedure Orientation of the part in the oven Cracks

Ring 1 40.49 Procedure I Bottom up YesRing 6 28.92 Procedure II Sideways YesRing 7 57.84 Procedure III Bottom down NoRing 9 52.05 Procedure III Bottom down NoRing 10 58.30 Procedure III Bottom down NoRing 11 63.62 Procedure III Bottom down NoRing 12 72.88 Procedure III Bottom down No

Table 5Shrinkage and the dimensional differences between top and bottom after sintering

Case Shrinkage in diameter Height after sintering (mm) Diameter difference (mm) Conical taper

Top Bottom

Ring 1 0.271 0.282 31.43 1.32 7.22E–02Ring 6 0.292 0.283 32.36 1.04 4.20E–02Ring 7 0.258 0.263 27.78 0.5 1.80E–02Ring 9 0.267 0.278 31.84 0.9 2.83E–02RRR

bl

tshtchh[

cdSpt

FR

(sftp

aseofsr

ing 10 0.256 0.266 30.18ing 11 0.254 0.259 29.93ing 12 0.249 0.254 29.86

een quantified by the amount of change in diameter over a unitength (conical taper) in this work.

Three sintering procedures (Fig. 3) and various part orienta-ions (Fig. 11) in the oven were evaluated, and the results areummarized in Table 4. It was observed that the sintering curvead a significant effect on the crack formation. The parts sin-ered using sintering Procedure III (Ring 7–Ring 12) are free ofracks while other parts which used sintering Procedure I and IIad cracks (Ring 1 and Ring 6). A slower sintering procedureelped to prevent cracks by minimizing the temperature gradient4].

According to the classic sintering theory [4], there are twoontributors to the conical shape. The first is the non-uniform

ensity distribution of the green part (shrinkage anisotropy).ince the bottom of the green part has a lower density com-ared with the top (Fig. 9), the bottom shrinks more than theop does and results in a conical shape as shown in Fig. 12big. 12. Illustration of the effect of shrinkage anisotropy and friction drag: (a)ing 12; (b) Ring 6; (c) Ring 1.

ddpisfRpc

4

ctctctbt

0.83 2.75E–020.62 2.07E–020.41 1.37E–02

Ring 6 was orientated sideways in the oven so that the conicalhape was purely due to shrinkage anisotropy). The other is theriction drag introduced by the support substrate, which restrictshe shrinkage of the bottom compared with the unrestricted toportion (Fig. 12c).

Table 5 shows detailed information regarding the shrinkagend the dimensional differences between top and bottom afterintering. Case Ring 1 in Fig. 12a demonstrates the combinedffect of friction drag and shrinkage anisotropy. Since the bottomf the green compact was placed facing upwards, the distortionrom the density gradient and friction drag will multiply. Mea-ured conical taper in this configuration is the largest, and theesult is confirmed by the observation. Therefore, to reduce theistortion by offsetting the distortion caused by the density gra-ient and the friction drag, the bottom of the green part waslaced facing down on the substrate. As confirmed by the con-cal taper measurement (Ring 7–Ring 12), the measured taperignificantly decreased. In addition, the effect of compactionorce on the distortion can be observed from Ring 9 throughing 12. A higher compaction force produced a denser greenart, which resulted in less shrinkage during the sintering pro-ess, and therefore helps to reduce conical shape.

. Conclusions

In this study, a large-scale ceramic part (Ø114 mm) was suc-essfully compacted and sintered using uniaxial die compactionechnique. The effects of die design, compaction pressure, lubri-ation, sintering procedure, and part orientation in the oven onhe P/M part quality were investigated, and the preferred process

onditions were discussed. Furthermore, a FEA tool was utilizedo predict the location of a crack for a disk shaped part. On theasis of the quantitative and qualitative analysis made herein,he following conclusions could be drawn: (1) A compaction

2 rocess

pocdcrtabdrtpiatsid

A

dT

R

[

[

[

[

[

[

[16] D. Hibbit, B. Karlsson, P. Sorensen, ABAQUS theory manual, version 5.4,

50 P. Chen et al. / Journal of Materials P

ressure range of 30–75 MPa is preferred for the compactionf zirconia powder using uniaxial die compaction. The less theompaction force, the less tendency for cracking, but more ten-ency for warpage after sintering. (2) In the case of disk-shapeeramic compact (FEA simulation), crack occurred around theegion where final density was the highest. The density distribu-ion curve showed an abrupt density distribution in the crackingrea. (3) The oil based graphite particle lubricant showed theest performance in the uniaxial compaction of zirconia pow-er. The friction between the powder and the tooling surface waseduced. Moreover, the tendency of zirconia powder sticking tohe tooling surface was eliminated to ensure a smooth separationrocess. (4) A two-piece split die design reduced the possibil-ty of cracking during ejection. (5) The conical shape distortionfter sintering from the shrinkage anisotropy could be offset byhe friction drag of the support substrate. (6) A slow multi-stepintering process (Procedure III) is preferred to prevent crack-ng. (7) A higher compaction pressure resulted in less distortionue to less shrinkage during sintering.

cknowledgement

We greatly acknowledge the help from Jie Feng on con-ucting the experiments and financial support from Powerixechnologies.

eferences

[1] F. Klocke, Modern approaches for the production of ceramic components,J. Euro. Ceram. Soc. 17 (1997) 457–465.

[2] R.M. German, Powder Metallurgy Science, second ed., Metal PowderIndustries Federation, Princeton, 1994.

[

ing Technology 190 (2007) 243–250

[3] D.C. Zenger, H. Cai, Common causes of cracks in P/M compacts, Int. J.Powder Metall. 34 (1998) 33–52.

[4] R.M. German, Sintering Theory and Practice, first ed., Wiley, New York,1996.

[5] A. Zavaliangos, Constitutive models for the simulation of P/M processes,Int. J. Powder Metall. 38 (2002) 27–39.

[6] P.A. Cundall, O.D.L. Strack, A discrete numerical model for granularassemblies, Geotechnique 29 (1979) 47–65.

[7] J. Lian, S. Shima, Powder assembly simulation by particle dynamicsmethod, Int. J. Numer. Methods Eng. 37 (1994) 763–775.

[8] D.T. Gethin, R.S. Ransing, R.W. Lewis, M. Dutko, A.J.L. Crook, Numeri-cal comparison of a deformable discrete element model and an equivalentcontinuum analysis for the compaction of ductile porous material, Comp.Struct. 79 (2001) 1287–1294.

[9] F.X. Sanchez-Castillo, J. Anwar, Molecular dynamics simulations of gran-ular compaction: the single granule case, J. Chem. Phys. 118 (2003)4636–4648.

10] A.L. Gurson, Continuum theory of ductile rupture by void nucleation andgrowth: Part I Yield criteria and flow rules for porous ductile media, J. Eng.Mater. T. ASME 99 (1977) 2–15.

11] E. Arzt, The influence of an increasing particle coordination on the densi-fication of spherical powders, Acta Metall. 30 (1982) 1883–1890.

12] D.C. Drucker, R.E. Gibson, D.J. Henkel, Soil mechanics and work hard-ening theories of plasticity, Trans. ASCE. 122 (1957) 338–346.

13] K.H. Roscoe, J.B. Burland, On the generalized stress–strain behaviour of‘wet’ clay, ENG PLAST (1968) 535–609.

14] K.T. Kim, S.W. Choi, H. Park, Densification behavior of ceramic pow-der under cold compaction, J. Eng. Mater. T. ASME 122 (2000) 238–244.

15] PM Modnet Computer Modelling Group, Comparison of computer modelsrepresenting powder compaction process, Powder Metall. 42 (1999) 301-311.

Pawtucket, Rhode Island, 1994.17] J.C. Cunningham, I.C. Sinka, A. Zavaliangos, Analysis of tablet com-

paction. I. Characterization of mechanical behavior of powder andpowder/tooling friction, J. Pharm. Sci. 93 (2004) 2022–2039.