Implant–abutment connections: influence of the design on...

Transcript of Implant–abutment connections: influence of the design on...

Implant–abutment connections: influence of the designon the microgap and their fatigue and fracture behavior of dentalimplants

F. J. Gil • M. Herrero-Climent • P. Lazaro •

J. V. Rios

Received: 29 December 2013 / Accepted: 28 March 2014

� Springer Science+Business Media New York 2014

Abstract Microgap between implant and abutment can

produce biological and mechanical problems such as peri-

implantitis and/or fatigue failures. The aim of this study

was to evaluate microgap size and fatigue behavior of

external and internal connections. In both systems the

torque to tighten the abutment screw of single crown

abutments was 45 Ncm. Fifty implants for each connection

type were studied. One subgroup (n = 5) was used by the

observation and evaluation of the microgap, other (n = 5)

was tested for fracture strength and the other (n = 40) was

subjected to dynamic loading. The internal connection

presents a lower microgap than the external ones. From

fatigue results, the external hexagon interface showed

superior result compared to the internal hexagon interfaces.

The tolerances in the internal connections are better and

favour the fatigue behavior but this factor alone is not

sufficient to improve the fatigue response in relation to the

external connections when the screw is subjected at the

same torque. The external system presents a higher value

of the area than the internal and it produces a better load

distribution. Microgaps and mechanical properties are very

important for the long-term behavior of the dental implants

and these aspects should be known by the implantologists.

1 Introduction

Most dental implant systems consist of two components: the

implant and the abutment. The first is the endosteal compo-

nent, which is placed in the first surgical phase, and the

second is the transmucosal connection, which is generally

attached after implant osseointegration to support the pros-

thetic restoration. Colonization of oral microorganisms

through gaps between these parts may produce soft tissue

inflammation or the failure of peri-implantitis treatment [1].

During chewing and biting, the prosthetic restoration

and the implant–abutment connection is affected by vari-

ous physiological forces, on a single molar implant this

might be about 120 N in the axial direction [2, 3]. In

addition, there might be a short force maximum up to an

average of 847 N for men and 595 N for women [4].

Cyclic loading forces during physiological function that do

not exceed the maximum strength of an implant–abutment

connection might loosen the implant–abutment connection

gradually or make it fail suddenly due to fatigue. The

reason for the fatigue failure is either a lack of force fitting

or form-closure of the connection design. The critical

reason for loosening of the implant–abutment connection is

the loss of preload at the abutment screw and the resulting

unscrewing or fatigue failure of the screw material [2].

An analysis has been recently published on implant

related complications which calculated a cumulative inci-

dence of connection related complications (screw loosen-

ing or fatigue) of 7.3 % after 5 years of clinical service [5].

Maeda et al. [6] and Khraisat [7, 8] studied the stress

distribution patterns between implants with external-hexa-

gon or internal-hexagon connection systems using in vitro

models. The results showed that almost the same force dis-

tribution pattern was found under vertical load in both sys-

tems. Fixtures with external-hexagon showed an increase in

F. J. Gil (&)

Department of Materials Science and Metallurgical Engineering,

ETSEIB, Universitat Politecnica de Catalunya, Av. Diagonal

647, 08028 Barcelona, Spain

e-mail: [email protected]

M. Herrero-Climent � P. Lazaro � J. V. Rios

Faculty of Dentistry, Universidad de Sevilla, C/Avicena s/n,

41004 Seville, Spain

123

J Mater Sci: Mater Med

DOI 10.1007/s10856-014-5211-7

strain at the cervical area under horizontal load, while

internal-hexagon fixtures the strain was at the fixture tip area.

Within limitations of the model study, it was suggested that

fixtures with internal-hexagonal showed widely spread force

distribution down to the fixture tip compared with external-

hexagon.

The problem of a microgap between implant and

abutment is biological and also mechanical. The biolog-

ical problem relates to the presence of bacteria that have

been found in the apical portion of the abutment screw [9,

10]; in vivo, this could produce a bacterial reservoir that

could interfere with the long-term health of the peri

implant tissues. The mechanical problem relates the mi-

cromovements and possible loosening or fracture due to

the fatigue of screw-retained abutments. Huang et al. [11]

studied the relationship between fractures surface mor-

phology and applied stress level for dental abutment

screw loaded in cyclic fatigue. They found a linear rela-

tionship between the number of cycles and the stress

applied to the screws.

The purpose of this study was to evaluate and compare

the implant–abutment microgaps for the two-piece abut-

ments for external hexagon joints (external connection) and

comparative for internal-cone joints with hexagon antiro-

tational device (internal connection). Furthermore, the

fatigue behavior was evaluated for each connection type.

The dental implants were sourced from the same implant

manufacturer, with identical surface and with the same

retention force of the connection screws.

2 Materials and methods

Two implant systems with the implant–abutment were

evaluated. The dental implants were fabricated by Klock-

ner� (SK2, with external connection and Essential Cone,

with internal connection). These specific systems are very

similar to other dental implants existing in the market with

comparable contact areas, and the results can be general-

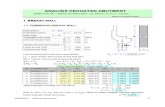

ized. Figure 1 illustrates the designs studied. In both sys-

tems the torque to tighten the abutment screw of single

crown abutments was 45 Ncm, leading to better force-fit.

Fifty dental implants for each connection type were stud-

ied. One subgroup (n = 5) was used for observation and

evaluation of the microgap, another subgroup (n = 5) was

tested for fracture strength and the remainder (n = 40) was

subjected to dynamic loading.

For evaluation of the microgaps, the implant–abutment

systems were embedded in a glycol methacrylate resin.

After polymerization, each specimen was sectioned along

its longitudinal axis with a high-precision diamond disc. A

total of three slides were obtained for each implant. The

samples were observed by scanning electron microscopy

(JEOL 6400, Japan) coupled with an analysis image sys-

tem. The sensitivity of the measures was 0.2 m. This

method is very similar at the technique to evaluate the

Fig. 1 a Implant–abutment with internal connection and b implant–

abutment with external connection

J Mater Sci: Mater Med

123

implant–abutment gap of an external hexagon implant

system as a function of radius proposed by Coelho [12].

Five flexural tests at 308 were conducted, at the selected

inclination, to determine the yield strength of the material

and the ultimate flexion strength. The resulting percentages

of yield strength that were obtained from these tests,

ranging from 60 to 90 %, were later used to perform fati-

gue tests to obtain the number of cycles until fracture.

The fatigue behavior and the fatigue limit of the pro-

totype were set using the Wohler’s curves (stress – number

of cycles) that describe the relation between the amplitude

of the cyclical tensions and the number of cycles to break.

During the test, the implant–abutment system was sub-

jected to both cyclical compressive and lateral forces,

without any lateral constraint. Forty specimens were tested.

The tests were performed in simulated body fluid [13] at

37 �C with the servo-hydraulic testing machine MTS

Bionix 858, which is specially designed to test biomaterials

because is equipped with triaxial stresses (tension, com-

pression and torsion). The torsion of 38 was applied in the

fatigue test, this value is the typical regarding the teeth

movement. This machine was equipped with a load cell

MTS of 10 KN, and controlled by means of a PC equipped

with the software TESTAR II�.

The tests were performed following the guidelines pre-

viously published by the FDA at the Class II Special

Controls Guidance Documents: Roots-form Endosseous

Dental Implants and Endosseous Dental Implants–Abut-

ments and the ISO 14801:2007. The tested implants sup-

ported an abutment that was in line with the axis of the

implant. The testing setup clamped the implant so that the

implant’s long axis made a 30� angle with the loading

direction of the testing machine and, consequently a flex-

ural load was applied (Fig. 2). The implants were fixed

with a 30� inclination from the z-axis of the traction–

compression machine. A 30� angle to the z-axis of the

tensile–compression machine is recommended by the

standards of the FDA as the most unfavorable position.

Moreover, the implant was placed 3 mm below the antic-

ipated crestal bone level, simulating 3 mm of bone

resorption.

The aim was to find the level of stress at which the

sample supported five million cycles, and which will be

considered the fatigue limit. Seven of the tests that were

carried out to determine the level of stress analyzed the

fatigue limit whilst three tests focused on the rest of the

tested stresses. The implants were loaded with a sinusoidal

function of fatigue at a frequency of 15 Hz and the rela-

tionship between maximum and minimum applied stress

was 10 %. The tests were performed at room temperature.

The obtained data was represented as number of cycles to

failure as a function of applied stress. The first stress

applied was 1450 N, a load lightly lower that the maximum

compressive strength, and the following loads decreased by

around a 10 %.

The data were statistically analysed using Student’s

t tests and one-way ANOVA tables with Tuckey’s multiple

comparison in order to evaluate statistically significant

differences between sample groups. The differences were

considered to be significant when P value \ 0.01. All

statistical analyses were performed with Minitab software

(Minitab release 13.0).

3 Experimental results

The gaps obtained are presented in Table 1. In some cases,

excellent adaptation between implant and screw-retained

abutment was observed as the separation distance was

lower than the bacteria diameter and consequently would

not permit infiltration of microorganisms. In some cases,

the connection is like cold-welding where the distance is

zero. The internal connection design presented a lower

Fig. 2 Scheme of the experimental setup during flexural and fatigue

tests

J Mater Sci: Mater Med

123

microgap than the external design with statistically sig-

nificant differences. In Fig. 3 we can observe an example

for each microgap connection type.

The fatigue behavior of each type of abutment–implant

connection can be observed in the S–N curves in Fig. 4.

Statistically, the external hexagon interface presented big-

ger fatigue long life than the internal hexagon interfaces.

A loss of retention between abutment and implant was

assessed as a failure. In all cases the failures were caused

by abutment screw loosening and later fracture, but not due

to destruction of the implant neck or shoulder. Analysis of

fractured screws by SEM revealed that the mode and the

region of fracture were the same for the two systems

evaluated. Fatigue striations were seen on the SEM

micrographs (Fig. 5). Such striations are an indication of

fatigue failure. Overloads or fast fracture zone, that is, the

portions of the components where final catastrophic failure

occurred were also observed. The fracture surfaces were

similar for all implants, as can be observed in Fig. 6. The

fractures are in the connection zone and fracture the body

of the implant. The international standards for fracture

fatigue behavior indicates that the fractures in the dental

implants must be localized in the connection abutment–

implant [14, 15].

4 Discussion

Binon and Curtis [16] indicated tolerances of manufactur-

ing as a reason for the described loose-fit of the prefabri-

cated parts and requested the manufacturer to improve the

fit of implants components. In loose-fit situations, the

possibility of horizontal movement and micro rotation

between implant and abutment screw and lower that the

forces to tighten it, micromovements could have led to a

progressive unscrewing of the abutment screw under con-

ditions dynamic loading. In our study, the main cause of

the high fatigue life of the external connection is due to the

size of the resistant section, the external system presents a

higher value of the area than the internal. This fact pro-

duces a better load distribution of the load and this is a

main factor that explains the differences in the mechanical

properties. The tolerances in the internal connections are

better and favour the fatigue behavior of the internal con-

nection system; however this factor is not sufficient to

improve the fatigue response in relation to the external

connections. Raoofi et al. [17] studied by finite element

analysis that the stress concentration decreased when the

internal surface area increase.

Many authors indicate that the external connections in

different implant–abutment systems present better fatigue

behavior due to the differences in force-fit in the connec-

tion design [2, 3, 5]. In all cases, the external connection

systems studied present a higher force-fit than the internal.

In this contribution, the force-fit was constant and conse-

quently this factor is not considered [1–3, 5].

Freitas-Junior et al. [18] evaluate the reliability and

failure modes of anterior single-unit restorations in internal

conical interface (ICI) implants using step-stress acceler-

ated life testing (SSALT). A number of implants were

used: Forty two ICI implants were distributed in two

groups (n = 21 each): AT-OsseoSpeedTM TX (Astra Tech,

Waltham, MA, USA) and another group SV-Duocon Sys-

tem Line, Morse Taper (Signo Vinces Ltda., Campo Largo,

PR, Brazil). The corresponding abutments were screwed to

Table 1 Measurements of the microgap for internal and external

connections

Type of connection Average of microgap (lm)

Internal 0.97 (0.09)

External 1.22 (0.08)

Each type of connection was measured in five different implants, the

total measures for each connection was 350. The result is the average

of all measurements and into brackets is the standard deviation. The

results present statistically differences with P \ 0.01

a

60 µm

0.4573 µm

0.4582 µm

4.673 µm 2.782 µm

60 µm

b

Fig. 3 Observation by optical microscope with image analysis the

microgap of two types of connections: a Internal and b external

J Mater Sci: Mater Med

123

the implants and standardized maxillary central incisor

metal crowns were cemented and subjected to SSALT in

water. Use-level probability Weibull curves and reliability

for a mission of 50,000 cycles at 200 N were calculated.

The tests showed no significant difference between the

groups tested (P [ 0.27) in all specimens of both designs

of ICI connection. The chief failure mode was abutment

fracture at the conical joint region and screw fracture at

neck’s region. Failure modes were similar.

The short external hexagon does not stabilize the con-

nection against lateral loads, and so the screws have to

absorb most of the load. This is usual in the implants with

height of the external hexagon around 0.6 mm. One reason

for the still good outcomes of this group may be the

improvements in screw design made by the manufacturer

and the increase of the height of the external hexagon. In

this study the height of the external hexagon was 1.8 mm.

This height produces an increase of the stability and an

increase of the flexural load transfer hexagon as shows the

scheme of Fig. 7.

Each implant–abutment interface has its advantages and

disadvantages. According to Maeda et al. [6] the external

hexagon interface has advantages such as suitability for the

two stage method, provision of an anti-rotation mechanism,

retrievability and compatibility among different systems.

However, increased screw loosening, component fracture,

and difficulty in seating abutments in deep subgingival

Fig. 4 S–N curves for each

connection type

Crack nucleation

Crack propagation

Fig. 5 Fracture surface observed by scanning electron microscope

Fig. 6 Fracture of the dental implants

J Mater Sci: Mater Med

123

tissues are problems commonly experienced with external

hexagon connectors.

The advantages of the internal hexagon following Ma-

eda are: ease in abutment connection, suitability for one

stage implant installation, higher stability and suitability

for single-tooth restoration, higher resistance to lateral

loads due to the lower centre of rotation and better force

distribution [6].

5 Conclusion

The internal connection had a smaller microgap than the

external ones with significant statistical differences. Very

good adaptation between the implant and the screw-

retained abutment were observed, in many cases the dis-

tances were smaller than the bacteria diameter and conse-

quently is not possible an infiltration of microorganisms.

The fatigue behavior of the external hexagon interface

presented superior result compared to the internal hexagon

interfaces. The high fatigue life of the external connection

is due to the size of the resistant section. This fact produces

a better load distribution of the load and this is a main

factor which explains the differences in the mechanical

properties.

Acknowledgments The authors are grateful to the CICYT

MAT2012-30706 and Generalitat de Catalunya (CTP Project) and

Andorra Government for funding the present work and to Klockner,

S.L. for kindly donating the material. The authors do not present any

interest conflict in this work

References

1. Steinebrunner L, Wolfart S, Bobmann K, Kern M. In vitro

evaluation of bacterial leakage along the implant–abutment

interface of different implant systems. Int J Oral Maxillofac

Implant. 2005;20:875–81.

2. Steinebrunner L, Wolfart S, Bobmann K, Kern M. Implant–

abutment interface design affects fatigue and fracture strength of

implants. Clin Oral Implant Res. 2008;19:1276–84.

3. Ritcher EJ. In vivo vertical forces on implants. Int J Oral Max-

illofac Implant. 1995;10:99–108.

4. Waltimo A. Studies on human bite force: a novel bite force

recorder and its clinical applications. Prosthetic dentistry. Hel-

sinki: Med-Habilitation; 1995. p. 199–210.

5. Pjetursson BE, Tan Y, Lang NP, Bragger U, Egger M, Zwahlen

M. A systematic review of the survival and complication rates of

fixed partial dentures (fpds) after an observation period of at least

5 years. Clin Oral Implant Res. 2004;15:625–42.

6. Maeda Y, Satoh T, Sogo M. In vitro differences of stress con-

centrations for internal and external hex implant–abutment con-

nections: a short communication. J. Oral Rehabil. 2006;33:75–8.

7. Khraisat A, Stegaroiu R, Nomura S, Miyakawa O. Fatigue

resistance of two implant/abutment joint designs. J Prosthet Dent.

2002;88:604–10.

8. Khraisat A. Stability of implant–abutment interface with a

hexagon mediated joint: failure mode and bending resistance.

Clin Implant Dent Relat Res. 2005;7(4):221–8.

9. Quirynen M, van Steenberghe D. Bacterial colonization of the

internal part of two stage implants: an in vivo study. Clin Oral

Implant Res. 1993;4(3):158–61.

10. Piatelli A, Scarano A, Paolantonio M. Fluids and microbial

penetration in the internal part of cement-retained versus screw-

retained implant–abutment connections. J Periodontol. 2001;72:

1146–50.

11. Huang HM, Tsai CM, Chang CC, Lin CT, Lee SY. Evaluation of

loading conditions on fatigue-failed implants by fracture surface

analysis. Int J Oral Maxillofac Implant. 2005;20(6):854–9.

12. Coelho AL, Suzuki M, Dibart S, Da Siva N, Coelho PG. Cross-

sectional analysis of the implant–abutment interface. J Oral

Rehabil. 2007;34(7):508–16.

13. Manero JM, Salsench J, Nogueras J, Aparicio C, Padros A,

Balcells M, Gil FJ, Planell JA. Growth of bioactive surfaces on

dental implants. Implant Dent. 2002;11:170–5.

14. Gil FJ, Aparicio C, Manero JM, Padros A. Influence of the height

of the external hexagon and surface treatment on fatigue life of

commercially pure titanium dental implants. Int J Oral Maxillofac

Implant. 2009;24:583–90.

15. Rodrıguez-Hernandez A, Juarez A, Engel E, Gil FJ. Streptococ-

cus sanguinis adhesion on titanium rough surfaces: effect of shot

blasting particles. J Mater Sci Mater Med. 2010;22:1913–22.

16. Binon PP, Curtis DA. A classification system to measure the

implant–abutment microgap. Int J Oral Maxillofac Implant. 2007;

22(6):879–85.

17. Raoofi S, Khademi M, Amid R, Kadkhodazadeh M. Moyahhedi

M.R. Comparison of the effect of three abutment–implant con-

nections on stress distribution the internal surface on dental

implants: a finite element analysis. J Dent Res Clin Dent Pros-

pect. 2013;7(3):132–9.

18. Freitas-Junior AC, Almeida EO, Bonfante EA, Silva NRFA,

Coelho PG. Reliability and failure modes of internal conical

dental implant connections. Clin Oral Implant Res. 2012;1:1–6.

doi:10.1111/j.1600-0501.2012.02443.x.

Fig. 7 Scheme of the influence of the external hexagon height of the

implant on the mechanical properties of the external connections

J Mater Sci: Mater Med

123

![Internal - Luciano Chinellato · AnyOne® Internal è -P_[\YL 3L]LS 7YVZ[OLZPZ EZ Post Milling Abutment Angled Abutment CCM Abutment Temporary Abutment [Titanium] Temporary Abutment](https://static.fdocuments.net/doc/165x107/5c038f7909d3f2156d8cd7fd/internal-luciano-anyone-internal-e-pyl-3lls-7yvzolzpz-ez-post-milling.jpg)