IMAS Conveyor Belts

Transcript of IMAS Conveyor Belts

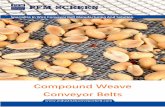

Conveyor Belts

IMAS Conveyor BeltsIMAS Conveyor Belts

About us

IMAS was founded in 1972 in Volos, Greece with a focus on the local energy sector of Greece and its Public Power Corporation (PPC). Since then, we have in-creased our capacity through continuous investment, with the last steel cord press added as recently as 2007. Today our plant is state of the art, from mixing lines to multi-cylinder Siempelkamp presses.

From its beginnings in the local market, IMAS quickly developed its export focus. Today our belts are appre-ciated across the globe, from the US in the west to Australia in the east. Millions of meters of belt providing top performance have proven us to be one of the leading suppliers in our industry.

With this experience combined with more than 100 years of knowledge within our Group in the field of conveyor belts, we are your first choice for all your conveyor belt needs.

Location

The IMAS plant is located on the east coast of Greece, approximately halfway between Athens and Thessaloniki.With our own port in Volos and the international port of Piraeus within a driving distance of approximately four hours, we are ideally positioned to execute our daily customer orders by truck all over Europe or by sea to the entire world.

Organization

At IMAS, you will find everything under one roof: Sales, Production, Development, Logistics, Quality Control, Purchasing, Human Resources, IT, Finance, Technical Service – everything shaped into a slim, effective and fast organization. This combined with our manufacturing setup makes us one of the fastest and most efficient operators on the market.

Being part of the Continental/ContiTech Group provides us with additional know-how in areas like advanced computer simulation, splice simulation and additional testing facilities.

Superior mechanical equipment

We produce our conveyor belts on the most reliable, modern equipment from manufacturers that specialize in the conveyor belt industry, such as Siempelkamp and Berstorff.

Our Roller Head line uses extruding technology enabling the production of both long and thick bubble free cover plates. Therefore the need for cover joins and lamination is now reduced to the minimum.

Our multi-cylinder Siempelkamp presses ensure even distribution of pressure during vulcanization the moment the tension control systems maintain the right tension on each cord inside the belt. These parameters result in a very uniform, straight running belt.

IMAS Conveyor BeltsIMAS Conveyor Belts

We offer fast local decisions and solutions based on a global network of expertise.

IMAS Conveyor Belts

In-house cord production

q Our own steel cord manufacturing plant, Syrma S.A., was founded in 1994 and has been expanded with various investments over the last years to a capacity of several thousand tons of finest steel cords for conveyor belts, in production around the clock, seven days a week.

q Our state-of-the-art facility, laboratory equipment and quality control system place various advantages at our fingertips that other belt manufacturers do not have. We have complete quality control over the entire production process of our cords.

q Thanks to our expertise in design, we are able to custom-design special steel cords for our customers. We make sure that our reinforcements and our other materials combine to form the perfect conveyor belt.

q Last but not least, the speed and flexibilitythat come with having the capability to manufacture our own cords make us faster in producing our belts than most other operators in our industry.

q Syrma steel cords have been used in thousands of kilometers of steel cord conveyor belts for more than 15 years – and have proven to deliver superior physical performance, rubber adhesion and rubber penetration, resulting in longer lifetimes.

Our range of products reaches widths of up to 2600 mm and breaking strengths of up to 8000 N/mm (ST 8000). We produce our steel cord conveyor belts in accordance with the respective standards as per the customer’s requirements, such as DIN 22131, DIN EN ISO 15236 or AS 1333 (Australian Standard). However, individual tailor-made belt constructions with a specific number of cords, pitch, and cord diameter are supplied where necessary; for instance, where only a part length needs to be spliced into an existing belt.

Our steel cord conveyor belts are distinguished by their extremely high transmission of forces, long lengths (up to 20 km center-to-center distance), and very high load-carrying capacities (up to 30,000 t/h). Our high-per-formance products ensure high troughability combined with low elongation and good straight-running characte-ristics. IMAS steel cord conveyor belts are successfully employed for a wide range of uses through a wide variety of available cover grades.

Due to the flexibility of our production facilities, we are able to offer our customers the capacity to design and produce conveyor belts in accordance with their particu-lar requirements. This may be necessary for instance in cases where our customers wish to add other compo-nents to the belt produced.

Examples of this include belts with special layouts to enable our customers to attach buckets for elevator belts. Very specific cord placements are required on such base belts, which we produce and deliver on a regular basis.

If you require a base belt with a particular belt layout, please feel free to contact us.

IMAS Conveyor BeltsIMAS Conveyor BeltsSteel Cord Belt Production

Top Cover

Transverse Reinforcements

Skim Rubber

Bottom Cover

Steel Cords

Designation Thicknesses Min pulley diame-ter** (mm) Drive &HT/Tail & LT/SnubCovers (mm) Total* (mm)

ST 630 6 + 4 12.5 400/315/250

ST 800 6 + 4 12.5 400/315/250

ST 1000 6 + 4 13.5 630/500/400

ST 1250 6 + 4 16.5 630/500/400

ST 1600 8 + 6 19 800/630/500

ST 1800 8 + 6 19 800/630/500

ST 2000 8 + 6 19 800/630/500

ST 2250 10 + 6 21 800/630/500

ST 2500 10 + 6 22.5 1000/800/630

ST 2800 10 + 8 24.5 1000/800/630

ST 3150 10 + 8 25.5 1250/1000/800

ST 3500 10 + 8 26 1250/1000/800

ST 4000 12 + 8 28.5 1250/1000/800

ST 4500 12 + 8 29 1400/1250/1000

ST 5000 12 + 10 32.5 1600/1400/1250

ST 5400 12 + 10 33 1600/1400/1250

ST 6300 12 + 10 34 1800/1600/1400

ST 7500 12 + 10 36.5 2200/2000/1800

* Approximate values** For precise calculations for your respective application please contact us.

Since the beginning of the 1970s, IMAS has been supplying high-quality steel cord conveyor belts to its customers around the globe.

IMAS Steel Cord belts are available with belt gauges up to 60 mm. Rip detection sensors can be installed during the production process. Belts can be supplied in standard or oval reels in order to minimize the number of required splices.

Standard range for Steel Cord Belts

Different tensile strengths, cover thicknesses and constructions are also available upon request. Belts are also available with rip protection on one or both covers.i

Edge rubberSteel Cables Carry Cover

Bottom CoverCable Diameter

Pitch

Belt Width

Bottom Cover thickness

Belt thickness

Transverse Rip Protection

Top cover thickness

Our textile conveyor belts are used in various different applications and industries such as the steel, cement, coal and sugar industries, as well as ship-loading facilities, mines, power plants etc.

IMAS multi-ply conveyor belts are available from two- to six-ply in widths of up to 2600 mm and with a total belt breaking strength of up to 3780 N/mm. Belt edges can be either molded or cut. Rip detection sensors can be installed during the production process.

Fabric or metallic reinforcements are available in one or both covers upon request.

IMAS Conveyor BeltsIMAS Conveyor BeltsTextile Belt Production

Designation Thicknesses Min pulley diameter** (mm)

Covers (mm) Total* (mm)

EP 250/2 3 + 1.5 6.5 250/200

EP 315/2 3 + 1.5 6.9 315/250

EP 400/2 4 + 2 8.7 315/250

EP 630/2 4 + 2 9.5 400/315

EP 400/3 4 + 2 8.9 315/250

EP 500/3 6 + 2 11.5 400/315

EP 630/3 6 + 2 11.8 400/315

EP 630/4 6 + 2 12.8 500/400

EP 800/4 8 + 3 16.2 630/500

EP 1000/4 8 + 3 17.7 800/630

EP 1250/4 8 + 3 18.3 800/630

EP 1600/4 8 + 3 19.9 1000/800

EP 1000/5 8 + 3 17.6 800/630

EP 1250/5 8 + 3 19.5 1000/800

EP 2000/5 10 + 4 25.3 1250/1000

EP 2500/5 10 + 4 26.4 1400/1250

EP 3150/5 10 + 4 28.9 1600/1400

* Approximate values** For precise calculations for your respective application please contact us.

Standard range for two-ply/multi-ply belts

They feature excellent adhesion between the cover and the fabric carcass and between one fabric ply and an-other. Complemented by one of our many different cover grades, our products will provide a long service life. We assist our customers in selecting the right belt for their applications in order to ensure that they can concentrate on their own production – without having to worry about their conveyor belts.

Our Standard belts are produced using EP fabrics. However, different fabric and weave types such as PP, CFW, EPP, DW and EE can be used as well.

Overland conveyorShip loading conveyor Pipe conveyor

Standard Application Belts

Different tensile strengths and cover thicknesses are also available upon requesti

IMAS multi-ply textile conveyor belts have a long record of reliable service under the most demanding conditions.

Top Cover

Skim Rubber

Textiles

Bottom Cover

IMAS Conveyor BeltsIMAS Conveyor BeltsTextile Belt Production

Steep-Angle BeltsRough-top pattern

Rough-top belts are produced in widths of 1200/1400/1500/1600 mm.

Light impression pattern

All our standard application belts can be produced with a light impression surface pattern for applications where increased friction between the conveyed material and the belt is required (e.g. straw/hay-baler belt).

Different cover thicknesses, grades and also belt strengths are available upon requesti

* Approximate values (V-Cleats: Approximate values without the Cleat)** For precise calculations for your respective application please contact us

Designation Thicknesses Cover Grade Min pulley diameter** (mm)

Covers (mm) Total* (mm)

Rough-top pattern

EP 250/2 2.0 + 0 4 DIN “Z” – ISO “L” 250/200

EP 400/3 2.0 + 0 4.9 DIN “Z” – ISO “L” 315/250

Light impression pattern

EP 250/2 2.0 + 0 4 DIN “Z” – ISO “L” 250/200

EP 400/3 2.0 + 0 4.9 DIN “Z” – ISO “L” 315/250

V-Cleats

EP 315/23.2 + 1.6 7.2

DIN “Z” – ISO “L” 250/2003.2 + 0 5.6

EP 400/23.2 + 1.6 7.5

DIN “Z” – ISO “L” 315/2503.2 + 0 5.9

EP 500/33.2 + 1.6 8.3

DIN “Z” – ISO “L” 400/3153.2 + 0 6.7

Chevron

EP 250/2 3 + 1.5 6.5 DIN “Z” – ISO “L” 250/200

EP 400/3 3 + 1.5 7.4 DIN “Z” – ISO “L” 315/250

Standard range

V-cleats

V-cleated belts are available in widths of up to 1800 mm.

Chevron

Chevron belts are available in widths of up to 800 mm. Stock items as shown below in lengths of 100 m.

A B C G H I

B-15 460

500 460 20 200 100 450

600 460 70 200 100 450

650 460 95 200 100 450

800 460 170 200 100 450

B-15 600

800 600 100 200 100 524

B-30 600

650 600 25 200 100 513

800 600 100 200 100 513

Cleat type

153,5 95,75

149,5

37,5

153,5

21

75

75

R10

6,5°

9,5°

12°

22°

6,5°

Cleat type

37,5

75

75 30

A

B CC

15

H

G

45°

30

25

11,2

30

20

14,3

8

15

30

25

11,2

30

20

14,3

8

15

153,5 95,75

149,5

37,5

153,5

21

75

75

R10

6,5°

9,5°

12°

22°

6,5°

One of the major differences between conveyor belts that are excellent and those that are not derives from the compounding expertise of the manufacturer. At IMAS, we only use quality material from certified suppliers. With a recipe base of more than 200 conveyor belt compounds in our group, we have a problem-solver for almost every application. If you have a special problem or request, we will develop the right compound for you.

Thanks to the combination of our modern, highly auto-mated production process and very experienced staff, we produce effective, high-quality compounds while our fully equipped laboratory constantly assures the high quality of our compounds.

On the right you will find a small excerpt from our range of compounds for conveyor belts.

IMAS Conveyor BeltsIMAS Conveyor BeltsCompound Production

COMPOUND DESCRIPTION

IMAS DESIGNATION Fabric Steel Cord

Tensile strength

Elonga-tion

Abrasion Resist-ance

Oil Resistant

Heat Resistant

General Conveying - High Performance

DIN - X / AS - M Superior Excellent Excellent – –

General Conveying DIN - Y / AS - N Very good Very good Very good – –

General Conveying - Low Abrasion

ISO - D / AS - N Very good Excellent Excellent – –

General Conveying - Low Abrasion

DIN - W / MA Excellent Excellent Excellent – –

Cut and Gouge C&G Superior Excellent Very good – –

Cut and Gouge Low Abrasion

C&G LA Excellent Excellent Excellent – –

Ultra Abrasion Resistance

AAA Very good Excellent Superior – –

Heat Resistant T 150 Excellent Superior Excellent – Very good

High Heat Resistant T 200 Good Excellent Excellent – Excellent

Flame Resistant DIN - K / DIN - S / AS-F / MSHA No18-CBA070005

Excellent Excellent Very Good – –

Flame Resistant Low Abrasion

DIN - K / DIN - S / MSHA No18-CBA070005

Excellent Excellent Excellent – –

Flame & Heat Resistant

DIN - K , T 100 Excellent Superior Very Good – Good

Self Extinguishing AS-S Very good Very good Excelent – –

Flame Resistant – Britain

MES 008 Very good Excellent Excellent – Good

Tunnel Belting UTS Very good Excellent Good – –

MSHA UndergroundMSHA30 CFR /14 Fire Sentinel

Very good Excellent Very good – –

Oil Resistant SOR Excellent Excellent Excellent Excellent –

Oil Resistant MOR Excellent Excellent Very Good Very good –

Soya Oil & Flame Resistant

MSHA SOR (Low Temp) Fair Excellent Good Excellent –

Oil & Flame Resistant

Flame & Oil Very good Very good Good Good –

From the outside every conveyor belt looks black. But there is more than meets the eye.

Our belts can be offered with various packaging options. These can be standard hubs, reels with wooden side-walls, fully enclosed steel reels or oval reels with or without sidewalls.

IMAS Conveyor BeltsIMAS Conveyor BeltsPackaging Options

Application engineering

We see ourselves as a solution partner to our customers. Apart from excellent products, this involves meeting their needs for advice and information about our products and their function within applications and processes. Our application engineers are always eager to give their technical advice based on excellent knowledge and experience in the world of conveying. With more than 100 years of conveyor belt history in our group, you can be sure you are talking to industry experts.

We provide standard support such as belt strength cal-culations, conveyor studies, belt selection, splice design, pulley requirements etc. to our customers. In addition, the use of high-tech solutions such as sophisticated simulation software, our own belt calculation software and the vast number of individual tools we have devel-oped over the decades we have been in operation equip our worldwide client base with the very best technical solutions. This enables our products to perform at their best in the context of our customers‘ applications.

We are where our customers are. This means that our application engineers spend a good portion of the year on the road helping our customers on-site to optimize belt choice or assist in conveyor system performance improvements.

Furthermore, we work closely with our local represen-tatives, who guarantee that the end customer will have prompt access to our extensive range of conveyor products and services. Through them, we extend our communication with our customers and satisfy their needs and requirements even more efficiently – whatever their language or time zone may be.

If the packaging for your belt requires special details (e.g. special lifting lugs/points), we are ready to make it happen.

Splicing materials

IMAS belts are of superior quality and we want our customers to be able to make full use of this quality. This requires a good splice, and apart from professional craftwork, good splice materials is the main prerequisite. In view of this, we have been providing splice kits for vulcanizing our products to our customers all over the world since our company was founded.

In our splice kits you will find all the materials you need for a belt splice:

Depending on the belt, the kit contains

q rubber solution q cleaning agent q skim/bonding and cover rubber plates q rubber strips q cover cloth q breaker fabric q silicon paper q polyethylene foil to facilitate a clean working process.

Naturally, we also deliver individual parts of our splice material to our customers. Our made-to-order kits, manufactured by our own splice kit department, always guarantee the freshest material of the highest quality – together with a service partner you can rely on, an essential requirement for obtaining a durable splice – and trouble-free operation of your belt.

Laboratory

IMAS has a fully equipped laboratory in order to control and ensure the quality of all our products for every pro-duction step. As far as we are concerned, there is no compromise when it comes to quality.

This starts with the receipt and testing of our raw materialsand tensile members and continues via a full inspection of every compound batch produced through to the com-plete testing of our semi-finished and finished products. Consequently, our customers can rest assured that they will always receive a competitive product with guaran-teed quality.

Here is a small selection of the tests that our products undergo:

Dimension, density, abrasion, adhesion forces, tensile strength, atmospheric aging, aging under temperature exposure, cold and hot temperature resistance, dynamic stresses, resistance and swelling under exposure to chemicals, oils and other aggressive media, rubber penetration, electrical conductivity, flame resistance, drum friction, oxygen index, troughability and corrosion,as well as a vast number of additional tests over all process steps.

However, the best testing equipment is useless without human expertise. In our laboratory, we work with an ex-perienced and highly specialized workforce that together can count more than a hundred years of experience in the conveyor belt industry.

In addition, we have access as part of our group to heavy test rigs for dynamic belt forces and splice efficiency, testing rigs for determining the effectiveness of energy-optimized compounds, computer simulation of splices, static and dynamic belt forces as well as usage of central research and development capabilities in hard-ware, software and engineers, e.g. for nanotechnology, spectral analysis and particle flow simulation. Needless to say, all these resources also make us extremely well equipped for developing our new products.

IMAS Conveyor BeltsIMAS Conveyor BeltsQuality Assurance & QM system

IMAS has established a state-of-the-art Quality Management System.

In order to respond to our customers’ needs as best as we can, quality plays a central role for us.

Quality procedures are an essential part of our produc-tion process. Since quality is built from the beginning, it is not just the final product that is checked for quality. Our quality control starts with the raw materials we receive and is implemented throughout production. As a result of this, IMAS is ISO 9001-certified.

Continuous improvement is essential for successful long-term business relationships with our customers. It is a responsibility for everyone in our company. We therefore also use ISO 9001 as a tool for ongoing im-provement of our processes, taking into account

q Safety

q Quality

q Efficiency

IMAS S.A.Industrial zoneP.O. Box 1050GR – 381 10 VolosTEL +30 24210 96500FAX +30 24210 96590WEB www.imas-conveyors.com