High Aspect Ratio Copper Filling of Through-Silicon-Vias ... · High Aspect Ratio Copper Filling of...

Transcript of High Aspect Ratio Copper Filling of Through-Silicon-Vias ... · High Aspect Ratio Copper Filling of...

High Aspect Ratio Copper Filling of Through-Silicon-Vias by Bottom-UpElectroplating for Fabrication of 3D Air-core MEMS Inductors

Io Mizushima*, Peter Torben Tang*, Hoà Lê Thanh** & Anpan Han**

Concept

Electroplating set-up and holders Bottom-up electroplating using different plating rates

Plating through the wafer

Pulse plating of copper

Conclusion

Acknowledgement

TT 160914

*) IPU, Kgs. Lyngby, Denmark [[email protected]]

**) DTU Danchip, Technical University of Denmark, Kgs. Lyngby, Denmark

Silicon

Copper

Aluminum oxide

The whole process has 12 steps, including coating of aluminium oxideon a silicon substrate, etching the coating with a mask, create through-silicon-vias (TSV), copper plating to close the TSVs, bottom-upelectroplating to fill the TSVs, plating of the top layer, etching of the copperwith a mask and finally etching of core silicon. In this work the copper filling of the through-silicon-vias with aspect ratio of 10:1(width 30 µm and depth 300 µm) by bottom-up electroplating is in focus. Influenceof current applied to the electroplating was investigated.

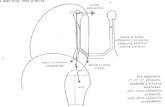

AnodeCathode

+-

Air bobling

The pulse waveform is consisting ofcurrent densities alternating 250 timesbetween 1.56 A/dm² for 20 ms and0.78 A/dm² for 20 ms of cathodic(normal) current, followed by 2.33 A/dm² for 500 ms ofanodic (reverse) current.

Repeat 250 times

Curr

ent densi

ty (

A/d

m²)

Time (ms)

Wetting using ultrasonic stimulation helps closing the bottom conductor, since air in structure can disturb elecroplating and create a porous or interrupted metal via.

Filling without vacuum treatment

Generally it is difficult to fill highaspect ratio TSVs. Degassing in water,

by using a vacuum chamber,improved copper filling

significantly.

Copper electroplating was applied succesfully for creating a toroidal inductor.Pulse plating was utilised for the top and bottom layers,

while low current density DC plating was applied for bottom-up plating.

Bottom-up electroplating of the TSVs could be achieved by introducing a wetting treatment subsequently using both ultra sound and vacuum.

Lower current density improved the uniformity of the copper filling during bottom-up filling of the TSVs, but also leads to increased process time.

Pulse plating can improve uniformity and reduce time consumption.

Direct current at 0.3 A/dm² for 33 hours Direct current at 0.6 A/dm² for 11 hours

Cross-section

Surface pictures

We are working for the development of a processfor MEMS fabrication of micro-scale air-coretoroidal inductors, especially designed forvery high frequency (30-300 MHZ)switch mode power supplies (SMPS).

Without wetting

With wetting

Sputtering of seedlayer

①

Electroplating bottom conductor

②

Bottom-up electroplating

③

Sputtering of seedlayer

④

Electroplating top conductor

⑤

Stainless steel plate

Silicon wafer with TSVs and copper coating closing the TSVs

Wire with pin contact

This work is part of a project called“TinyPower: Ultra compact integrated power supplies”

financed by Innovationsfonden in Denmark under file number 67-2014-1