HF LT (50-100 Ton) Operator's Manual X40873h (May-2005)

-

Upload

bulboaca-bogdan -

Category

Documents

-

view

145 -

download

23

description

Transcript of HF LT (50-100 Ton) Operator's Manual X40873h (May-2005)

Issue 05/2005

HYDRAULIC PRESS BRAKE

OPERATOR’S MANUAL

X40873H

BP 40040 – 95912 Roissy aéroport CDG cedex – Tel.: +33 (0)1 49 90 30 00, Fax: +33 (0)1 49 90 31 99

2/10 CONTENTS Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

Index Issue Updated by Details of revision

D 02/2002 Update to cater for common electric cabinet.

E 12/2002 M. Ahmed - Suppression of the SA2 key selector switch. Auxiliary function F5 replace it now.

- SA1 key selector switch is now replaced by a selector switch without key.

Ch. 3 pages 6 to 9. Ch. 4 pages 9 to 11. Ch. 6 pages 3 to 7, 9 and 10.

F 09/2003 Ph. Jacquet - Updated, add the “Akas” option, control pannels.and USA machines cycles.

G 09/2004 Ph. Jacquet Updated : - Presentation of page 3 chapter 1. - Label safety chapter 2. - Add note “Switch off operation” ch. 3 & 6. - Pages 19 to 23 ch.5 “expert clamp. - Add paragraph 5.6. chapter 5.

H 05/2005 Ph. Jacquet Updated, - Ch.2 , safety label position.

Modifications of Fig.2.4 & 2.5. - Ch.5 add paragraph for joined mounting

of standard distance pieces. Modification paragraph 5.5.3 & 5.5.4..

- Ch.7 add oil caracteristics.

Read the manual carefully to obtain a thorough knowledge of this machine. Strictly follow the installation, operating and maintenance instructions given in this manual to avoid the risk of operator injury and damage to the press brake. Keep this document to hand, and refer to it whenever necessary. Amada, Tremblay, December 2002. Any representation, translation, adaptation or reproduction, even partial, by any method or in any country without prior permission is illegal and would make the offender subject to legal action.

CONTENTS 3/10 HF LOW TONNAGE OPERATOR’S MANUAL – X40873G Issue 05/2005

LIST OF ADDENDA

Modification coming from Reason Destination Application

4/10 CONTENTS Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

HYDRAULIC PRESS BRAKE OPERATOR’S MANUAL

IMPORTANT NOTE ACCEPTANCE We loaded your press brake onto the carrier's vehicle. The carrier acknowledged receiving it in perfect condition. However, in the case of a problem during shipping (which can happen), or if you notice signs of damage (impact marks, etc.) on your machine, we would like to remind you that you should formulate your reservations as follows: A – On the delivery voucher submitted to you for acceptance by the carrier. B – By notifying the carrier and us (for information) by registered letter within 48 hours at the

latest.

FOR ALL PROBLEMS DURING MACHINE INSTALLATION

Telephone ? ................................................. +33 (0)1 49 90 30 00 Fax ? ............................................................. +33 (0)1 49 90 31 99

CONTENTS 5/10 HF LOW TONNAGE OPERATOR’S MANUAL – X40873G Issue 05/2005

CONTENTS 1. GENERAL DESCRIPTION ............................................................................................... 1

1.1. DESCRIPTION............................................................................................................... 3

1.2. PRINCIPLE..................................................................................................................... 5

2. ACCEPTANCE, INSTALLATION AND SAFETY MEASURES.................................. 1

2.1. GENERAL INFORMATION ......................................................................................... 3

2.1.1. MARKING............................................................................................................... 3

2.2. PREPARING THE SITE ................................................................................................ 7

2.2.1. STANDARD STROKE WITH STANDARD SPEED AND HIGH SPEED .......... 8 2.2.2. LONG STROKE WITH STANDARD SPEED AND HIGH SPEED..................... 9

2.3. MACHINE RECEPTION ............................................................................................. 10

2.4. RECEPTION & HANDLING....................................................................................... 11

2.4.1. LIFTING ................................................................................................................ 11 2.4.2. BASIC PRINCIPLES............................................................................................. 13 2.4.3. EQUIPMENT......................................................................................................... 19 2.4.4. SPECIAL PARTS FOR TRANSPORT ................................................................. 20

2.5. ELECTRICAL CONNECTIONS ................................................................................. 21

2.5.1. GENERAL CHARACTERISTICS OF THE MAINS SUPPLY ........................... 21 2.5.2. EARTH................................................................................................................... 21 2.5.3. MAINS-RELATED AND ENVIRONMENT-RELATED INTERFERENCE ..... 22 2.5.4. POWER SUPPLY CABLE CHARACTERISTICS .............................................. 25

2.6. WORKSTATION LIGHTING ..................................................................................... 26

6/10 CONTENTS Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

2.7. SAFETY PRECAUTIONS ........................................................................................... 27

2.7.1. GENERAL POINTS .............................................................................................. 27 2.7.2. REGULAR INSPECTION AND SAFETY POLICY ........................................... 32 2.7.3. ARRANGEMENT OF WORKSTATIONS .......................................................... 33 2.7.4. CONTROL DEVICES ........................................................................................... 35 2.7.5. RULES FOR SAFE OPERATION........................................................................ 37

2.8. MACHINE OPERATING AND STORAGE CONDITIONS ...................................... 44

2.9. MACHINE CHARACTERISTICS............................................................................... 45

2.9.1. STANDARD STROKE WITH STANDARD SPEED AND HIGH SPEED ........ 45 2.9.2. LONG STROKE WITH STANDARD SPEED AND HIGH SPEED................... 46

2.10. INFORMATION ON NOISE ..................................................................................... 47

2.11. NORMAL USE, RESERVATIONS, AND EXCLUSIONS ...................................... 48

3. COMMISSIONING ............................................................................................................. 1

3.1. CLEANING .................................................................................................................... 2

3.2. INSTALLATION OF CONTROL DEVICES................................................................ 2

3.3. CHECKING THE MAINS POWER SUPPLY............................................................... 4

3.4. MACHINE LEVELLING ............................................................................................... 4

3.5. PUTTING THE MACHINE INTO OPERATION ......................................................... 5

3.6. OVERALL CHECK........................................................................................................ 6

4. TECHNICAL DESCRIPTION........................................................................................... 1

4.1. MECHANICAL STRUCTURE...................................................................................... 3

4.2. MECHANICAL CONNECTIONS ................................................................................. 4

4.3. ELECTRONIC STROKE CONTROL AND PARALLELISM BALANCING SYSTEM 5

4.3.1. ELIMINATING SOURCES OF ERROR................................................................ 7 4.3.2. PROPORTIONAL VALVE TECHNIQUE FOR CONTINUOUS RELIABILITY 7 4.3.3. PRECISE CENTRING OF THE BEAMS............................................................... 8

CONTENTS 7/10 HF LOW TONNAGE OPERATOR’S MANUAL – X40873G Issue 05/2005

4.4. LOCATION OF CONTROL AND SIGNALLING DEVICES...................................... 9

4.5. PRESS BRAKE OPERATING LIMITS IN OFF-CENTRE WORK........................... 10

4.6. PRESSURE GAUGE .................................................................................................... 10

5. FORMING TECHNIQUE & TOOLING .......................................................................... 1

5.1. GENERAL POINTS ....................................................................................................... 3

5.2. AIR BENDING ............................................................................................................... 7

5.3. COINING ........................................................................................................................ 8

5.4. LIST OF STANDARD TOOLS...................................................................................... 9

5.5. TOOL INSTALLATION .............................................................................................. 11

5.5.1. STANDARD FAST PUNCH CLAMPING SYSTEM .......................................... 11 5.5.2. “AMACLIP” PUNCH CLAMPING SYSTEM (OPTION)................................... 15 5.5.3. « EXPERT » CLAMPING SYSTEM – MANUAL VERSION (OPTION).......... 20 5.5.4. « EXPERT » PNEUMATIC CLAMPING SYSTEM – AUTOMATIC VERSION (OPTION)............................................................................................................... 24 5.5.5. PROCEDURE TO BE OBSERVED FOR TOOL INSTALLATION................... 28 5.5.6. CHANGING TOOLS (WITH AMNC NUMERICAL CONTROL)..................... 33

5.6. SPECIAL ACCESSORIES AND OPTIONS ............................................................... 39

5.7. INSTALLATION AND ADJUSTMENT OF DISTANCE PIECES............................ 39

5.8. PUNCHING .................................................................................................................. 44

6. OPERATION........................................................................................................................ 1

6.1. START-UP...................................................................................................................... 2

6.2. DESCRIPTION OF CYCLES (OUT OF US MARKET) ............................................. 3

6.2.1. LAYOUT OF CONTROLS PANELS ..................................................................... 4 6.2.2. DESCRIPTION OF CONTROL AND SIGNALLING DEVICES ....................... 11 6.2.3. BASIC VERSION MACHINE (WITHOUT LIGHT GUARD) ........................... 13 6.2.4. MACHINE EQUIPPED WITH SICK LIGHT GUARD OPTION ....................... 16 6.2.5. MACHINE EQUIPPED WITH LASER BEAM OPTION ................................... 16

6.3. MOBILE EMERGENCY STOP................................................................................... 19

6.4. START-UP.................................................................................................................... 19

8/10 CONTENTS Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

6.5. DESCRIPTION OF CYCLES ...................................................................................... 20

6.5.1. LAYOUT OF CONTROLS PANELS ................................................................... 21 6.5.2. BASIC VERSION MACHINE (WITHOUT LIGHT GUARD) ........................... 23 6.5.3. MACHINE VERSION WITH LIGHT GUARD ................................................... 24 6.5.4. MACHINE VERSION WITH TWO HAND CONTROL OPTION ONLY ......... 25

6.6. PLC MESSAGES LIST ................................................................................................ 28

6.6.1. MACHINE FAULT MESSAGES ......................................................................... 28 6.6.2. MACHINE STATUS MESSAGES ....................................................................... 47 6.6.3. OPERATOR MESSAGES..................................................................................... 51

7. MAINTENANCE ................................................................................................................. 1

7.1. INTRODUCTION........................................................................................................... 2

7.2. MACHINE PERIODIC MAINTENANCE .................................................................... 5

7.2.1. MAINTENANCE OF THE HYDRAULIC INSTALLATION ............................... 8 7.2.2. OIL CHANGES ..................................................................................................... 11 7.2.3. FILLING PROCEDURE........................................................................................ 11

7.3. RECOMMENDATIONS .............................................................................................. 12

7.3.1. SPECIFIC DAILY TEST PROCEDURE.............................................................. 13

7.4. TROUBLESHOOTING ................................................................................................ 26

7.4.1. TROUBLESHOOTING TABLE ........................................................................... 26 7.4.2. REGULATORY PERIODIC (QUARTERLY) INSPECTION: GENERAL POINTS............................................................................................................................ 27

APPENDIX A – PROGRAMMING MANUAL

APPENDIX B – MACHINE SCHEMATICS AND LISTING (see in the electric cabinet of the machine)

APPENDIX C – BACKGAUGE

APPENDIX D – SPECIAL MACHINES

APPENDIX E – OPTIONS

APPENDIX F – SUPPLIERS DOCUMENTATION

CONTENTS 9/10 HF LOW TONNAGE OPERATOR’S MANUAL – X40873G Issue 05/2005

APPENDICES

IMPORTANT NOTE

Quality Control department completes this technical manual by adding certain number of appendices relating to the options & accessories supplied with the machine i.e. the supplied manual complies fully with your machine. The list of these additional documents is part of the Quality Control file, which is delivered with the machine. At the time of delivery, this file is placed inside the document tray attached to the inner side of the electric cabinet door.

10/10 CONTENTS Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

GENERAL DESCRIPTION Chapter 1 1/6 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

1. GENERAL DESCRIPTION

2/6 Chapter 1 GENERAL DESCRIPTION Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

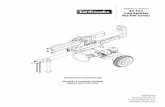

Figure 1.1

GENERAL DESCRIPTION Chapter 1 3/6 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

1.1. DESCRIPTION The purpose of this document is to facilitate the installation of your High Fidelity hydraulic press brake (Fig. 1.1) and its connection to the electrical and pneumatic supply systems. This product line includes the following models: - HF 50-12 (50 tons / 1.2 meter) - HFx 50-20 (50 tons / 2 meters) - HFx 80-25 (80 tons / 2.5 meters) - HFx 100-3 (100 tons / 3 meters) X is added to specify the level of equipment provided on your machine (T, E or P).

----------- NUMERICAL CONTROL T CD2000 E OP2000 P AMNC

All models are delivered:

� In a basic version without light curtain, � Equipped with a “A”, “B” or “C”-type back gauge � In option: - light curtain, which is used as front protection and as an operation

cycle control device or

- laser safety system used as front protection only. Note : In this manual, “tons” is very often used instead of international measurement unit

“kN”. We remind you that 9.81 kN is equivalent to one ton.

4/6 Chapter 1 GENERAL DESCRIPTION Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

Figure 1.2

F1 and F’1 = Bending force A and A’ = Counter acting points

GENERAL DESCRIPTION Chapter 1 5/6 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

1.2. PRINCIPLE The machine is a manual load/unload hydraulic press brake. HF hydraulic press brakes are down stroking machines equipped with an numerical controller for the control and adjustment of all bending parameters. These press brakes are equipped with a central reaction lower beam to ensure bending quality. An electrohydraulic servosystem controls the travel and ensures that the Upper Beam (UB) remains perfectly parallel to the Lower Beam (LB). These machines can be equipped with various options (back gauge, front gauge, etc.), all Amada tools, and other traditional tools, as well as a range of accessories. (Contact our Regional Sales Representative to discuss your specific requirements.)

For items heavier than 25 kg, a handling device must be provided for the operator. This device is not included in the Amada supply (see § 5.5).

REVIEW OF THE CONVENTIONAL DESIGN OF PRESS BRAKES Traditional press brakes with an operating upper beam exhibit an elastic deformation during bending in opposite directions on each beam due to the reactions of the part under the thrust of the jacks located at the ends. These deformations are detectable by slightly less penetration of the punch in the die in the center than at the ends (Fig. 1.2).

6/6 Chapter 1 GENERAL DESCRIPTION Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

AMADA SYSTEM: Slotted beam (for 35- to 100-ton press brakes). The lower beam is a slotted plate. The arrangement, size, and shape of the slots are designed to allow the lower beam to deform in the same direction and with the same deformation as the upper beam under the action of the bending force. The lower beam is welded to the flanges (Fig. 1.3). ADVANTAGES Because the small but inevitable elastic deformation of the two beams occurs in the same direction and has the same value, the punch has constant penetration in the die over the entire bending length, thus ensuring a perfect angle. The small deformation of the beams does not affect the linearity of the bend because the stress induced in the worksheet remains well within the elastic region.

Fig. 1.3

F1 and F’1 = Bending force A and A’ = Counter acting points

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 1/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

2. ACCEPTANCE, INSTALLATION AND SAFETY MEASURES

2/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 3/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

2.1. GENERAL INFORMATION 2.1.1. MARKING

The marking on your press-brake corresponds to the following specifications : a) Name and address of the manufacturer. b) Type of machine. c) Serial number. d) Date machine is manufactured. e) Weight of the press-brake without any tooling or sub-equipment. f) If needed, weight of the main parts and sub-equipment to be removed with lifting devices.

A specific marking will then be afixed on these items. g) Maximum tonnage. h) Data concerning the electric, hydraulic and pneumatic supplies. A specific marking will

then be attached to the optional equipments. i) Overall response time and minimum separation distance. They are highly dependent upon

the type of protection device installed (safety guard for instance). Additional marking is also possible whenever several types of protection devices have been selected.

4/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

j) Warning on residual risks. On HFT

On HFE

j

j

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 5/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

On HFP

k) Overall stroke of the beam. l) Noise level (acoustic pressure).

j

Plate for a machine equipped with a light guard (option).

i

6/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

Plate for a machine with laser beam protection “LazerSafe” model.

Plate for a machine with laser beam protection “Akas” model.

m) Warning related to high speed operation (only concerns high speed machines).

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 7/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

2.2. PREPARING THE SITE The press brake must be installed on a stable, rigid floor. A concrete slab 120 to 150 mm thick with a flat surface (maximum tolerance 2 mm per metre) must be laid in the work area. Please contact our technical department for the installation requirements. HF press brakes are manufactured as welded box structures with a low centre of gravity. Anchoring them to the floor is therefore optional. The press brake must be accessible from all four sides:

- At the rear, allow clearance of approximately 1 metre to allow various maintenance operations and backgauge adjustment to be performed, the same goes to the electrical cabinet side.

- Allow a clearance slightly greater than the maximum bending length of the machine on at least one of the two sides. The purpose of this is to allow worksheets that are at least as long as the press brake to be unloaded from the side.

Figure 2.1

Length

Hei

ght

Wid

th

8/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

2.2.1. STANDARD STROKE WITH STANDARD SPEED AND HIGH SPEED

DESCRIPTION UNITS MODELS

Standard speed HF 50-12 HF 50-20 HF 80-25 HF 100-3

High speed HF 50-12 S HF 50-20 S HF 80-25 S HF 100-3 S

With CD 2000 (HFT) mm 1 850 2 950 3 410 3 990

With OP 2000 (4) (HFE) mm 2 165 3 161 3 621 4 201

Mac

hine

le

ngth

(1)

With AMNC (5) (HFP) mm n/a 3 458 3 918 4 498

With CD 2000 (3) (HFT) mm 1 610 1 820 1 800 1 940

With OP 2000 (4) (HFE) mm 2 165 2 450 2 450 2 450

Mac

hine

w

idth

(2)

With AMNC (5) (HFP) mm n/a 2 450 2 450 2 450

Machine height mm 2 300 2 450 2 550 2 700

GENERAL net weight (6) kg 3 350 4 600 5 600 6 600

Distance between uprights mm 1 035 1 665 2 125 2 705

Thickness of the uprights mm 35 35 35 35

Centre distance between upright axis mm 1 070 1 700 2 160 2 740 (1) The dimensions are with the arm and the NC maximum extended on the exterior, and all doors closed.

(2) The dimensions are with the arm and the NC maximum extended in front, and all doors closed. (3) With light guard, add 140mm to this dimension. With a laser beam protection, add 100mm to this

dimension. For transport, reduce by 140mm.

(4) For transport, reduce length by 256mm and width by 380mm. (5) For transport, reduce length by 553mm and width by 580mm. (6) Add to the machine weight, depending on the options, corresponding weight from the following table :

HF BT

Material Description Units 1,20 m 2 m 2,50 m 3 m AMACLIP sectionalised distance pieces kg 5 8 10 13 Sick light guard system kg 250 250 250 250 LazerSafe system kg 90 90 90 90 Akas system kg 40 40 40 40 Fixed front table/support kg 14 14 14 14 Single manual finger stop assembly kg 12 12 12 12 Programmable front table kg n/a 200 220 240 Work follower – Single arm kg n/a 440 460 480 Work follower – Twin arms kg n/a 640 660 680 Work follower – Single arm + Parking kg n/a 620 640 660 Work follower – Twin arms + Parking kg n/a 820 840 860 Sick light guard system for Parking kg 280 280 280 280 WILA hydraulic clamping kg n/a 120 140 160 n/a : not available

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 9/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

2.2.2. LONG STROKE WITH STANDARD SPEED AND HIGH SPEED

DESCRIPTION UNITS MODELS

Vitesse standard HF 50-12 L HF 50-20 L HF 80-25 L HF 100-3 L

Vitesse rapide HF 50-12 LS HF 50-20 LS HF 80-25 LS HF 100-3 LS

With CD 2000 (HFT) mm n/a 2 955 3 415 3 995

With OP 2000 (4) (HFE) mm n/a 3 166 3 626 4 206

Mac

hine

le

ngth

(1)

With AMNC (5) (HFP) mm n/a 3 463 3 923 4 503

With CD 2000 (3) (HFT) mm n/a 1 952 1 952 2 052

With OP 2000 (4) (HFE) mm n/a 2 450 2 450 2 450

Mac

hine

w

idth

(2)

With AMNC (5) (HFP) mm n/a 2 450 2 450 2 450

Machine height mm n/a 2 770 2 770 2 860

GENERAL net weight (6) kg n/a 5 000 5 750 7 000

Distance between uprights mm n/a 1 660 2 120 2 700

Thickness of the uprights mm n/a 40 40 40

Centre distance between upright axis mm n/a 1 700 2 160 2 740 (1) The dimensions are with the arm and the NC maximum extended on the exterior, and all doors closed.

(2) The dimensions are with the arm and the NC maximum extended in front, and all doors closed. (3) With light guard, add 140mm to this dimension. With a laser beam protection, add 100mm to this

dimension. For transport, reduce by 140mm.

(4) For transport, reduce length by 256mm and width by 380mm. (5) For transport, reduce length by 553mm and width by 580mm. (6) Add to the machine weight, depending on the options, corresponding weight from the following table :

HF BT

Material Description Units 1,20 m 2 m 2,50 m 3 m AMACLIP sectionalised distance pieces kg 5 8 10 13 Sick light guard system kg 250 250 250 250 LazerSafe system kg 90 90 90 90 Akas system kg 40 40 40 40 Fixed front table/support kg 14 14 14 14 Single manual finger stop assembly kg n/a n/a 12 12 Programmable front table kg n/a 200 220 240 Work follower – Single arm kg n/a 440 460 480 Work follower – Twin arms kg n/a 640 660 680 Work follower – Single arm + Parking kg n/a 620 640 660 Work follower – Twin arms + Parking kg n/a 820 840 860 Sick light guard system for Parking kg 280 280 280 280 WILA hydraulic clamping kg n/a 120 140 160 n/a : not available

10/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

2.3. MACHINE RECEPTION Recommendations before handling and installation. Prohibited procedures: Never press against, or attach handling equipment (slings, hooks, straps, etc.) to the following components:

- Lower beam, - Upper beam, - Electrical cabinet, - NC pendent arm,* - Mechanical guards, - “C” frame (Goose necks), - Machine covers, - Backgauge.

Refer to Section 2.3 to identify the recommended floor support areas.

IMPORTANT NOTE CERTAIN AREAS OF THE MACHINE ARE NOT DESIGNED TO WITHSTAND THE WEIGHT OF A PERSON WITHOUT DEFORMATION. THESE AREAS ARE IDENTIFIED BY THE LABEL SHOWN BELOW.

Figure 2.2 * With NC type : “OPERATEUR 2000” and “AMNC”.

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 11/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

2.4. RECEPTION & HANDLING 2.4.1. LIFTING Before the vehicle arrives, provide a crane with sufficient capacity to unload the press brake from the vehicle. Ensure that the access doors are sufficiently tall and wide to receive the machine, or its case (in case of sea worthy packing). To handle the press brake, use the two sling holes located towards the front on the upper part of the side frames (see fig. 2.3).

CAUTION: Lifting forces should only be applied to the sling points provided for this purpose. Never apply force to the underside of the beams, electrical cabinets, covers, etc.

For all machine handling operations, observe the following recommendations:

� Attach the lifting beam directly, with a load per strand, not exceeding the maximum allowable load.

� Lift and set down the machine gently, avoiding any side impact on the

machine, or any impact on lowering it to the floor.

� To direct the machine during handling, press on the frame or its packaging only; never press on the beams, electrical cabinets, covers or guides.

CAUTION: When a press brake has been crated for sea transport, handling it and removing it from the crate are tricky procedures. We strongly advise you to seek professional assistance. For information on this point, do not hesitate to contact Amada. The instructions in this section are given for information only, and do not engage the responsibility of Amada.

12/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

Figure 2.3

LIFTING BEAM

Only use these holes for anchoring lifting slings

Center of gravity

Only use these holes for anchoring lifting slings

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 13/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

2.4.2. BASIC PRINCIPLES Lifting forces must only be applied to the anchoring points provided for this purpose and a lifting beam or sling should be used for machine handling.

Center of gravity

Distance between uprights

Machine weight

∅ anchoring

holes Press-brake X Y Z mm kg mm

50-12 807.5 ≅ 1 400 500 35 3 350 65

50-20 870 ≅ 1 400 770 35 4 600 65

80-25 926 ≅ 1 400 950 35 5 600 65

100-3 1 026 ≅ 1 400 1 150 35 6 600 65

50-20 L 908 ≅ 1 600 770 40 5 000 65

80-25 L 960 ≅ 1 600 950 40 5 750 65

100-3 L 1 068 ≅ 1 600 1 150 40 7 000 65

NOTE For options, see § 2.2.1. & 2.2.2.

14/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

The holes at the top front and back of the side frames are used to anchor the machine during transport, but only the front holes are used to handle the machine.

LOAD DISTRIBUTION ACCORDING TO SLING ANGLES.

Example A : 45° angle → 50% of load weight on each sling.

Example B : 90° angle → 75% of load weight on each sling.

WE RECOMMEND NOT TO EXCEED AN ANGLE OF 90°.

The table below specifies the distance between uprights as well as the minimum length of the slings to be used for the handling operation.

Press-brake Distance in mm between uprights

Minimum length of the slings in mm

50-12 1 035 2 000

50-20 1 665 2 400

80-25 2 125 3 100

100-3 2 705 4 000

50-20 L 1 660 2 400

80-25 L 2 120 3 100

100-3 L 2 700 4 000

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 15/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

16/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

Figure 2.4

CAUTION: The choice of footing or anchoring points other than those specified in Fig. 2.3 and Fig. 2.4, is prohibited. Incidents resulting from a failure to comply with these instructions may lead to the suspension of your guarantee.

The following table gives the load distribution on the footing

LOAD PER FOOT (kg) Machine Type Front: 420 x 300 Rear: 150 x 150

50-12 50-20 80-25 100-3

920

1 400 1 850 2 270

630 900 950

1 030

Mandatory ground footing areas for installation or for moving on skates.

Prohibited areas

Areas authorised for shipping/transport

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 17/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

ANCHORING THE MACHINE TO THE GROUND :

Figure 2.5

NOTE All dimensions are given in mm.

Machine type A (mm) B (mm) E (mm)

50-12 1 200 1 236,5 894

50-12 S 1 200 1 236,5 894

50-20 1 840 1 305 1 535

80-25 2 320 1 305 2 015

100-3 2 900 1 405 2 595

18/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

Figure 2.6

Figure 2.7

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 19/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

2.4.3. EQUIPMENT Handling operations must be performed as follows: - Using lifting gear such as a gantry or crane. Use the sling points. These holes can directly

receive the shackles to which the hoist rings are attached. - If appropriate lifting equipment is not available, the press brake can be moved on skates

(Figs. 2.5 and 2.6).

CAUTION: Strictly observe the authorised support areas as shown in Fig. 2.4.

20/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

2.4.4. SPECIAL PARTS FOR TRANSPORT For transport purposes, the upper beam is mechanically held at top dead centre using two props (Item 1), the backgauge cross member is immobilised using two brackets (Item 2), each C-frame side door is blocked using a bracket (Item 3) and a red coloured spacer is mounted in between the motor and it’s mounting plate (Item 4). These accessories are removed by the Amada technician during commissioning, before starting up the machine. They should be kept in a safe place for future use (if the machine is moved to another location in the future).

Only on 80 and 100 Tons machines

CAUTION IN NO CASE AN UPPER BEAM LOWERING COMMAND BE GIVEN WHEN THE IMMOBILISING DEVICES ARE IN POSITION.

2 1

4 3

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 21/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

2.5. ELECTRICAL CONNECTIONS Correct operation of an electrical system depends on the quality of its power supply ; it must be stable and free of interference. The installation must be designed and built in accordance with the regulatory requirements in force. 2.5.1. GENERAL CHARACTERISTICS OF THE MAINS SUPPLY - Power supply: Three-phase (according to mains). ±10% in steady-state, ±20% in transient (20 ms). - Pulse mode: 50% of rated value, maximum duration 5 ms - Harmonics: Maximum 5% - Frequency: 50 or 60 Hz (according to mains). - Electrical power supply line: Special supply line should be drawn for the EXCLUSIVE use

of the system from the main LOW VOLTAGE panel. The entire system is powered by a single three-phase + earth cable.

2.5.2. EARTH This equipment lacks double insulation hence requires an earthing connection. This is also important for machine operation and to drain electrical noise to the ground. The earthing conductor must have a sufficient cross-section. It must be connected to the terminal board of the power supply panel. Like the electrical installation, this earthing connection must be periodically checked by an approved organisation. The resistance of the earthing connection measured must comply with the applicable laws and standards. The green/yellow earthing conductor is exclusively reserved for the system. It is directly connected to the earthing terminal.

22/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

2.5.3. MAINS-RELATED AND ENVIRONMENT-RELATED INTERFERENCE

CAUTION: Never solder or weld a component to the machine using any process whatsoever. This could damage the mechanical, electrical, and electronic devices.

Certain electronic components may be subjected to abnormal or excessive voltages or currents liable to cause their destruction. The installation of adapter components without a galvanic connection to the mains (voltage stabiliser, inverter, converter unit, transformer, isolating transformer, etc.) may need to be considered. If necessary, the quality of the electrical power supply should be checked by an approved organisation, and an analysis of the results should determine the type of equipment required. The following types of interference can be considered as a disturbance to any electronic system: • Electrostatic Discharge Electrostatic discharge is particularly critical where the ambient relative humidity is low. It is not unusual for a person or group of people on the move to generate discharges amounting to several thousand volts when touching a door handle or metal frame. It may be necessary to install antistatic equipment. The machine has passed tests to European Standard EN 61000.4.2 concerning immunity to electrostatic discharge. • Mains Transients Transients are spurious pulses propagating along mains conductors which may affect system operation. They may be from an internal source, e.g. welding unit, or any other machine generating mains interference, or they may be from an external source, e.g. stormy weather, neighbouring factory, etc. The machine has passed tests to European Standard EN 61000.4.4 concerning immunity to fast transients. • Stormy Weather The charges that accumulate during a storm cause transients in electrical lines or connecting cables. Do not use excessively long overhead lines. • Magnetic Fields A variable magnetic field causes induction in circuit loops—a major source of interference voltage. Cathode ray tubes are sensitive to magnetic fields, and display this sensitivity by a change in image chromatics or geometry. This is why they are equipped with protective shielding.

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 23/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

• Medium- or High-Frequency Electromagnetic Radiation This type of interference can cause many problems in systems (operational amplifiers, computer memory, etc.). In general, the extent of the disturbance depends on the duration and intensity of the radiation. It may be caused by nearby radar systems or radio transmitters (military, police, FM radio station, etc.), or even by poorly filtered cathode ray tubes. For optimum operation of your machine, install the press brake in an environment that is free of the disturbances mentioned above (reference values : field 0.2 to 0.5 V/m, frequency band 10 kHz to 1 GHz). Although the machine has passed tests to European Standards EN 50140 and 50141, we recommend that you install the press brake in an environment that is free of the above-mentioned types of interference.

24/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

Figure 2.8

NOTE Component layout, not binding.

Example of wire attachments for the customer supply cable to QS1

Earth terminal

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 25/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

2.5.4. POWER SUPPLY CABLE CHARACTERISTICS The characteristics of the power supply cable must comply with the safety regulations in force. Cable cross-sections (mm²) are given for a line less than 20 m long. They are different for the three models in the product range, and for a 400-V power supply. For any other specifications, refer to standard.

Example : EN 60204-1 (IEC 204-1).

Manufacturer-recommended cross-section

Country Voltage / Frequency

Europe 400 V / 50 Hz

≤ 7,5 kW

10,5 kW

18 kW

4 mm²

4 mm²

6 mm²

See Figure 2.8 as well electric diagram on how to pass the incomming power supply cable through the electric cabinet. The power supply cable should never be passed through the “C” frame in front of the electrical cabinet. The machine is equipped with its own current protection devices, but the supply line must be equipped with a cutoff device to protect it from short circuits and overcurrents (not included in Amada supplies). The cable and its mechanical protection devices, if any (cable troughs, raceways, sheaths, etc.) must have a protection rating according to the mechanical risks and corrosive agents to which they are liable to be exposed (not included in Amada supplies). The routing of cables and their protective equipment must not create any hazard (falling) to personnel. Connect the three power supply wires directly to the corresponding terminals of the circuit breaker, with the earth wire (green/yellow) directly on the earth terminal intended for this purpose. The circuit breaker is designed to accommodate up to three padlocks. We recommend that you install a padlock immediately, to prevent the system being switched on until the Amada Department Services technician arrives to put your machine into operation.

CAUTION: All work on electrical installations must be performed by qualified personnel trained for the purpose in order to prevent any accidents or damage to equipment.

26/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

2.6. WORKSTATION LIGHTING

CAUTION: Ensure that the workstation has sufficient lighting for the parts to be worked on.

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 27/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

2.7. SAFETY PRECAUTIONS 2.7.1. GENERAL POINTS During machine installation, operation, and maintenance, apply all necessary safety measures, and the following in particular : • Do not adjust or service the machine until you have read the manual. • All electrical work must be performed by a qualified electrician, to avoid all equipment

damage or physical injury. • Never place your hands between tools for any reason. • Do not modify the control circuits or any component of the machine. • Never use the machine with any of its safety devices removed or disabled. • Do not enter inside the safety device covered area nor in the hazardous zone. • Daily inspect the machine before starting work to ensure that :

- All protective devices are in place. - There is no obstruction in between the tools. - There is a free access to command devices. - The floor around the machine is free of grease, oil, and water.

• Never wear a tie, scarf, or loose clothing when adjusting or operating a press brake. • Make it a rule that a single qualified, trained operator performs machine adjustments. When

working on large parts, the operator may be helped by an assistant operator whose sole task is to help handle the blank. The assistant must have an equivalent control panel (electric footswitch) to authorise the operator to start the cycle. We supply on request, special equipment, to allow working on 2 stations or plus, with or without light guard.

• Before machine inspection or maintenance, switch off the main electrical isolating switch

unless power is required for the procedure concerned. In such cases, only personnel with the appropriate training are authorised to carry out the procedure.

• Wear protective gloves whenever possible.

28/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

• On rare occasions when the user bends parts whose overall size exceeds the length of the

machine's beam, protective measures must be implemented to prevent injury to other persons. If this type of job is performed frequently, additional protective measures must be permanently installed, in association with the machine's control circuit where appropriate.

CAUTION : Use of the machine by unqualified, untrained personnel engages the employer's liability (Labour Law L 233-5-1) as well as the operator's liability (Labour Law L 230-3). Applies to France only.

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 29/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

Important note relating to Personal Protective Equipments (PPE)

The so-called “Personal Protective Equipments” (PPE) are not included in Amada supplies. You will find below as informative examples the type of Personal Protective Equipments that one will require on our machines:

• gloves, • helmets, • ear guards, • goggles, • goggles to protect against laser radiations, • safety shoes, • etc.

It is the responsibility of the user of the PPE to ensure that the equipment he /she is using fully complies with the European Directive 89/686/CE. This verification should be carried out with in the guide-lines of the European Directive 89/656/CE. The said directive is transposed in the French Labour Law “Code de Travail” and applies to the employer (Act 93-41 dated 11/01/1993 and article R233-1 and R233-83-3) i.e. all French employers are obliged to:

• ensure that the appropriate PPE are selected relating the risks involved, • supply the appropriate PPE to the employee concerned, • ensure that the employee is using them efficiently, • ensure their compliance with the regulation, • inform people who are responsible for the implementation (work shop manager,

foremen, etc.), • ensure the PPE are in perfect working condition and periodic maintenance is carried

out, • inform users which potential risks are protected by the use of PPE, • train and lead users in the regular use of PPE.

In any case, the PPE which are in compliance (self certified or certified by a notified body) should have: A CE marking (visible and affixed firmly) and showing: Ø the name or the trade mark of the manufacturer, Ø identified either by commercial name or the reference of the PPE, Ø the size, if implies, Ø the expiry date, if implies,

and should be accompanied by the information leaflet and user manual along with the CE declaration stating that it complies fully with the European Directive 89/686/CE.

30/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

CAUTION: The machine may not be used in an explosive environment.

The operation and maintenance of this machine are strictly reserved for qualified professional personnel. For this purpose, Amada Department Services provides training for operators, fitters, programmers, and maintenance technicians on its own premises or on the customer site.

• Fire Prevention & Emission of Harmful Substances HF press brakes present a low risk of fire or emission of harmful substances. Even through,

we recommend that you keep fire extinguishers for electrical equipment and oil near the machine.

• Ensure that the strength and length of the tools used are compatible with the pressure setting

(see Para. 2.9, Machine characteristics and Para. 5.5 tool installation). Press brakes are supplied with the following safety equipment :

- A set of two footswitches (closing/opening), - Cycle selector key switch, - Self controlled side and rear guards, - Self-controlled electrohydraulic circuit.

Options:

1) Light guard to protect the front area. 2) Another control unit for assistant operator, including 2 footswitches

(opening/closing). 3) A laser beam, to protect the front area.

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 31/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

The press brakes listed in Appendix IV of Machine Directive 98/37/CE have fulfilled the requirements of the Type Testing procedure, as certified by NORISKO, a notified body registered with the European Community by the French Ministry of Labour. Each machine delivered in European Union is therefore accompanied by a declaration of conformity like the following example :

32/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

2.7.2. REGULAR INSPECTION AND SAFETY POLICY

NOTE The below-explained items are valid for France only. Any other country should refer to its current and domestic regulation.

� Article R233.11 of the labour law and the Act dated 5 March 1993, modified by the

Act dated 4 June 1993, require preventive maintenance to be performed on a quarterly basis. The purpose of this regular servicing is to detect any fault liable to cause an accident in advance, so that such faults can be rectified.

The results of this service call are recorded in a safety register opened by the Site Manager and made available to the Health and Safety Executive and the CHSCT (if any) at all times. This measure applies to any manual-feed press working on cold rolled metals. The servicing must be performed under the responsibility of the Site Manager by qualified persons trained in risk prevention. A list of such personnel is made available to the Health and Safety Executive. For all utilisation of press-brake, the user is obliged of : - Use the protection devices in order to secure the front faces on press-brakes. - Arrange the working stations through the installation of devices suited to the parts to be

bent : part-holder , adjustable table. - Think out of a convenient working organization due to secure the passing-through of

batches of new parts. - As for safety instructions, provide the proper training to operators and particularly to non-

experienced benders or temporary workers.

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 33/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

2.7.3. ARRANGEMENT OF WORKSTATIONS There are five separate working zones, which are as follows:

1 Electrical cabinet 2 Backgauge adjustment 3 Start-up and Programming* 4 Production 5 Assistant Operator in the event when production is carried out by two operators

(Caution : the assistant operator should be provided with similar equipment as for the main operator. See § 2.7.1).

* When equipped with “OPERATEUR 2000” controller or “AMNC” controller

* When equipped with « CD2000 » controller

NOTE Visuals, not binding.

1

2

3 4 5

1

2

4 5 3

34/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

Figure 2.11

Figure 2.9 Figure 2.10

1 2

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 35/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

2.7.4. CONTROL DEVICES The press brake is supplied with a control device composed of one opening footswitch 1 and one closing footswitch 2 (Fig. 2.10). When the press brake is controlled by two operators, a second unit (option), identical to the first, is required. A selector key switch (option) is used to switch it on. Depending on the type of NC fitted to your machine, the teaching will be carried out as follows: - With the help of an electronic hand wheel remote controller having magnetised base plate,

supplied as standard accessory and can be moved around (figure 2.9). For further details, see appendix "A2" programming manual (machine equipped with “OPERATEUR 2000” NC).

- Directly using the push buttons on the NC key- pad (figure 2.11). For further details, see appendix “A3”, programming manual (machine equipped with “CD2000” NC).

- With the help of an electronic hand wheel remote controller having magnetised base plate, supplied as standard accessory and can be moved around (figure 2.9). For further details, see appendix "A4" programming manual (machine equipped with “AMNC” NC).

CAUTION : Working from the rear side of the machine is strictly forbidden.

36/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

Figure 2.12

Figure 2.13

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 37/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

2.7.5. RULES FOR SAFE OPERATION � Release the part to be bent as soon as it is gripped between the tools (Fig. 2.12).

� Install or remove the tools (§ 5.5 Fig. 2.13) in strict compliance with the procedure described in the Operator Manual and/or the recommendations specific to your tooling.

To avoid damage to your tooling or any accident, Amada urge you to follow strictly the procedure below :

• Every time you change a program, select adjustment mode and mute stop.

• Carryout a dry cycle (without material). • Check visually that all parameters correspond to the tooling

mounted on the machine, the mute point is 6 mm above sheet pinch point and the end of bend is correct.

• Then and only then choose the normal operating mode for the program in question.

CAUTION: Handling devices for heavy parts are not included in the Amada supplies. They must be installed for risk-free use in accordance with ergonomic principles.

38/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

Figure 2.14

Figure 2.15

Figure 2.16

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 39/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

� Never attempt to support the end of the worksheet by holding it on either side of the tools. Only install the tool length required for the current job on the machine (Fig. 2.14).

� Never place your hand between the worksheet and the backgauge during operation (Fig. 2.15).

� Never place your part against/over the backgauge finger before backgauge is positioned on programmed position.

� No part of your body must enter the hazardous area during bending operations (Fig. 2.16).

40/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

Figure 2.17

Figure 2.18

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 41/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

� Beware of sudden movements of the worksheet during bending (Fig.

2.17).

� Observe the allowable tool loads (Fig. 2.18 and Para. 5.5). For example: - 1.2 T/cm for standard punches, except: - 1.5 T/cm for heavy punches, - 0.5 T/cm for punches with extra thin blades.

(1 T = 10 kN) The specific value for each tool type is marked on the side of the tool and is also shown in the special Tool catalogue.

42/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

Figure 2.19

Figure 2.20

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 43/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

� The dutch bending or hemming tool should be firmly secured to the lower beam (Fig. 2.19). This type of tooling shouldn’t be used on “High Speed” press brakes i.e. where working speed can reach 20 mm/s.

� Never hold the sheet by its folded edge; hold it from the sides (Fig. 2.20).

44/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

2.8. MACHINE OPERATING AND STORAGE CONDITIONS To ensure long life for the electronic and hydraulic components, conditions should be maintained within the following limits: Min. Max.

Ambient machine storage temp. ............................. -10°C ................................... +50°C Ambient operating temp. ..........................................+5°C ................................... +35°C Oil temp. ...................................................................+5°C ................................... +80°C Relative humidity ......................................................20% .................................... 75%

For temperatures below 5°C, the NC unit must remain powered to keep the components and circuit at a normal temperature. No equipment that produces swarf, dust, paint flakes, etc. must be installed in the immediate vicinity of the machine. If this is not possible, apply all possible measures to protect the press brake from all factors liable to hinder its smooth operation.

CAUTION: Amada engineer will put your machine into operation. Please provide a supply of test sheets for this purpose. Select the material and sheet thicknesses you use most often.

CAUTION : Any prior use of the machine will lead to suspension of the guarantee. Validity of the guarantee will not be restored until the installation has been inspected and, where necessary, the machine has been repaired at your expense.

CAUTION : Use of the machine by unqualified, untrained personnel engages the employer's liability (Labour Law L 233-5-1) as well as the operator's liability (Labour Law L 230-3). These labour laws applies to France only.

NOTE: To gain maximum benefit from our technician's visit, remember to remove the equipment from its crates and degrease it before the technician's arrival.

If the oil temperature is below 5°C, there is a risk of the machine operating incorrectly. To prevent this, press the STOP button, and then press the opening footswitch for 5 to 10 minutes (see §. 3.7).

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 45/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

2.9. MACHINE CHARACTERISTICS 2.9.1. STANDARD STROKE WITH STANDARD SPEED AND HIGH SPEED

DESCRIPTION UNITS MODELS Standard speed HF 50-12 HF 50-20 HF 80-25 HF 100-3

High speed HF 50-12 S HF 50-20 S HF 80-25 S HF 100-3 S Nominal force kN 500 500 800 1 000

Minimum force 1 kN 40 40 70 75

Table length mm 1 270 2 090 2 570 3 110 Table width mm 60 60 60 90 Work surface height mm 960 960 960 960 Open height without tools mm 370 470 470 470 Cylinder stroke mm 150 200 200 200 Throat depth mm 100 420 420 420 Distance between uprights mm 1 035 1 665 2 125 2 705 Max. pressure bar 270 270 275 280 Number of cycles 4 4 4 4 Oil capacity 2 litres 55 55 / 110 90 / 185 110 / 225

With CD2000 (HFT) mm 1 850 2 950 3 410 3 990 With OP2000 (HFE) mm 2 165 3 161 3 621 4 201

Machine length 3

With AMNC (HFP) mm n/a 3 458 3 918 4 498 With CD2000 (HFT) mm 1 610 1 820 1 800 1.940 With OP2000 (HFE) mm 2 165 2 450 2 450 2 450

Machine width 4

With AMNC (HFP) mm n/a 2 450 2 450 2 450 Machine height mm 2 300 2 450 2 450 2 700

GENERAL net weight 5 kg 3 350 4 600 5 600 6 600

Number of adj. dist. Pieces 6 6/8 10/13 13/17 15/21

Height of distance pieces mm 120 120 120 120 lg 835 mm 1 2 3 4 Number of

tools lg 415 mm 3 5 6 7

Motor power (Europe) 7 kW 4 4 / 7,5 7,5 / 15 7,5 / 15

Pump capacity (Europe) 2 cm3/T 8,2 8,2 / 16,4 13,3 / 26,6 15,8 / 31,6 Motor power (USA) 7 kW - 4 / 9 7,5 / 12,5 7,5 / 17 Pump capacity (USA) cm3/T - 6,4 / 12,8 10, 2/ 20,4 13,3 / 26,6

Max. approach speed 2 mm/s 100 100 / 200 100 / 200 100 / 200

Max. work speed 2 et 8 mm/s 10 10 / 20 10 / 20 10 / 20 Max. return speed 2 mm/s 100 100 / 200 100 / 200 100 / 200

AMADA EUROPE S.A. constantly strives to improve its products, and reserves the right to alter their characteristics at any time.

1 Value affecting the smallest allowable length of tools (Para. 5.5). 2 Standard speed / High speed. 3 The dimensions are with the arm and the NC maximum extended on the exterior, and all doors closed. 4 The dimensions are with the arm and the NC maximum extended in front, and all doors closed. For HFT models, add 140mm to this dimension for the light guard option, and add 100mm for a laser beam protection option. 5 Weights are approximate and correspond to basic machines, for optional equipment, see § 2.2.1. 6 Standard distance pieces / Abutting distance pieces. 7 Machine power = Motor power + 3 kW. 8 20mm/s work speed is incompatible with the “Akas” system

46/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

2.9.2. LONG STROKE WITH STANDARD SPEED AND HIGH SPEED

DESCRIPTION UNITS MODELS

Standard speed HF 50-20L HF 80-25L HF 100-3L

High speed HF 50-20LS HF 80-25L HF 100-3LS

Nominal force kN 500 800 1 000

Minimum force 1 kN 40 70 75

Table length mm 2 090 2 570 3 110

Table width mm 60 60 90

Work surface height mm 960 960 960

Open height without tools mm 620 620 620

Cylinder stroke mm 350 350 350

Throat depth mm 420 420 420

Distance between uprights mm 1 660 2 120 2 700

Max. pressure bar 270 275 280

Number of cycles 4 4 4

Oil capacity 2 litres 55 / 110 90 / 185 110 / 225

With CD2000 (HFT) mm 2 955 3 415 3 995

With OP2000 (HFE) mm 3 166 3 626 4 206 Machine length 3

With AMNC (HFP) mm 3 463 3 923 4 503

With CD2000 (HFT) mm 1 952 1 952 2 052

With OP2000 (HFE) mm 2 450 2 450 2 450 Machine width 4

With AMNC (HFP) mm 2 450 2 450 2 450

Machine height 3 mm 2 770 2 770 2 860

GENERAL net weight 5 kg 5 000 5 750 7 000

Number of adj. dist. Pieces 6 10/13 13/17 15/21

Height of distance pieces mm 120 120 120

lg 835 mm 2 3 4 Number of tools lg 415 mm 5 6 7

Motor power (Europe) 7 kW 4 / 7,5 7,5 / 15 7,5 / 15

Pump capacity (Europe) 2 Cm3/T 8,2 / 16,4 13,3 / 26,6 15,8 / 31,6

Motor power (USA) 7 kW - 7,5 / 12,5 7,5 / 17

Pump capacity (USA) Cm3/T - 10, 2/ 20,4 13,3 / 26,6

Max. approach speed 2 mm/s 100 / 200 100 / 200 100 / 200

Max. work speed 2 et 8 mm/s 10 / 20 10 / 20 10 / 20

Max. return speed 2 mm/s 100 / 200 100 / 200 100 / 200

AMADA EUROPE S.A. constantly strives to improve its products, and reserves the right to alter their characteristics at any time.

1 Value affecting the smallest allowable length of tools (Para. 5.5). 2 Standard speed / High speed. 3 The dimensions are with the arm and the NC maximum extended on the exterior, and all doors closed. 4 The dimensions are with the arm and the NC maximum extended in front, and all doors closed. For HFT models, add 140mm to this dimension for the light guard option, and add 100mm for a laser beam protection option. 5 Weights are approximate and correspond to basic machines, for optional equipment, see § 2.2.1. 6 Standard distance pieces / Abutting distance pieces. 7 Machine power = Motor power + 3 kW. 8 20mm/s work speed is incompatible with the “Akas” system.

ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Chapter 2 47/48 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

2.10. INFORMATION ON NOISE The measurements methods and the operating conditions used comply with EN 31202 standards. 1 – EQUIVALENT ACOUSTIC PRESSURE LEVEL AT WORKSTATION

LAeq: The equivalent continuous acoustic pressure level at the workstation, LAeq, is less than 75 dB(A).

2 – PEAK ACOUSTIC PRESSURE LEVEL AT WORKSTATION

Lpc: The peak acoustic pressure level at the workstation, Lpc, is less than 130 dB

Measurements were carried out at 1 m from the front side, at the centre of the machine and at a height of 1.6 m.

48/48 Chapter 2 ACCEPTANCE, INSTALLATION AND SAFETY MEASURES Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

2.11. NORMAL USE, RESERVATIONS, AND EXCLUSIONS Normal Use Bending and forming of sheet metals of various types of material and thicknesses by inserting the blank to be folded in between punch/die, whose shape and size depend on the properties of the material. Bending can be performed by one of the following methods:

- Air bending or three-point bending, - Bottoming - Coining

In all cases, it is essential to observe the tool unit load limits. Reservations and Exclusions Punching is not permitted on this type of machine. Bending/forming of any material other than sheet metals, such as plastics (PVC, Makrolon, polycarbonate, etc.) in particular, should not be undertaken without consulting the supplier and checking the mechanical properties (ductility, strength, formability, etc.) of the product concerned.

COMMISSIONING Chapter 3 1/6 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

3. COMMISSIONING

2/6 Chapter 3 COMMISSIONING Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

3.1. CLEANING To gain maximum benefit from our technician's visit, we strongly recommend that you remove the equipment from its crates and degrease it before the technician arrives. Use paraffin to remove the grease or storing polish, and oil the machined surfaces to prevent oxidation.

CAUTION: Never use abrasive products or solvents liable to damage surfaces with protective coatings.

3.2. INSTALLATION OF CONTROL DEVICES The footswitch is supplied wired and connected. It is in a box secured to the backgauge.

CAUTION: Do not remove this box. Our technician will do so.

COMMISSIONING Chapter 3 3/6 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

IMPORTANT NOTE AFTER LEVELLING, TIGHTEN THE TWO NUTS OF THE ADJUSTMENT SYSTEM ON BOTH THE UPRIGHTS.

Figure 3.1

Levelling screw

4/6 Chapter 3 COMMISSIONING Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

3.3. CHECKING THE MAINS POWER SUPPLY As supplied, the machine is intended to run on a three-phase 400 V 50/60 Hz power supply. Any other voltage requires a transformer (not supplied). 3.4. MACHINE LEVELLING To set your machine up with the correct geometry, apply the following procedure strictly. Because your press is designed not to be anchored to the floor, the concrete slab must be flat to within 2 mm per metre. Horizontal levelling does not require great accuracy; 1 mm per metre is sufficient. The levelling of each upright is performed using each of the two screws at the rear of the machine (Fig. 3.1). The perpendicularity reference is taken with a precision level (accurate to 0.05 mm/m) placed on a straightened rule which is in turn resting on two dowel pins in each of the uprights. Tolerances: ±0.05 mm/m per upright, and 0.05 mm/m with respect to each other.

IMPORTANT NOTE

THE MACHINE MUST NOT REST ON SUPPORTS OTHER THAN THOSE DEFINED IN FIG. 2.4 (CHAPTER 2) OF THIS MANUAL. For specific installation conditions, contact Amada Technical Department.

COMMISSIONING Chapter 3 5/6 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

3.5. PUTTING THE MACHINE INTO OPERATION START-UP

. SEE CHAPTER 6.1.

DIRECTION OF ROTATION � Check the direction of rotation of the hydraulic unit. To do this:

- Start the pump by turning the key selector to the right. - Compare the direction of rotation of the motor blades to the red arrow on the motor

casing.

- If the direction does not match, stop the pump rotation by turning the key

selector to Position 0. - After switching off the main circuit breaker of the machine swap 2 phases at the

supply terminals.

NOTE Switch off operation. First step : turn the motor start up key switch to the 0 fix position. Second step : turn the handle of the main circuit breaker to position 0.

6/6 Chapter 3 COMMISSIONING Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

3.6. OVERALL CHECK � Check the mountings of all covers and casings. � Check that no foreign body is present on the ball screws of the backgauge axes or the guide

rails. � Check that the cables are secure in the stuffing boxes (electrical power supply cable), and

check the cable grip at the bottom of the electrical cabinet (footswitch). In the electrical cabinet, check that the earthing wires are properly connected to the terminal blocks.

� Check that the limit switches are operating correctly. � Check that no cover is liable to be caught during movement. � Check that all the indicator lights, machine stops and key switches are operating correctly. � Check that the light guard (if any) is operating correctly. Refer to the specific Appendix

concerning the light guard. WARM-UP In the event of a low ambient temperature, it may be necessary to warm up the hydraulic circuit. To do the warm up, apply power to the machine, start up the hydraulic unit, and lets climb up the temperature for 5 to 10 minutes.

TECHNICAL DESCRIPTION Chapter 4 1/10 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

4. TECHNICAL DESCRIPTION

2/10 Chapter 4 TECHNICAL DESCRIPTION Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

Figure 4.1

TECHNICAL DESCRIPTION Chapter 4 3/10 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

4.1. MECHANICAL STRUCTURE Comprising: (Fig. 4.1) 1) A welded frame, including:

- Two uprights (Items 1 and 1’) - Two groundplates (Items 2 and 2’) - One connecting beam (Item 3) - One lower beam (Item 6)

2) Removable mechanical components:

- One moving upper beam (Item 5)

4/10 Chapter 4 TECHNICAL DESCRIPTION Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

4.2. MECHANICAL CONNECTIONS 1) The upper beam is supported by the uprights via the two hydraulic cylinders. Four sets of

track-eccentric roller assemblies ensures the perfect guiding of the upper beam, and at the same time provide the means for axial adjustment.

A linearity device with a push-pull system located at the rear of the upper beam ensures that this beam is perfectly linear, resulting in straight bends.

2) There are two hydraulic cylinders. Their purpose is to transmit the required bending force

to the upper beam, and to provide lateral guidance. The NC unit synchronises them via very high precision linear scales to obtain parallelism and positioning accuracy to within 1/100th mm.

The piston rods press on the upper beam via spherical supports. This linkage ensures that the piston is perfectly aligned in the cylinder by maintaining the reaction due to the thrust effects in the axis of the uprights.

3) The lower beam is welded to the machine uprights at each end. 4) A uniquely designed external “C” frame that remains rigid under all bending conditions

insures that accurate ram positioning is maintained even with the side frame deflection. The reference of the moving beam is taken completely independently of the side frame to avoid introducing any error resulting from side frame deflection.

TECHNICAL DESCRIPTION Chapter 4 5/10 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

4.3. ELECTRONIC STROKE CONTROL AND PARALLELISM BALANCING SYSTEM The clever design of the catches which are located exactly in the bending axis of the fixed and mobile beams allows the reference positions of the mobile beam to be read accurately, independently of the slightest deformation of the frame. The great rigidity of the strong external “C” frames and the securing of the linear glass scales provide a reading to 1/100th of a millimetre, irrespective of the loads applied to the frame and the beams. Extremely Accurate Incremental Measurement The linear scale is made of glass and has a grid (40-µ steps). It represents the travel of the upper beam with positioning of ±0.01 mm between the punch and the die.

Measurement scale (Y1-Y2)

Line grid

Reference mark

Photo-electrics cells

6/10 Chapter 4 TECHNICAL DESCRIPTION Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

To B’ B

From Y2

Reference

Y1

TECHNICAL DESCRIPTION Chapter 4 7/10 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

4.3.1. ELIMINATING SOURCES OF ERROR Under normal conditions of press brake use, several parameters have a direct effect on the accuracy of the bending angle. � Oil viscosity (temperature). � Operating pressure (working force). � Position of the parts (if off-centre, this leads to unequal forces on the uprights). Because it is virtually impossible to have full control over all these factors, risk of error introduction, which is liable to affect the bending quality. A new technique allows Amada to eliminate these risks completely. 4.3.2. PROPORTIONAL VALVE TECHNIQUE FOR CONTINUOUS RELIABILITY This extremely sophisticated electronic regulating technique guarantees perfect balancing of the parallelism by making it independent of factors liable to alter it. Two incremental linear sensors Y1 and Y2 are mounted at each end of the upper beam. The sensors are directly connected to the electronics of the NC controller A of the Machine. This controls the oil flow to each cylinder via proportional valves B and B’. When the upper beam is lowered, the sensors continuously record the changing positions very accurately. These signals are immediately sent to the NC controller, which checks the respective values. The slightest difference between the data supplied by the sensors automatically triggers oil level compensation and pressure balancing. On HFP, adding some pressure sensors will improve the accuracy of the results.

8/10 Chapter 4 TECHNICAL DESCRIPTION Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

4.3.3. PRECISE CENTRING OF THE BEAMS The upper beam is guided by a set of four pairs of generously sized roller guide assemblies (1) running on hardened ground steel surfaces, securely fastened to the machine uprights. The maximum spread between the upper and lower roller guide assemblies (E max) ensures precise alignment and centring of the beams, with perfect rigidity. Reference cylinder D provides lateral positioning.

TECHNICAL DESCRIPTION Chapter 4 9/10 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

4.4. LOCATION OF CONTROL AND SIGNALLING DEVICES • EITHER ON NUMERICAL CONTROL OR ON CONTROL PANEL

- SEE CHAPTER 6 OPERATION

10/10 Chapter 4 TECHNICAL DESCRIPTION Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

4.5. PRESS BRAKE OPERATING LIMITS IN OFF-CENTRE WORK The further a point is from the centre of the machine, the smaller the available resultant force at that point. This information is taken into account by the NC controller, which calculates the force required according to the user-programmed part position. 4.6. PRESSURE GAUGE A pressure gauge is placed on the outer side of the left upright. By comparing the displayed pressure (in bars) to the maximum pressure given in the machine characteristic table § 2.9 in Chapter 2, you can see if the machine is reaching its operating limits.

The NC unit permits to limit the force according to the tool (refer to limit values in tool catalogues).

Pressure gauge

FORMING TECHNIQUE & TOOLING Chapter 5 1/46 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

5. FORMING TECHNIQUE & TOOLING

2/46 Chapter 5 FORMING TECHNIQUE & TOOLING Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

Figure 5.1

Figure 5.2

Figure 5.3

Figure 5.4

FORMING TECHNIQUE & TOOLING Chapter 5 3/46 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

5.1. GENERAL POINTS Bending consists of forming parts from flat sheets. Deformation is linear and simultaneous over the entire length of the part on a finite machine and tool, and continuous when rollers are used (infinite length). Fig. 5.1: Punch and die. Press brake. Fig. 5.2: Gripper plate and punch. Press. Tangent bending. Hole cut off edge. Fig. 5.3: Fixed gripper plate, rotating beam. Folding press. Fig. 5.4: Rotating grippers plates.

4/46 Chapter 5 FORMING TECHNIQUE & TOOLING Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

Figure 5.5

Figure 5.6

Figure 5.7

FORMING TECHNIQUE & TOOLING Chapter 5 5/46 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

Fig. 5.5: Fixed guide and rotating gripper plate. Manufacture of shrouds. Fig. 5.6: Three rollers. Roll bending machine. Fig. 5.7: Flat roller. Infinite bending length. Angular variation limited to each pair of rollers. This list of forming methods is not exhaustive. This chapter only deals with punch-and-die bending (Fig. 5.1). There are two basic bending techniques: - AIR BENDING Commonly performed because it requires relatively low bending forces. - COINING Requires forces equal to three to five times those of air bending. Allows the inside radius to be coined, which practically eliminates the elasticity of the material.

6/46 Chapter 5 FORMING TECHNIQUE & TOOLING Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

Figure 5.8

Figure 5.9

• Distance of penetration

Sheet contact

t = thickness

Die = 8 to 10 t.

FORMING TECHNIQUE & TOOLING Chapter 5 7/46 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

5.2. AIR BENDING During air bending, the sheet metal retains certain amount of elasticity in the plastic region. An acute angle, higher than the desired angle, is generally performed to compensate for the opening due to spring back effect. The NC unit is designed to take into account all these parameters required for air bending. Our standard air bending tools too are designed accordingly. The bending chart located in the press brake’s electrical cabinet indicates the required force and internal radius which can be obtained in relation with the other characteristics (thickness, die opening, etc.). During air bending, the sheet is in contact with the tools at three points (A, B1, B2) as shown in Figure 5.8. To obtain quality bend using air bending, it is necessary that the die opening is 8 to 10 times the sheet thickness. (For angles ≥ 135°, it is preferable to use a die opening 10 to 12 times the sheet thickness). In this way, sheet deformation is interrupted before it reaches the bottom of the die. NOTE If there is a specific requirement for bending, e.g. edge dimension, inside radius, etc., use the technique for air bending at the bottom of the die (partial coining) or coining. AIR BENDING AT BOTTOM OF DIE OR PARTIAL COINING (Fig. 5.9) In this case, the sheet penetrates to the bottom of the die and is supported by the sides, with no increase in the bending force. This type of bending is seldom used because of the inaccuracy of the results obtained. Coining should be chosen over partial coining whenever possible.

8/46 Chapter 5 FORMING TECHNIQUE & TOOLING Issue 05/2005 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H

5.3. COINING This type of bending is comparable to stamping. The end of the punch penetrates the sheet at the bottom of the die, rupturing the elasticity of the sheet, which is then bent exactly to the shape of the punch.

- In practice, for a 90° bend: - Die width = 5 to 8 times the thickness. - Die angle = 90°. - Punch angle = 90°.

The state of the part is similar to that shown in Figure 5.9 for partial coining, except that the forces at the end of bending are 3 to 5 times the air bending forces, which causes the coining of the sheet. NOTE The choice of punch radius is very important for coining, because it determines the inside radius of the bend (stamping of the punch in the sheet). Coining can only be performed with a punch and die of the same angular value. Very high bending forces must be applied; these may reach values from 3 to 5 times those shown on the air bending chart.

CAUTION: Because coining involves very high forces, take great care to check the strength of your tools. Never exceed the applicable force limits. These values depend on the type of tool, and should normally be shown in tool catalogues (§ 5.5).

FORMING TECHNIQUE & TOOLING Chapter 5 9/46 HF LOW TONNAGE OPERATOR’S MANUAL – X40873H Issue 05/2005

5.4. LIST OF STANDARD TOOLS

(Refer to “Amada’s Press Brake Tooling” catalogue) Qualitative characteristics common to the whole range: � Easy to store. � Easy for one person to handle. � Hardened working surfaces. � Standardised mounting systems. � Special profiles suited to different sheet

thicknesses. � Wide range of profiles suited to all