Herman Miller Case Study

-

Upload

vishal-dave -

Category

Documents

-

view

1.350 -

download

1

Transcript of Herman Miller Case Study

Case Study

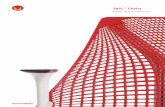

Herman Miller: The Invention and Renewal of an Iconic Manufacturer

Name: Vishal Dave

Email: [email protected]

Course: GM 599

Strategic Management in Global Environment

Professor: Matthew Schigur

Herman Miller's Design Yard is a place where people and ideas meet. The people include employees, guests, consultants, customers. The ideas are as varied as the people themselves--designers, engineers, writers, researchers, planners, marketers. As a facility that supports connection and communication, the Design Yard seeks to leverage the culture of participation that has sparked ideas at Herman Miller for many years.

Since its opening, the Design Yard has been a kind of learning lab--a place to experiment and evaluate, observe and respond. Whether it's an innovative product concept or a new take on an established program, the Design Yard provides a setting where ideas can take hold and where lessons learned can have a far-reaching impact. That ethos makes it the perfect place for Herman Miller to put a new product line to the test. The current test, really a learning opportunity, involves approximately 60 employees and the process of their relocation to a newly configured area near the entrance of the Design Yard. These residents, including the company's senior executives, are now working in an environment that's significantly different from the ones they left. Featuring Canvas Office Landscape, the space addresses the need shared by many organizations for environments that support both individual and collaborative work.

As the first phase of a two-year redo of the entire Design Yard, this project serves as a foundation for the overall effort. What's learned from it, in terms of both product application and project implementation, will help inform the rest of the initiative. "At the same time that we're providing employees with a new workspace, we're showing others how we're thinking about the office environment," says Steve Panse, leader of the Canvas commercialization effort. "This project demonstrates how Canvas works in our own space. It expresses our eagerness to learn from it. We're committed to using what we learn to continue the ongoing expansion of its capabilities." With its ability to create everything from private offices and systems settings to benching applications and collaborative areas, Canvas is the linchpin of the installation. "It's a single, integrated platform that unifies the look, feel, and function of an environment," says Panse. "Here at the Design Yard it provides a consistent theme that calms the whole landscape and ties it together." Paula Edwards, a Herman Miller workplace strategist who helped develop the Canvas applications within the space, notes that Canvas has a more "residential feel" than other office-furniture choices. "Canvas can create spaces that are friendly and approachable," she says. "Its low-profile storage components, for example, can replace return walls and open up views and accessibility." It's important to realize that the people who are now working in the new space didn't just land there. Prior to their move--including some executives moving from private offices to 6 x 6 stations and some heads-down workers moving from smaller to larger workstations--the company made sure that everyone was kept informed and involved in the process that led them to their new environment.

To that end--and as the Design Yard redo continues--Herman Miller's Performance Environments group is following the steps that it takes customers through as they prepare for changes in their office environments: visioning; space utilization data; place mapping and financial modeling; change

management; post-occupancy evaluation. (An additional step, repurpose, wasn't used for this project.) Tracy Brower, along with Paula Edwards, has been leading the process at the Design Yard.

"It's really helpful to have a clear process, one that's replicable," says Brower, director of Performance Environments. "It's a discipline that helps us be really clear on the front end about objectives and then to move forward efficiently and effectively. We're approaching this project with the knowledge that everything counts, that it's really important to pay attention to each person. How well people are treated sends an important message to them and to the rest of the organization." To keep residents informed and comfortable with the process, "town hall" meetings were held. In addition, people were selected to serve as liaisons, connecting regularly with their groups and keeping them in the loop as plans progressed. New protocols and guidelines for living and working in the space were created as part of the overall effort to support the residents. "Going in, people need to know the design so they understand what's reasonable for them to expect," Brower adds. The change goes beyond furniture. "We're not asking people to work the same way in a different space," says Brower. "We're asking them to work differently in this space, and that requires some adaptation."

Challenges

Prior to implementing FM: Space, Herman Miller used three different processes to manage workplace information – a work order system, a real estate system and paper floor plans for space management. The systems did not “talk to each other” making workplace information difficult to gather and share. With the initial implementation of the FM: Systems solutions thirteen years ago, Herman Miller addressed these challenges. Over time, Herman Miller has continued to expand its implementation to address new business problems and create a comprehensive integrated workplace management system (IWMS).

Solution

In 1996 Dave Kuiper, corporate workplace strategist for Herman Miller, and his team reviewed several CAFM systems, evaluating them for capabilities, ease of operation and cost. After deciding upon FM: Space, Herman Miller’s in-house team proceeded with implementation. The team prepared CAD drawings, imported data from Human Resources, tested and then launched the system. Herman Miller implemented the FM: Interact Workplace Management Suite with the hands-on support of the FM: Systems consulting services team. Now that implementation is complete, all departments in the west Michigan facility use the expanded system – from site coordinators to project managers to workplace strategists. With FM: Interact the company benefits from enterprise-wide access to drawings and reports, stacking and strategic planning capabilities, and continued productivity improvements.

Results

Kuiper and his team have realized significant benefits as a result of implementing FM: Systems’ technology. These benefits include:

•Reduced annual move spend. Herman Miller cut move costs from $2 million per year to less than $250,000 per year. They realized move spend reductions by enabling the use of space standards to simplify the move process, eliminating unneeded reconfiguration projects and reducing warehousing of furniture and related assets.

•Increased productivity of the workplace strategies group. Since using FM: Space and companion modules, the company has been able to implement more efficient and automated workplace processes. This has directly resulted in enormous savings in time and effort, enabling Herman Miller to reduce move times by 88%. Kuiper notes, “FM: Interact helped us improve planning and coordination and, as a result, we can complete moves in one day as compared to seven days before implementation.”

•Improved customer service with enterprise access to facility information. Since implementing FM: Interact, all employees have benefited from web-based access to employee information, floor plans, and views of move or service request status. Enterprise access to their facility data has helped Herman Miller improve customer service. “Our customer satisfaction score went from 90% to 97% during a three year period,” said Kuiper.

•Improved accuracy of facility data. Better visibility into space and occupancy has helped Herman Miller improve utilization of space and served as the foundation for move and service request process improvements.

•Automated publishing to CAD drawings. With FM: System’s Dynamic Drawings component, Herman Miller is able to automatically show updated information on CAD drawings in a web browser. In the past, the organization was publishing this information manually three times per week. Now end-users are able to get real-time, visual displays of move plans, vacancies, etc.

In addition to the benefits listed above, Herman Miller’s latest expansion of FM: Interact will continue to improve productivity. “FM: Interacts integration with Crystal Reports gives us the capability to do better reporting and make reports available online,” says Kuiper. “Right now we have several different areas of the company that are interested in getting access. IT is interested in having this information as well as telecom. In the past we had a manual process to generate a Crystal Report, and then we had to email it to the individual or department – FM: Interact saves us a lot of time by letting employees view real-time workplace reports from their Web browsers.” Kuiper is also excited about the stacking and strategic planning module. The robust stacking feature allows Herman Miller to better determine future space requirements – an important factor considering the nearly 50% churn rate manufacturing companies endure – helping to best utilize the available space and reduce churn rates.

Additionally, the company plans to expand its use of the asset module beyond artwork in order to track telecom and IT resources, and plans to deploy FM: Interact internationally when their new UK facility opens.