Heinputter 2

Transcript of Heinputter 2

Recommendation for commissioning testing

of medium voltage cables

The recommendation

© 2011 SebaKMT – MADE in GERMANY 2

Recommendation for commissioning

testing of medium voltage cables.

Includes:

Sheath testing

Withstand testing

PD testing

The treatment recommendation was created by the same work group,

which was responsible for the development of the VDE Cable Data Base

Members of this working group are specialists of

- 18 Power Utilities

- 4 Universities

- 4 Service providers for testing and diagnosis

- 1 Accessory manufacturer

- 1 Cable consulting company

- 4 Manufacturers of PD measuring systems

Note: VDE cable database is a web-based database where PD measurements are stored

and where also the PD affected accessories has been inspected. This get a better

knowledge about the type of faults and its remaining life time. (www.VDE-Kabeldatenbank.de)

Initiators

© 2012 SebaKMT – MADE in GERMANY 3

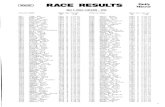

The experience of 20 years commissioning testing with 0.1 Hz VLF test

voltage indicate, that by a voltage test, only the very serious workmanship

failures are detected.

There is a large variety of workmanship failures, which pass the com-

missioning tests, and fail only after several months or years of operation.

Target

Fulfillment of the statutory requirements of the Operation Safety Act, the

BGV A3 and the VDE 0105 in respect to the commissioning test of newly

installed resp. modified electrical systems.

Quality control of newly installed cables/ accessories by PD testing

Gaining information for the condition assessment of cable systems

Motivation

© 2012 SebaKMT – MADE in GERMANY 4

Sheath Material PE PVC

Identification 2Y Y

Cable types (examples) NA2XS(F)2Y NA2XSY

Test voltage type DC DC

Test voltage level < 5 kV < 3 kV

Test duration < 5 min < 5 min

Typical leakage current < 100 µA/km < 800 µA/km @ 3 kV

Table 1: Test voltage levels and requirements

Contents Cable sheath testing

© 2012 SebaKMT – MADE in GERMANY 5

N A 2X S 2Y 1 x 150 rm /25 12/20 kV

Norm cable acc. to DIN VDE

Conductor Material (A = Al / C = CU)

Shield (S = Cu / K = Pb)

Dielectric (2X = XLPE / Y = PVC)

Sheath (2Y = PE / Y = PVC)

Description of German abbreviations of cables

Contents Cable sheath testing

© 2012 SebaKMT – MADE in GERMANY 6

Table 2: Overview of the voltage levels and durations to be used for plastic

and paper mass impregnated MV cables after repair or reallocation.

Insulation DC AC 45 Hz < f < 65 Hz AC f = 0,1 Hz

Test Level

UT = x Uo

Test

duration

min

Test

Level

UT = x Uo

Test

duration

min

Test Level

UT = x Uo

Test

duration

min

PVC Uo/U=6/10 kV

34 to 48 kV

Uo/U=12/20 kV

67 to 96 kV

Uo/U=18/30 kV

76 to 108 kV

15 to 30

2

30

XLPE, PE 2 60 3 60

PILC and mixed

cables with PVC

Uo/U=6/10 kV

34 to 48 kV

Uo/U=12/20 kV

67 to 96 kV

Uo/U=18/30 kV

76 to 108 kV

15 to 30

2

30

3

30

Mixed cables of

XLPE/PE with

PVC and PILC

2

60

3

60

Contents Cable withstand testing (aged/ in-service cables)

© 2012 SebaKMT – MADE in GERMANY 7

Experiences of 20 years commissioning tests with 0.1 Hz VLF test voltages

indicated that this reveals only the very serious workmanship failures. There

is a large variety of workmanship issues which pass the VLF commissioning

tests, and fail only after several months/ years of operation under load.

Field statistics on newly installed cables indicates that test failures appear

within 15 to 30 minutes of operation. Test durations of 60 minutes produced

no additional information or results. Therefore, a test duration of 30 minutes

is considered as sufficient.

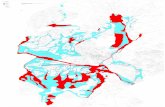

A significant amount of the faults that are probably not detected during the

withstand tests can be detected and localized by an additional partial

discharge measurement.

Testing of cable insulation after new installation of pure XLPE Cables

Contents Cable withstand testing (new cables)

© 2012 SebaKMT – MADE in GERMANY 8

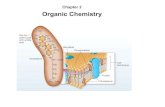

PD Measurements for commissioning tests

PD measurements allows to check the cable installation quality as well

as the condition of the complete system installation. Potential fault

spots can be detected in an early stage, and an evaluation of the

system and a budgeting of the required investments can be made.

A fundamental rule is:

Partial discharges occurring at U0 indicates a high risk of operating.

PD measurement test systems with the following type of voltages are

commercially available:

0.1 Hz VLF (VLF – Very Low Frequency)

20 – 300 Hz AC (AC – Alternating Current)

100 – 500 Hz damped AC ( DAC – Damped AC)

Contents Cable withstand testing (new cables)

© 2012 SebaKMT – MADE in GERMANY 9

PD Measurement for quality assurance on newly installed systems

Newly installed cable accessories are, with a correct installation, PD free up

to at least 1.7 U0.

Field experiences showed that some types of accessories require several

load changes resp. temperature cycles, before they are PD free. This has

to be considered during the evaluation, or the PD test has to be repeated

after some load cycles.

The voltage has to be increased in steps up to the maximum test voltage

level. Possible PD signal have to recorded.

The test voltage has to be present for a sufficient duration to enable a

reliable detection of fault spots and to confirm the dielectric strength.

Contents Cable withstand testing (new cables)

© 2012 SebaKMT – MADE in GERMANY 10

PD Measurement for quality assurance on newly installed systems

For different voltage types, the following test procedure is recommended:

0,1 Hz VLF - Stepwise increase of the test voltage up to 2 U0

- 10 minutes stress duration @ 2 U0 to test the

dielectric strength and operational readiness

20 – 300 Hz - Stepwise increase of the test voltage up to 2 U0

- 5 minutes stress duration @ 2 U0 to test the

dielectric strength and operational readiness

100 – 500 Hz DAC - Stepwise increase of the test voltage up to 1.7 U0

- VWD (multiple test 50 cycles) @ 1.7 U0 to test the

dielectric strength and operational readiness

Contents Cable withstand testing (new cables)

© 2012 SebaKMT – MADE in GERMANY 11

Test result Evaluation Recommendation

No detectable

PD

Test passed Requirement BNL < 100 pC (BNL = background noise level)

For cables with high attenuation (during calibration with 1000 pC, no end

reflection detectable) the PD measurement must be performed from

both ends.

Ui < Uo Test not passed Replacement of the affected accessories, new measurement on the new

installed accessory (confirmation of the PD fault spot only based on

visible installation errors, there are not PD tracks visible)

Entry into www.VDE-Kabeldatenbank.de)

For operational reasons, a temporary net operation after passed test

acc. to table 2 is permittable.

Ui between 1

and 1.7 Uo

Commissioning

of the cable

system possible,

but repeated

tests after 4 to 8

weeks

Result of the repeated measurement:

- If Ui 1.7 Uo the test is passed

- If Ui < 1.7 Uo the test is not passed

-Replacement of the affected accessories (visual inspection to identify

the installation errors and PD fault spots (Voids, de-lamination,

tracking/PD erosion) Entry into www.VDE-Kabeldatenbank.de)

In exceptional situations, at Ui between 1.2 and 1.7 Uo, the system can

be released for continuous operation. In this case annual repeated

measurements to control the stability of Ui have to be performed.

Contents Cable withstand testing (new cables)

Table 3: Evaluation and recommendation of measurement results

© 2012 SebaKMT – MADE in GERMANY 12

Case Procedure Requirements

New cables

(completely new installation)

- Sheath testing

- 0.1 Hz VLF test

alternatively

- PD measurement

Table 1

Table 2, Part 2.2

Table 3

Aged cables

(Fault elimination, partial

replacement, re-jointing, loop

insertion

- Sheath testing

- 0.1 Hz VLF test

alternatively

- PD measurement

Table 1

Table 2, Part 2.2

Table 3

The PD measurement has to be considered as a qualitative valuable part of the

commissioning test

Contents Final recommended procedures

Table 4: Recommendation for testing of MV cables

© 2012 SebaKMT – MADE in GERMANY 13

Contact

Name: Hein Putter

Telefon: 0049-1759361560

E-Mail: [email protected]

Thank you for your attention!

© 2012 SebaKMT – MADE in GERMANY 14

For more info please visit our website:

www.sebakmt.com © 2012 SebaKMT – MADE in GERMANY 15