Grain Bag Loader Set-up Instructions...OWNER’S MANUAL AND THOROUGHLY UNDERSTAND ... DOCUMENTATION...

Transcript of Grain Bag Loader Set-up Instructions...OWNER’S MANUAL AND THOROUGHLY UNDERSTAND ... DOCUMENTATION...

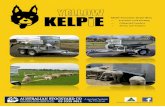

Grain Bag Loader Set-up Instructions

1N31088

Site Preparation

Lightly scrape the ground, removing weeds, sticks,stones and stubble that could penetrate the grain bagfrom the entire grain bag storage site. When removingdebris from the site, be careful not to loosen the ground.The grain bag storage site should remain as firm aspossible and free from debris to minimize grain bagdamage. Chemical can be sprayed on the site to controlweeds and grasses reducing nesting habitat for rodents.

NOTE: Maximum grade should be limited to grades lessthan 5%.

Grain Bag Placement

The grain bags should be positioned North - South on thestorage site. This will allow the grain bags to be exposedto the sun evenly.

NOTE: If the grain bags are positioned East - West, theSouth side of the grain bags will be exposed tothe sun the entire day and may lead tooverstretching and damage to the grain bags.

Start the grain bag on the lowest elevation of the storage site. This will aid in the loading of the grain bag and also assist in preventing any moisture from entering the bag both at the starting end and at the finishing end.

NOTE: It is NOT recommended to position the grainbags across a slope. This places added stresson one side of the grain bag and may cause thebag to overstretch. It also prevents water fromshedding away from and / or running along thelength of the grain bag.

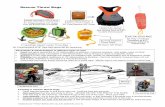

Grain Bag SpacingSide By Side

When storing grain bags side by side, space the grainbags a minimum of 18 ft. (5.48 m) apart. This will allowadequate space for the unloading equipment and trucksto travel between the bags during the unloading process.

In The Field

When storing grain bags in the field, position the grainbags in a line. This will help prevent animals (rodents andother pests) from using the bags as a shelter from theweather and from natural predators.

NOTE: Maintain adequate space (20-26 ft. (6.09-7.92 m)is recommended) between the grain bags for theunloading equipment and transport vehicles totravel between the bags.

� WARNING: Do Not place grain bags near or under power lines.

MAKE SURE ALL PERSONNEL HAVE READ THE OWNER’S MANUAL AND THOROUGHLY UNDERSTAND

SAFE AND CORRECT OPERATING PROCEDURES.

KEEP THE OWNER’S MANUAL AND ENTIRE DOCUMENTATION PACKET IN THE STORAGE

COMPARTMENT PROVIDED ON YOUR GRAIN BAG LOADER. THE OWNER’S MANUAL MUST BE AVAILABLE

FOR ALL OPERATORS. CONTACT LOFTNESS MANUFACTURING IF OWNER’S MANUAL IS NOT

PRESENT.

PRODUCT SUPPORTLOFTNESS MFG. 1 - 800 - 828 - 7624

FOR OPERATING INSTRUCTIONSwww.loftness.com

18 ft.(5.48 m)

BAG1

BAG2

BAG3

20 - 26 ft. (6.09 - 7.92 m)

BAG2

BAG1

2 Grain Bag Loader Instructions

In Depots

When storing grain bags in depots, position the bags inpairs approximately 5 ft. (1.5 m) apart and a minimum of18 ft. (5.5 m) between pairs. 5 feet (1.5 m) is adequatespace for the unloader to operate without damaging theadjacent grain bag. Maintaining an 18 foot (5.5 m)spacing between pairs will allow the transport vehicleadequate space to travel. Load the pair of grain bagsopposite from each other. When unloading the grainbags, this will allow the unloading equipment to finishunloading one bag and move directly over and start theunloading of the second bag.

Initial Set-up

The PTO driveline is shipped in the storage position. Theoperation hitch is also shipped in the upright storageposition.

NOTE: Lowering the operation hitch requires twopeople.

Remove the retaining clip (1) and pin and lower theoperation hitch.

NOTE: Remove the transport wheels (if equipped) at thistime. Store wheels in a convenient location awayfrom the work area.

Install the leveling ratchet (1) between the operation hitchand drive housing using the two pins (2) and retainingclips (3).� WARNING: Never attempt to make any

adjustments while the tractor engine is running or the key is in the “ON” position in the tractor. Before leaving the operator’s position, disengage power to the machine and remove ignition key.

� WARNING: The grain bag loader hitch is heavy. Always use two people to lower and raise the hitch.

1

1

2

2

3

3

Grain Bag Loader Set-up Instructions

3N31088

Initial Set-up (Cont’d)

Remove the retaining clip (1) and pin (2) from both PTOdriveline storage cradles. Remove the driveline (3).

Reinstall the pins and retaining clips into the storagecradles.

Raise or remove the PTO driveline guard (1). Removethe guard by removing the two retaining clips (2) and pin(3).

Install key (1) into the keyway of the grain bag loadershaft. Align the PTO driveline coupler (2) with the key andslide the driveline onto the shaft.

Install the cross bolt (3).

Tighten set screw (4) securing the PTO driveline to thegrain bag loader shaft.

NOTE: Check cross bolt (3) and set screw (4) fortightness after the first hour of operation.

Lower or install the PTO driveline guard.

Attach the safety chain from the PTO driveline shield tothe retaining clip (5).

� CAUTION: Periodically check all guards, shields and structural members. Replace or repair anything that could cause a potential hazard.

1

23

1

22

3

� CAUTION: Never use a steel hammer when connecting or disconnecting a PTO shaft.

1

2

5

4

3

4 Grain Bag Loader Instructions

Installing The Grain Bag Loader On The Tractor

Move the tractor away from the transport hitch, andreposition the tractor in front of the operation hitch.

Install an implement pin (1) (1-1/8 in. to 1-1/4 in. pin)through the operation hitch and tractor drawbar. Installretaining clip (2) securely fastening the grain bag loaderto the tractor.

Install the safety chain around the tractor drawbar (1) andhook the chain together (2).

Installing The Grain Bag

NOTE: Installing the grain bag requires two people.

Release the latch (1) and lower the grain bag lift.

Press the bottom (OUT) of the switch (2) to lower thegrain bag lift, and press the top (IN) the switch to raisethe lift.

Release the latch (1) and rotate handle (2)counterclockwise to lower the tray.

To raise the bag tray, engage the latch (1) and rotate thehandle clockwise to raise the tray.

� WARNING: Do not allow anyone to operate the machine until he or she has read the owner’s manual and is completely familiar with all safety precautions.

� WARNING: It is the operator’s responsibility to be aware of machine operation and work area hazards at all times.

1

2

1

2

� WARNING: The grain bag is heavy. Always use two people to place the grain bag on the tray.

2 1

1

2

Grain Bag Loader Set-up Instructions

5N31088

Installing The Grain Bag (Cont’d)

Unfold the grain bag.

NOTE: The bag stretch indicator markings of grain bagshould be positioned approximately 48 inches(121.92 cm) up on the side of the tunnel forbetter visibility by the operator.

Place the grain bag on the lift. Raise the lift to the top ofgrain bag loader housing.

Position a pickup in front of the grain bag loader. With thetwo people in the box of the pickup, slide the grain bagforward onto the grain bag loader housing.

Lower the grain bag lift and return to the storage position.

Place the bottom of the grain bag into the tray.

Slide the grain bag into the tray until it contacts the backof the tray.

Raise the bag pan until there is approximately 1 - 1/2 in.(38.1 mm) of space between the grain bag and bottomside of the grain bag loader housing.

NOTE: The space between the bag pan and the grainbag loader housing must be even from side toside for the grain bag to unfold correctly duringthe bagging operation. Adjust the bag pan ifneeded.

Inspect the rubber flap (1) on the grain bag loaderhousing. The rubber flap should be free and should coverthe grain bag in the tray. The rubber flap must hangoutside the tray.

NOTE: The rubber flap will help the grain from flowingback into the unused portion the grain bag.

1

1 - 1/2 in.(38.1 mm)

6 Grain Bag Loader Instructions

Installing The Grain Bag (Cont’d)

If the space is not the same as the winch side of the bagpan, loosen the two jam nuts (1) and adjust the turn-buckle until the space is equal from side to side. Tightenthe jam nuts.

Secure the grain bag to the grain bag loader with thecord. Position the cord so that the folds from the bag are3 inches (7.62 cm) behind the bag. Make sure one layerof the bag is underneath the cord. Pull the bag from theoutside folds (1).

NOTE: For longer life, store the bungy cord out of thesunlight when not in use.

Grain Bag Loader Positioning

NOTE: When loading the grain bags, move the loadingequipment and position it facing up the slope.Loading the grain bags up the slope will aid theoperator in braking the machine.

Move the grain bag loader into position facing up theslope. Stop the tractor and exit the tractor.

Place a marker at the starting edge of the grain bag andstretch it along the side of the tractor. Extend the markerout in front of the tractor and as straight as possible to thedesired length. Secure both ends of the marker.

NOTE: The marker will help the tractor operator tomaintain a straight line during the grain bagloading process. Unloading the grain bags ismuch more efficient if the bags are kept straightduring the loading process.

1

1

� WARNING: Stay away from overhead power lines.

� WARNING: Do not allow anyone to operate the machine until he or she has read the owner’s manual and is completely familiar with all safety precautions.

� WARNING: Do not allow persons under the influence of alcohol, medications, or other drugs that can impair judgment or cause drowsiness to operate or maintain the machine.

Grain Bag Loader Set-up Instructions

7N31088

Getting Started

During the loading process, the operator of the tractor isrequired to remain in the operator’s position at all times tostart and stop the PTO shaft and to keep the tractor /grain bag loader moving in a straight line with the grainbag. Position a person along side the grain bag loader(on the side away from the grain loading equipment) tomonitor the grain bag and to increase or decrease grainbag loader brake pressure as needed. The operator ofthe grain transport vehicle is required to remain in theoperator’s position at all times during the loading processto move the grain transport vehicle and monitor when thevehicle is empty.

Move the tractor and grain bag loader into position.

Getting Started (Cont’d)

Sealing The Grain Bag

Remove approximately 10 - 13 ft. (3.1 - 3.9 m) of thegrain bag from the grain bag loader, align the bag endsand fold the two outer edges of the bag. Start the foldapproximately 2 ft. (0.6 m) up on the bag and then fold ittowards the center of the bag. Place a board underneaththe folded end of the bag (the board should be longenough to reach the entire width of the bag), then place asecond board on top of the bag. With the folded end ofthe grain bag positioned between the two boards, fastenthe boards together, flatten the end, roll the sealed enddownward a minimum of three times around the boards,and fold it underneath the grain bag as far as possible 3 -5 feet (.9 - 1.52 m). As the grain bag is being filled, theweight of the grain will provide downward pressure on theseal and help create an additional seal to help preventmoisture from entering the grain bag.

� WARNING: Do not allow anyone to operate the machine until he or she has read the owner’s manual and is completely familiar with all safety precautions.

� WARNING: Do not wear loose hanging clothes, neckties, or jewelry. Long hair is to be placed under a cap or hat. These precautions will help prevent you from becoming caught in any moving parts on the machine.

� WARNING: Always have an operator in the tractor while the machine is in operation.

� WARNING: The machine requires an operator at all times. Never leave the machine running and unattended.

8 Grain Bag Loader Instructions

Filling The Grain Bag

Move the transport vehicle into position along side thegrain bag loader.

Extend the transport vehicle’s auger and center it abovethe hopper on the grain bag loader.

With operator of the tractor in the operator’s position,engage the PTO. Gradually increase the PTO speed to540 RPM.

Engage the transport vehicle’s auger and start loadinggrain into the hopper of the grain loader.

Check the bag seal as the grain begins to flow into thegrain bag to assure that fold remains underneath, andthat the grain is flowing to the end of the bag creating theseal.

Adjusting The Bag Pan HeightUsing the tractor’s hydraulics, raise or lower the machineso that the bag pan height is 8 to 10 inches (20.3-25.4cm) above the ground.

Getting Started (Cont’d)

Adjusting Brake Pressure

Turn the wheel clockwise to increase the brake pressure.

NOTE: Adjusting the brake pressure will help maintainproper filling of the grain bags, decreasing thechance of damage to the bag during the loadingand storage of the bag.

NOTE: The bag’s manufacturer provides markerlocations which will tell you what the bag’smaximum stretch should be.

It is recommended to operate the brake pressurebetween 400 - 700 PSI.

NOTE: DO NOT exceed 1200 PSI!

Grain Bag Loader Set-up Instructions

9N31088

Releasing Brake Pressure

Turn the wheel counterclockwise to decrease the brakepressure.

End of Bag Loading

NOTE: When the grain bag is full, seal the bag as soonas possible to eliminate the chance of excessmoisture entering the bag and damaging thegrain.

Leave approximately 10-13 ft. (3.1-3.9 m) of the grainbag empty for sealing.

NOTE: The entire 10-13 ft. (3.1-3.9 m) of unused bag isnot needed for sealing the bag but will aid in theunloading process.

Seal the grain bag with the same procedure used whenstarting a new grain bag. See “Sealing The Grain Bag” onpage 7.

Once the loaded grain bag has been sealed, it isrecommended that heavy items such as used tires beplace over the finished end to cover any loose parts ofthe bag end. Also inspect the grain bag for any loosecreases and tape them down.