Preliminary studies of seamless flux-cored wires stored in ...

Flux Cored

-

Upload

nikola-sambrailo -

Category

Documents

-

view

340 -

download

8

Transcript of Flux Cored

Flux cored wireIdeal combination of high quality and high

efficiency

Dipl.-Ing. IWE Michael ReimannProduct Manager

OERLIKON SwitzerlandWelding conference Lima, Peru 25.11.2005

2

Arrangement of flux cored wires

Seamless flux cored wire

Metal cored wire

Rutil flux cored wire

Basic flux cored wire

3

Flux cored wire classification Fluxofil 14 HD

DIN EN 758 T 46 2 P M 1 H5T : Flux cored wire46 : Yield and tensile Strenght2 : ToughnessP : Slag fast freezing slagM : Mixed gas 82% Ar 18% CO21 : All welding positionH5 : Diffusible hydrogen H2

ASME Code Sec.II/CAWS SFA 5.20 E 71T-1 M H4

E : Electrode7 : Yield, tensile Strenght and toughness1 : welding position H,F,VU,OHT-1M : Slag characteristic, shielding gasH4 : Diffusible hydrogen H2

4

Welding project with Fluxofil 14 HD

5

Welding project with Fluxofil 14 HD

WPS Fluxofil 14 HD with weldycar

6

WPS Fluxofil 14 HD with weldycar

Root pass on ceramic backing

7

WPS Fluxofil 14 HD with weldycar

Front view on round ceramic backing

8

WPS Fluxofil 14 HD with weldycar

Fixation the weldycar

9

WPS Fluxofil 14 HD with weldycar

Root pass on ceramic backing

10

WPS Fluxofil 14 HD with weldycar

CurrentI=225AVoltageU=24VWelding speedVs=13cm/minWire speed8,0m/minWeld deposit3,5 Kg/h

Cap welding

11

WPS Fluxofil 14 HD with weldycar

Nahtvorbereitung Lagenaufbau

Schweißparameter

Joint preparation

Welding parameters

Layers set up

12

WPS Fluxofil 14 HD with weldycar

Weldycar fixed in transver position

13

WPS Fluxofil 14 HD with weldycarTransver welding on ceramic in action

14

WPS Fluxofil 14 HD with weldycarNahtvorbereitung Lagenaufbau

Schweißparameter

Joint preparation

Welding parameters in transver position

Layers set up

15

Fluxofil 14 HD in project operation

16

Fluxofil 14 HD in project operation

17

Fluxofil 14 HD in project operation

18

Fluxofil 14 HD in project operation

19

Flux cored wire application tank building

20

Flux cored wire application tank building

Joint preparationVessel

21

Fluxofil 14 HD Application pipe junction

22

Flux cored wire application hall truss

23

Flux cored wire application exhibition hall

24

Fluxofil 14 HD in all welding position

25

Calculation comparison between solid and flux coredwire

Schweißverfahren MAG- FülldrahtMAG- MassivdrahtSchweißzusatz Fluxofil 14 HD

Ausführungen HalbmechanisiertNahtvorbereitungLagenaufbau

Lagenzahl/RaupenzahlSchweißpositionDrahtdurchmesser (mm)Schweißstrom I (mm)Schweißspannung U (V)Schweißgeschwindigkeit Vs (cm/min)Abschmelzleistung SG (Kg/h)Schweißzeitfaktor ED (%)Lohnsatz LS (Euro/h)Schweißzusatzpreis SZP (Euro/Kg)Schutzgaspreis SP (Euro/l)Schutzgasmenge SM (l/min)Gemeinkostenfaktor GKF (%)

Carbofil 1

1,545

Halbmechanisiert

PF1,2140

300

3L/3R

130,930.0115

1813

3L/3RPF1,221023263,045133,30.0115300

12 90°

26

Calculation comparison between solid and flux coredwire

Schweißverfahren MAG- Fülldraht MAG- MassivdrahtSchweißzusatz Fluxofil 14 HDAusführungen HalbmechanisiertNahtvorbereitungLagenaufbau

Lagenzahl/RaupenzahlSchweißnahtgewicht SNG (Kg/m)

Hauptzeit Th ( min/m )Hauptzeit + Nebenzeit T ( min / m )

Schweißzusatzkosten KZ (Euro/m)Schutzgaskosten KS(Euro/m)

Lohnkosten KL (Euro/m)Gemeinkosten KG (Euro/m)Fertigungskosten KF (Euro/m)

Gesamtkosten KGe (Euro/m)

Ersparnis Euro/m

Ersparnis %

Carbofil 1halbmechanisiert

3L/3R1,20

48,00106,67

1,12

94,43

0,87

23,1169,3392,44

3L/3R1,20

24,0053,33

3,960,87

11,56

45,94

34,6746,22

51,05

43,38

12 90°

27

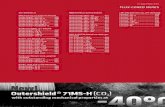

Fluxofil 14 HD - Data sheet -

Standards: DIN EN 758 T 46 2 P C 1 H5 / T 46 2 P M 1 H5AWS/ASME SFA-5.20 E71T-1 H4 / E71T-1M H4

Applications and properties:The higher fil ling degree of FLUXOFIL 14 HD results in higher current carrying capacity and deposition rate. Weldingspeed is thereby essentially increased which leads to a saving of time and reduction of costs. It can be used in allpositions with only one setting of welding parameters (24 volts, wire feed = 9m/min, wire dia. 1,2 mm). FLUXOFIL 14HD is employed in manual welding, as well as in fully mechanized welding by means of the orbital welding unit CI-TOTRACK OSG-O1 or the vert ical welding set CITOTRACK VSG-O1. It is preferably used under mixed shield ing gasand is characterized by low spatter loss, good slag removal and finely rippled, pore-free welds without undercuttinginto the base metal.Materials:

EN-Designation DIN-Designation EN-Designation DIN-/AWS-DesignationS185 St 33 S235 to S355 St 37.0 to St 52.0S235 to S355 St 37-2 to St 52-3 P235 to P355 St 37.4 to St 52.4P235 St 35.8 P265 St 45.8L210 to L415 StE 210.7 to StE 415.7 L360 to L485 StE 360.7 TM-StE 480.7 TML290, L320 StE 290.7TM, StE 320.7TM P235GH, P265GH HI, HII

X42 to X65 P295GH 17 Mn 4StE 255 S(P)275 to S(P)460 StE 285to StE 460A, B, D, E AH 32 to EH 36GS-38 GP240R GS-45

Please observe admissible operating temperature for welding consumable and base material.Qualification tests: TÜVApprovals: DB, ABS, DNV, GL, LRSIndications as to approvals, see appendix.Analysis of all-weld metal (typical values in %):

C Si Mn0,05 0,55 1,2

Mechanical properties of all-weld metal (single values are typical values):Impact energy ISO-V [Joule]Heat treatment Yield strength

[N/mm²]Tensile strength

[N/mm²]Elongation

A5 [%] -20 °CAW >460 550 650 >22 >80

AW = as-weldedChemical composition and mechanical properties apply to the use of shielding gas:

DIN EN 439 - M21 (82 Vol. % Ar + 18 Vol. % CO2)Shielding gas as to DIN EN 439: M21 (ARCAL 21), C1 (carbon dioxide)Consumption: 12 15 l/min for Ø £1,6 mmWelding parameters and deposition rate, see: B 131

Form of delivery:Wire cage reel K300 (16 kg)

Wire diameters [mm] 1,0 1,2 1,6Further forms of delivery on request.

Type of current/Polarity/Welding positions:

Rutile tubular cored electrode for MAG-welding, with fast-freezing slag

FLUXOFIL 14 HD

28

Fluxofil 14 HD - advantages -

Easy handling in all welding position

- High deposition rate in all welding position

- To use in fully mechanized welding processes

- One side welding on ceramic backing

- Less spatter during the welding process

- Easy slag removal

- Very good penetration

- Seamless wire

- Less fume and less hydrogen content

- High efficiency

29

Application Metal cored wire Fluxofil M8

30

Metal cored wire Fluxofil M8 - advantages -

- Easy handling in H and F welding position

- Seamless wire

- Less fume and less hydrogen content

- High deposition rate in H and F welding position

- To use in fully mechanized welding processes

- One side welding on ceramic backing

- Less spatter during the welding process

- Very good penetration

- High efficiency

- Very good ristriking

31

Application Metal cored wire Fluxofil M8

32

Application Metal cored wire Fluxofil M8

33

Application Metal cored wire Fluxofil M8

34

Application Metal cored wire Fluxofil M8

35

Application Metal cored wire Fluxofil M8

36

Variable applications with flux cored wires

37

Variable applications with flux cored wires

38

Variable applications with flux cored wires