Fluid Power, Control, Actuation, Monitoring and ...

Transcript of Fluid Power, Control, Actuation, Monitoring and ...

Aerospace Marine Defense W IRM

-~ ..

Fluid Power, Control, Actuation, Monitoring and ElectromechanicalProducts on the Boeing 737-600, -700, -800, -900

The third-generation Boeing 737, corn- engines, the takeoff noise level is below nance, and maximum commonality withprises a family of jetliners designed to stringent new noise requirements. the existing fleet of 737s. This expan-be among the quietest and most fuel- sion is built on the 737 tradition of lowefficient aircraft in the world. They inoor- The new 737s also feature a fully inte- acquisition and operating costs; simplic-porate the latest technology in light- grated flight management system (FMS) ity, reliability, and ease of operation;weight materials, systems and engines, for automatic control and guidance of market versatility; and passenger satis-The result is 20 to 30 percent less fuel the aircraft. The FMS assures that the faction. Only the 737-600, -700, -800consumption per seat. aircraft flies the most efficient route and and -900 meet these requirements for

flight profile for reduced fuel consump- the entire 100 to 189-seat market withThis new high technology family of 737s tion, flight time and crew workload, while four sizes of the same airplane.offers better fuel economy, reduced linking together digital processors thatnoise levels, and a fully integrated flight control navigation, guidance and engine

* management system. Each new 737 is thrust. Vickers Aerospace Marine Defensepowered by General Electric CFM56-7 Group, a recognized leader in theengines. Four versions of the engine The 737-600, -700, -800 and -900 offer design and manufacture of advancedare available, rated at 20,000 pounds of additional range and altitude capability, power and motion control equipment,thrust for the 737-600 to 26,200 pounds faster speed, lower fuel burn and noise, suppliers numerous products on theof thrust for the 737-900. With the new greater reliability, simplified mainte- Boeing 737-600, -700, -800 and -900.

G5-22A * 1/99

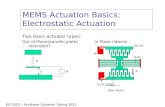

The Hydraulic SystemThe 737's hydraulic systems are adapted The Hydraulic System Simplifiedfrom the highly successful 737 system.Three independent sub-systems desig- -_tnated System A, System B, and standby,deliver hydraulic fluid at a pressure of3025 psi (209 bar) to operate flight con-trols, flap systems, thrust reversers, land-ing gear and brakes. Engine Pump Motorpump Engine Pump Motorpump

PV3-240-18 MPEV3-056-7 PV3-240-18 MPEV3-056-7Hydraulic power for systems A and B isgenerated by a Vickers Fluid Power Divi-sion engine-driven pump (EDP) and anAC electric motor-driven pump (ACMP) in stand-byeach system. A bent axis motor provides Motorpump1 65W01 020hydraulic power for the trailing edge flapdrive system.

Vickers Sterer Division, provides hydrau- Transfer valve 4 Each Pressure Sensitive 4 Eachlic controls including pressure sensitive 69660-1 Hydraulc So0eno0 d 67940-2 450H0-1flow limiting, solenoid and transfer valves.

Fluid systems monitoring products pro-duced by the Vickers Tedeco Division in-clude magnetic chip collectors, liquid lev- NG. MG Actuation Auto Pilot Trailing Edge Flap Auto PilotNG. Steering Control System Drive Motor Control Systemel indicators and float activated level sen- MF -152-13sors.

Systems A and B operate the primaryflight controls (ailerons, elevators andrudder). If both systems are unavailable, PTUthe ailerons and elevators are operated Other Control Other Controlby mechanical back-up system; the rud- Functions Functionsder would be powered by the standbysystem .

In addition to its primary control functions,System A provides hydraulic power to thelanding gear, nose wheel steering, alter-nate brakes, inboard flight spoilers,ground spoilers and left engine thrust re-verser System B, in addition to its prima-ry functions, provides hydraulic power tothe brakes, leading and trailing edge flapsystems, outboard spoilers and the rightengine thrust reverser The standby sys-tem is normally off and serves as a back-up to System A and B to power the rud-der, leading edge flaps and slats (exten-sion only) and the thrust reverser.

-. 3~~w-

Summary xSterer Division

CTY PERMODEL NO. DESCRIPTION A/C67940-2 Pressure Sensitive Flow Limiter 1

69660-1 Hydraulic System Transfer Valve 145080-1 Hydraulic Solenoid ValveTrail 8 67940-2

Pressure SensitiveFlow LimiterThis device limits the amount of down-stream flow to a very small amount un-til the upstream system pressurereaches 2500/2700 psi (1 72/186 bar).When system upstream pressurereaches the set point, the valve opensto permit 10/20 gpm (38/76 Umin.)downstream flow. The valve (PN67940-2) is insensitive to downstreampressure and will remain open as longas the upstream pressure exceeds theset point.

69660-1 * Two pressure inlet ports and oneHydraulic System pressure outlet port. One inlet re-

Transfer Valve turn port and two outlet return ports.* Pilot solenoid operated to the alter

This valve provides flow to the landing nate position. The solenoid hasgear system for gear retraction and dual parallel coils for redundancy.nose wheel steering from either hy-draulic systems. * Intersystem leakage control to keep

the two hydraulic systems sepratedThe valve incorporates the following at all times. 45080-1features:458 1

* Spring and pressure loaded to the * Rip stop construction. Hydraulic Solenoid Valvenormal position. * Position indication.

This is a normally closed (dual coil) so-lenoid operated 3-way valve used as afirst stage pilot control valve. This hy-draulic solenoid valve is capable ofmillions of cycles and is used on theBoeing 737 in numerous locations.

R " for, t sIT *ml Rffi The solenoid (PN 45080-1) features adual parallel electrical coil. If one ofthe coils should suffer an open circuitthe valve will still function.

6355Stabilizer Trim Motor ActuatorThis actuator consists of a brushless DC motor driving a two stage gear train,providing the required torque and speed to make the trim stabilizer Containedwithin the actuator are the electronics necessary to convert three phase, 115/200,400 Hz, AC power to DC voltage required for the brushless DC motor operationas well as the control, power drive, and monitor circuitry. The digital control, fea-

- -| _ jturing an Intel 87C196 microprocessor, offers a low part count, simplified ap-I I I I I T | | l l | | proach to motor control, fault monitoring, and detection. The power recirculating

I || |] || |design avoids returning power to the source and increases the efficiency of theunit.

1 65W01022Standby MotorpumpAuxiliary hydraulic power is providedby a 3.7 gpm (14 Umin.), 2700 psi _v(186 bar), A.C. Electric Motor Pump _dry weight is 23.5 lbs. (10.66 kg).

SummaryFluid Power Division

CITY PERMODEL NO. DESCRIPTION A/CMPEV3-056-7 AC Electric Motor-driven Pump 2PV3-240-18 Engine Driven Pump 2MF1-152-13 Trail Edge Flap Drive Motor 1165W01022 Standby Motorpump 1

1 A6166 2E2699 2D2492, 202738, 2D2519Magnetic Chip Collector Float Activated Level Sensor Liquid Level IndicatorThe 1A6166 magnetic chip collector is This Tedeco sensor is located in the The liquid level indicators provide alocated in the lubricating fluid flow of APU of the airplane, and senses three viewing port that allows the operator tothe Auxiliary Power Unit (APU). It traps levels of the fluid - Full, Add, and Low measure fluid level without power.ferrous wear debris by magnetic at- - in the Auxiliary Power Unit. The unit The indicator incorporates a high-con-traction. This prevents the particles interfaces with the APU control panel, trast lens for improved viewing. Thefrom causing damage to the compo- and has internal redundancy for in- 2D2492 is located on the engine oilnents. The analysis of these particles creased reliability . tank. The 2D2738 and the 2D2519may provide an early warning of ab- are located on the Auxiliary Powernormal wear or breakdown of compo- Summary Unit,nents within the APU, thus increasing Tedeco Divisionits life.

QTY PERMODEL NO. DESCRIPTION A/C1A6166 Magnetic Chip Collector 22E2699 Float Activated Level Sensor 22D2492, 2D2738, 2D2519 Liquid Level Indicator 61 B7363-1 Electric Chip Detector for CFM56-7 Engines 2

A~~~~~~~ I

MPEV3-056-7AC Electric Motor-driven PumpAuxiliary hydraulic power for inflight op- operate at inlet pressures down to 5.0erations and ground operations is pro- inches of mercury absolute, and pro-vided by two fluid-cooled AC electric mo- vides a continuous source of coolingtor-driven, 2700 psi (186 bar) variable flow for the electric motor. The unit pro-MF1l-152-13 displacement, pressure compensated in- duces 6.0 gpm (22 Umin.) at 2700 psi

Trailing Edge Flap Drive Motor line piston pumps. The electric motor (186 bar). Displacement is 0.452 cu.converts aircraft electrical power to rotary in/rev. (7.40 ml/rev). Motorpump dryTrailing edge flap actuation is provided shaft motion to drive the inline piston weight is 36.25 lbs. (16.44 kg).

by one Vickers 3000 psi (207 bar), pump. An integral boost pump super-constant displacement, nine-piston, bent- charges the fluid pressure available ataxis hydraulic motor. Displacement is the piston pump inlet which allows the1.52 cu. in. /rev. (24.91 ml/rev). Motor piston pump toweight is 13.21 lbs. (5.99 kg).

PV3-240-1 8Engine Driven Pump The PV3-240-18 incorporates the fieldHydraulic power for both hydraulic sys- proven, reliable PV3-240-2 and -10tems is supplied by two 37.5 gpm (142 pump rotating components together withL/min.), 3750 rpm, variable displace- improved reliability and weight reductionment, 3025 psi (209 bar), pressure com- technology developed from the B-777pensated inline piston pumps. Dis- engine driven pump program. It is de-placement is 2.4 cu. in./rev. (39.33 ml/ signed to fit in the envelope of therev). Pump dry weight is 32 lbs. (14.5 PV3- 160-4 pump used on earlier Boe-kg). ing 737s. This model incorporates a

one-piece housing, to eliminate remov-als due to external leakage at partingline seals.

The Vickers Aerospace Marine Defense GroupThe Vickers Aerospace Marine Defense Group and Aeroquip Corporation offer a synergistic multi-technology capability serving aaerospace, marine, defense markets worldwide. The result is a new dimension of system capabilities and quality products from initial Wconcept throughout life cycle.

A. Manufacturing* Sales * Service Centers

Global locationsVkkers Incorporated Vickers Systems Divison Vckers Systems Divison Vickers Systems Division Vckers Systems DmsronFluid Potwer Division Aeroquip Vickers Limied Aeroguip Vickers Intematonal GntH Aeroquip Vickers S PA. Aeroquip-Vckers S.A.5353 Highland Drive Aerospace Manne Defense Group Aerospace Marne Delerns Group Aerospace Marine Defense Group Aerospace Marine Delense GroupJacksion, MS 39206-3449 Larchwood Avenue Am Joseph 16 Via Monzese 34 La Parc Club des Septs DeniersUSA Bedhatplon 61273 Wehrhnei Vignade, Milan 20060 Bat2Phone (601) 981 2811 Hampshire P09 3QN Germany Italy 78, Cheirn des Septs-DeniersFax: 60t) 987-5255 England Phone: (49) 6081-1030 Phone: (39)02 95058-222 31200 Toulouse

Phone: (44)1705466451 Fae: (49(6081-103229 Fax: (39)02 9566730 FranceFax: (44) 1705-492400 Phone (33) 5 61573-333

Fax: (33)551578-m

TOKIMEC, Incorporated Vickers, Incorporated Vickers. Incorporated Vkckers Incorporated Vkckers, IncorporatedAsro & Deense Division Tedeco Division Electromncdahnal Division Sterer Division Aerospace Marine Defense Group16-46, Minam-Kajnatuz-Chome 24 E. Glenolden Ave. 36275 Paterson Ave. 4690 Colorado Blvd, 49A LPL Plaza 124 Altaro StreetOhta-Ku, Tokyo 144 Glenolden, PA 19036 Grand Rapids, Ml 49558 Los Angeles CA 90039 Salcedo Village, Makae City

Japan USA USA USA PhilippinesPhone (03)3737-8641 Phone (610)583-9400 Phone: (616)949-1090 Phone: (818(490-0200 Phone: (63)28160148Fax: (03) 3737-8S68 Fax (610) 583-3985 Fax (616) 949-2744 Fax: (818) 241-3772 Fax: (63)2 845 3348

http://wwnvickers-systems.com*For the sales otffce nere you contactany of the above Vickers addresses.

© 1999, Vickers, Incorporated, All rights reserved.