Finite Element Modelling for Elastic Plastic Stress ... · Finite element elastic-plastic analysis...

Transcript of Finite Element Modelling for Elastic Plastic Stress ... · Finite element elastic-plastic analysis...

International Conference on Challenges and Opportunities in Mechanical Engineering, Industrial Engineering and Management Studies 188

(ICCOMIM - 2012), 11-13 July, 2012

ISBN 978-93-82338-03-1 | © 2012 Bonfring

Abstract--- The focus of this paper is on the use of ANSYS software for elastic-plastic stress analysis. NAFEMS

(International association for the Engineering analysis community) India is proposing a benchmark for nonlinear

finite element analysis: Material non-linearity. The objective of this study is to present accurate target solutions to

this test problem. The Finite Element Model is developed using ANSYS. It is validated using another NAFEMS

Benchmark namely a thick walled cylinder under internal pressure for which target solutions are available in the

NAFEMS document [1]. Using this Finite Element Model, Target solutions to the test problem are graphically

presented and discussed. A number of agencies in India and worldwide will be contributing target solutions to the

same problem. This will be consolidated before NAFEMS issuing the Benchmark.

Keywords--- Elastic Plastic Stress Analysis, Non-linear Finite Element Analysis, Material nonlinearity,

Rectangular Plates with Circular cut-out, Linearly Varying In-Plane Tensile Load

I. INTRODUCTION

HE use of thin plates is very common in many engineering applications, such as offshore platforms, ship decks

and hulls, box sections of bridge girders and aircraft industries. There is often a need for cut-out in the plates for

services, inspection and maintenance, etc. The presence of these holes changes the stress distribution and cause

reduction in its strength and buckling characteristics. Analysis of such systems was mainly carried out for axial

compressive forces resulting in instability [2] and elasto-plastic buckling in the system [3, 4], axial tensile loading to

study on Stress Concentration Factors [5] and non-linear behaviour subjected to shear loading [6]. While in this case

the analysis is carried out in axial tensile loading resulting in Materials to exhibit nonlinearities as loads and

deformations increase.

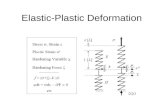

When ductile metals are loaded beyond elastic range, the initial linear stress response will give way to a

complicated nonlinear response, characterized by a much-reduced modulus and different stress behaviour along load

and unloading path. Finite element elastic-plastic analysis is no longer linear, but a set of nonlinear equations that

needs to be solved iteratively. Typically, we divide the applied load into small increments so as to have a better

numerical performance.

The Finite Element Model is developed using ANSYS software, a pioneer in the discipline of nonlinear analysis.

ANSYS has both penalty-based and Lagrangian multiplier based mixed u-P formulations. Lagrange multiplier based

formulation is available in the 180-series solid elements, and is meant for nearly incompressible elasto-plastic,

nearly incompressible hyperelastic and fully incompressible hyperelastic materials [7]. ANSYS employs the

"Newton-Raphson" approach to solve nonlinear problems. The "top" level consists of the load steps that we define

explicitly over a "time" span. Within each load step, we can direct the program to perform several solutions

(substeps or time steps) to apply the load gradually. At each substep, the program will perform a number of

equilibrium iterations to obtain a converged solution.

Bhavesh Govind Naik, Department of Mechanical Engineering, Dayananda Sagar College of Engineering, Bangalore.

Shivashankar R. Srivatsa, Department of Mechanical Engineering, Dayananda Sagar College of Engineering, Bangalore.

PAPER ID: MED32

Finite Element Modelling for Elastic Plastic

Stress Analysis: Development, Validation and

Case Study Bhavesh Govind Naik and Shivashankar R. Srivatsa

T

International Conference on Challenges and Opportunities in Mechanical Engineering, Industrial Engineering and Management Studies 189

(ICCOMIM - 2012), 11-13 July, 2012

ISBN 978-93-82338-03-1 | © 2012 Bonfring

II. NAFEMS BENCHMARK

The Finite element modelling for elastic plastic stress analysis using ANSYS software is validated using

NAFEMS Benchmark namely a thick walled cylinder under internal pressure for which target solutions are available

in the NAFEMS document [1].

A thick walled cylinder of internal radius and external radius is subjected to a

uniform internal pressure (fig 1). Exploiting Symmetry, one octant of the cylindrical tube has been modelled. The

sector is discretised using Plane 183 element (8-noded quadrilateral) in ANSYS. A typical mesh generated is shown

in fig 2. Axisymmetric boundary conditions are enforced along lines AB and CD. The internal pressure is applied

along AC. The material properties of the mild steel cylinder are listed in table 1. Bilinear uniaxial stress strain curve

for an elastic perfectly plastic material used in the analysis is shown in fig 3.

Figure 1: Thick Walled Cylinder

Subjected to Internal Pressure

Figure 2: Finite Element Model of

an Octant of Cylinder

Figure 3: Bilinear Uniaxial Stress

Strain Curve for an Elastic Perfectly

Plastic Material

Figure 4: Stress Distribution for a Cylinder under Internal Pressure

A maximum pressure of 160 N/mm2 is applied in steps. The predicted hoop stress (σyy) and Radial stress (σxx)

along the x-axis are plotted in fig 4. These results arefound to closely match with the target solutions reported in the

NAFEMS document [1].

To study the effect of Tangent modulus on the behavior of the cylinder, computations are performed with

Tangent Modulus =1250 N/mm2.The internal pressure is applied in load steps of 80, 100, 120, 140, 160 and 165

N/mm2. The radial, hoop and von Mises stresses are plotted in fig 5.

-1

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1

0.5 0.6 0.7 0.8 0.9 1

Case 1 = 80 N/mm2

Case 2 = 100 N/mm2

Case 3 = 120 N/mm2

Case 4 = 140 N/mm2

Case 5 = 160 N/mm2

P / P max = 0.5

P / P max = 0.625

P / P max = 0.75

P / P max = 0.875

P / P max = 1.0

σxx/σo

σyy/σo

σxx/σo

σyy/σo

Radius r/b

max

International Conference on Challenges and Opportunities in Mechanical Engineering, Industrial Engineering and Management Studies 190

(ICCOMIM - 2012), 11-13 July, 2012

ISBN 978-93-82338-03-1 | © 2012 Bonfring

Figure 5: Plot of Radial, Hoop and Von Mises Stress from Inner Radius to outer Radius for Various Load Steps of

80,100,120,140,160 and 165 N/mm2.

Comparison of figure 4 and figure 5 shows the significant influence of the tangent modulus on the stress

distribution.

III. NAFEMS INDIA PROPOSED BENCHMARK

A rectangular plate of uniform thickness with a central circular hole as shown in fig 6 is fixed at one end and

subjected to maximum axial tensile stress of 272 N/mm2 at other end. The material properties of the rectangular

plate are listed in table 2. Bilinear uniaxial stress strain curve for an elastic plastic material used in the analysis is

shown in fig 7. The objective is to perform elastic-plastic stress analysis and to report maximum equivalent plastic

strain and stress and their locations.

Figure 6: Proposed Bencmmark Problem Figure 7: Bilinear Isotropic Hardening Material for

Proposed NAFEMS Benchmark

Table 2: Rectangular Plate Material Properties: No. of Plane 183 Elements = 1144

Elastic Modulus, E 200000 N/mm2

Poisson's ratio, ν 0.3

Yield Stress, σY 400 N/mm2

Tangent Modulus, ET 1250 N/mm2

Radial

Hoop

von Mises

P =80 N/mm2

P =165 N/mm2 P =160 N/mm2

P =120 N/mm2

P =140 N/mm2

P =100 N/mm2

International Conference on Challenges and Opportunities in Mechanical Engineering, Industrial Engineering and Management Studies 191

(ICCOMIM - 2012), 11-13 July, 2012

ISBN 978-93-82338-03-1 | © 2012 Bonfring

Figure 8: FE Mesh of Proposed Benchmark

Considering symmetry, one half of the problem has been modelled. Plane183 elements (8-noded quadrilateral)

that deal with both small and large strains, with a variety of material options including elasto-plasticity, have been

used to create FE model. Plasticity is defined by yield stress and the elastic-plastic tangent modulus. A typical finite

element model is shown in fig 8. One end is rigidly fixed with all DOF and other end is subjected to axial load,

Symmetric boundary condition is applied across horizontal centre line.

Initial Pressure of 110 N/mm2 initiates the plate to yield. Load is then increased in steps to 130, 150, 170, 190,

210, 230, 250 & 272 N/mm2. The variation of von Mises equivalent stress and the equivalent plastic strain along the

hole boundary are presented in figures 9 and 10.

Figure 9: Rectangular Plate with Hole stress Distribution

0

100

200

300

400

500

600

0 5 10 15 20 25 30 35 40

vom

Mis

es s

tres

s

Node path on circumference of hole

P= 110 MPa

P=150 MPa

P=190 MPa

P=230 MPa

P=250 MPa

P=272 MPa

International Conference on Challenges and Opportunities in Mechanical Engineering, Industrial Engineering and Management Studies 192

(ICCOMIM - 2012), 11-13 July, 2012

ISBN 978-93-82338-03-1 | © 2012 Bonfring

Figure 10: Rectangular Plate with Hole Equivalent Plastic Strain Distribution

IV. CONCLUSION

Finite element modelling using ANSYS is validated for elastic plastic stress analysis using NAFEMS

benchmark. It is then applied to provide target solutions to a test problem of a benchmark proposed by NAFEMS

India. The Maximum Equivalent stress of 547.91 N/mm2 and maximum plastic strain of 0.11787 is observed at

maximum pressure of 272 N/mm2. The results reported are believed to be accurate. Results from other contributors

preferably using different FEA software will be compared with these results before issuing a new benchmark.

REFERENCES

[1] E. Hinton (Editor). NAFEMS - Introduction to Non Linear finite element analysis, NAFEMS, Glasgow, UK,

1992.

[2] M. Aydin Komur, Mustafa Sonmez, Elastic buckling of rectangular plates under linearly varying in-plane

normal load with a circular cutout, Mechanics Research Communications, 2008, 35, 361–371.

[3] M. Aydin Komur, Elasto-plastic buckling analysis for perforated steel plates subject to uniform compression,

Mechanics Research Communications, 2011, 38, 117–122.

[4] Khaled M. El-Sawy, Aly S. Nazmy, Mohammad Ikbal Martini, Elasto-plastic buckling of perforated plates

under uniaxial compression, Thin-Walled Structures, 2004, 42, 1083–1101.

[5] J. Rezaeepazhand, M. Jafari, Stress concentration in metallic plates with special shaped cutout, International

Journal of Mechanical Sciences, 2010, 52, 96–102.

[6] Emanuele Maiorana, Carlo Pellegrino, and Claudio Modena, Non-linear analysis of perforated steel plates

subjected to localised symmetrical load, Journal of Constructional Steel Research, 2009, 65, 959–964.

[7] Grama R. Bashyam, ANSYS Mechanical - A powerful Non-Linear Simulation Tool, ANSYS Inc., 2007.

[8] Carlo Pellegrino, Emanuele Maiorana, and Claudio Modena, Linear and non-linear behaviour of steel plates

with circular and rectangular holes under shear loading, Thin-Walled Structures, 2009, 47, 607–616.

[9] Juan José del Coz Díaz, Fco. Suarez Domínguez, Paulino J. Garcia Nieto, Non-Linear Analysis of Base Plates

in Automated Storage Systems, Proceedings of International ANSYS User‘s Conference, 2004, 55.

0

0.02

0.04

0.06

0.08

0.1

0.12

0.14

0 5 10 15 20 25 30 35 40

Pla

stic

Str

ain

Node path on circumference of hole

P= 110 MPa

P=150 MPa

P=190 MPa

P=230 MPa

P=250 MPa

P=272 MPa