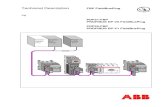

Final Report FBP

description

Transcript of Final Report FBP

1 1H. Schellens (piezo-expert and owner of Heinmade, supplier of piezo cerramics)Ken (Chinese component expert, employee of J&R electronics in China)J. Kunzmann (piezo-expert and R&D Manager at Smart Material GmbH)D. Goossens (industrial design professional and owner of Bureau CQ)A. Bouman (industrial design professional and owner of Bureau CQ) M. Taya (piezo-expert and researcher at University of Washington)R. van Schaijk (piezo-expert and researcher at High Tech Campus)M. Pot (industrial design professional and owner of Bureau CQ)D. Roosegaarde (artist and owner of Studio Roosegaarde)A. Cottaar (science-expert and researcher at TU/e)O. Tomico (user expert and researcher at TU/e)P. de Boom (Owner of 0900-Design)M. Verkuijl (Sustainability expert)

theme & coachacross realitiesv.o. winthagen

in collaboration withBureau CQ

Binckhorstlaan 362516 BE Den Haag

02|02|09 15|06|09

Energy Harvesting TableMarco van Beers | s060152

2 23 3“Simplicity is the ultimate sophistication.”

- Leonardo da Vinci

2 23 3Introduction

Visions

Objective

Process

Design

Technology

Users

Life Cycle Assessment

References

CD with appendices

4

6

9

11

15

29

39

45

55

57

4 45 5mentioned facts, although this is obvi-ous and logically there’s no such prod-uct yet. Tables are, currently, still just a surface where one can place objects on, or work at. Although some attempts are made, for example the Microsoft Surface (big touchscreen) and the Panasonic’s Intelligent Table. Both have more in com-mon with a tablet PC then with a table.This product idea connects to my vision in a way that it addresses the possibil-ity to explore a new area of interested, namely energy harvesting. Moreover it is a logic outcome of a combination of facts. The energy harvesting table also allows me to put the three keywords of my vision in practice. The project created a functional, minimal product which al-lows otherwise lost energy be reused in a practical, simple way. In general I

The project ‘Energy Harvesting Table’ was shaped during my internship at Bureau CQ when they offered me the opportunity to start my own project. The idea of an energy harvesting table was created after exploring for products which never had undergone an evolution. Products like tables, beds, curtains and many others. While I was brainstorming about table I noticed how much I actually touched the table. Looking to other people at tables I noticed they did the same thing. All this mechanical energy, generated by the im-pacts of persons and products, is basi-cally lost in the table. Interesting would therefore be if this energy could be cap-tured and transformed into electrical energy. The lost energy can be more ef-ficiently used by powering applications. This is logically derived from previous

INTRODUCTIO

N

4 45 5wanted to look if I’m capable of making a new project relevant, consistent and logically.

At first the table seems an ideal sustain-able product, which is communicated by the idea of energy harvesting and materi-al use. However, the product (at product level) as it is now is not more sustainable but it can be when improved (explained at the chapter ‘life cycle assessment’). This raises the question on what is more important, the fact that it should be a more sustainable product or the number of people you reach with its sustainable image because not everyone is busy with sustainability.

The project is a direct collaboration with Bureau CQ, a small industrial design

company suited in The Hague which fo-cusses mainly on domestic appliances. They can manage the entire process from idea to product, including production. They’ve done successful projects for Princess, Vrumona (Dutch dealer of Pep-si and Royal Club), KLM and many oth-ers. Recently they opened a new Studio in China where they can fully supervise engineering and production of their de-signs. They found the project idea, com-mercially, interesting and wanted to act as a support during this project. Bureau CQ main interests lies at getting more knowledge about other technologies and getting a commercially interesting concept. For me this is a good opportu-nity to experience a direct collaboration with the business world and a design company.

6 67 7Vision Marco | Design, in my view, should be about three key words: Consistency, Relevancy and Logic. These three key-words should come back in the final product and the decisions which are made. I try to do this as much as pos-sible, although because I’m still growing as a designer it will not always be ap-plied successfully.

Currently my weakness lies at electron-ics, I know the basics and can apply them but I find it hard to create more complex circuits and integrate them into a prod-uct. My stronger points are my visual and conceptual skills when combined can create interesting output. I have ac-quired a more practical way of designing where I try to be hands on and down to earth in my thinking and process in order

Vision on project | This project/concept originated from the logic idea of making use of lost energy. What I wanted is to make a concept based on relevant, con-sistent and logic decisions. Placed in a relevant context, with a relevant target group while being consistent in making my design solutions. The initial point of this project was therefore to design an energy harvesting table which trans-forms lost energy into useable electric energy. Later on this transformed and got more defined based on logic decisions.

VISIONS

6 67 7to create ‘simplicity’.In my opinion there are far too much products which exceed their functional-ity and lose the ‘wow-factor’ of the origi-nal idea because designers won’t rea-son why a product should be like that, instead they make (technology pushed) designs because ‘It just can’ with the question “why not?” in the back of their minds (e.g. the overkill of functionality of the mobile phones). I therefore asked myself the question ‘why?’, I find that technology should support the product but it’s not a necessity.

I see myself as an extremely motivated and hard working creator of realistic, useable products which are understand-able and simple, which shows in the feedback I got over the past three years.

I try to open my perspective by consum-ing as much information as possible and therefore having new visions and be-coming more critical. Moreover I find it interesting to create innovative products and explore areas which are not yet ex-plored or are up and coming. Ideally this would create products which can make a difference and add value to peoples life. Moreover I want to be an all-round designer with a holistic and profession-al approach, with a broad spectrum of knowledge in many different fields which I can apply quickly on different projects individually or in a team, with a focus on conceptual and innovative, though realistic, products. In the end I would de-scribe my work as typical Dutch design, which is pure, honest and raw. Most of all it is clean and simple.

8 89 9

8 89 9During this project I wanted to achieve a better understanding on electronics and technology in general because this competency needs to be developed more. Moreover I wanted to achieve an innovative product which makes sense, breathes Consistency, Relevancy and Logic and makes a statement.

In order to accomplish such a product several areas of investigation can be de-termined:What is energy harvesting and how can it be achieved?How does piezo-electricity work?What is the most suited context and tar-get group for the table?How can it be realized with a sustainable vision?How do other tables look like?In general there should be a final con-cept, a prototype table and the main questions should be answered and in-tegrated in the final concept. Ideally this prototype needs to be tested and verified with users in order to create an improved generation of the product.

OBJECTIVE

10 1011 11

PROCESS

10 1011 11In my opinion this project had a differ-ent process then conventional process at the Industrial Design faculty. The main difference lies at its starting point. I started with little to no knowledge, just an idea ‘an energy harvesting table’. At project descriptions at our faculty we usually can conduct several important points. The target group is defined, the problem is defined and the context is defined. Three important points which were absent in the beginning in my project. Next to developing the concept

PROCESS

and the technology, there was also the need to find a context, target group and added value for that target group. Creat-ing a more complex and time consuming project because these different factors need to be balanced out and are basi-cally the backbone of the entire concept. Therefore this process focussed more on discovering what these factors actually are and on creating a balance between them. While in a conventional project the factors are usually balanced out, or are already there and only need ‘fine tuning’. This directly implies you take a different road towards the final concept. This pro-cess had different parallel tracks (target group, added value and context), where the conventional process goes in a circle (preferably an up going spiral due to its iterative nature).

12 1213 13idea concept

usercontext

added valuetechnology

12 1213 13Briefingby Client

Research

Ideas

Concept Focus on visuals

Detailing/Engineering

Production

Client

Communicated withinone week to the client

‘professional’ industrials design process as I would want to apply it at ID TU/e

14 1415 15

14 1415 15DESIGN

Idea Generation and Concept Develop-ment | The project originated from the idea of transforming otherwise lost en-ergy into usable energy. With mind maps I explored the current table, and its con-text in order to get a better grip on the matter. Three main, interesting, areas of use came upfront from the first explora-tions: Leisure (hobbies, relaxations and social activities), Work and Eating. These areas act as possible areas where the table could add value. During the as-signment ‘Co-Reflection’ I searched with users for an added value and context which the concept could offer, which is explained under the section users. (see

16 1617 17maps. This all is then combined in the final part of the idea generation where we use a combination of ‘Fantastic story telling’ and ‘Reframing Matrixes’. This fi-nal part is the most important, since this connects technology, table (design) and user all together into possible interest-ing solutions.

Fantastic story telling is a technique where one tells their ideal solution. This gives great out of the box ideas and new insights in users needs. Reframing matrix gives also out of the box ideas, because you define different personas and from those personas you generate ideas to solve the problem. Interestingly two main conclusions conclusions from those brainstorms could be drawn. One was the creation of ambience the other

appendix A on the CD)

In order to get grip on different low power applications (explained in the section technology) a mind map was created, but also a visit to the CeBIT fair (on of the biggest technology fairs in Europe) in Hannover, Germany took place to see what kind of new technologies and appli-cations are developed. Although it had no direct impact on the applications it served as an interesting explorationThese explorations were needed to set up a big idea generation session (see appendix B on the CD) with the staff of Bureau CQ in order to see get a commer-cial vision on the functions and context of the table. The set up was as follow: first warming up then we’ll explore tables and context with brain dumps and mind

16 1617 17was creating a useful application. These 2 main conclusions. Those will be in-cluded as one of the characteristics of the table.

The context and target group of the table will be explained under the section user.

The shape of the table is obviously in-herent with the desires of the users, the requirements of technology and new trends in design. Technology gave the following requirements (more on this in the section technology): Lightweight construction of the table top and room for technology. The context requires a fixed seating area at the table and sustainable material use, and the us-ers require ergonomics (explained in the section users). A form design study

took place (at 0900 design and design daily’s) to see what kind of tables are al-ready there what kind of characteristics the tables in the target groups segment have. This study gave the following re-quirements: natural and relaxed colors, the shape needs to be clean, with direct visible contours and lines.A sketch session followed where differ-ent shapes were drawn regarding those previous mentioned requirements. Shapes which met the requirements were digitalized and reviewed. One final shape was chosen and improved. The final shape is attractive, clean and allows fixed seating. It was chosen be-cause it has firm and edgy characteristic (the straight edges of the seat and the rectangular shape of the table) while the two corner edges give that soft and ap-

18 1819 19As the table generates energy a quick and logic connection is made towards sustainability.The table therefore could act as more sustainable solution to current tables. This also creates an extra added value with the product. The table itself is made out of wood, this decision was based af-ter the search for different renewable, inexpensive and sustainable materials. Concrete, wood and bamboo were on first selection the most interesting ma-terials. Concrete is cheap, sustainable, it doesn’t leave traces of chemicals into the ground while it’s being used but concrete does not have a second life (although it can be reused in new con-crete). This means the energy which is put into the concrete is lost, which is not in line with the harvesting of lost en-

proachable feeling. Therefore the shape supports the concepts vision and gives the following statement through its shape: sustainability is a necessity and your friend. The shape allows also for en-ergy generation through its seating area, piezo elements can also be placed at connection between seats and legs (de-fined in the technology section). More over this shape allows for face to face contact and equality of the user, since no one can sit at the head of the table. Production wise this shape is easy to produce, thanks to the straight surfaces and edges. There are no difficult connec-tions, angels or bends. As it is easier to produce, it requires less effort and thus connects back to create a more sustain-able table.

18 1819 19ergy of the concept. Bamboo and wood are therefore the most suited since they have a second life (their energy can be used again) and are renewable. Both ma-terials do not leave traces of chemicals when they are recycled or placed into/onto the ground. Bamboo grow very fast and therefore the best renewable materi-al. The combination of both is very inter-esting. Bamboo is strong and versatile, this will be applied in the table surface and seating areas. FSC wood will be ap-plied for the two legs. The wood will be made weather proof and painted while the bamboo will show its structure and natural beauty after a coat of lacquer.The applications of the design are both connected to the context and the user. The applications will be further defined in the section User.

Design Problems and Solutions | The main problems during this project were to find added value for the user with this table and to find a way to transform me-chanical energy into electrical energy. Moreover I find it hard to come up with good low-power applications from the user support. Mainly due to the lack of confidence of making hard decisions, the decisions were hard because of the strong connections of all factors. If you change one factor, all others change with it. I tried to look for the perfect balance. On all occasions I fell back on logic rea-soning and asking myself if the solutions were necessary. This resulted, in my opinion, in a more down to earth con-cept. Still it learned me to be more confi-dent in decision making.

20 2021 21First shapes

20 2021 21

22 2223 23

22 2223 23

24 2425 25

24 2425 25

26 2627 27

26 2627 27

28 2829 29Current issues | When the project started I had no idea on how to transform me-chanical energy into electric energy and how much it would generate. I concluded the following (which will be further ex-plained below): The energy generating material should be piezo electric ceramic made out of PZT. This has the advantage that it uses less space then the use of electro magnetics. Moreover it requires less components and material to as-semble and therefore easier in mainte-nance. In combination with the context (explained under the section users) so-lar energy harvesting is a logic add-on. The most important information which came upfront was the information that only low-power applications could be powered by such technology.Thus, the energy harvesting table works

TECHNOLO

GY

28 2829 29with two principles, piezo electricity and solar power. Piezo electricity is used to harvest the mechanical energy which is supplied by the user, embedded in the hollow area in the table top. In the out-side solar energy is also lost, this oth-erwise lost energy will ben transformed into electric energy by the use of solar panels which are integrated into the ta-ble.

The piezo-electric effect was discovered by Curie(1). He applied pressure (pres-sure = piezo) on a crystal, this crystal released a small current (1). This way of energy transformation occurs when a crystal or ceramic the internal structure creates a potential difference when it is deformed by applying pressure. When this pressure is removed, the structure

comes back to it’s original structure and releases a small current (1). Although this effects generates electricity by deforma-tion, it also deforms by applying energy. A typical characteristic of piezo material is the linear relation between applied stress and voltage generated. Another typical characteristic is the generation of an AC current, which occurs due to the double shift in the crystal structure (2,3,4). One of the interesting aspects of piezo electric material is the possibility to generate thousands of volts from one crystal when you apply a very high pres-sure (10). This is the principle used in an electric lighter. Although you can gener-ate thousands of volts with such a crys-tal, there is not much current generated. Inevitably the power such material gen-erate is low. However tests have shown

30 3031 31many types of elements which all have their own polarity and direction of pres-sure. Due to these direction the power output also changes when you apply a stress in a different direction. Some ele-ments are even stacked upon each other to generate a higher output. Also the out-put depends on the material, PZT is the most interesting because it has a rela-tively very high current output (4). This material is therefore used as elements in the table.

Other possibilities of energy harvesting are electromagnetic and photovoltaic energy transformation where the last one is mostly used in the form of solar cells. The first one is mostly known as the dy-namo on your bicycle. I chose for piezo electricity because of its compactness

that such material can charge a battery in a reasonable amount of time (4). When multiple elements are active you can combine those small currents and charge a capacitor. One can conclude that by the previous mentioned charac-teristics piezo electric elements can not be used to power large applications such as computers and vacuum cleaners. However, it is very suited to capture ‘am-bient energy’ (energy from the environ-ment which is not used) and to use it for small appliances. (2, 3, 5, 9, 11, 12). Due to this the table will power small applica-tions instead of large ones.

The power of such element depends on several variables: the frequency of the stress (Hz), the stress itself and it de-pends on the type of element. There are

30 3031 31compared to magnetic energy genera-tion. Magnetic energy generation has the disadvantage that it requires different components to generate energy (a coil, a magnet and casing). The coil requires many different material uses, especially manny wraps of copper wire. All in all this creates bulky and heavy elements. Moreover it only transforms 25% of the mechanical energy into electrical energy.

Solar energy is used quite a lot these day, the efficiency of the panels im-proved enormously over the years, there are even panels which could harvest sunlight indoors and flexible solar pan-els. Both ways of energy harvesting are sustainable and are solutions towards alternative energy sources. Therefore both energy harvesting methods are

implemented in the table. The power generation of solar cells lies in perfect conditions around 1000 watt per square meter. The energy generation of piezo electric elements lies somewhat lower, around 100 milliwatts per element. (4) Adding all elements together they can charge, in combination with solar cells, batteries to power small applications.

Induction is used to supply the small ap-plications (light sound and music) with power. I chose induction to be used on several logic reasons. Since there are multiple applications (light, music and charging) they need to be connected to the table, usually this requires different types of connections. This connection should be weather proof because the table is placed outside. Therefore in-

32 3233 33implemented in a table. I used other ex-isting energy harvesting methods and combined the elements and theories into my own system (see reference list). The main problem during this develop-ment is the unpredictable result the sys-tem has, specifically the PZT beams. This depends on several factors, namely: the quality of the material used, the thick-ness/length/width of the beams, the force and repetition of the mechanical energy applied. I started first form a pressure point of view, to generate energy by using the pressure applied on the surface of the table. Although this seems logically, it generates too less energy because very high pressure is needed. Several experts advised me to look in to vibrations. The point of letting vibrate the elements

duction is very interesting, it allows one type of connection and it can be made fully weather proof. Moreover the appli-cations should be specifically designed to be used with the induction area and therefore it also creates a more com-mercially interesting product. One could think of supplying different kinds of add-ons for the table like different sets of light. Induction works with two coils are placed closely together. When a current goes through one coil a magnetic field is generated. The second coil, which is put closely to the other coil, catches this magnetic field and transforms this mag-netic field into a current.

Project Goals | During this project I de-veloped a system which harvests energy from humans and energy from the sun,

32 3233 33seems therefore much more interest-ing. This means that the energy is trans-formed into motion in the element. By the compression of each side when the element bends energy is generated and released.

Technical configuration | The system works as follows: Energy is generated by vibration of the piezo elements and solar energy captured by the solar cells. This energy is stored in a capacitor and this capacitor charges a battery. The el-ements are placed inside the surface of the table, and placed at a small dis-tance from the top so the energy of the impacts will be optimally absorbed by the elements in order to let them vibrate (see image). The battery, which will be charged by the elements and solar cells,

is placed inside the leg of the table. The applications, light, charging and music all work by induction. There’s a small induction area on the center of the table where you can place the application on. There are 2 stripes of flexible solar cells on top of the table, placed in the center where impacts rarely occur. In total there are 100 elements divided over the table, 50 on each side. This is done to capture each impact efficiently all over the table. 4 piezo stacks are placed on the four up-per corners of the bench. They generate electricity by pressure applied by the sitting users when they move. A good prediction on what the system should generate is basically impossible because many different factors are involved, pre-viously mentioned. The generated power should be tested.

34 3435 35

34 3435 35piezobeam

solar cell

capacitor

batterysystem

36 3637 37The table is hollow at the inside, this is to make room for the electronics. Un-

derneath the top surface elements are attachted.

Double layer piezo beam, placed under-neath the table surface

36 3637 37

38 3839 39USERS

38 3839 39Project focus | What I want is to define a target group which fits the concept. I want to see what they like and how they live. Do they live in a certain context or do they have special hobbies? But mostly I’m interested in how the concept would place itself, which user does it at-

tract and what are their characteristics. I can gather this information by talking (an interview) to design resellers, users, de-sign experts and designers. Besides that I want to explore the context and applica-tions of the table by observation and re-search, to find where the concept could add value. This all is to create a relevant concept to the users.

User Research Approaches and FindingsI wanted to find out what actually hap-pens at a table in order to define the con-text and define the desired applications. During the assignment Co-Reflection I ex-plored with users what they actually did at a table. As previous mentioned, their activities suited my three areas of use: Leisure, Work, Eating. Besides these ar-eas of use, there are also different types

USERS

40 4041 41The home environment is particularly interesting because of its commercial value. Much interaction in different cat-egories of use take place hourly. As it showed from observation every 9 sec-onds a significant impact takes place on the table while ‘working’ on it.

OutsideThe outside is very interesting because usually there’s no direct access to power. The outside table could generate ambi-ence during activities such as barbecu-ing or relaxing with friends.

WorkThe desk is, unconsciously, used a lot during office hours. People type, use the mouse, draw, write, move their limbs, etc. Much mechanical energy is lost dur-

of contexts where table can be used. Which are inherent to the types of activi-ties which take place.

RestaurantIn a restaurant a lot of human-table in-teraction takes place, where people dine intensively throughout the day. Interest-ing ideas can be created to support the restaurant in its service towards the cus-tomer but also to support the restaurant personal in their function/efficiency or even to reduce energy costs. Therefore the table can act in three supportive ways which is commercially interesting for the restaurant as they can deviate from others. Six contexts were defined by me to be investigated. A small summary:

Home

40 4041 41ing this day, still there are several work-spaces which have their own interac-tions. Although this surface is only used during working hours.

CounterA shop counter/table is placed at several central areas where people pay for the goods. During opening hours the table is intensively used because people place many products on them during opening hours. This is only at shops which run. Therefore this could be an interesting context to develop an application for. Possible applications are, again, light and energy for a cash register or a pin machine. BarInteresting application would be to in-tegrate the table in some kind of bar

shape. This is usually a surface where people can sit behind or get their drinks from. Generally the interaction on the bar is from leaning, placement of glass-es or food. The bar will be used during opening hours with a variable intensity. Although this is not a product for con-sumers it is something where the bar can deviate itself.

KitchenIn a kitchen professional cooks work, they chop and do all kinds of actions on surfaces. The surface is touched in-tensively in a professional kitchen. A vibe of performance is present in such areas, where maybe applications could enhance this. It could power timers, or other small electronic applications in the kitchen like lights or actuators which

42 4243 43available, or when there is no access to energy. The context which is most suited for this is the ‘outside’ context. It has no direct access to power, therefore the table can act as a great addition to the users current outdoor garden experi-ence. The outside has even more unique points:It has sunlight, an interesting sustain-able energy sourceThis context connects technology, user and nature all togetherThere is no real innovative outdoor furni-tureThe concept can also be applied as street furniture at gas stations etc.

The target group was also one of the un-known factors at the start of this project. In order to determine the target group I

give feedback to the user on certain ac-tion.

For visuals see appendix c.

I explored the home environment, the restaurant and the outside a little deep-er. The first two contexts were explored with users through the assignment co-reflection. The goal was to find suitable applications ideas (or values) for these contexts. I concluded from the user needs that most suited applications are simple and ‘obvious’. Most ideas and needs involved ambience creating appli-cations like light and sound.All are interesting contexts for an energy generating table, but what context would fit the best to such a product. Energy is obviously most wanted when it’s not

42 4243 43described the characteristics/values of the table and looked for a target group which connects those characteristics and values. The product is expensive and should address a more high-end custom-er. It addresses the current sustainability thought and is a subject to talk about. Moreover it has a ‘design’ appearance and has big contrasts in its color use. It is new and innovative and therefore ad-dresses a younger target group.

Combining these decision points with the user needs the following ‘obvious’ applications were developed: Light, mu-sic and charging. Light and music ad-dress the user needs of ambience creat-ing applications. Charging addresses the need of a functional application. There is one problem, users usually don’t ‘use’ a

table when being outside. Users will re-lax at the table or move away from it. In order to keep the user close to the table the seats are fixed to the legs, moreover this gives extra stability.During my observations on table use by taping and analyzing the video on the amount of ‘significant impacts’ by the user. I concluded that on average each 9 seconds a user will generate a significant impact on the table. Given the anthropo-morphic charts created by NASA (13) you can conclude that significant forces are generated by the users limbs.

The table is made according to dimen-sions set by different ergonomic stud-ies. These dimensions can be fine tuned according to a prototype. For technical drawings see appendix D.

44 4445 45most outdoor furniture (between 5 and 10 years) and expected technical lifetime (max. 10 years). (27)An additional feature, rechargeable bat-tery operated light, will also be added to the comparison.

TransportTransport will be mainly done from China, where all the manufacturing takes place, to The Netherlands. Components are mostly produced in China of both tables. Transportation of both can be done in a flatpack manner in containers over sea. The noticeable difference in transport is the weight difference in both tables. Due tot the use of massive wood and RVS the Royal Botania is heavier (a little over 60 kg, BRON) then the hollow energy har-vesting table, partly made of light bam-

In order to see wether the table is indeed more sustainable then a normal table or not and to define its break even point a so-called ‘Life Cycle Assessment’ needs to take place. With a life cycle assess-ment you look to 4 factors (transport, material, toxicity and energy) which de-termine the environmental impact of a product. As this design is about energy harvesting I will look further at embod-ied energy of such a product. In order to get a better understanding if it would be better I compared with a normal outdoor table (Flexy, by Royal Botania). This table is somewhat similar in size, appearance and price range to the Energy Harvesting Table.The assessment was taken over an economic lifetime of 5-10 years. This is based on the guarantee you get with

LIFE CYCLE ASSESSMENT

44 4445 45boo (est. 55kg (2x 7.5 kg for the seats, 2x 10 kg for the legs and 10 for the table top and electronics)). Therefore the lighter table will be better to transport (lighter, so it requires less power to move from A to B and less power means less fos-silic fuels), but in the bigger picture the lighter table requires more components which need individual transportation to the factory and therefore the emission of CO2 is higher. Transportation of the nor-mal table emissions 130 kg CO2 and the energy harvesting table 140 CO2. A dif-ference of 10 kg CO2.

MaterialBoth tables are made out of wood (teak). The main difference lies within the use of Bamboo and electronics in the energy harvesting table in comparison with the

use of RVS at the Royal Botania. Teak has an eco index of 0,407 Pt, RVS has an eco index of 0,443 Pt (if fully recycled which usually doesn’t happen). Bamboo can be compared to Ash because of its fast growing rate and young ripeness, it has an eco index of 0,408 Pt., the ceramics used in the table can be discarded be-cause they don’t have significant mass. So the Royal Botania table has an total of 0.850 and the Energy Harvesting Table a total of 0.815. All materials can be fully degraded and recycled, instead of the electronics but they can be reused in other products.Moreover the Energy Harvesting Table has solar cells embedded. In order to create solar cells a lot of energy is used, however they have their break even point in 5 to 10 years.

46 4647 47ToxicityBoth tables are obviously toxic by the use of rechargeable batteries, although these are better then normal batteries and meet environmental requirements they still contain chemicals (28). The table has batteries in it (2x AA) which need to be replaced after approximately 5 years (a rechargeable battery has a life span of 1000 charge cycles, which can be compared to thousand full days of use). Therefore the table uses 4 AA recharge-able batteries during its life. (29)Although rechargeable batteries have 20% less human health toxicity impact then normal batteries (15) and have 32 times less impact on the environment then normal batteries (30). Toxicity can be measured by the emission of Cd and Ni by the battery in the environment

(TU Delft, Idemat)

EnergyThe Royal Botania doesn’t acquire en-ergy to be used, it also doesn’t gener-ate energy unlike the Energy harvesting table. When used with light the Royal Botania table does require energy while the Energy Harvesting Table doesn’t. Therefore the Royal Botania requires powerplants to run for its energy supply. Over a 10 year life span this comes to the use of around 25% of the evenings a year for around 3 hours. This comes down to 90*3=270 hours of light. A bright ‘green led’ light uses around 5 watt’s (5J a sec-ond). So the light uses (270*60*60 = 900000s) more then 4500000J a year. In ten years this is 45MJ.

46 4647 47while the materials are acquisitioned, manufactured and recycled. In total 1.61 g Cd and 2.712g Ni is released per kg of battery. A battery weighs 50g. and 4 batteries are used. This comes down to a total of 0.322 g of Cd and 0.5424 g of Ni which is released in the environment for each table in ten years. The remainder material is recycled into other batteries (paper). Because both

Break even pointIn estimate total the life cycle of the en-ergy harvesting table will consume 5000 MJ of energy, this is divided over manu-facturing, transportation, use and dis-posal. The energy harvesting table requires the most energy while being manufactured (2100 MJ) and while being transported (by plane, 1900 MJ), the least amount of energy is used while the table is be-ing disposed (1000 MJ). This is a little more then the outdoor table mentioned earlier, this would consume around 3770 MJ (manufacturing 1300 MJ, Transport 1800 MJ, and disposal 670 MJ) and 45MJ of energy in 10 years. This is a difference of 1185 MJ (1230 000 000 J) between the energy harvesting table and the table of Royal Botania. (all values are reli-

48 4849 49energy. Then we have the generation by vibrational use is around 100 milliwatts per element. This energy will be around a quarter of the energy harvested by solar power. Creating a total reduction of 67.5 MJ and 11.625 kg of CO2 over 10 years. In total this table has a lower CO2 emis-sion by transportation, but has a higher embodied energy (it requires more en-ergy to be made, transported and dis-posed). Therefore it is in 10 years not more sustainable then a normal table. Although, an experienced estimation by Mr. Verkuijl, the table would reach its break even point in 5 to 10 years and therefore not making it more bad then a normal table. More interesting is the ex-tra function you get for the same amount of money.

able approximates and determined by IDC, an industrial design development and consultancy agency) (30) 1185 MJ comes down to the use of 0.32 MJ each day. The energy generation of the energy harvesting table is hard to determine because of many different unknown fac-tors which depend on its use. Although a rough determination can be made. The generation of solar energy is in perfect conditions 1000 watt per square meter, Milieu Centraal has a calculation tool of what the energy generation would be per area of solar energy panels. For the table (area of 0.125 m2) this comes to a gen-eration of 1.5 kWh each year.The reduction of CO2 generated by fossil fuels is 0.93 kg, over 10 years this comes to an energy generation of 15 kWh (54 MJ) and a reduction of 9.3 kg of CO2 by solar

48 4849 49Conclusion & improvement for LCAThe table is as it is now not yet more sus-tainable then a normal table. It seems sustainable at first because it generates energy, and by the use of sustainable materials to make the table, the manu-facturing takes a lot of energy and has a higher CO2 emission then a normal table. Although it has a higher embodied energy it reaches its break even point in 5 to 10 years by the energy generation. The normal table basically never reaches it break even point because it only costs energy in its lifecycle, while the energy harvesting table generates energy to come to a break even point. Therefore creating an equal sustainable table. Im-proving the sustainability of the energy harvesting table can be done by moving the manufacturing of the table to the

Netherlands, which will result in a more costly product due to higher labour rates, and reducing the weight of the electron-ics. This will cut the embodied energy from 5000 MJ to 1586 MJ (Manufactur-ing 530 MJ, Transport 56 MJ and disposal 1000MJ). The CO2 emission will be cut from 140 kg to 4.1 kg. This means that the table then will be more sustainable then the Royal Botania table (4415 MJ and 130 kg of CO2 emission).

50 5051 51Did I created a consistent, logic and rel-evant project? In my opinion it succeed-ed to a certain point and I think I can be quite satisfied for applying these three keywords for the first time since I discov-ered them last semester. The project is consistent due to applying my decisions and my reasoning in the same way throughout this process. The concept has no irrelevant features and is consistently based on my vision, on the

CONCLUSIO

N

50 5051 51projects vision and logic reasoning. For example, the material use is consistent with the decision of creating a more sus-tainable table which is logically derived from the energy harvesting feature. This brings me to the next point, logic. All decisions were based on logic steps or are derived from facts, see previous ex-ample. Another example of one of the logic decisions is decision to place the table outside, because the outside of-fers a powerless context. The table can therefore add something to that spe-cific context that wasn’t quite available before. But is the concept relevant? This point can be improved to make it more relevant to the users. As it is know, the concept only relevant to the current sus-tainability thought. The table doesn’t come from the need of the user, or from

a great opportunity for the user. There-fore the project may not be as relevant as other Industrial Design projects done at the faculty. The main thing I would do differently when I could do this project again is to make earlier more confident decisions.

Estimates of the energy generation of the table can not be verified at the mo-ment of writing. I’m currently waiting for a shipment from China with the piezo ceramic elements. However technology will be implemented after couple of days after delivering the report. I can con-clude that the benches are placed to low in the prototype, I applied the required ergonomic distance from the ground and ergonomic distance from the ground to the table top. Although I didn’t keep in

52 5253 53I find it interesting to apply those words into a project, and to try to create a more holistic and 1+1=3 result. This project also showed me that I want to design more practical, useful and still innova-tive products, which address needs and problems in a ‘airy’ way (which this proj-ect doesn’t directly do). It also became more apparent that my interest definitely doesn’t lie in ‘over intelligent’ products which observe and give the user feed-back on its behavior (or some other sys-tem) or the ‘How can you..?’ projects, which in my view usually doesn’t add value but creates more problems. I find designing such products more like an ‘invul oefening’ then a real challenge of creating a total new product that ad-dresses needs and problems.

my mind the table top itself adds 7 cm to the hight, and therefore the table top is too high in relation to the seating area therefore the seating area needs to be heightened with 10 cm. Moreover to al-low easier placement the seating are needs to be 10 cm smaller. Still it has a sturdy solid construction.

The project contributed to my develop-ment in such a way that gained experi-ence with technology, process and col-laborating with many different experts and professional designers. Moreover the project had an impact on my vision in such a way that it became more real and funded by applying. It showed me that it is hard to achieve to combine these three keywords into balanced project, mainly due to the lack of experience. Still

52 5253 53As mentioned before the project origi-nated from the idea of making use of lost energy. This idea is connected to the current sus-tainability movement as this movement implies we should think of the environ-ment in many ways, one of them is the ef-ficient/wise use of energy. But why does the final design matter to the world? Why does it need to exist?Both important questions coming from my vision.The table needs to exist because: In the end the table is more sustainable then a normal outdoor table. Therefore it has less impact on the environment. By being more sustainable it creates aware-ness for sustainability at consumers, which helps to spread the message of becoming more sustainable. Moreover it

shows that we can use energy that oth-erwise is lost to our benefit and is a step towards a more sustainable lifestyle.

In general the table needs to be there because it is a step towards more sus-tainable living and innovative furniture. It is simple, supports my vision and ad-dresses the use of otherwise lost energy. Moreover it needs to be there because it allowed me to learn and put my vision and way of working in practice.This answers the question which I asked in the beginning (what is more impor-tant? Sending a sustainable message or an actual sustainable product). In my opinion both. Without the message no-body will get the actual table, but without being actually sustainable the message is not logically connected to the table.

54 5455 55

REFERENCES

54 5455 55Book1. Philips, PiezoCeramics, 2003

Conference paper2.Kim, S. Low power energy harvesting with piezoelectric generators. University of Pittsburg, 19963. Parker, M. Ambient Energy Harvesting. The Univeristy of Queensland, 20034. Sodano, H.; Inman, D.; Park, G. Comparison of piezoelectric energy harvesting devices for re charging batteries, Journal of intelligent material systems and structures, 2005, Vol. 16, p. 799 - 807.5. McNair, B. Piezoelectric based energy harvesting, 20086. Fisher, F. Piezoelectric-based application development, A senior report, 2008, Stevens Institute of Technology.7. Howells, C. Piezoelectric energy for soldier system, ?, US Army CERDEC C2D8. Tayahi, M. Piezoelectric generator powering remote sensing networks, ?, University of Nevada.9. Minazara, E.; Vasic, D.; Costa, F. Piezoelectric generator harvesting bike vibrations energy to supply portable devices, ?, Universite de Cergy-Pontoise10. Morgan Electro Ceramics, Piezo High Voltage Generators11. Arms, S; Townsend, C.; Churchill, D.; Galbreath, J.; Mundell, S. Power management for energy harvesting wireless sensors, 2005, MircroStrain Inc.12. Sosnicki, O.; Lherment, N.; Claeyssen, F. Vibration energy harvesting in aircraft using piezoelec-tric actuators, 2006, Cedrat Technologies.13. NASA, Anthropometry14. Amec, Energy harvesting from piezoelectric composites, 200615. Parsons, D. The environmental impact of disposable versus re-chargeable batteries for con-sumer use. The International Journal of Life Cycle Assessment, Vol. 12, No. 3. (20 May 2007), pp. 197-203.

Personal communication15. Bouman, A. Personal communication on designing. 200916. Goossens, G. Personal communication on solar energy. 200917. Pot, M. Personal communication on chinese manufacturers. 200918. Schaijk, R. van. Personal communication on energy harvesting. 200919. Schellens, H. Personal communication on energy harvesting. 200920. Roosegaarde, D. Personal communication on energy harvesting. 200921. Cottaar, A. Personal communication on electronics. 2009.22. Ken. Personal communication on Chinese components. 200923. Kunzmann, J. Personal communication on energy harvesting. 200924. Tomico, O. Personal communication on user involvement. 200925. Taya, M. Personal communication on energy harvesting. 200926. Boom, P. de. Personal communication on target group. 2009Websites27. www.gratisadviseurs.nl28. www.aboutmyplanet.com29. http://products.planetark.org/paproducts/varta.cfm30. http://www.lcacalculator.com

REFERENCES

56 5657 57

56 5657 57