Fatigue Behavior of High Volume Fly Ash Concrete Under Constant Amplitude and Compound Loading

-

Upload

iaeme-publication -

Category

Documents

-

view

220 -

download

0

Transcript of Fatigue Behavior of High Volume Fly Ash Concrete Under Constant Amplitude and Compound Loading

-

7/30/2019 Fatigue Behavior of High Volume Fly Ash Concrete Under Constant Amplitude and Compound Loading

1/12

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 3, Issue 2, July- December (2012), IAEME

404

FATIGUE BEHAVIOR OF HIGH VOLUME FLY ASH

CONCRETE UNDER CONSTANT AMPLITUDE AND

COMPOUND LOADING

Aravindkumar.B.Harwalkar1

andDr.S.S.Awanti

2

1

Associate Professor, Department of Civil Engineering, P.D.A.College ofEngineering, Gulbarga, Karnataka State, India.

e-mail: [email protected] and Head, Department of Civil Engineering, P.D.A.College of

Engineering, Gulbarga, Karnataka State, India.

e-mail: [email protected]

ABSTRACT

Road projects in future have to be environmental friendly and cost effective apart

from being safe so that society at large is benefited by the huge investments made in the

infrastructure projects. To achieve this, component materials of the pavement system have to

be optimized with reference to cost effectiveness, sustainability and fatigue behavior. Thispaper presents a study on fatigue behavior of high volume fly ash concrete (HVFAC) and

conventional concrete (PCC) under constant amplitude fatigue loading. Also behavior of

HVFAC was studied under compound fatigue loading. In the present investigation HVFAC

mix with cement replacement level of 60% with low calcium fly ash has been used.

A total number of 95 prism specimens of HVFAC were tested under constant

amplitude fatigue loading. Also 100 prism specimens of PCC were tested under constant

amplitude fatigue loading for comparative studies. All prism specimens were of size

75mm100mm500mm and were tested under flexural fatigue loading using haiver sine

wave loading. Frequency of fatigue loading was kept at 4Hz. Lognormal model was verified

for probability distribution of fatigue life. Studies indicated that lognormal model was

acceptable for fatigue life distributions at all stress levels for both HVFAC and PCC. The

parameters of distribution exhibited dependency on stress levels and type of concrete.

Relations between stress level and fatigue life were developed for both HVFAC and PCC.

These relations were found to be dependent on type of concrete.

A total number of 24 prism specimens were tested under compound fatigue loading.

Based on the results of compound fatigue loading the validity of Miners hypothesis for high

volume fly ash concrete was verified. It was found that Miners hypothesis gives both unsafe

and over safe predictions of failure. Miners sum was found to be dependent on type of

compound loading and sequence of loading.

INTERNATIONAL JOURNAL OF CIVIL ENGINEERING AND

TECHNOLOGY (IJCIET)

ISSN 0976 6308 (Print)

ISSN 0976 6316(Online)

Volume 3, Issue 2, July- December (2012), pp. 404-415

IAEME: www.iaeme.com/ijciet.asp

Journal Impact Factor (2012): 3.1861 (Calculated by GISI)www.jifactor.com

IJCIET

IAEME

-

7/30/2019 Fatigue Behavior of High Volume Fly Ash Concrete Under Constant Amplitude and Compound Loading

2/12

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 3, Issue 2, July- December (2012), IAEME

405

Keywords: Compound fatigue loading; High volume fly ash concrete; Probability

distribution; lognormal.

1. INTRODUCTION

Fatigue strength is an important property which has to be taken into account in the

design of various concrete structures requiring long fatigue life. Especially the understanding

of the behavior of a concrete road under fatigue loading is vital for the design and the

performance prediction. Also there is a need for optimization of materials in the rigid

pavement system with regard to long term fatigue resistance at lowest cost and ecologically

sound choices.

Many researchers have carried out studies on developing fatigue models for plain

concrete. Majority of the researchers [1-3] have developed the fatigue model relating the

stress level (S) which is defined as the ratio of maximum stress applied in cyclic loading to

static flexural strength, to number load cycles to failure (N), termed as fatigue life. This

relation is commonly called as Wholer equation. The second form of fatigue model given by

Vesic et al [4] and Treybig et al [5] is a power equation relating S and N. Jakobsen et al [6]

included the effect of ratio of minimum stress to maximum stress in cyclic loading, which is

known as stress range (R), in the S-N relation for fatigue. Hsu [7] developed a more general

expression for fatigue strength involving four variables i.e., S, N, R and period of cyclic

loading (T). But the most commonly used fatigue model for design of concrete pavements is

the one given by Wholer equation.

In literature [8-9] variable amplitude fatigue studies have been carried out on plain

concrete to verify the validity of Miners hypothesis. Miners hypothesis assumes that

damage accumulates linearly with the number of cycles applied at a particular stress level. As

per Miners hypothesis the failure criterion is written as:

-----------

----- (1)

Where ni = number of cycles applied at stress level i

Ni = number of cycles to failure at stress level i

k = number of stress levels used

Studies carried out by Siemes (8) on plain concrete proved the validity of Miners

rule. But the studies carried out by Holmen (9) found variable amplitude loading to be more

damaging than that predicted by Miners hypothesis.

As per the definition given by Mehta [10], a concrete having minimum cement

replacement level of 50% by fly ash is termed as high volume fly ash concrete (HVFAC).

Limited studies [11-13] are available on fatigue behavior of HVFAC. Ramkrishnan et al [13]

have developed an S-N relation for HVFAC with cement replacement level of 58% usingthird point flexural fatigue loading at a frequency of 20Hz.

In the development of S-N model it has been assumed that the non dimensional term

S eliminates the influence of static ultimate strength of concrete and hence eliminates the

effect of water-cement ratio, type and gradation of aggregate, type and amount of cement, age

of concrete. But there are concerns over influence of static strength of concrete on S-N

relation due to variation in fracture toughness. There is also very limited literature available

on fatigue behavior of HVFAC under compound and variable amplitude fatigue loading.

-

7/30/2019 Fatigue Behavior of High Volume Fly Ash Concrete Under Constant Amplitude and Compound Loading

3/12

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 3, Issue 2, July- December (2012), IAEME

406

2. RESEARCH SIGNIFICANCE AND SCOPE

In the present investigation an attempt has been made to study the fatigue behavior of

HVFAC under constant amplitude and compound fatigue loading. Multistage constant amplitude

loading has been used as compound fatigue loading in the present investigation. The fatigue testresults of HVFAC were compared with that of reference concrete (PCC). To investigate the fatiguebehavior a series of prism specimens of size 75mm100mm500mm were tested under flexural

fatigue loading.In the present investigation HVFAC mix satisfying the criteria of pavement quality concrete

was developed using a cement replacement level of 60% with low calcium fly ash. A total number of100 PCC prism specimens were tested under constant amplitude fatigue loading. For HVFAC, 95prism specimens were tested under constant amplitude fatigue loading. Probability distributions were

developed for experimental results of fatigue lives. S-N relations were established from regression

analysis of fatigue data. A total number of 24 specimens of HVFAC have been tested under

compound fatigue loading to verify the validity of Miners hypothesis.

3. LABORATORY TESTS

3.1 Materials

The ordinary Portland cement from single batch has been used in the present investigation.The coarse fraction consisted of equal fractions of crushed stones of maximum size 20mm and 12mm.

Low calcium fly ash satisfying the criteria of fineness, lime reactivity and compressive strengthrequirements [14] has been used in the investigation. Fine aggregate used was natural sand with

maximum particle size of 4.75mm. Polycarboxylic based superplasticizer has been used as high rangewater reducing admixture (HWRA) to get the desired workability. The optimum dosage of

superplasticizer for each type of concrete was fixed by carrying out compaction factor test.

3.2 Mixture Proportions

A minimum grade of M30 which results in a minimum static flexural strength of 3.8N/mm2

has been specified for pavement quality concrete by Indian Roads Congress [15]. Trial mixes were

developed to achieve M35 grade HVFAC at cement replacement of 60%, which was the optimumreplacement percentage with water to cementitious ratio of 0.3. Water to cementitious ratio utilized in

the investigation i.e., 0.3 was the lowest value that could be used from the limitation of reduction inwater content that can be achieved using HWRA and usage of conventional means of mixing and

compaction. Corresponding conventional concrete was used as reference concrete (PCC). Mixtureproportions of the two types of concrete are shown in table 1.

Table 1 Mixture Proportions of Concrete

Mixture

Components

PCC HVFAC

Cement (OPC 53 grade) in kg/m3

Class F fly ash in kg/m3

Water in kg/m3Superplasticizer in liter/m

3

Saturated surface dry sand in kg/m3

Saturated surface dry coarse aggregate

in kg/m3

440

0

13215.4

937.6

1059

176

264

1323.5

858.2

1059

-

7/30/2019 Fatigue Behavior of High Volume Fly Ash Concrete Under Constant Amplitude and Compound Loading

4/12

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 3, Issue 2, July- December (2012), IAEME

407

3.3 Test Procedure and Test Results

3.3.1 Static Testing

Cube specimens of size 150mm150mm150mm were used for determining compressive

strength. For static flexural strength, specimens of similar size to that of fatigue specimens have beenused. An effective span of 400mm has been used for both static flexural strength and fatigue strength

determination. All the strength properties were determined after a curing period of 28days. Static

compressive strength and flexural strength values are shown in table 2.

Table 2 Mechanical Properties of Concrete

Property of concrete/

Type of concrete

28 day compressive strength

in MPa

28 day static flexural strength

in MPa

Conventional concrete

HVFAC60

62.3*

40.8*

6.9*

5.3*

* Mean value of six specimens

3.3.2 Fatigue Testing

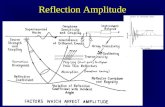

3.3.2.1 Constant Amplitude Fatigue Testing: Fatigue test specimens were tested under one-third

point loading using frequency of loading as 4Hz. Since the present investigation was aimed atpavement application haiver sine wave form of cyclic loading was used. Typical fatigue test set up

and loading pattern used are shown in figures 1 and 2 respectively. All the fatigue specimens weretested after 90 days from casting so as to give allowance for sufficient strength gain. Specimens were

cured for 28 days by ponding method and then covered with polythene bags up to 90 days. Minimumstress in fatigue loading was maintained at 1% of maximum stress. Minimum stress was used mainly

to prevent any possible movement of specimens at support during testing and to simulate residual

stresses in the pavement to a certain degree. Beyond the upper limits of stress levels used for different

types of concrete in the present investigation, the fatigue life values were insignificant to be recorded

i.e., they were typically less than 10. For HVFAC at all cement replacement levels the lower limit of

stress level used was based on the criteria, when none of the test specimens failed even after ofapplication of one lakh cycles of fatigue loading. PCC was tested for eight stress levels and HVFAC

was tested at seven stress levels. Constant amplitude Fatigue test results for PCC and HVFAC aretabulated in table 3 and 4 respectively. Fatigue life values have been arranged in the increasing order

so as to facilitate probability analysis.

Figure 1 Flexural fatigue test setup Figure 2. Typical constsant amplitude fatigue loading

-

7/30/2019 Fatigue Behavior of High Volume Fly Ash Concrete Under Constant Amplitude and Compound Loading

5/12

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 3, Issue 2, July- December (2012), IAEME

408

Table 3 Fatigue Life of PCC at Different Stress LevelsTestspecimenno.

S=0.85 S=0.81 S=0.76 S=0.71 S=0.65 S=0.61 S=0.57 S=0.53

1 22 84 158 1327 5289 16488 46582 100000*2 43 97 284 1489 7213 20312 48270 100000*3 69 105 312 2596 8863 22268 52164 100000*4 78 152 382 3642 10322 34511 54416 100000*5 82 184 411 4149 12723 39920 56005 100000*6 94 198 474 5218 16523 46718 66012 100000*7 102 288 578 6629 18708 51512 73676 100000*

8 110 432 694 8383 20391 61512 80520 100000*9 122 682 916 9558 21262 77812 81891 100000*

10 138 730 1182 12009 23992 81800 100000* 100000*11 ---- ---- ---- ---- 24771 92477 100000* 100000*

12 ---- ---- ---- ---- 27344 100000* 100000* 100000*

13 ---- ---- ---- ---- 32811 100000* 100000* 100000*14 ---- ---- ---- ---- 40887 100000* 100000* 100000*15 ---- ---- ---- ---- 44816 100000* 100000* 100000*

*specimen did not fail after the application of given number of cycles of loading

-- data not available

Table 4 Fatigue Life of HVFAC at Different Stress Levels

Test

specimen

no.

S=0.80 S=0.75 S=0.70 S=0.65 S=0.60 S=0.54 S=0.50

1 44 78 312 4159 5324 18785 100000*

2 48 102 422 5802 6852 19084 100000*3 52 146 584 6802 7102 21039 100000*

4 65 182 886 7759 8404 22259 100000*

5 72 212 1092 8759 12723 29384 100000*

6 88 292 1109 9259 14785 32911 100000*

7 92 344 1243 10014 15680 45512 100000*

8 99 459 1422 12008 22348 62214 100000*

9 112 582 1586 14620 28109 68743 100000*

10 120 889 1704 14882 36891 76544 100000*

11 ---- ---- 1959 16822 45841 82477 100000*

12 ---- ---- 2390 16822 49869 86792 100000*

13 ---- ---- 3532 18826 52113 100000* 100000*14 ---- ---- 4426 23426 59641 100000* 100000*

15 ---- ---- 3962 28110 65869 100000* 100000*

* specimen did not fail after the application of given number of cycles of loading

-- data not available

-

7/30/2019 Fatigue Behavior of High Volume Fly Ash Concrete Under Constant Amplitude and Compound Loading

6/12

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 3, Issue 2, July- December (2012), IAEME

409

3.3.2.2. Compound Fatigue Testing: Compound fatigue testing was carried out on HVFAC

specimens only. Two stage, three stage and four stage constant amplitude fatigue loadings have been

used as compound fatigue loading. In two stage loading test specimen was subjected to a fixed

number of load cycles at a particular stress level in the first stage and after the first stage amplitude

was changed corresponding to second stress level and maintained constant up to failure. In three stagefatigue loading three stress levels have been applied to the test specimen. Fixed numbers of loadcycles were applied for two stress levels and testing was continued up to failure at the third stress

level. In four stage loading fixed numbers of load cycles were applied for three stress levels and atfourth stress level specimen was tested up to failure. Minimum stress was maintained at 1% of the

corresponding maximum stress for all the specimens. Test results of compound fatigue loading wereused to check the validity of Miners hypothesis for HVFAC.

4. PROBABILITY ANALYSIS OF CONSTANT APLITUDE FATIGUE TEST RESULTS

Since the fatigue lives for both types of concrete showed larger scatter, an attempt to

determine the probabilistic distributions was made. Few researchers [16-17] have developed Weibull

distribution models for fatigue lives at different stress levels in case of conventional concrete. In the

present study lognormal distribution models were developed and verified for different stress levels.Conservatively for few specimens which did not fail after the application of one lakh cycles of

loading at some of the stress levels fatigue life value has been taken as one lakh cycles in theprobability analysis.

4.1 Determination of Lognormal Distribution Model

The probability density function of lognormal distribution model is given by equation (2).The parameters of lognormal distributions are and which are mean and standard deviation of

observed ln (N) values. In the equation (2), X represents ln(N) values.

(2)

The values lognormal distribution parameters for all the types of concretes and at differentstress levels are shown in table 5. It can be seen that the parameters of lognormal distribution aredependent on type of concrete and the stress level.

Table 5 Lognormal Distribution Parameters for Fatigue Lives at Different Stress Levels

Type of concrete Stress level Parameters of log normal distribution

PCC 0.85 4.3450 0.5501

0.81 5.4036 0.7867

0.76 6.1377 0.5925

0.71 8.3841 0.7565

0.65 9.7882 0.6293

0.61 10.8915 0.63210.57 11.2150 0.3007

HVFAC 0.80 4.3158 0.3599

0.75 5.5329 0.7742

0.70 7.2237 0.7795

0.65 9.3603 0.5369

0.60 9.9538 0.8700

0.54 10.7820 0.6580

-

7/30/2019 Fatigue Behavior of High Volume Fly Ash Concrete Under Constant Amplitude and Compound Loading

7/12

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 3, Issue 2, July- December (2012), IAEME

410

4.2 Model Verification

Probabilistic models developed in the present investigation were tested using

Kolmogorov-Smirnov test. For conducting this test, the test statistic D2 was calculated using

equation (3) in which FO

(Nj) is the observed distribution of N and FN (Nj) is the hypothesizeddistribution of N and m is the total number of specimens.

.. (3)

The D2 values were compared with critical D2 for the given sample size and

significance level of 5%. If calculated value is less than critical D2, model is accepted. The

basic calculations for verification of lognormal model for PCC at stress level of 0.85 are

shown in table 6. The D2 values and verification of lognormal distributions for both types of

concretes at different stress levels are shown in table 7. It can be seen that lognormal model

was accepted for both types of concretes at all stress levels.

Table 6 Kolmogorov-Smirnov Test for Lognormal Distribution for PCC at Stress Level of 0.85

Table 7 Kolmogorov-Smirnov Test for Lognormal Distribution at Different Stress Levels

Type of

concrete

Stress level Maximum D2

from lognormaldistribution

D2 for 5%

significancelevel

Inference

PCC 0.81 0.1583 0.41

Lognormalmodels for

fatigue lifedistributions

are acceptedin all the

cases

0.76 0.0781 0.41

0.71 0.1230 0.41

0.65 0.0739 0.340.61 0.1628 0.34

0.57 0.1609 0.34

HVFAC 0.80 0.1445 0.41

0.75 0.0901 0.41

0.70 0.0868 0.34

0.65 0.0757 0.34

0.60 0.1208 0.34

0.54 0.1462 0.34

Nj j FO(Nj)

= j/m

FN(Nj)

from

lognormaldistribution

D2 for

lognormal

distribution=| F

O(Nj)-

FN(Nj)|

Maximum

D2 from

lognormaldistribution

D2 for 5%

significanc

e level andm=10

Inference

22 1 0.1 0.0113 0.0887

0.1449 0.41

Lognormal

model forfatigue life

distribution is

accepted

43 2 0.2 0.1443 0.0557

69 3 0.3 0.4201 0.1201

78 4 0.4 0.5085 0.1085

82 5 0.5 0.5447 0.0447

94 6 0.6 0.6408 0.0408102 7 0.7 0.6946 0.0054

110 8 0.8 0.7409 0.0591

122 9 0.9 0.7980 0.1020

138 10 1 0.8551 0.1449

-

7/30/2019 Fatigue Behavior of High Volume Fly Ash Concrete Under Constant Amplitude and Compound Loading

8/12

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 3, Issue 2, July- December (2012), IAEME

411

5. DETERMINATION OF S-N RELATION

S-N relations were developed by carrying out regression analysis on fatigue test data

of constant amplitude loading. The S-N curves determined for the two types of concretes are

shown in figure 3. S-N relations for PCC and HVFAC are shown in equations (4) and (5)respectively along with R

2values where R is the coefficient of correlation. It can be seen that

S-N relations are dependent on type of concrete i.e., on the strength of concrete. In the

present investigation existence of upper limits of stress levels for fatigue loading, dependent

on type of concrete, was observed. The 95% confidence limits using constant variance were

determined for both PCC and HVFAC. Upper and lower confidence limits along with S-N

curve for PCC and HVFAC are shown in figures 4 and 5 respectively. Lower confidence

limits are important in design of structures.

S = -0.0358Ln(N) + 0.9948 (R2=0.9332) --------------- (4)

S = -0.0338Ln(N) + 0.9389 (R2=0.8759) --------------- (5)

S-N Curve for PCC and HVFAC

y = -0.0358Ln(x) + 0.9948

R2 = 0.9332 -- Eqn for PCC

y = -0.0338Ln(x) + 0.9389

R2 = 0.8759 -- Eqn for HVFAC

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

0 20000 40000 60000 80000 100000 120000

Fatigue Life in No. of Cycles of Loading

Stress

Level(S)

S-N Curve

for PCC

S-N Curve

for HVFAC

Log. (S-N

Curve for

PCC)

Log. (S-N

Curve for

HVFAC)

Figure 3. S-N Curves for PCC and HVFAC

S-N Curve and 95% Confidence Limits for PCC

y = -0.0358x + 0.9948

R2

= 0.9332 -- S-N curve

y = -0.0358x + 1.0439

-- Upper 95% confidence limit eqn

y = -0.0358x + 0.9457

-- Lower 95% confidence limit eqn

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

0 2 4 6 8 10 12 14Ln(N)

Stress

Leve

l(S)

S-N Curve

Upper 95%

confidence

limit

Lower 95%

confidence

limit

Linear (S-N

Curve)

Linear

(Upper 95%

confidence

limit)Linear

(Lower 95%

confidence

limit)

Figure 4. S-N Curve and 95% confidence limits for PCC

-

7/30/2019 Fatigue Behavior of High Volume Fly Ash Concrete Under Constant Amplitude and Compound Loading

9/12

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 3, Issue 2, July- December (2012), IAEME

412

S-N Curve and 95% Confidence Limits for HVFAC

y = -0.0338x + 0.9389

R2 = 0.8759 -- S-N curve

y = -0.0338x + 0.9977

-- Upper 95% confidence limit eqn

y = -0.0338x + 0.8801

-- Lower 95% confidence limit eqn

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

0.000 2.000 4.000 6.000 8.000 10.000 12.000 14.000

Ln(N)

StressLevel(S)

S-N Curve

Upper 95%confidence

limit

Lower 95%confidencelimit

Linear (S-N

Curve)

Linear (Upper

95%confidencelimit)Linear (Lower

95%confidencelimit)

Figure 5. S-N Curve and 95% confidence limits for HVFAC

6. ANALYSIS OF TEST RESULTS OF COMPOUND FATIGUE LOADING

Test results of compound fatigue testing along with calculation of cumulative damage

factor for HVFAC are shown in tables 8 to 11. Stress levels shown in the tables 8 to 11 are

given in the order in which they have been applied to the specimens during testing. Fatigue

lives at different stress levels in tables 8 to 11 have been calculated from equation (5).

Cumulative damage factor i.e., Miners sum varied between 0.824 and 2.103. Miners sum

showed dependency on type of compound fatigue loading and also on the sequence of

loading.

Table 8. Cumulative Damage Factors for HVFAC for Two Stage Compound Fatigue Loading

Specimen

no.

No. of load cycles applied at

Stress level

Fatigue Life at

Stress Level

Cumulative damage

factor

M=(n1/N1)+(n2/N2)

S=0.55 S=0.6 S=0.55 S=0.6

(n1) (n2) N1 N2

1 20000 20672 99302 22621 1.115

2 20000 21453 99302 22621 1.150

3 20000 24550 99302 22621 1.287

4 40000 27683 99302 22621 1.627

5 40000 25894 99302 22621 1.548

6 40000 19527 99302 22621 1.266

Table 9. Cumulative Damage Factors for HVFAC for Two Stage Compound Fatigue Loading

Specimen

no.

No. of load cycles

applied at Stress

level

Fatigue Life at

Stress LevelCumulative damage

factor

M=(n1/N1)+(n2/N2)S=0.65 S=0.6 S=0.65 S=0.6

(n1) (n2) (N1) (N2)

1 2000 9861 5153 22621 0.824

2 2000 15683 5153 22621 1.081

3 2000 13187 5153 22621 0.971

4 1000 17122 5153 22621 0.951

5 1000 15566 5153 22621 0.882

6 1000 19891 5153 22621 1.073

-

7/30/2019 Fatigue Behavior of High Volume Fly Ash Concrete Under Constant Amplitude and Compound Loading

10/12

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 3, Issue 2, July- December (2012), IAEME

413

Table 10. Cumulative Damage Factors for HVFAC for Three Stage Compound Fatigue Loading

Specimen

no.

No. of load cycles applied

at Stress level

Fatigue Life at Stress

LevelCumulative

damage factor

M=(n1/N1)+(n2/N2)

+(n3/N3)S=0.55 S=0.6 S=0.65 S=0.55 S=0.6 S=0.65(n1) (n2) (n3) (N1) (N2) (N3)

1 40000 6000 2838 99302 22621 5153 1.219

2 40000 6000 3836 99302 22621 5153 1.412

3 40000 6000 4126 99302 22621 5153 1.469

4 20000 10000 3645 99302 22621 5153 1.351

5 20000 10000 3358 99302 22621 5153 1.295

6 20000 10000 5372 99302 22621 5153 1.686

Table 11. Cumulative Damage Factors for HVFAC for Four Stage Compound Fatigue Loading

Specimenno.

No. of load cycles applied atStress level

Fatigue Life at Stress Level Cumulativedamage factor

M=(n1/N1)+

(n2/N2)+(n3/N3)

+(n4/N4)

S=0.55 S=0.6 S=0.65 S=0.7 S=0.55 S=0.6 S=0.65 S=0.7

(n1) (n2) (n3) (n4) (N1) (N2) (N3) (N4)

1 40000 5000 1000 911 99302 22621 5153 1174 1.594

2 40000 5000 1000 811 99302 22621 5153 1174 1.509

3 40000 5000 1000 1025 99302 22621 5153 1174 1.691

4 20000 10000 2000 1258 99302 22621 5153 1174 2.103

5 20000 10000 2000 852 99302 22621 5153 1174 1.757

6 20000 10000 2000 1042 99302 22621 5153 1174 1.919

7. CONCLUSIONS

Based on experimental investigations following conclusions were made.

For probability distribution of fatigue life lognormal distribution model was found tobe satisfactory for both PCC and HVFAC at all stress levels.

Parameters of lognormal model were found to be dependent on type of concrete andthe stress level.

There is an upper limit for stress level in fatigue loading which is dependent on typeof concrete, beyond which fatigue life value was insignificant.

S-N relations obtained from regression analysis were found to be dependent on typeof concrete i.e., mainly on the static strength of concrete. Following are the S-N

relations for PCC and HVFAC

S = -0.0358Ln(N) + 0.9948 -------- for PCC

S = -0.0338Ln(N) + 0.9389 -------- for HVFAC

Miners sum varied between 0.824 and 2.103. Hence Miners hypothesis gives bothunsafe and over safe predictions for failure of HVFAC under compound fatigue

loading.

Miners sum shows dependency on type of compound fatigue loading and also onsequence of loading.

-

7/30/2019 Fatigue Behavior of High Volume Fly Ash Concrete Under Constant Amplitude and Compound Loading

11/12

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 3, Issue 2, July- December (2012), IAEME

414

8. ACKNOWLEDEGEMENT

The financial support under Research Promotion Scheme from All India Council for

Technical Education, New Delhi, India, is gratefully acknowledged.

REFERENCES

1. Hilsdorf, H.K., and C.E.Kesler. Fatigue Strength of Concrete under Varying

Flexural Stresses.ACI Journal Proceedings, Vol. 63, No. 10, 1966, pp. 1059-1076.

2. Ballinger, C.A. Cumulative Fatigue Damage Characteristics of Plain Concrete.

Highway Research Record, No. 370, 1972, pp. 48-60.

3. Tepfers, R., and T.Kutti. Fatigue Strength of Plain, Ordinary, and Lightweight

Concrete.ACI Journal Proceeding, Vol. 1979, pp. 635-652.

4. Vesic, A.S., and S.K.Saxena. Analysis of Structural Behavior of Road Test Rigid

Pavements.Highway Research record, No.291, 1969, pp. 156-158.

5. Treybig, H.J., McCullough, B.F., Smith, P., and H.Von Quintus. Overlay Design

and Reflection Cracking Analysis for Rigid Pavements. Development of New Design

Criteria. FHWA Report No. FHWA-RD-77-76, Vol.1, 1977.

6. Aas-Jakobsen, K. Fatigue of Concrete Beams and Columns. NTH Institute of

Betonkonstruksjoner, Trondheim, Bulletin No. 70-1, Norway, 1970, 148 pp.

7. Hsu, T.T.C. Fatigue of Plain Concrete. ACI Journal Proceeding, Vol. 78, No. 4,

1981, pp. 292-305.

8. A.J.M.Siemes. Miners Rule with Respect to Plain Concrete Variable Amplitude

Tests.ACI Special Publication, No. SP-75, 1987, pp. 343-371.

9. Jan Ove Holmen. Fatigue of Concrete by Constant and Variable Amplitude

Loading.ACI Special Publication, No. SP-75, 1987, pp. 71-109.

10. P.K.Mehta. High Performance, High Volume Fly Ash Concrete for Sustainable

Development. Proceedings of International Workshop on Sustainable Development and

Concrete Technology, Ottawa, Canada, 2002, pp. 3-1411. Tse, E.W., Lee, D.Y., and F.W.Klaiber. Fatigue behavior of Concrete Containing

Fly ash.ACI Special Publication, No. SP-91, 1986, pp. 273-289.

12. Naik, T.R., and S.S.Singh. Fatigue Property of Concrete with and without mineral

admixtures. ACI Special Publication, No. SP-144, 1994, pp. 269-288

13. Ramakrishnan, V., Malhotra, V.M., and W.S.Langley. Comparative Evaluation of

Flexural Fatigue Behavior of High Volume Fly Ash and Plain Concrete. ACI Special

Publication, No. SP-229, 2005, pp. 351-368.

14. IS 3812 (Part 1): 2003, Pulverized Fuel ash-Specification for use as Pozzolana in

Cement, Cement mortar and Concrete.Bureau of Indian Standards, New Delhi, India.

15. IRC: SP:62-2004, Guidelines for the design and Construction of Cement Concrete

Pavements for Rural Roads.

16. Byung Hwan Oh. Fatigue-Life Distributions of Concrete for Various StressLevels. ACI Materials Journal, Vol.88. No. 2, 1991, pp. 122-128.

17. Shi, X.P., Fwa, T.F., and S.A.Tan. Flexural Fatigue Strength of Plain Concrete.

ACI Materials Journal, Vol. 90, No. 5, 1993, pp. 435-440.

18. Dr. Shanthappa B. C.,Dr. Prahallada. M. C. and Dr. Prakash. K. B., Effect Of

Addition Of Combination Of Admixtures On The Properties Of Self Compacting Concrete

Sub-Jected To Alternate Wetting And Drying International Journal of Civil Engineering &

Technology (IJCIET), Volume 2, Issue 1, 2011, pp. 17-24, Published by IAEME

-

7/30/2019 Fatigue Behavior of High Volume Fly Ash Concrete Under Constant Amplitude and Compound Loading

12/12

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 3, Issue 2, July- December (2012), IAEME

415

19. A.S Jeyabharathy, Dr.S.Robert Ravi and Dr.G.Prince Arulraj Finite Element

Modeling Of Reinforced Concrete Beam Column Joints Retrofitted With Gfrp Wrapping

International Journal of Civil Engineering & Technology (IJCIET), Volume 2, Issue 1, 2011,

pp. 35-39, Published by IAEME.

20. M.N.Bajad, C.D.Modhera and A.K.Desai, Influence Of A Fine Glass Powder OnStrength Of Concrete Subjected To Chloride Attack International Journal of Civil

Engineering & Technology (IJCIET), Volume 2, Issue 2, 2011, pp. 01-12, Published by

IAEME.

21. H.Taibi Zinai, A. Plumier and D. Kerdal, Computation Of Buckling Strength Of

Reinforced Concrete Columns By The Transfer-Matrix Method International Journal of

Civil Engineering & Technology (IJCIET), Volume 3, Issue 1, 2012, pp. 111 - 127, Published

by IAEME.

22. P.A. Ganeshwaran, Suji and S. Deepashri, Evaluation Of Mechanical Properties

Of Self Compacting Concrete With Manufactured Sand And Fly Ash International Journal

of Civil Engineering & Technology (IJCIET), Volume 3, Issue 2, 2012, pp. 60 - 69,

Published by IAEME.

23. K. Sasiekalaa and R. Malathy, Flexural Performance Of Ferrocement Laminates

Containing Silicafume And Fly Ash Reinforced With Chicken Mesh International Journal of

Civil Engineering & Technology (IJCIET), Volume 3, Issue 2, 2012, pp. 130 - 143, Published

by IAEME.