Euro Code Flat_slabs

Transcript of Euro Code Flat_slabs

-

7/30/2019 Euro Code Flat_slabs

1/17

HHOOWW TTOO DDEESSIIGGNN

CCOONNCCRREETTEESSTTRRUUCCTTUURREESS

Flat Slabs

-

7/30/2019 Euro Code Flat_slabs

2/17

I nst ruct ions fo r t he Members o f BI BM, CEMBUREAU, EFCA and ERMCO:

"All or part of the information contained herein may be used, translated and adapted at nationallevel with reference and credit to the original publication issued by the European ConcretePlatf orm" . (See guidelines)I t is t he responsibili t y of the Member s (nat ional associat ions) of BI BM, CEMBUREAU, EFCA andERMCO to tr anslate and/ or adapt t his publication w it hin th eir national framew ork, to publish it

under th eir own name and logo and to disseminate it t o their contacts at nati onal level. The logo ofth e European Concrete Platf orm cannot be used at national level.

I t is t he responsibili t y of the Member s (nat ional associat ions) of BI BM, CEMBUREAU, EFCA and

ERMCO to submit for authorisation th e national version of th e Concise Eurocode 2 and t he "How toleaflets" to t heir respective nati onal standardisation comm it tee responsible for t he Eurocodes.

Copyright: Name of national concrete platf orm or nat ional MemberAcknowledgements to the European Concrete Platform ASBL

To be adapted at nat ional level:

Copyright: Name of national concrete platform or National member, date

Acknow ledgement s to t he European Concrete Platfor m ASBL

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means,electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of (Name of national concrete platform or

National member).

Published by Name of national concrete platform or National memberEditor:

address

country

Layout & Printing by Name of national concrete platform or National member

All information in this document is deemed to be accurate by (Name of national concrete platform or National member)at the time of goinginto press. It is given in good faith.

Information on (Name of national concrete platform or National member)document does not create any liability for its Members. While the

goal is to keep this information timely and accurate, (Name of national concrete platform or National member)cannot guarantee either. Iferrors are brought to its attention, they will be corrected.

The opinions reflected in this document are those of the authors and (Name of national concrete platform or National member)cannot beheld liable for any view expressed therein.

All advice or information from (Name of national concrete platform or National member) is intended for those who will evaluate thesignificance and limitations of its contents and take responsibility for its use and application. No liability (including for negligence) for any lossresulting from such advice or information is accepted.

Readers should note that all (Name of national concrete platform or National member)publications are subject to revision from time to timeand therefore ensure that they are in possession of the latest version.

-

7/30/2019 Euro Code Flat_slabs

3/17

How to design concrete structures using Eurocode 2

7. Flat slabs

IntroductionThis should be redrafted as appropriate

in a country

Designing to Eurocode 2

This guide covers the analysis and design of concrete flat slabs to

Eurocode 21. Eurocode 2 does not contain the derived formulae or

specific guidance on determining moments and shear forces. This has

arisen because it has been European practice to give principles in the

codes and for the detailed application to be presented in other sources

such as textbooks.

The first guide in this series, How to design concrete structures using

Eurocode 2: Introduction to Eurocodes2

, provides an overview ofEurocodes including terminology.

Where NDPs occur in the text in this publication, recommended valuesin EN 1992 are used and highlighted in yellow. The UK values havebeen used for NDPs embedded in figures and charts and the relevantNDPs are scheduled separately to assist other users in adapting thefigures and charts.(derivations can be found at www.eurocode2.info). A

list of symbols related to flat slab design is given at the end of this guide.

Analysis

The following methods may be used: Equivalent frame method

Finite element analysis

Yield line analysis

Grillage analogy

The Eurocode gives further advice on the equivalent frame method in

Annex I. Once the bending moments and shear forces have been

determined, the following guidance can be used for the design of flat

slabs.

Design procedure

A procedure for carrying out the detailed design of flat slabs is shown in

Table 1. This assumes that the slab thickness has previously been

determined during conceptual design. More detailed advice on

determining design life, loading, material properties, methods of

analysis, minimum concrete cover for durability and bond, and control of

crack widths can be found in another guide in this series, How to designconcrete structures using Eurocode 2: Getting started

3.

-

7/30/2019 Euro Code Flat_slabs

4/17

Fire resistance

Eurocode 2, Part 12: Structural fire design4, gives a

choice of advanced, simplified or tabular methods for

determining the fire resistance. Using tables is the

fastest method for determining the minimum

dimensions and cover for flat slabs. There are,

however, some restrictions and if these apply furtherguidance can be obtained from specialist literature.

Rather than giving a minimum cover, the tabular

method is based on nominal axis distance, a. This is

the distance from the centre of the reinforcing bar to

the surface of the member.

It is a nominal (not minimum) dimension, so the

designer should ensure that a cnom + link + bar/2

The requirements for flat slabs are given in Table 2

Flexure

The design procedure for flexural design is given inFigure 1; this includes derived formulae based on the

simplified rectangular stress block from Eurocode 2.

Where appropriate Table 3 may be used to determine

bending moments for flat slabs.

-

7/30/2019 Euro Code Flat_slabs

5/17

Whichever method of analysis is used, Cl. 9.4.1 requires

the designer to concentrate the reinforcement over the

columns. Annex I of the Eurocode gives

recommendations for the equivalent frame method on

how to apportion the total bending moment across a bay

width into column and middle strips to comply with Cl.

9.4.1. Designers using grillage, finite element or yield

line methods may also choose to follow the advice in

Annex I to meet this requirement.

Eurocode 2 offers various methods for determining the

stress-strain relationship of concrete. For simplicity the

method presented here is the simplified rectangular

stress block (see Figure 2).

The Eurocode gives recommendations for the design of

concrete up to class C90/105. However, for concrete

strength greater than class C50/60, the stress block is

modified. It is important to note that concrete strength is

based on the cylinder strength and not the cube strength

(i.e. for class C28/35 the cylinder strength is 28 MPa,

whereas the cube strength is 35 MPa).

-

7/30/2019 Euro Code Flat_slabs

6/17

Deflection

Eurocode 2 has two alternative methods of designing for

deflection; either by limiting span-to-depth ratio or by

assessing the theoretical deflection using the

Expressions given in the Eurocode. The latter is dealtwith in detail in another guide in this series, How todesign concrete structures using Eurocode 2: Deflection

calculations5.

The span-to-depth ratios should ensure that deflection is

limited to span/250 and this is the procedure presented

in Figure 3. The span-to-depth ratios are

appropriate where the structure remains propped during

construction or until the concrete attains sufficient strength

to support the construction loads. It can generally be

assumed that early striking of formwork will not significantly

affect the deflection after installing the cladding and/or

partitions6.

Punching shear

The design value of the punching shear force, VEd, will

usually be the support reaction at the ultimate limit state.

Standard factors for edge and corner columns that allow

for moment transfer () are greater in Eurocode 2.

However,can be calculated directly from Expressions

(6.38) to (6.46) of the Eurocode to give more efficient

designs.

Corrected Fig 3 at end of file

-

7/30/2019 Euro Code Flat_slabs

7/17

In Eurocode 2 the maximum value of shear at the

column face depends on the concrete strength

used.

The control perimeters for rectangular columns in

Eurocode 2 have rounded corners.

Where shear reinforcement is required the

procedure in Eurocode 2 is simple; the point at

which no shear reinforcement is required can be

calculated directly and then used to determine theextent of the area over which shear reinforcement is

required.

It is assumed that the reinforcement will be in a

radial arrangement. However, the reinforcement

can be laid on a grid provided the spacing rules are

followed.

The procedure for determining the punching shear

requirements is shown in Figure 6.

As an alternative to using shear links, proprietary shear studrails may be used. Eurocode 2 (Figure 6.22) allows them tobe laid out in a radial or cruciform pattern and gives spacingrequirements for both. Other techniques are available forincreasing punching shear resistance and these arecovered in a best practice guide.

Figure 6Procedure for determining punching shear capacity

-

7/30/2019 Euro Code Flat_slabs

8/17

Rules for spacing and quantity ofreinforcement

Minimum area of reinforcement

The minimum area of longitudinal reinforcement in the main

direction is As,min = 0.26 fctmbtd/fyk but not less than0.0013bd(see Table 6).

The minimum area of a link leg for vertical punching shear

reinforcement is1.5Asw,min /(sr.st) 0.08(fck

)/fyk.

which can be rearranged asAsw,min (sr.st)/F

wheresr = the spacing of the links in the radial directionst = the spacing of the links in the tangential directionFcan be obtained from Table 10

Maximum area of reinforcement

Outside lap locations, the maximum area of tension or

compression reinforcement should not exceedAs,max = 0.4 Ac

Minimum spacing of reinforcementThe minimum spacing of bars should be the greater of:

1 x Bar diameter

Aggregate size plus 5 mm

20 mm

Maximum spacing of main reinforcementFor slabs less than 200 mm thick the following maximum

spacing rules apply:

For the principal reinforcement: 3h but not more than

400 mm

For the secondary reinforcement: 3.5h but not more

than 450 mm

3.68

4.50

4.97

5.28

5.58

6.02

6.72

7.38

8.00

Corrected Table 7 at end of file

-

7/30/2019 Euro Code Flat_slabs

9/17

The exception is in areas with concentrated loads or areas of

maximum moment where the following applies: For the principal reinforcement: 2hbut not more than

250 mm For the secondary reinforcement: 3hbut not more than

400 mm, where his the depth of the slab.

For slabs 200 mm thick or greater reference should be made

to Section 7.3.3 of the Eurocode orHow to design concretestructures using Eurocode 2: Getting started3.

Spacing of punching shear reinforcementWhere punching shear reinforcement is required the

following rules should be observed.

It should be provided between the face of the column

and kdinside the outer perimeter where shearreinforcement is no longer required. kis 1.5, unless the

perimeter at which reinforcement is no longer requiredis less than 3dfrom the face of the column. In this casethe reinforcement should be placed in the zone 0.3dto1.5dfrom the face of the column.

There should be at least two perimeters of shear links. The radial spacing of the links should not exceed 0.75d

(see Figure 9).

The tangential spacing of the links should not exceed1.5dwithin 2dof the column face.

The tangential spacing of the links should not exceed2dfor any other perimeter.

The distance between the face of the column and thenearest shear reinforcement should be less than 0.5d.

Note

-

7/30/2019 Euro Code Flat_slabs

10/17

References1 EN 199211, Eurocode 2: Design of concrete structures General rules and rules for buildings.2 NARAYANAN, R S & BROOKER, O. How to design concrete structures using Eurocode 2: Introduction to

Eurocodes. The Concrete Centre, 2005.3 BROOKER, O. How to design concrete structures using Eurocode 2: Getting started. The Concrete Centre, 2005.4 EN 199212, Eurocode 2: Design of concrete structures. General rules structural fire design.5 WEBSTER, R & BROOKER, O. How to design concrete structures using Eurocode 2: Deflection calculations. The

Concrete Centre, 2006.

6 PALLETT, P. Guide to flat slab formwork and falsework. Construct, 2003.

Additional references for precast construction1. EN 13224 - Ribbed floor elements2. EN 13747 - Floor plates for floor systems3. EN 15037-1 - Beam-and-block floor systems - Beams4. prEN 15037[-2 to -5] - Beam-and-block floor systems - Blocks5. EN 1168 - Hollow core slabs6. EN 13369-Common rules for precast concrete products

AcknowledgementsThis guide was originally published by BCA and The Concrete Centre in the UK. The authors of the original publication

were R MossBSc, PhD, DIC, CEng, MICE, MIStructE and O BrookerBEng, CEng, MICE, MIStructE

Europeanised versions of Concise EC2 and How To LeafletsConvention used in the text

1. Nationally determined parameters that occur in the text have been highlighted yellow

2. Text is highlighted in pink indicates that some action is required on the part of thecountry adapting the documents for its use

-

7/30/2019 Euro Code Flat_slabs

11/17

Tables & Charts: Word versions (corrected text highlighted in green)

T a b l e 1 F l a t sl a b d e s i gn p r o c e d u r e

Further guidanceStep TaskChapter in thispublication

Standard

1 Determine design life 2: Ge t t i n g st a r t e d NA to EN 1990

2 Assess actions on the slab 2: Ge t t i n g st a r t e d EN 1991 (10 parts) andNational Annexes

3 Determine which combinations ofactions apply

1: In t r o d uc t i o n t o E u r o c o d e s

NA to EN 1990

4 Determine loading arrangements 2: Ge t t i n g st a r t e d NA to EN 1992115 Assess durability requirements and

determine concrete strength2: Ge t t i n g st a r t e d

6 Check cover requirements forappropriate fire resistance period

2: G e t t i n g st a r t e d and Table 2

EN 199212: Section 5

7 Calculate min. cover for durability, fireand bond requirements

2: Ge t t i n g st a r t e d EN 199211 Cl 4.4.1

8 Analyse structure to obtain criticalmoments and shear forces

2: G e t t i n g st a r t e d and Table 3

EN 199211 Section 5

9 Design flexural reinforcement See Figure 1 EN 199211 Section 6.110 Check deflection See Figure 3 EN 199211 Section 7.4

11 Check punching shear capacity See Figure 6 EN 199211 Section 6.4

12 Check spacing of bars 2: Ge t t i n g st a r t e d EN 199211 Section 7.3

13Check resistance to moment transferfrom column to slab

EN 199211 Annex I 1.2(5)

N o t e NA = National Annex

T a b l e 2 : M i n i m u m d i m e n si o n s a n d a x i s d i s t a n c e s f o r r e i n f o r c e d c o nc r e t e sl a b s

Minimum dimensions (mm)Standard fire resistance

Slab thickness, hs Axis distance, aREI 60 180 15a

REI 90 200 25

REI 120 200 35

REI 240 200 50

Notes1 This table is taken from EN 199212 Table 5.9.2 The axis distance is to the outer layer of reinforcement3 The table is valid only if the detailing requirements (see note 4) are observed and, in the normal temperature

design, redistribution of bending moments does not exceed 15%.4 For fire resistance of R90 and above, at least 20% of the total top reinforcement in each direction over

intermediate supports required by EN 199211 should be continuous over the full span. This reinforcement

should be placed in the column strip.

5 There are three standard fire exposure conditions that may need to be satisfied:

R Mechanical resistance for load bearing

E Integrity of separation

I InsulationKeya Normally the requirements of EN 199211 will determine the cover

-

7/30/2019 Euro Code Flat_slabs

12/17

F i g u r e 1 P r o c e d u r e f o r d e t e r m i n i n g f l e x u r a l r e i n f o r c e m e n t ( a s s u m i n g t h e r e c o m m e n d e d e x p r e s s i o n f o r , cc

( = 1 . 0 ) a n d c ( = 1 . 5 )

Determine K from Table 4 or 214.0137.0547.0'2 = K where

Is K K ?

Compression reinforcementrequired not recommended

for typical slabs

No compression reinforcement required

Yes

No

Obtain lever arm z from Table 5 or

[ ] dKdz 95.00.3112

+=

Calculate tension reinforcement required from

A s= M/fyd.z

Check minimum reinforcement requirements(see Table 6)

A s,min = 0.26 fctmbt d/fyk where fck 25

Check maximum reinforcement requirements A s,max = 0.04 Ac for

tension or compression reinforcement outside lap locations

Concrete class

C50/60? Outside scope of this publication

Yes

No

START

Determine K from:ckfbd

M

K 2=

Carry out analysis of slab todetermine design moments

(M) (Where appropriate usecoefficients from Table 3)

Arranged with horizontaldividing line in final printedcopy (x2)

-

7/30/2019 Euro Code Flat_slabs

13/17

T a b l e 3 Be n d i n g m o m e n t c o e f f i c i e n t s f o r f l a t s l a b s ( Su b st i t u t e d a t a c o m m o n l y u se d i n t h e c o u nt r y )

End support/slab connectionPinned ContinuousEndsupport

End span Endsupport

End span

Firstinteriorsupport

Interiorspans

Interiorsupports

Moment 0 0.086Fl 0.04Fl 0.075Fl 0.086Fl 0.063Fl 0.063Fl

Notes1 Applicable to slabs where the area of each bay exceds 30 m2,

Qk 1.25 Gk and qk 5 kN/m22 F is the total design ultimate load, l is the effective span3 Minimum span > 0.85 longest span, minimum 3 spans4 Based on 20% redistribution at supports and no decrease in span moments

T a b l e 4 V a l u e s f o r K (a ssu m i n g t h e r e c o m m e n d e d e x p r e ssi o n f o r a n d t h e r e c o m m e n d e d v al u e f o r c)

% redistribution (redistribution ratio) K

0 1.00 0.196a10 0.90 0.182a

15 0.85 0.16820 0.80 0.153

25 0.75 0.13730 0.70 0.102Keya It is often recommended that K should be limited to 0.168 to ensure ductile failure

T a b l e 5 z/d f o r s in g l y r e i n f o r c e d r e c t a n g u l a r s e ct i o n s ( a s s u m i n g t h e r e c o m m e n d e d v a l u e f o r c)

K z/d K z/d

0.07 0.944 0.15 0.871

0.08 0.936 0.16 0.861

0.09 0.927 0.17 0.85

0.10 0.918 0.18 0.839

0.11 0.909 0.19 0.828

0.12 0.900 0.196 0.821

0.13 0.891

0.14 0.881

T a b l e 6 Mi n i m u m p e r c e n t a g e o f r e i n f o r c e m e n t r e q u i r e d

fck fctm Minimum % (0.26fctm/fyka)

25 2.6 0.13%

28 2.8 0.14%

30 2.9 0.15%32 3.0 0.16%35 3.2 0.17%40 3.5 0.18%

45 3.8 0.20%50 4.1 0.21%

Keya Where fyk = 500 MPa

-

7/30/2019 Euro Code Flat_slabs

14/17

F i g u r e 3 P r o c e d u r e f o r a s se s si n g d e f l e c t i o n

The Eurocode is ambiguous regarding linear interpolation. It is understood that this was the intention of the drafting committee.

Is basic l/d F1 F2 F3 Actual l/d?

Determine Factor 1 (F1)For ribbed or waffle slabs

F1 = 1.1 0.1 ((bf/bw) 1) 0.8

(bf is flange breadth and bw is rib breadth)

Otherwise F1 = 1

Yes

Increase

A s,prov

Determine Factor 3 (F3)

F3 = 310/s

Where s = Stress in reinforcement at serviceabilitylimit state (see Figure 5)

s can be assumed to be 310 MPa (i.e. F3 = 1.0)

Check complete

Determine basic l/d from Figure 4

Determine Factor 2 (F2)Where the slab span exceeds 8.5 m and it supports

brittle partitions, F2 = 8.5/leffOtherwise F2 = 1.0

START

No

-

7/30/2019 Euro Code Flat_slabs

15/17

F i g ur e 6 P r o c e d u r e f o r d e t e r m i n i n g p u n ch i n g sh e a r c a p a c i t y

Determine concrete punching shear capacity (without shearreinforcement), vRd,c from Table 8where l = ( ly lz)

0.5

( ly lz are the reinforcement ratios in two orthogonal directions forfully bondedtension steel, taken over a width equal to column width

plus 3d each side)

Punching shearreinforcement not

required

Determine value of factor (refer to Figure 7 or Expressions (6.38) to

(6.46) of the Euroode)

Is vEd,max < vRd,max? Redesign slab

No

Yes

Is vEd > vRd,c?

No

Yes

START

Determine value ofvEd, (design shear stress) from:vEd,max = VEd/(u1deff)

where u1 is length of control perimeter(see Figure 8)

Determine value ofvRd,max from Table 7

Determine value ofvEd,max (design shear stress at face of column) from:vEd,max = VEd/(uideff)where: ui is perimeter of column

deff= (dy + dz)/2 (dy and dz are the effective depths in orthogonal directions)

Determine area of punching shear reinforcement per perimeter from:A sw = (vEd 0.75vRd,c)sru1/(1.5 fywd,ef)where sr is the radial spacing of shear reinforcement (see Figure 9)

fywd,ef= 250 + 0.25 defffywd (see Table 9)

Determine the length of the outer perimeter where shearreinforcement not required from:

uout,ef= VEd/(vRd,cd)

Determine layout of punching shear reinforcement (see Spacing of

punching shear reinforcement section and Figure 9)

Greek beta

-

7/30/2019 Euro Code Flat_slabs

16/17

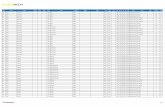

T a b l e 7 V a l u e s f o r vR d , m a x a ssu m i n g t h e r e c o m m e n d e d v a l u e s f o r , cc a n d c)

fck vRd,max

20 3.68

25 4.50

28 4.97

30 5.28

32 5.58

35 6.0240 6.72

45 7.38

50 8.00

T a b l e 8 vR d , c r e si s t a n c e o f m e m b e r s w i t h o u t s h ea r r e i n f o r c e m e n t , M P a

Effective depth, d (mm)I

200 225 250 275 300 350 400 450 500 600 750

0.25% 0.54 0.52 0.50 0.48 0.47 0.45 0.43 0.41 0.40 0.38 0.36

0.50% 0.59 0.57 0.56 0.55 0.54 0.52 0.51 0.49 0.48 0.47 0.45

0.75% 0.68 0.66 0.64 0.63 0.62 0.59 0.58 0.56 0.55 0.53 0.511.00% 0.75 0.72 0.71 0.69 0.68 0.65 0.64 0.62 0.61 0.59 0.57

1.25% 0.80 0.78 0.76 0.74 0.73 0.71 0.69 0.67 0.66 0.63 0.61

1.50% 0.85 0.83 0.81 0.79 0.78 0.75 0.73 0.71 0.70 0.67 0.65

1.75% 0.90 0.87 0.85 0.83 0.82 0.79 0.77 0.75 0.73 0.71 0.68

2.00% 0.94 0.91 0.89 0.87 0.85 0.82 0.80 0.78 0.77 0.74 0.71

k 2.000 1.943 1.894 1.853 1.816 1.756 1.707 1.667 1.632 1.577 1.516Notes

1 Table derived from: vRd,c = (0.18/c) k (100 Ifck)1/3 0.035 k1.5fck

0.5 where

k = 1 + (200/d) 2 and I = ( ly lz) 0.02, ly = A sy/(b d) and lz = A sz/(b d) and c =1.52 This table has been prepared for fck = 30;Where I exceeds 0.40% the following factors may be used:

fck 25 28 32 35 40 45 50

Factor 0.94 0.98 1.02 1.05 1.10 1.14 1.19

T a b l e 9 V a l u e s f o r fy w d , e f

deff fywd,ef

150 288

175 294

200 300

225 306

250 313

275 319300 325

325 331

350 338

Greek rho

-

7/30/2019 Euro Code Flat_slabs

17/17

T a b l e 1 0 Fa c t o r , F, f o r d e t e r m i n i n g As w , m i n

fck Factor, F

25 1875

28 1772

30 1712

32 1657

35 158540 1482

45 1398

50 1326

Notefck has been taken as 500 MPa

Se l e c t e d s y m b o l s

Symbol Definition Value

A c Cross sectional area of concrete b hA s Area of tension steel

A s2 Area of compression steel

A s, prov Area of tension steel provided

A s, reqd Area of tension steel required

b Width of slab

d Effective depth

d2 Effective depth to compression reinforcement

fcd Design value of concrete compressive strength cc fck/c

fck Characteristic cylinder strength of concrete

fctm Mean value of axial tensile strength 0.30 fck2/3 for fck C50/60 (fromTable 3.1, Eurocode 2)

hs Slab thickness

K Factor to take account of the differentstructural systems

See NA

leff Effective span of member See Section 5.3.2.2 (1)

l/d Limiting span-to-depth ratio

M Design moment at the ULS

x Depth to neutral axis (d z)/0.4

xmax Limiting value for depth to neutral axis 0.8( 0.44)d where 1.0

z Lever armcc Coefficient taking account of long term effects

on compressive strength and of unfavourableeffects resulting from the way load is applied

1.0

Ratio of the redistributed moment to the elasticbending moment

m Partial factor for material properties 1.15 for reinforcement (s)

1.5 for concrete (c)

0 Reference reinforcement ratio fck/1000

Required tension reinforcement at mid-span toresist the moment due to the design loads (or atsupport for cantilevers)

A s/b d

Required compression reinforcement at mid-span to resist the moment due to the designloads (or at support for cantilevers)

A s2/b d