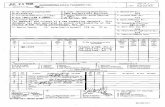

ENGINEERING DATA TRANSMITTAL 622827

Transcript of ENGINEERING DATA TRANSMITTAL 622827

ENGINEERING DATA TRANSMITTALPage 1 of J

622827

2. To: (Receiving Organization)

Distribution3. From: (Originating Organization)

NHC/TWRS Immob/S&D Project4. Related EDT No.:

5. Proj./Prog./Dept./Div.:

W519/TWRS Privat. Phase I

6. Design Authority/ Design Agent/Cog.

Engr.:

J. W. Shade

7. Purchase Order No.:

8. Originator Remarks:

For Approval and Release plus DOE-RL Receipt Acknowledgement9. Equip./Component No.:

10. System/BLdg./Facility:

11. Receiver Remarks: 11A. Design Baseline Document? [] Yes [X] No 12. Major Assm. Dwg. No.:

13. Permit/Permit Application No.:

14. Required Response Date:

DATA TRANSMITTED

(A)Item (B) Document/Drawing No.

(D)Rev.No.

(E) Title or Description of DataTransmitted

ApprovalDesig-nator

for

mittat

Origi-natorDispo-

Receiv-er

Dispo-

HNF-SD-TWR-EV-001 TWRS Phase IPrivatization SiteEnvironmentalBaseline andCharacterization Plan

Approval Designator (F) Reason for Transmittal (G) Disposition (H) & (I)

E, S, Q, D or N/A(see WHC-CM-3-5,Sec. 12.7)

1. Approval 4. Review2. Release 5. Post-Review3. Information 6. Dist. (Receipt Acknow. Required)

1. Approved2. Approved w/comi3. Disapproved w/ct

4. Reviewed no/comment5. Reviewed w/comment6. Receipt acknowledged

17. SIGNATURE/DISTRIBUTION(See Approval Designator for required signatures)

(K) Signature ID Date (M) MSIN(H)

Disp. (L) Date (M) MSIN

Design A u t h o r i t y R. J. Parazin

Design Agent

Cog.Eng. J.U. Shade ̂ (jj, U. T. Thompson

Cog. Mgr.A.F. choho

OA N/A

Safety: N/A

18.

J. W, Sha<

SigriatureofEDTOriginator

Authorized Representative Datefor Receiving Organization

A. R. ChohoMl*Design Authority/Cognizant Manager

2 1 . DOE APPROVAL ( i f requ i red)C t r l . No.

[] Approved[] Approved w/comments[] Disapproved w/comments

BD-7400-172-2 (05/96) GEF097

BD-7400-172-1

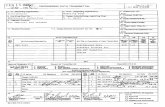

INSTRUCTIONS FOR COMPLETION OF THE ENGINEERING DATA TRANSMITTAL(USE BLACK INK OR TYPE)

Pre-assigned EDT number.

Enter the individual's name, title of the organization, or entity (e.g.. Distribution) that the EDT is beingtransmitted to.Enter the title of the organization originating end transmitting the EDT.

Enter EDT numbers which relate to the data being transmitted.

BLOCK(11*

(2)

13)

(4)

15] •

TITLEEDT

To: (Receiving Organ

From: (Originating Or

Related EDT No.

Proj./Prog./Dept./Div.

ization)

ganization)

(7)

(8)*

(9)

(10)

(11)

(11 A)*

(12)

(13)

(14)

(15)*

(16)

Purchase Order No.

Originator Remarks

Equipment/Component No.

System/BIdg. /Facility

Receiver Remarks

Design Baseline Document

Major Assm. Dwg. No.

Permit/Permit Application No.

Required Response Date

Data Transmitted

(A)* Item Number

(B)* Document/Drawing No.

(C)* Sheet No.

(D)* Rev. No.

(E) Title or Description ofData Transmitted

(F)* Approval Designator

(G) Reason for Trans mitt a I

(H) Originator Disposition

(I) Receiver Disposition

Key

Signature/Distribution

IQ)

(H)

(J)

IK)'

(L>*

(Ml*

Reason

Disposition

Name

Signature

Date

MSIN v /

Signature of EDT Originator

(19) Authorized Representativefor Receiving Organization

(20)* Design Authority/CognizantManager

(21)* DOE Approval

Enter the Project/Pro gram/Department/Division tttle or Project/ProgiOrder Number or Organization Code.

Design Authority (for Design BaselineDocumentsJ/Cognizant Engineer (forall others)/Design Agent

acronym or Project Number, Work

Enter the name of the individual identified as being responsible for coordinating disposition of the EDT.

Enter an ~X" in the appropriate bo:Documents, if required.

• Enter related Purchase Order (P.O.) Number, if available.

• Enter special or additional comments concerning transmittsl, or "Key" retrieval words may be entered.

9 Enter equipment/component number of affected item, if appropriate.

• Enter applicable system, building or facility number, if appropriate.

• Enter special or additional comments concerning transmtttal.

Consult with Design Authority for identification of Design Baseline

Enter applicable drawing number of major assembly, if appropriate.

Enter applicable permit or permit application number, if appropriate.

Enter the date a response is required from individuals identified in Block 17 (Signature/Distribution).

Enter sequential number, beginning with 1, of the information listed on EDT.

Enter the unique identification number assigned to the document or drawing being transmitted.

Enter the sheet number of the information being transmitted. If no sheet number, leave blank.

Enter the revision number of the information being transmitted, if no revision number, leave blank.

Enter the title of the document or drawing or a brief description of the subject if no title is identified.

Enter the appropriate Approval Designator (Block 15). Atscitem listed, i.e., SQ, ESQ, etc.

indicate the appropriate approvals for each

nittal (see Block 16).Enter the appropriate code to identify the purpose of the data tra

Enter the appropriate disposition code (see Block 16).

Enter the appropriate disposition code (see Block 16).

Number codes used in completion of Blocks 15 (G), (H), and (I), and 17 (G), (H) (Signature/Distribution).

Enter the code of the reason for transmittal (Block 16).

Enter the code for the disposition (Block 16).

Enter the signature of the individual completing the Disposition 17 (H) and the Transmittal.

Obtain appropriate signature(s).

Enter date signature is obtained.

Enter MSIN. Note: If Distribution Sheet is used, show entire distribution (including that indicated on Page 1of the EDT) on the Distribution Sheet.

Enter the signature and date of the individual originating the EDT (entered prior to transmittal to ReceivingOrganization). If the EDT originator is the Design Authority (for Design Baseline Documents)/CognizantEngineer (for all others) or Design Agent, sign both Blocks 17 and 18.

Enter the signature and date of the individual identified by the Receiving Organization Design Authority (forDesign Baseline DocumentsJ/Cognizant Engineer (for all others) as authorized to approve disposition of theEDT and acceptance of the data transmitted, as applicable.

Enter the signature and date of the Design Authority/Cognizant Manager. (This signature is authorizationfor release.)

Enter DOE approval (if required) by signature or control number that tracks the approindicate DOE action. , , ,

al to a signature, and

'Asterisk denote the required minimum items check by Configuration Documentation prior to release; thei e the minimum releas

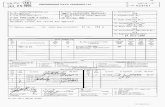

HNF-SD-TWR-EV-001, Rev. 0

TWRS PHASE I PRIVATIZATION SITEENVIRONMENTAL BASELINE ANDCHARACTERIZATION PLAN

C.H. Chou, V.S. Johnson, S.P. Reidel, J.W. Shade*Pacific Northwest National Laboratory, Richland, WA 99352* Numatec Hanford Company, Richland, WA 99352U.S. Department of Energy Contract DE-AC06-96RL13200

EDT/ECN: • 62047§Org Code: 8C452B&R Code: EW3130010

630Charge Code: D633DTotal Pages: •-W5J54

Key Words: TWRS Phase I Privatization, Environmental Baseline,Characterization Plan

Abstract: This document provides a plan to characterize and develop anenvironmental baseline for the TWRS Phase I Privatization Site beforeconstruction begins. A site evaluation study selected the former GroutDisposal Area of the Grout Treatment Facility in the 200 East Area asthe TWRS Phase I Demonstration Site. The site is generally clean andhas not been used for previous activities other than the GTF. A DQOprocess was used to develop a Sampling and Analysis Plan that wouldallow comparison of site conditions during operations and after Phase Iends to the presently existing conditions and provide data for thedevelopment of a preoperational monitoring plan.

TRADEMARK DISCLAIMER. Reference herein to any specific conmercial product, process, or service bytrade name, trademark, manufacturer, or otherwise, does not necessarily constitute or imply itsendorsement, recommendation, or favoring by the United States Government or any agency thereof orits contractors or subcontractors.

Printed in the United States of America. To obtain copies of this document, contact: DocumentControl Services, P.O. Box 950, Mailstop H6-08, Richland WA 99352, Phone (509) 372-2420;Fax (509) 376-4989. '

VrtsM^J\.

DATE: ^ KANFORD

elease Approval Release Stamp

Approved for Public Release

A-6400-073 (01/97) GEF321

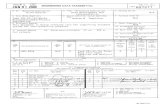

HNF-SD-TWR-EV-001Revision 0

TWRS Phase I Privatization SiteEnvironmental Baseline andCharacterization Plan

C. J. ChouV. G. JohnsonS. P. ReidelJ. W. Shade

Date PublishedSeptember 1997

Prepared for the U.S. Department of EnergyAssistant Secretary for Environmental Management

Project Hanford Management Contractor for theU.S. Department of Energy under Contract DE-AC06-96RL13200

Approved for public release; distribution is unlimited

HNF-SD-TWR-EV-001, Rev. 0

CONTENTS

1.0 Introduction 1.11.1 Approach 1.1

1.1.1 Site Considerations 1.21.1.2 Development of the Plan 1.2

1.2 Background 1.31.3 Disposal Decisions 1.4

1.3.1 Phased Privatization Concept for Treatment of Tank Waste 1.51.3.2 Location of Facilities 1.6

2.0 Hanford Site Physical and Environmental Description and Background Information 2.12.1 Geography 2.12.2 Climate 2.1

2.2.1 Temperature 2.42.2.2 Precipitation 2.42.2.3 Dust and Blowing Dust 2.42.2.4 200 East Area Climate Data 2.4

2.3 Geology 2.52.3.1 Geologic Setting of the Hanford Site : 2.52.3.2 Geology of the TWRS Phase TDemonstration Site ; 2.10

2.4 Hydrogeology 2.152.4.1 Hanford Hydrogeologic Setting 2.152.4.2 Uppermost Aquifer System 2.152.4.3 Hydrogeology of the TWRS Phase I Demonstration Site 2.15

2.5 Groundwater Quality/200 East and 200 West Areas Contaminant Plumes 2.182.5.1 Metals-Arsenic (Filtered) 2.192.5.2 Anions-Nitrate 2.292.5.3 Tritium 2.292.5.4 Beta-Emitting Radionuclides 2.302.5.5 Alpha-Emitting Radionuclides 2.30

2.6 Soil Quality 2.322.7 Air Quality 2.352.8 Summary 2.35

3.0 Data Quality Objectives Process 3.1Description of Data Quality Objectives Process 3.1

3.2 Description of the Issue to be Addressed 3.13.2.1 Conceptual Model 3.3

3.3 Decisions to be Made : 3.73.4 Inputs to Decision 3.10

3.4.1 Information Categories 3.103.4.2 Resource Constraints and Cost Saving/Deferral Alternatives 3.103.4.3 Information Sources 3.11

3.5 Study Boundaries 3.123.6 Decision Rules 3.12

3.6.1 Constituents of Concern 3.123.6.2 Sample Size 3.12

HNF-SD-TWR-EV-001, Rev. 0

CONTENTS (cont.)

3.7 Specify Limits on Decision Error 3.153.7.1 Statistical Objectives 3.153.7.2 Selection of the Statistical Parameter 3.153.7.3 Sample Size Determination (for Estimating Means) : . . 3.16

3.8 Optimize Design for Obtaining Data 3.173.8.1 New Data 3.183.8.2 Application of the Baseline Data 3.21

4.0 Description of Characterization Tasks 4.14.1 Surface and Near-Surface Characterization 4.1

4.1.1 Anthropogenic Features and Surface Contamination Map 4.14.1.2 Surface Soil Characterization Activities 4.3

4.2 Subsurface Characterization 4.44.2.1 Vadose Zone Characterization Activities 4.44.2.1.1 Shallow (3 m) Borings 4.44.2.1.2 Deeper (15-m) Borings 4.44.2.1.3 Geophysical Logging 4.54.2.2 Sampling and Analysis 4.5

4.3 Airborne Paniculate Contaminant Baseline Monitoring 4.5

5.0 References 5.1

APPENDIXES

A Sampling and Analysis Plan

Al Field Sampling PlanA2 Quality Assurance Project Plan

B Relative Hazard Index Values for Envelope D Tank Waste Constituents

HNF-SD-TWR-EV-001, Rev. 0

LIST OF FIGURES

1.1 Map Showing TWRS Phase I Demonstration Site 1.72.1 Map of Hanford Site and TWRS Phase I Demonstration Site 2.22.2 Major Geographic Features of the Hanford Site 2.32.3 Joint Frequency Diagram for Wind Directions at the Hanford Site 2.62.4 Generalized Geologic Features of the Hanford Site 2.72.5 Stratigraphic Nomenclature of the Hanford Site 2.82.6 Late Neogene Stratigraphy of the Pasco Basin Emphasizing the Ringold Formation 2.92.7 Location of Boreholes at and near the TWRS Phase I Demonstration Site 2.122.8 Stratigraphic Units and Lithology at the TWRS Phase I Demonstration Site 2.132.9 Geologic Map of the 200 East and West Areas and Vicinity 2.14

2.10 Hanford Site and Outlying Areas Water Table Map, June 1996 2.172.11 200 East Area and Adjacent Areas Water Table Map, June 1996 2.202.12 Arsenic Contamination in the 200 East and 200 West Areas 2.212.13 Nitrate Plume in the 200 East and 200 West Areas 2.222.14 Tritium Distribution in the Uppermost Aquifer Beneath the 200 Areas 2.232.15 Gross Beta Distribution in the Uppermost Aquifer Beneath the 200 Areas 2.242.16 Technetium-99 Distribution in the Uppermost Aquifer Beneath the 200 Areas 2.252.17 Iodine-129 Distribution in the Uppermost Aquifer Beneath the 200 Areas 2.262.18 Gross Alpha Distribution in the Uppermost Aquifer Beneath the 200 Areas 2.272.19 Operable Unit Boundaries for the 200 East Area 2.282.20 Aerial Radiation Survey (conducted July-August 1988) 2.312.21 Spot Gamma Contamination Identified by Ground Level Radiation Survey 2.332.22 Sampling Locations in and near the TWRS Phase I Demonstration Site 2.342.23 The 200 East Area Air Sampler Locations 2.362.24 Annual Average 90Sr, 137Cs, and 23™°Pu Concentrations in Air

for Hanford Separations Area and Vicinity 2.383.1 DQO Process Flow Chart 3.23.2 Conceptual Model of Existing Soil Column Near the TWRS Phase I Demonstration Site 3.43.3 Conceptualization of a Spill Scenario 3.6

3.4a Hypothetical Release of Airborne Contaminants from Waste Immobilization Plant 3.83.4b Deposition Pattern from Hypothetical Release of Particulates

from Waste Immobilization Plant 3.93.5a Surface Soil Sampling Grid for Phase I Demonstration Site 3.193.5b Surface Soil Sampling Grid for Phase I Demonstration Site 3.203.5c Surface Soil Sampling Locations for the Waste Transfer Corridor 3.22

HNF-SD-TWR-EV-001, Rev. 0

LIST OF TABLES

2.1 Annual Average Paniculate Radionuclide Concentrations from Air MonitorsNear the TWRS Phase I Demonstration Site, FY 1995 2.37

3.1 Sample Sizes Needed for Various Combinations of Margin of Errorsand CV (%) at 95% Level of Confidence 3.17

4.1 Summary of Various Tasks for the TWRS Phase I Characterization 4.2

HNF-SD-TWR-EV-001, Rev. 0

TERMS

AL action levelANOVA analysis of varianceCRBG Columbia River Basalt GroupCSB canister storage buildingCV coefficients of variationDCG Derived Concentration GuidesDL detection limitDOE U.S. Department of Energy'sDST double-shell tanksDQO Data Quality ObjectivesDWS drinking water standardEcology Washington State Department of EcologyEIS environmental impact statementEPA U.S. Environmental Protection AgencyGPR ground-penetrating radarGTF Grout Treatment FacilityHMS Hanford Meteorological StationHLW high-level radioactive wasteILAW immobilized high-activity wasteJFD joint frequency distributionLAW low-activity wasteLLW low-level wasteMCL maximum contaminant levelMDC minimum detectable concentrationmsl mean sea levelMT metric tonMTU metric tons of uraniumOBL operating background levelPC privatization contractorsPCB polychlorinated biphenylPFP Plutonium Finishing PlantPHMC Project Hanford Management ContractorsPUREX Plutonium-Uranium Extraction (process or Plant)REDOX Reduction-Oxidation (Facility)RFP request for proposalROD record of decisionSAP sampling and analysis planSST single-shell tanksTBP tributyl phosphateTEDF Treated Effluent Disposal FacilityTri-PartyAgreement Hanford Federal Facility Agreement and Consent OrderTWRS Tank Waste Remediation SystemWAC Washington Administrative Code

HNF-SD-TWR-EV-001, Rev. 0

TERMS (continued)

WHC Westinghouse Hanford CompanyWRS Wilcoxon Rank SumWWQS Washington Water Quality Standard

HNF-SD-TWR-EV-001, Rev. 0

1.0 Introduction

The U.S. Department of Energy's (DOE) Hanford Site in Washington State has the most diverse andlargest amount of radioactive tank waste in the United States. Recently, as part of the cleanup mission, DOEawarded privatization contracts for pretreatment and immobilization of the waste for final disposal. Thework will begin with a demonstration phase (discussed in Section 1.3.1). The demonstration phase is dividedinto Phase IA, a project planning and conceptual design phase, and Phase IB, the demonstration facilityconstruction and operation phase that is expected to process up to 13% of the Hanford Site tank waste.

This report contains the plan for characterizing the environment and developing an environmentalbaseline at the demonstration site before construction activities begin. The report also contains the DataQuality Objectives (DQO) used to define the input requirements needed to obtain characterization data toestablish a preconstruction environmental baseline and a summary of existing information on the Phase IDemonstration Site.

1.1 Approach

The DOE requires environmental baseline surveys before the startup of new facilities as part of itsgeneral environmental program (DOE 1988a) and as required by DOE Order 5484.1 (EnvironmentalProtection, Safety and Health Protection Information Reporting Requirements [DOE 1981]).Characterization plans are necessary to determine existing conditions and assess relative risks and hazardsbefore construction and operation of facilities. In addition, baseline site conditions must be known toimplement privatization site lease agreements with DOE.

The DOE guidance on the management of low-level waste (LLW) (DOE 1990a) indicates that a completeenvironmental monitoring program should consist of four phases. These phases should correspond with thefour phases in the life cycle of the facility: (1) characterization (preconstruction), (2) preoperational,(3) operational, and (4) post-operational.

This plan covers only the preconstruction characterization phase. The plan addresses the TWRS Phase IDemonstration Site; the utility and road corridors are addressed separately by the Project HanfordManagement Contractors (PHMC). A primary use of the preconstruction characterization data is to confirmthe suitability of the site and to decide optimum locations for the demonstration plants within thepredesignated area. Data acquired and considerations made during the characterization phase are designed tobegin establishing an environmental baseline. In addition, the data will be used to either extend or confirmthe adequacy of existing data for the preoperational phase. Until the process design is established and theexact location of the plants within the designated construction area are specified, a preoperational,operational, or post-operational monitoring plan cannot be prepared. However, this plan provides afoundation on which the later plans can be based and provides early characterization data on whichconstruction-related decisions can be based. Ultimately, the final environmental baseline will be developedusing data collected from this plan and from the preoperational plan.

The characterization activities are the responsibility of the PHMC; the DOE has designated that anindependent third party will collect the data and establish the environmental baseline.

1.1

HNF-SD-TWR-EV-001, Rev. 0

1.1.1 Site Considerat ions

The Tank Waste Remediation System (TWRS) Phase I Demonstration Site was initially designated as theGrout Disposal Area, which would have contained the vaults of grouted LLW produced by the GroutTreatment Facility (GTF). An initial characterization effort (Swanson et al. 1988) and performanceassessment (Kincaid et al. 1995) were conducted for that project. At the west end of the site, the GTF projectexcavated a pit about 100 m by 120 m by 15 m deep where 5 grout vaults were constructed. In addition,21 boreholes were drilled at the GTF site.

The TWRS Phase I Demonstration Site was selected through a site evaluation process (Shord 1996). Alarge database of characterization and environmental monitoring information is available for the site.Geohydrology, hydrology, and groundwater quality data are available in Hanford Site documents. Siteenvironmental activities include monitoring air, soil, groundwater, and biota. Annual environmentalmonitoring reports are issued by Pacific Northwest National Laboratory and the DOE management andoperations contractor (previously Westinghouse Hanford Company [WHC] and Rockwell HanfordCompany).

AH available reports and information were used to select the GTF as the TWRS Phase I DemonstrationSite (Shord 1996). Other than for the GTF project, the site has not been used, although several areas west ofthe site were used for waste disposal. During GTF characterization activities, borehole drilling, andconstruction and excavation of the GTF vault pit, no subsurface contamination was encountered. Minorsurface radiological contamination was located as part of previous characterization activities, but all datasuggest that the TWRS Phase I Demonstration Site is a "clean" site. Existing groundwater contaminationbeneath the TWRS Phase I Demonstration Site is from upgradient sources (see Section 2.5).

1.1.2 Development of the Plan

This plan was originally intended for use in developing an environmental baseline that would allowcomparison of project site conditions during operations and after Phase I ends to existing conditions. It alsowas intended as a guide for characterizing the site and, to the extent possible, to provide data for developinga preoperational monitoring plan.

After reviewing all the available data, the DQO process was used to develop a sampling and analysisplan. The DQO process was developed by the U.S. Environmental Protection Agency (EPA) to ensure thatthe type, quantity, and quality of environmental data used in the decision-making process are appropriate fortheir intended use. The DQO process includes both qualitative and quantitative components. Thequantitative aspect uses statistical methods to design the most efficient field investigation that controls thepossibility of making an incorrect decision. The qualitative aspect seeks to encourage good planning for fieldinvestigations and complements the statistical design. The process is both flexible and iterative. The endproduct or objective of this effort is a cost-efficient sampling and analysis plan (SAP). For the data collectioneffort, emphasis is on addressing the question "what data are needed to address the decisions that need to bemade?"

Characterization activities are costly. Typically, characterization samples are required from the surfaceand subsurface and are analyzed by laboratories for various compositions and properties. In the past, manycharacterization plans were criticized because sampling schemes could not be justified and the types ofanalyses really required were unclear. As a result, arbitrary grids with close spacings often were set up andanything that could be analyzed for was obtained from samples sent to the laboratories (e.g., Appendix IX list

1.2

HNF-SD-TWR-EV-001, Rev. 0

of analyses). By emphasizing what decisions will be made with the data, the DQO process focused on keyproblems or questions that the characterization plan was to address so that only needed data were collected.However, this required critical information on past uses of the land and, equally important, why thecharacterization was required. That is, what would be done on the land, where would facilities be placed, howwould they be constructed, and what kind of processes would be used in the facilities? •

In 1996 after the privatization contractors (PC) were selected, it was recognized that PC input wasessential so that information required for the preconstruction baseline could be incorporated into the DQOprocess. The types of data important to the DQO process included the following:

• The area required and the type, layout, preliminary design, and location of facilities (i.e., location ofprocessing facilities, feed tanks, and depth of excavations needed for foundations)

• The general nature of the process. The nature of the process is required to assess various releasescenarios, routes of exposure, and potential environmental hazards associated with the plantoperations.

Unfortunately, the DQO team could not get adequate information to develop the plan as originallyintended because the privatization contract does not require conceptual designs for immobilization facilitiesuntil December 1997. Much of the information required to complete a more detailed site characterizationplan tailored to site-specific needs is expected to be contained in several documents requested from the PC atthe end of Phase IA. These include the following:

• Technical report (Standard 2), which includes the process flow sheet description and waste treatmentprocess.

• Product and secondary waste plan (Standard 3), which describes the method of compliance withwaste specifications.

• Deactivation plan (Standard 8), which describes the procedures for deactivating the facility afterPhase IB is completed.

1.2 Background

High-level radioactive waste (HLW) has been stored in large underground tanks at the Hanford Site since1944. The total number of storage tanks is 177; 149 are single-shell tanks (SST) and 28 are double-shelltanks (DST). The caustic waste contained in the tanks consists of many different chemicals and radionuclidesin various phases and forms, including liquid, slurry, salt cake, and sludge. Estimates of the total tank wasteinventory vary, depending on the assumptions used to develop them. The total inventory of HLW in the177 underground tanks was estimated at 232,000 m3 (61 Mgal) by Schmittroth (1995). The privatizationrequest for proposal (RFP) (Wagoner 1996) indicates an inventory of approximately 240,000 metric tons(MT) of processed chemicals (about 56 Mgal) with 177 million curies of activity. These are the sameapproximations listed in the recently issued TWRS final environmental impact statement (EIS) (DOE 1996).Waste was retrieved from some of the tanks to reduce the heat load. The waste was processed to recover MSrand 13?Cs, which were converted to salts, then doubly encapsulated in metal containers and stored in waterbasins. This inventory consists of approximately 1,900 capsules measuring 6.7 cm (2.6 in.) in diameter by52 cm (20.5 in.) long. The capsules contain 134 MCi, decayed to December 31, 1999 (Petersen 1996). Thisinventory will be processed in addition to the tank waste. An effort to develop a best basis standard inventory

1.3

HNF-SD-TWR-EV-001, Rev. 0

of chemicals and radionuclides in Hanford Site tanks is under way. When completed, the effort will produceboth global and tank-by-tank inventories (Kupfer et al. 1996).

The radioactive waste came from plutonium and uranium recovery processing of approximately100,000 metric tons of uranium (MTU) from irradiated fuel, radionuclide recovery processing of tank waste,and other sources including laboratories and reactor decontamination solutions). The major chemicalseparation processes included the following:

• The bismuth-phosphate process for plutonium recovery• The tributyl phosphate (TBP) uranium recovery process• The reduction-oxidation (REDOX) process• The plutonium-uranium extraction (PUREX) process• B Plant waste fractionation.

Smaller waste volumes were generated from various development programs and the Plutonium FinishingPlant (PFP) operations.

Waste volumes have been reduced by decanting dilute waste to ground and conducting evaporatorconcentration processes with the evaporator bottoms returned to tanks. Other uranium recovery and volumereduction programs resulted in the addition of ferrocyanide and other chemicals to selected tanks. Over theyears, waste has been transferred and mixed among individual tanks in some tank farms either by specifictank-to-tank transfer or by cascade, as well as waste transfer among tank farms, resulting in considerablevariability in individual tank inventories. (See Kupfer et. al [1996] for a more detailed description of tankwaste variability.)

1.3 Disposal Decisions

An EIS issued in 1987 (DOE 1987) and a record of decision (ROD) issued in 1988 (53 FR 12449)focused on disposal of the tank waste. Conclusions from the ROD are as follows:

• Strontium and cesium capsules would be packaged and disposed of in a geologic repository.

• DST waste would be separated into two fractions. The high-activity fraction would be vitrified anddisposed of in a geologic repository. The low-activity fraction would be solidified with grout anddisposed of in near-surface vaults.

• Additional development and evaluation would be done on SST waste before making a disposaldecision.

Since the 1988 ROD was issued, the following events have occurred:

• Significant tank safety issues were identified concerning ferrocyanide and flammable gas generation.

• The DOE, EPA, and Washington State Department of Ecology (Ecology) signed the HanfordFederal Facility Agreement and Consent Order (Tri-Party Agreement) (Ecology et al. 1989).

• B Plant was eliminated from consideration as a waste pretreatment facility.

1.4

HNF-SD-TWR-EV-001, Rev. 0

• The TWRS Program was established by WHC in 1991 to safely treat, store, and dispose of the tankwaste.

• Retrieval of SST waste was included as a planning basis in the TWRS Program.

• The 1989 Tri-Party Agreement was renegotiated in September 1993 (Ecology et al. 1994) and wassigned by all parties in January 1994. A decision was made to use the vitrification option for bothLLW and HLW. The grout concept was put on hold because of retrievability problems andperformance uncertainties related to hazardous materials.

• A TWRS EIS was issued in August 1996 and includes a multiple disposal option (DOE 1996).

• A program to establish standard inventories of chemicals and radionuclides in individual tanks and aglobal inventory of all 177 tanks was initiated (Kupfer et al. 1996). This program established thebest basis inventories, resolved inconsistencies, and provided both global and tank-by-tankinventories for a variety of Hanford Site waste management activities.

The TWRS Program now focuses on resolving tank safety issues, planning for waste retrieval,developing waste pretreatment and treatment facilities, and evaluating waste storage and disposal needs.Vitrification and onsite disposal of LLW are embodied in the strategy described in the Tri-Party Agreement.The pretreatment and immobilization operations for both LLW and HLW will be conducted by privatecontractors. In response to the RFP (Wagoner 1996), two teams received contracts for the demonstrationphase of tank waste immobilization.

1.3.1 Phased Privatization Concept for Treatment of Tank Waste

As noted in Section 1.3, DOE has decided to privatize the treatment of most of the radioactive hazardouswaste contained in the underground waste storage tanks on the Hanford Site. Privatization is defined asvendors, under contract with DOE, using private funding to design, permit, construct, operate, and deactivatetheir own equipment and facilities to treat radioactive hazardous tank waste (or mixed waste as defined in theWashington Administrative Code [WAC] 173-303). Payment for these services takes the form of a fixedprice per unit of product meeting DOE specifications. Vendors are selected through a competitive process.

Privatization activities have been divided into two phases. Phase I, a "proof of concept" phase, is todemonstrate the capabilities of privatization through the treatment of up to 13% of the mixed waste stored atthe Hanford Site. Once demonstrated, privatization will be expanded into Phase II to treat the rest of thewaste.

During Phase I, readily retrievable and well-characterized selected DST waste would be retrieved andprocessed in two separate demonstration facilities. The waste processed during Phase I could also includeselected SST waste. Compositions of the low-activity waste (LAW) to be processed in Phase I are given inwaste composition Envelopes A, B, and C in the RPP; HLW compositions in Phase I are given in EnvelopeD. Both facilities would process liquid waste to produce immobilized LAW; one facility would produce bothimmobilized LAW and HLW. The facilities for LAW and HLW would be constructed as separate parts, butboth could be on the same site.

Phase I will be conducted in two parts. Phase IA will last about 20 months with 16 months for planningand conceptual design by the private contractor and 4 months for DOE review. Phase IB will consist of plant

1.5

HNF-SD-TWR-EV-001, Rev. 0

construction and operation to process about 2800 MT of sodium waste as LAW and 245 MT of wasteoxides, excluding the sodium and silicon, as HLW. A possible extension of the Phase IB contract wouldproduce an additional 2300 MT of sodium waste as LAW. Phase IB is expected to last 10 to 14 years with a5- to 9-year process period. Up to 13% of the Hanford Site waste will be processed in Phase IB, which willconclude with the completion of facility deactivation.

The immobilized LAW (ILAW) would be sealed in packages at treatment facilities and then transportedto an interim onsite storage facility, where it would be stored for eventual disposal. Based on the RFPspecification, between 13,000 and 18,000 ILAW waste packages are expected to be produced during Phase I.Currently, the four remaining grout vaults are being considered as an interim storage facility forapproximately the first 5,000 ILAW packages, with the rest slated to be stored in newly constructed facilities.The HLW would be placed in canisters and transported to an interim onsite storage facility, currentlyconsidered to be a part of the spent fuel canister storage building (CSB), where it would await shipment to apermanent geologic repository, currently anticipated to be the Yucca Mountain Project.

The LAW treatment facility would operate for 10 years. The HLW treatment facility is planned tooperate for 6 years, but could be extended to 10 years.

Phase II would be implemented as a separate contract following successful implementation of Phase I.Implementation of Phase II could involve continued operation of Phase I facilities plus construction of a full-scale separations and LAW vitrification facility and a full-scale HLW vitrification facility. Phase II wouldinclude the retrieval and treatment of the remaining DST and SST waste, as well as the waste contained in themiscellaneous underground storage tanks.

1.3.2 Location of Facilities

The two Phase I facilities will be located on the east side of the 200 East Area within the TWRS Phase IDemonstration Site (Figure 1.1). This site originally was to be the GTF but that project was canceled. Wastetransfer lines and utility lines would be constructed through corridors into the Phase I Demonstration Site.Phase II facilities are currently planned for construction in the central part of the 200 East Area (Shord 1995)along with additional ILAW storage and disposal facilities.

1.6

N 136250

CANTON AVENUE

ELECTRIC SUBSTATION

LAV DOWN AREA

LAYDOWN AREA

UPGRADED ROAD

UTILITY CORRIDOR

LIQUID EFFLUENT

3

g"

O N 135000

3O D151A

POTABLE WATER

OVHO ELECTRIC

WASHINGTON STATEGRID SYSTEMCOORDINATE INMETERS

" N "135250 "N 135750 jm jm

HNF-SD-TWR-EV-001, Rev. O

2.0 Hanford Site Physical and Environmental Descriptionand Background Information

The Hanford Site was established in 1944 as a U.S. Government nuclear materials production facility.During its history, Site missions have included nuclear reactor operation, storage and reprocessing of spentnuclear fuel, and management of waste. Current activities primarily involve waste management and Siterestoration. The inactive fuel reprocessing facilities and the radioactive waste management facilities arelocated in the 200 East Area and 200 West Area (Separations Area). These facilities are currently operatedbythePHMC.

Chapter 2 summarizes the physical and environmental conditions of the Hanford Site. This summary isbased on an extensive database obtained from characterization studies, waste management activities, andnuclear projects over the past 50 years. These reports and databases are too numerous to list in this overview.

2.1 Geography

The Site covers 1450 km2 (560 mi2), as shown in Figure 2.1, comprising parts of Benton, Franklin,Grant, and Adams counties. Use of the Site is institutionally controlled by DOE for national security andhealth and safety reasons.

The Columbia River enters the Hanford Site at the northwest corner and crosses over to form part of theeastern boundary as it flows southward. The Yakima River flows from west to east, forming part of thesouthern boundary of the Site and emptying into the Columbia River at the Tri-Cities (Richland, Kennewick,and Pasco). The Site is bordered on the north by the Saddle Mountains and on the west by the RattlesnakeHills (Figure 2.2). Dominant natural features include the Columbia River, anticlinal ridges of basalt in andalong the Hanford Site boundary, and sand dunes located near the Columbia River. The surrounding basalticridges rise to elevations as high as 1100 m (3600 ft).

The most broadly distributed vegetation is sagebrush, wheatgrass, bluebunch wheatgrass, and other shrubplant species common to central Washington State.

2.2 Climate

The climate of the Pasco Basin can be classified as midlatitude semiarid or midlatitude desert, dependingon the classification scheme used. Summers are warm and dry with abundant sunshine. Large diurnaltemperature variation results from intense solar heating during the day and radiational cooling at night.Daytime high temperatures in June, July, and August periodically exceed 38°C (100°F). Winters are coolwith occasional precipitation. Outbreaks of cold air associated with modified Arctic air masses can reach thearea and cause temperatures to drop below -18°C (0°F). Overcast skies and fog occur periodically during thewinter.

2.1

WASHINGTON

•ao

TWRSPhase I

200 AREAS Demonstration,

HNF-SD-TWR-EV-001, Rev. 0

Figure 2.2. Major Geographic Features of the Hanford Site.

2.3

HNF-SD-TWR-EV-001, Rev. 0

2.2.1 Temperature

At the Hanford Site, the annual average temperature is 12°C (53 °F). July is typically the warmest monthwith an average maximum temperature of 33°C (91 °F), an average minimum temperature of 16°C (61 °F),and an average temperature of 25°C (76°F). January tends to be the coolest month with an averagemaximum temperature of 4°C (38°F), an average minimum temperature of -4°C (24°F), and an averagetemperature of 0°C (32°F). Observed temperature extremes for the Hanford Site range from 45 °C (113 °F)to -31 °C (-23°F). The highest temperature ever recorded on the Site was 46°C (115°F) on July 27,1939.The lowest temperature ever recorded was -33 °C (-27°F).

2.2.2 Precipitation

The annual average precipitation value at the Hanford Meteorological Station (HMS) is 16.8 cm (6.6 in.).The wettest year was 1950 at 29.1 cm (11.45 in.); the driest was 1976 at 7.6 cm (2.99 in.). On average, 54%of normal annual precipitation falls during November through February. December is the wettest month,receiving, on average, 2.6 cm (1.03 in.), and July is the driest month receiving, on average, only 0.46 cm(0.18 in.). The wettest month on record is June 1950 with 7.4 cm (2.92 in.); September 1991, August 1988,and August 1955 recorded no precipitation. An average of 125 days per year have a trace (less than0.013 cm [0.005 in.]) or more of precipitation. The average number of days per month with a trace or moreranges from 16 days in January to 5 days in July. Only 24 days a year receive totals of 0.25 cm (0.1 in.) ormore. During the 49-year period of record (1945 through 1994), only 3 days have had 2.5 cm (1 in.) or moreof precipitation.

Total annual snowfall, which includes all frozen precipitation, varies from a low of 0.76 cm (0.3 in.) to142 cm (56.1 in.). The average annual snowfall is 38 cm (15 in.). The record snow depth at HMS is55.9 cm (22 in.) in December 1996, but the record snow depth on the Hanford Site is 61 cm (24 in.) inFebruary 1916.

2.2.3 Dust and Blowing Dust

Dust and blowing dust (locally resuspended) occur frequently, with blowing dust the most commonlyobserved. Dust and blowing dust are recorded at HMS when horizontal visibility is reduced to 9.65 km(6 mi) or less. Dust is carried into the area from distant sources and may or may not occur during strongwinds. Dust has been observed with wind speeds ranging from 1.8 m/s (4 mph) to 13.4 m/s (30 mph).Blowing dust occurs when dust is resuspended locally by strong winds. Wind speeds during blowing dustrange from 8.5 m/s (19 mph) to 35.8 m/s (80 mph). The average number of days per year with dust orblowing dust is 5. The greatest number recorded in any year is 20, while the fewest is 0. The greatestnumber of days with dust or blowing dust in any month was 9 in May 1980, just after the Mt. St. Helenseruption. Dust and blowing dust occur most frequently between March and May and again in September andoccur least frequently during November and December.

2.2.4 200 East Area Climate Data

Data collected from the 200 East Area meteorological tower are from the location closest to the TWRSPhase I demonstration site. This makes them the most accurate data for characterizing the dispersionclimatology of the 200 East Area. The joint frequency distribution (JFD) of hourly averaged wind data from

2.4

HNF-SD-TWR-EV-001, Rev. 0

the 200 East Area meteorological tower for the 9-year period from January 1982 to December 1991 areprovided in Schreckhise et al. (1993). Figure 2.3 is a wind rose and a wind speed histogram representing theJFD data for the Hanford Site. The wind rose data indicate that winds from the west-northwest sector occurmost frequently (nearly 20% of the time). That is, the emissions are transported toward the east-southeastsector. Winds out of the northwest and west also occur with a relatively high frequency (12% and 11%,respectively). For hours of unstable directions, wind from the west-northwest and northwest sectors occurmore frequently than the other directions. Winds also are more frequently from the west-northwest sectorduring stable conditions.

2.3 Geology

2.3.1 Geologic Setting of the Hanford Site

The Hanford Site lies within the Columbia Plateau, which consists of a thick sequence of tholeiitic basaltflows called the Columbia River Basalt Group (CRBG). These flows have been folded and faulted over thepast 17 million years, creating broad structural and topographic basins separated by asymmetric anticlinalridges. Sediments up to 518 m (1,700 ft) thick have accumulated in some of these basins. Basalt flows ofthe CRBG are exposed along the anticlinal ridges, where they have been uplifted as much as 1097 m(3,600 ft) above the surrounding area. Overlying the CRBG in the synclinal basins are sediments of the lateMiocene, Pliocene, and Pleistocene ages. The Hanford Site lies within one of the larger basins, the PascoBasin. The Pasco Basin is bounded on the north by the Saddle Mountains and on the south by RattlesnakeMountain and the Rattlesnake Hills (Figure 2.4). Yakima Ridge and Umtanum Ridge trend into the basin andsubdivide it into a series of anticlinal ridges and synclinal basins. The largest syncline, the Cold Creeksyncline, lies between Umtanum Ridge and Yakima Ridge and is the principal structure containing the DOEwaste management areas and the TWRS Phase I Demonstration Site. The geology of the Hanford Site isdescribed in detail in Volume 1 of DOE (1988b).

Figure 2.5 shows the main stratigraphic units at the Site. In ascending order, they are the CRBG(Miocene), the Ringold Formation (Miocene-Pliocene), the Plio-Pleistocene unit, and the Hanford formation(Pleistocene). A regionally discontinuous veneer of recent alluvium, colluvium, and/or eolian sedimentsoverlies the principal stratigraphic units.

2.3.1.1 Ringold Formation. The Neogene-age Ringold Formation is composed of weakly to moderatelyconsolidated and compacted fluvial coarse-grained gravels and sands as well as fine-grained muds associatedwith lacustrine and fluvial overbank environments (Figure 2.6). These strata record a history of alluvial-lacustrine sedimentation and pedogenic activity associated with the ancestral Columbia River system (Fechtet al. 1987; Lindsey 1991; Reidel et al. 1994). Ringold deposits overlie basalts and are overlain by latePliocene- and Pleistocene-aged deposits.

The Ringold Formation at the Hanford Site represents deposits of the ancestral Columbia and SnakeRivers between 8 and 3 million years ago. The depositional system was a braided stream channel with thetwo rivers joining in the area of the present White Bluffs. The deposits on the Hanford Site represent aneastward shift of the Columbia River from the west side of the Site. The Columbia River first flowed acrossthe west side and up Dry Creek, crossing over the Rattlesnake Hills at Sunnyside Gap. The river eventuallyshifted to a course that took it through Gable Gap and south across the present 200 East Area and the TWRSPhase I Demonstration Site.

2.5

HNF-SD-TWR-EV-001, Rev. 0

0 10 20 30Frequency of Occurrence (%)

0 4 8 Kilometers1 i ii—r0 2 4 6 8 Miles

Lines indicate direction from which wind blows;line length is proportional to frequency of occurrence.

SG97010239.3

Figure 2.3. Joint Frequency Diagram for Wind Directions at the Hanford Site.Hanford Meteorological Station Monitoring Network Wind Roses at 10-m Level, 1995.

2.6

3do'

3

O

O

Sentinel Frenchman HillsGap j

zT'r :>;>'^^?

Sadfllo Mountar - v

Pfisco BasinBoundary

' • • / - —

-N-

; * Itanlord Site; ^ < Bouncliiry

PalouseSlope

15 Kilometers

Anticline

•j—I Syncline

Thrust Fault

HNF-SD-TWR-EV-001, Rev. 0

(Formal and Informal)Sediment Stratigraphy

or Basalt Rows

ijillji ij!! i ill! 1' 111!!JS!SS!3!eiS!Hanford formation

PHo-Plelstocene Intervalmember of Savage Island

d Formation /member of Taylor Flat/ member of Wooded Island

Ice Harbor Member

Elephant Mountain Member

Pomona Member

Esquatzel Member

Asotln Member

Wilbur Creek Member

Umatllla Member

Priest Rapids Member

Frenchman Springs Member

member of Sentinel Bluffs

of Slack Canyon

of Grouse Creekof Wapshllla Ridgeof Mt. Horribleof China Creekof Teepee Butteof Buckhorn Springs

member of Rock Creek

lember of American Bar

basalt of Basin Cttv

basalt of Ward GaptaB of Elephant Mountain

Rattlesnake Ridge Interbedbasalt of Pomona

basalt of Gable Mountain

basalt of Huntzlngerbasalt of Lapwalbasalt of Wahlukebasalt of Sllluslbasalt of Umatllla

Mabton interbed

basalt of Rosalia

basalt of Roza

basatt of Lyons Ferrybasalt of Sentinel Gapbasalt of Sand Hollmbasalt of Silver Fallsbasatt of Ginkgobasalt of Pa louse Falls

basalt of Museumlisa It of Rocky Coulee

basatt of Leveringbasalt of Cohassettbasalt of BirKettbasalt of McCoy Canyonbasalt of Umtanum

•The Grande Ronde Basalt consists of at least 120 major basaK flows comprising 17 members.Nj, R2. N-j, and Rj are magnetostratigraphic units.

Figure 2.5. Stratigraphic Nomenclature of the Hanford Site.

2.8

HNF-SD-TWR-EV-001, Rev. 0

Idealized Suprabasalt Subsurface Stratigraphy of the Hanford Siteand Stratigraphic Nomenclature

S°°c

- • = — = \ Plio-Pleistoce^^gJL. j Pre-Missoula

liliili

mm

Gravel-rich

Sand-rich

Silt-rich

Pedogeniccarbonate

Basalt

Stratigraphic Units

- Hanford formation

Ringold unit E

Ringold unit E

^ • Ringold sub E unit

Ringold unit C

Ringold sub C unit

Ringold unit B/D

-X, Ringold lower mud unit

Ringold unit A

Sub Rinqold fine sediments

Basalt

Figure 2.6. Late Neogene Stratigraphy of the Pasco Basin Emphasizing

the Ringold Formation. (Column not to scale)

2.9

HNF-SD-TWR-EV-001,Rev. 0

Traditionally, the Ringold Formation in the Pasco Basin and Hanford Site has been divided into thefollowing informal units from bottom to top: (1) gravel, sand, and paleosols of the basal unit; (2) clay andsilt of the lower unit; (3) sand and gravel of the middle unit; (4) mud and lesser sand of the upper unit; and(5) basaltic detritus of the fanglomerate unit (DOE 1988b). Ringold strata also have been divided on thebasis of facies types and fining upwards sequences (Tallman et al. 1981; DOE 1988b; Lindsey et al. 1992).

2.3.1.2 Hanford Formation. The Hanford formation is an informal name that represents all the deposits ofthe cataclysmic floods of the Pleistocene (2 Ma to 13 ka). Glacial Lake Missoula formed in the Clark ForkRiver valley behind continental glaciers that spread south as far as the present Columbia Plateau. GlacialLake Missoula was impounded behind an ice dam that may have given way as many as 40 times, allowing theimpounded water to spread across eastern Washington and form the Channeled Scablands. These floodwaters collected in the Pasco Basin and formed Lake Lewis, which slowly drained through the small watergap in the Horse Heaven Hills called Wallula Gap. Evidence has been found for at least four majorcataclysmic flood sequences in and around the Hanford Site. Three principal types of deposits were leftbehind by the floods: high-energy, coarse-grained facies, low-energy slackwater rhythmite facies consistingof rhythmically bedded silt and sand of the Touchet Beds, and plane-laminated sand facies representing anenergy- transition environment.

The Hanford formation typically has been divided into a variety of sediment types, facies, or lithologicpackages. Recent reports covering the Hanford formation (Lindsey 1991; Reidel et al. 1992) have recognizedthree basic facies: gravel-dominated, sand-dominated, and silt-dominated. These facies generally correspondto the coarse gravels, laminated sands, and graded rhythmites, respectively. The Hanford formation thickensfrom as little as 30 m (100 ft) in the 200 West Area to more than 100 m (300 ft) in the 200 East Area.

Gravel-dominated strata consist of coarse-grained sand and granule-to-boulder gravel that displaymassive bedding, plane to low-angle bedding, and large-scale cross-bedding in outcrop. Matrix commonly islacking from the gravels, giving them an open-framework appearance. The sand-dominated facies consists offine- to coarse-grained sand and granules that display plane lamination and bedding and, less commonly,plane and trough cross-bedding in outcrop. Small pebbles and pebbly interbeds (<20 cm [8 in.] thick) may beencountered. The silt content of these sands varies, although, where its content is low, an open-frameworktexture may occur. The silt-dominated facies consists of silt and fine- to coarse-grained sand formingnormally graded rhythmites. Plane lamination and ripple cross-lamination are common in outcrop.

2.3.1.3 Holocene Surficial Deposits. Holocenesurficial deposits consisting of silt, sand, and gravel forma thin (<5 m [16 ft]) veneer across much of the Hanford Site. In the 200 West Area and the southern part ofthe 200 East Area, these deposits consist primarily of laterally discontinuous sheets of wind-blown silt andfine-grained sand.

2.3.2 Geology oftheTWRS Phase I Demonstration Site

The geology and hydrology of the 200 Areas have been the subject of much study and many reports overthe years (i.e., Myers et al. 1979; Myers and Price 1981; Gephartetal. 1979; Tallman et al. 1979; Grahamet al. 1981; Routson and Johnson 1990; DOE 1988b; Lindsey, 1991; Lindberg et al., 1993).

The 200 East Area lies on the Cold Creek bar, a geomorphic remnant of the cataclysmic floods of thePleistocene. As the flood water raced across the lowlands of the Pasco Basin and Hanford Site, it lost energyand began leaving behind deposits of sand and gravel. The 200 Area Plateau is one of the most prominent

2.10

HNF-SD-TWR-EV-001, Rev. 0

deposits. The Plateau lies just south of one of the major channelways across the Hanford Site that forms thetopographic lowland south of Gable Mountain.

Borehole data provide the principal source of geologic, hydrologic, and groundwater information for the200 East Area and the TWRS Phase I Demonstration Site (Figure 2.7). Numerous boreholes (both vadosezone boreholes and groundwater monitoring wells) have been drilled in the 200 East Area for groundwatermonitoring and waste management studies. However, data are limited within the TWRS Phase IDemonstration Site; only one characterization borehole (2-E25-234) (Figure 2.8) was drilled, and it did notpenetrate the entire stratigraphic section. Most boreholes in the 200 East Area have been drilled using thecable tool method. Some boreholes were drilled with rotary and wire-line coring methods. Geologic logsbased on these boreholes are constructed by examining chips and cuttings, which limits information on all butthe broadest stratigraphic units. Chip samples typically taken at 1.5-m (5-ft) intervals are routinely archivedat the Hanford Geotechnical Sample Library.

2.3.2.1 Structural Framework. The TWRS Phase I Demonstration Site is located south of the GableMountain segment of the Umtanum Ridge anticline and about 3 km (2 mi) north of the axis of the Cold CreekSyncline (Figure 2.8), which controls the structural grain of the basalt bedrock and Ringold Formation. Thebasalt surface and Ringold Formation trend roughly southeast-northwest parallel to the major geologicstructures of the site. As a result, the Ringold Formation and the underlying CRBG gently dip to the southoff the Umtanum Ridge anticline into the Cold Creek syncline.

Geologic mapping at the Hanford Site has not identified any faults in the vicinity of the TWRSPhase I Demonstration Site (Figure 2.9) (DOE 1988b). The closest faults are along the Umtanum Ridge-Gable Mountain structure north of the site and the May Junction fault east of the site.

2.3.2.2 TWRS Phase I Demonstration Site Stratigraphy. The post-basalt stratigraphy for the TWRSPhase I Demonstration Site is shown in Figure 2.8. Approximately 100 to 125 m of suprabasalt sedimentsoverlie the basalt bedrock at the TWRS Phase I Demonstration Site.

Basalt Bedrock. The Elephant Mountain Basalt forms the bedrock beneath the TWRS Phase IDemonstration Site. It dips to the south from 105 m elevation above mean sea level (msl) at the north end ofthe site to 75 m above msl at the south end.

Ringold Formation. Most of the area beneath the TWRS Phase I Demonstration Site consists of asingle coarse-grained fluvial sequence belonging to unit A of the Ringold Formation. The upper surface ofunit A is relatively flat to the north but dips southward beneath the southern portion of the TWRS Phase IDemonstration Site. The relatively flat northern portion of unit A was probably truncated and beveled offduring Pleistocene cataclysmic flooding, which caused more erosion to the north of the TWRS Phase IDemonstration Site (Lindberg et al. 1993). Distinguishing the unit A of the Ringold Formation from theoverlying lower gravel sequence of the Hanford formation is often difficult because of their similar coarse-grained textures.

2.11

HNF-SD-TWR-EV-001, Rev. 0

• 2-E26-8

2-EZ7-7

2-E27-13

2-E26-6

•2-E24-6

2-E25-13

2-E26-43

2-E25-9* *

• 2-E25-34

• 6-43-452-E26-13*

• 2-E26-12

/

210 B-3P'ii'J Syste-JM*n Lol-S,

Pi: '6-43-43

6-42-42B» ~

' " ! 6-42-42A»

2-E25-28 /

((2-E25-2

2-E24-5 2-E25-1

2-E25-42* ' ' ^ • 2 - E 2 5 - 2 3 42-E25-35»2-E25-37J»

T2-E25-17 * • •j 2-E25-19 /j 2-E25-20

| 2-E25-22

2-E17-4

2-E17-12

2-E17-6

200 East Area Boundary

2-E16-11

6-36-46P«

• 2-E25-32P

2-E25-29*

2-E25-39

I TWRSj_Phase II Demonstration| Site

6-37-43

SG96120139.22

Figure 2.7. Location of Boreholes at and near

the TWRS Phase I Demonstration Site.

2.12

HNF-SD-TWR-EV-001, Rev. 0

North

225

200

175

150

125

TWRS Phase I Demonstration Site

GroutPit

2-E25-26 1 2-E25-33 2-E25-27

2-E25-234 ,

South

Elephant Mt. MemberColumbia River Basalt Group

teSSS] Sandy Mud to Muddy Sand

Sand

Gravelly Sand

Sandy Gravel toMuddy Sandy Gravel

Boulders or Cobbles

Columbia River Basalt

20 m

4 m I VE-5X

Hug ~ Hanford formation,Upper Gravel Sequence

H s ~ Hanford formation,Sandy Sequence

Hlg — Hanford formation,

Lower Gravel Sequence

Unit E - Ringold Fm. Unit E

LM - Ringold Fm. Lower Mud Unit

Unit A -Ringold Fm. Unit A

2-E25-27 -Wel l NumberSG96120139.14

Figure 2.8. Stratigraphic Units and Lithology at the TWRS Phase I

Demonstration Site. (See Figure 2.7 for well locations.)

2.13

i<fa'

iS>

Fault, bar and ball on down throw side,teeth on thrust fault

Ql=LoessQa = Alluvium

Qda = Active Sand Dunes

L-V>-V.-Vj Stabilized Sand Dunes

Hanford Formation - Sands

f | Hanford Formation - Gravel

Columbia River Basatt Group

R25E Yaklma Ridge Anticline R26E R27E

HNF-SD-TWR-EV-001, Rev. 0

The fine-grained overbank and lacustrine deposits of the lower mud unit are not present beneath most ofthe TWRS Phase I Demonstration Site but do appear to exist along the eastern edge of the site to B-Pond andto the south of the site. The lower mud unit is significant hydrologically because it may act as a confininglayer that influences the movement of groundwater in the area. However, the lower mud unit is not presentdirectly beneath the TWRS Phase I Demonstration Site, so it should not affect the groundwater flow systemin this area. Near the TWRS Phase I Demonstration Site, cataclysmic floods eroded into the RingoldFormation and blanketed the area with mostly coarse-grained, loosely consolidated deposits of the Hanfordformation.

Hanford Formation. Within the area, the Hanford formation has been divided into threelithostratigraphic sequences: a lower gravel sequence, a sandy sequence, and an upper gravel sequence(Lindsey et al. 1992). The lower gravel sequence consists of deposits composed predominantly of poorlysorted, basalt-rich sandy gravels with occasional discontinuous lenses of gravelly sand, sand, and muddy sandto sandy mud. The sandy sequence consists of multiple beds of loose sand interstratified with layers of sandygravel, gravelly sand, muddy sand, and sandy mud. The upper gravel sequence is not present in theimmediate vicinity of the TWRS Phase I Demonstration Site.

Fine-grained beds of mud and sand in the vadose zone beneath waste-disposal facilities could cause localperching of groundwater and lateral migration of contaminants. These types of strata are discontinuouswithin the Hanford formation and do not extend far laterally, but they could lead to localized spreading asliquid waste moves through the vadose zone.

The Hanford formation varies from about 65 to 95 m thick and consists predominantly of sands andgravelly sands. The lower gravel to gravelly sand is about 10 to 30 m thick and rests on an irregular Ringoldsurface. The Hanford formation sandy sequence varies from 30 to 80 m thick. The upper gravelly sandsequence is irregular, varying from 0 to 15 m across the area.

Holocene Deposits. Much of the TWRS Phase I Demonstration Site has been excavated and cleared ofvegetation. Only parts of the northern and eastern portions are undisturbed. Across most of the area, theHolocene sediments are at most a few meters thick. These are primarily stabilized eolian deposits.

2.4 Hydrogeology

Hanford Site hydrogeology is discussed in several studies (Gephart et al. 1979; Graham et al. 1981;Graham etal. 1984; DOE 1988b, Vol. 2, Chapter 3; and Delaney et al. 1991). Sections 2.4.1 through 2.4.3summarize Hanford Site hydrogeology.

2.4.1 Hanford Hydrogeologic Setting

Primary surface-water features associated with the Hanford Site are the Columbia River and its majortributaries, the Yakima and Snake Rivers. West Lake, about 4 ha (10 acres) in area and less than 1 m (3 ft)deep, is the only natural lake within the Hanford Site (DOE 1988b). Wastewater ponds, cribs, and ditchesassociated with nuclear fuel processing and waste disposal activities also are present.

Recharge rates are suggested to range from near 0 to more than 10 cm/yr (4 in./yr), depending on surfaceconditions (Gee 1987; Routson and Johnson 1990). Low recharge rates occur in fine-textured sediments

2.15

HNF-SD-TWR-EV-001, Rev. 0

where deep-rooted plants grow. The larger values are interpreted to occur in areas having a coarse gravellysurface and no vegetative cover (e.g., disturbed areas such as around the tank farms).

Approximately one-third of the Hartford Site is drained by the Yakima River system. Cold Creek and itstributary, Dry Creek, are ephemeral streams within the Yakima River drainage system. Both streams drainareas along the western part of the Yakima River. Surface flow, which may occur during spring runoff orafter heavier-than-normal precipitation, infiltrates and disappears into the surface sediments.

The hydrogeology of the Pasco Basin is characterized by a multiaquifer system that consists of fourhydrogeologic units corresponding to the upper three formations of the CRBG and the sediments overlyingthe basalts. The basalt aquifers consist of the CRBG flood basalts and relatively minor amounts ofintercalated fluvial and volcaniclastic sediments of the Ellensburg Formation. Confined zones in the basaltaquifers are present in the sedimentary interbeds and/or interflow zones that occur between dense basaltflows. The main water-bearing portions of the interflow zones are networks of interconnecting vesicles andfractures of the flow tops and flow bottoms (DOE 1988b). The aquifer above the basalt is a regionallyunconfined aquifer and is contained largely within the sediments of the Ringold Formation and Hanfordformation.

2.4.2 Uppermost Aquifer System

The uppermost aquifer system is unconfined regionally beneath the Hanford Site and lies at depthsranging from less than 0.3 m (1 ft) below ground surface near West Lake and the Columbia and Yakimarivers to greater than 107 m (350 ft) in the central portion of the Cold Creek syncline. Groundwater in theaquifer system occurs within the glaciofluvial sands and gravels of the Hanford formation and thefluvial/lacustrine sediments of the Ringold Formation.

A water table contour map of the uppermost aquifer for the Hanford Site is shown in Figure 2.10. Theposition of the water table in the western portion of the Site is generally within Ringold unit E gravels. Thewater table in the eastern portion of the Site is generally within the Hanford formation. Hydraulicconductivities for the Hanford formation (601 to 3048 m/day [2,000 to 10,000 ft/day]) are much greater thanthose of the gravel facies of the Ringold Formation (186 to 930 m/day [610 to 3,050 ft/day]) (Graham et al.1981).

The base of the uppermost aquifer system is defined as the top of the uppermost basalt flow. However,fine-grained paleosols, overbank, and lacustrine deposits in the Ringold Formation locally form confininglayers for Ringold fluvial gravels underlying gravel unit A. The uppermost aquifer system is boundedlaterally by anticlinal basalt ridges and is approximately 152 m (500 ft) thick near the center of the PascoBasin.

Sources of natural recharge to the uppermost aquifer system are rainfall and runoff from the higherbordering elevations, water infiltrating from small ephemeral streams, and river water along influent reachesof the Yakima and Columbia Rivers. Discharge from the uppermost aquifer is primarily to the ColumbiaRiver (Graham et al. 1981, DOE 1987, DOE 1988b).

Artificial recharge to the uppermost aquifer occurs principally from Hanford wastewater disposalpractices at surface ponds, ditches, and various cribs in the 200 East and 200 West Areas. Two of the largestrecharge mounds have developed beneath the 200 West and 200 East Areas at U-Pond and B-Pond,respectively. Under U-Pond, which was decommissioned in 1985, the water table had risen in excess of 26 m

2.16

HNF-SD-TWR-EV-001, Rev. 0

• Basalt Above Water Table

~ Water-Table Co

Dashed W W

' Monitoring Well

97jpm004 March 11,1997 '

Figure 2.10. Hanford Site and Outlying Areas Water Table Map, June 1996.(From Hartman and Dresel 1997)

2.17

HNF-SD-TWR-EV-001, Rev. 0

(85 ft) after 40 years of operation. The mound under B-Pond has risen more than 9 m (30 ft) (Graham et al.1981). These facilities are associated with wastewater disposal from fuel and waste processing activities andreceive or have received treated liquid effluents with varying chemical characteristics. Liquid effluent is nowrouted to a disposal site north of 200 West Area and the Treated Effluent Disposal Facility (TEDF). Withdecreasing discharges to the groundwater, the water table at these artificial mounds is decreasing.

2.4.3 Hydrogeology of the TWRS Phase I Demonstration Site

Two major hydrogeologic units are present beneath the TWRS Phase I Demonstration Site: the vadosezone and the saturated zone. The vadose zone, which is about 80-m thick, consists of high-permeabilitysediments of the Hanford formation.

The uppermost aquifer in the vicinity of the TWRS Phase I Demonstration Site is dominated by thefluvial gravel unit A of the Ringold Formation. The water table is in the Ringold Formation in the westernand central portion of the demonstration site and in the Hanford formation in the southeastern andnorthwestern portions. The aquifer thickens to the south; the saturated thickness of unit A, combined withthe saturated portion of the Hanford formation, is approximately 30 m in the northern portion of the site andas much as 60 m in the southern portion (Swanson et al. 1988, Lindberg et al. 1993).

Although the general groundwater flow direction is from west to east in the vicinity of the 200 East Area,artificial recharge from the B-Pond system perturbs this general trend. For example, the resultinggroundwater mound (Figure 2.11) creates flow directions in the vicinity of the TWRS Phase I DemonstrationSite that are currently opposite the general west-to-east flow directions. The inferred flow, based on current,water table elevations, is from the northeast to the south-southwest beneath the project site (i.e., from higherto lower water table elevations). As the influence of the groundwater mound diminishes with distance, thegeneral west-to-east flow prevails. As discharge volumes continue to decline in the future, the perturbationsin groundwater flow direction discussed earlier will subside.

2.5 Groundwater Quality/200 East and 200 West AreasContaminant Plumes

Groundwater quality for the 200 East Area and TWRS Phase I Demonstration Site is closely linked togroundwater quality in the 200 West Area. Groundwater analyses of wells from the TWRS Phase IDemonstration Site are available in Hartman and Dresel (1997) and are modeled in Figures 2.12 through2.18. Plumes from the 200 West Area commingle with 200 East Area contaminant plumes now or will in thefuture, depending on changes in the hydrologic flow regime induced primarily by wastewater discharges to theB-3 expansion lobe of B-Pond and the TEDF pond. Contaminant plume distribution patterns also are goodindicators of the response of past groundwater flow directions to changes in wastewater disposal practices.

Several contaminant plumes have been detected in the groundwater in the 200 East Area. These includelocalized plumes of arsenic, 137Cs, 90Sr, and 239/2«pu as well as plumes of cyanide, alpha, beta, IMI, and "Tc,which are of more intermediate extent. Widespread contaminant plumes exist for nitrate and tritium.

The following plumes have many different sources and are associated primarily with past-practicedisposal activities. The following discussion is limited to contaminants that exceed drinking water standards.For additional details about groundwater quality conditions, see Hartman and Dresel (1997) and

2.18

HNF-SD-TWR-EV-001, Rev. 0

Groundwater Field Characterization for the 200 Agregate Area Management Study (WHC 1993a). Theplumes that exceed the drinking water standards are discussed in the following order:

• Metals-arsenic• Anions-nitrate• Tritium• Beta-emitting radionuclides-gross beta, "Tc, and'29l• Alpha-emitting radionuclides-gross alpha.

Each contaminant map illustrates the extent of the plume that exceeds the most stringent regulatorystandard applicable to the contaminant. The standards have been noted in the legend for each map. In somecases, the detection limit (DL) or minimum detectable concentration (MDC) is greater than the most stringentstandard (e.g., arsenic). In each of these cases, the minimum isopleth has been selected at a value close to theDL. For reference, the operable unit boundaries for the 200 East Area are shown in Figure 2.19.

An additional contour that is less than the most stringent regulatory standard has been added to illustratethe potential extent of some contaminant plumes (e.g., tritium and MTc). When such a contour is included, adashed line has been used to help distinguish it from the standard-exceeding contours.

2.5.1 Metals-Arsenic (Filtered)

The Washington Water Quality Standard (WWQS) for arsenic is 0.05 ppb as defined in WAC 173-200.This value is two orders of magnitude less than the detection limit (i.e., 5 ppb) and three orders of magnitudemore stringent than the drinking water standard (DWS) and maximum contaminant level (MCL) of 50 ppb.Arsenic contamination is illustrated in Figure 2.12. The only regulatory standard exceeded in any well in the200 East and 200 West Areas is the WWQS.

The source of arsenic in the groundwater is from discharges from the PUREX Plant and B Plant. Arsenicwas discharged near the TWRS Phase I Demonstration Site at the 216-A-37-2 Crib, the 216-A-30 Crib, andthe216-A-37-lCrib.

Concentrations of arsenic are very low or below detection in wells upgradient of the TWRS Phase IDemonstration Site, while arsenic is common in monitoring wells downgradient. Generally lowconcentrations of arsenic are found in the groundwater within the deeper portions of the unconfined aquifer,the semiconfined aquifer, and the confined aquifer.

In most cases, arsenic levels in downgradient wells from the TWRS Phase I Demonstration Site havebeen decreasing or have remained constant over the last several years. The arsenic level in Well 299-E25-30,which approached the DWS of 50 ppb in 1988 (46 ppb), dropped dramatically in 1989 and has remainedrelatively low (<15 ppb). Since 1988, none of the other wells has exceeded 20 ppb arsenic. It appears thatarsenic will continue at current relatively low concentration levels for some time.

2.19

HNF-SD-TWR-EV-001, Rev. 0

Figure 2.11. 200 East Area and Adjacent Areas Water Table Map, June 1996.(From Hartman and Dresel 1997)

2.20

HNF-SD-TWR-EV-001, Rev. 0

200 Areas Arsenic (filtered)Groundwater Plume Map^ Concentration Isopleth In Parts per Billion {ppb)

* Concentration values shown ifor the period 1/1/91 -10/1/93Detection LimitDrinking Water StandardMaximum Concentration UmftWa Water Quality Standard1/25 Derived Concentration Guide

BC Cribs

TWRSPhase[

DemonstrationSite

SyCtibsB Pond Complex

0 3,000 Feet' i i r 11 I l I I0 1,000 Meters

SG97010239.6

Figure 2.12. Arsenic Contamination in the 200 East and 200 West Areas.

2.21

HNF-SD-TWR-EV-001, Rev. 0

200 Areas NitrateGroundwater Plume Map* W Concentration Isopleth In Parts per Billion

' Concentration values Mown are average valuesfortfte period 1/1/91 - 10/1/93

Detection Umlt SOD ppbDrinking Water Standard 45,000 ppbMaximum Concentration Umlt 45,000 ppbWa Water Quality Standard N/A.1/25 Derived Concentration Guide N/A

• Well

TWRSPhase I

BC Cribs Demonstration

0 3,000 Feet

SG97010239.7NEW

Figure 2.13. Nitrate Plume in the 200 East and 200 West Areas.

2.22

HNF-SD-TWR-EV-001, Rev. 0

200 Areas TritiumGroundwater Plume Map

SConcentration values shown ereaverage values for the period1/1/91 -10/1/93

Detection LimitDrinking Water StandardMaximum Concentration LimitWa Water Quality Standard

SG97010239.8

Figure 2.14. Tritium Distribution in the Uppermost Aquifer Beneath the 200 Areas.

2.23

HNF-SD-TWR-EV-001, Rev. 0

200 Areas BetaGroundwater Plume Map

Detection UmKOrinHng Water StandardMaximum Concentration UmKWa Water Quality Standard1/25 Derived Concentration Guide

EHE33

• 1

0-50 ppb

50 -250 ppb

250-500 ppb

500-1000ppb

>1000 ppb

• Well

^ Basalt

* By Cribs

K«4 B Pond Complex

0

0

3,000 Feet

i i i1,000 Meters

BC Cribs

TWRSPhase I

DemonstrationSite

Figure 2.15. Gross Beta Distribution in the Uppermost Aquifer Beneath the 200 Areas.(Contour units are in pCi/L.)

2.24

HNF-SD-TWR-EV-OOl, Rev. 0

200 Areas Technetium-99Groundwater Plume Map*Soo Concentration Isopleth In pCI/L

* Concentration values shown are average valuesfor the period 1/1/91 -10/1/93Detection UmitDrinking Water StandardMaximum Concentration UmitWa Water Quality Standard

15pCUL900pCi/L900pCl/L

1/25 Derived Concentration Guide 4000 pCl/L

B-PondComplex

BC Cribs DemonstrationSite

0 3,000 Feet

1 i i i I0 1,000 Meters

Figure 2.16. Technetium-99 Distribution in the Uppermost Aquifer Beneath the 200 Areas.

2.25

HNF-SD-TWR-EV-OOl, Rev. 0

200 Areas Iodine-'Groundwater Plume Map^ U Concentration tsopleth In pCl/L

Detection Limit 1 pCI/LDrlnWng Water Standard 1 pCE/LMaximum Concentratlofl Limit 1 pCl/LWa Water Quality Standard N/A1/25 Derived Concentration Guide 20pCI/L

SG97010239.11

Figure 2.17. Iodine-129 Distribution in the Uppermost Aquifer Beneath the 200 Areas.

2.26

HNF-SD-TWR-EV-001, Rev. 0

200 Areas Gross AlphaGroundwater Plume Map

Concentration tsopleth in pCi/L

Concentration values shown are average valuesfor the period 1/1/91 -10/1/93Detection Limit 1 pCl/LDrinking Water Standard 15 pCl/LMaximum Concentration Limit N/AWa Water Quality Standard 15 pCi/L1/25 Derived Concentration Guide N/A

BC Cribs

[•.-"••V/j 0-15pCi/L

^ ^ 15-1S0pCi/L £

| l ® 1 5 0 - 1500 pCl/L g

• • >1500pCi/L

• Well

%3 Basalt

!??j B Pond Complex

•k By Cribs

0 3,000 Feet

I i i i 10 1,000 Meters

TWRSPhase 1

DemonstrationSite

SG97010239.12

Figure 2.18. Gross Alpha Distribution in the Uppermost Aquifer Beneath the 200 Areas.

2.27

3era'

I

w

B Plant AA

B-PondComplex

TWRSPhase I

DemonstrationSite

Legend:

0 1000 Feet

0 ^300 Meters

200 East Area Fence

Aggregate Area Boundary

Operable Unit Boundary

TWRS Treatment Complex

SG97010239.13

HNF-SD-TWR-EV-001, Rev. 0

2.5.2 Anibns—Nitrate

Nitrate contamination (>45,000 ppb) is widespread in the 200 West Area with smaller plumes in andnorth of the 200 East Area (Figure 2.13). The contamination from the 200 West Area has been transportedfar beyond the eastern boundary of the area. Insufficient wells have been installed in the area immediatelywest of the 200 East Area to assess the potential for this plume to have reached the border of the 200 EastArea. The same problem exists in the interpretation of the extent of tritium contamination.

The highest average concentration of nitrate in and adjacent to the 200 East Area is 350,000 ppb andoccurs in Well 699-50-53 A, which is located just to the north of the 200 East Area. The contaminationappears to result from disposing of scavenged uranium recovery wastes to the BY cribs in the 200 East Areaduring the 1950s. Two plumes located in the southeastern corner of the 200 East Area are centered on wellsthat monitor facilities that have at some time received effluent from either the PUREX Plant or the242-A Evaporator. The maximum average concentration associated with a facility receiving PUREX effluentis 293,000 ppb and occurs in Well 299-E25-13 in the A-AX tank farm. Nitrate also has been detected in onewell located in the northwestern corner of the 200 East Area and two wells just north of the basalt subcropnortheast of 200 East Area near the decommissioned Gable Mountain Pond. The contaminant levels are justabove the DWS of 45,000 ppb.

Nitrate levels in 200 East Area downgradient (southeast) wells have been slowly decreasing or remainingconstant over the last several years. Nitrate levels in upgradient (northwest) wells, on the other hand, havebeen increasing since 1991 but are still well below the DWS. These increases are probably caused by thediversion of most nitrate-bearing wastewater from the surrounding cribs and ditches directly to B-Pond.

2.5.3 Tritium

Tritium is discussed separately from the other beta-emitting radionuclides because it is an extremelyweak beta emitter and its unique chemistry makes it the most mobile of the radionuclides and an excellentcontaminant tracer to determine water flow paths and travel times. Tritium contamination (DWS of20,000 pCi/L) extends beneath large portions of the 200 East and 200 West Areas (Figure 2.14).

A large plume of tritium originates in the southern part of the 200 West Area, extends eastward towardthe 200 East Area, and may intercept plumes beneath the 200 East Area. Well control is insufficient to definethe relationship of the plumes.