“Engineer your future” at the Science Museum 36

Transcript of “Engineer your future” at the Science Museum 36

Delivering the Caithness Moray power link 8Setting the foundation for investment 14Is-Limiter makes UK debut 20Celebrating engineering talent and innovation 38

“Engineer your future” at the Science Museum 36

ffwdFocus on power products

and power systems

1 |15

2 abb.com/ffwd Power products and power systems

Welcome

Stephen Trotter ABB Managing Director, Power Systems UK

ffwd issue 1/15 • The customer newsletter of ABB Power Products and Power Systems • Subscription newsletter available as printed or electronic copy. Subscribe online at abb.com/ffwd • Contact and feedback [email protected] • Publisher ABB Limited, Power Systems Division, Outlon Road, Stone, Staffordshire ST15 0RS. Phone 01785 825 050

8 The Caithness Moray project

ffwd 1 |15

Dear Reader,The challenges for those of us working in

the electricity sector in the UK remain firmly in place with ‘energy trilemma’ requiring a balance between the competing priorities of ensuring energy security, reducing costs and reducing carbon dioxide emissions.

Announced in September 2014, ABB is delivering the Caithness Moray HVDC con-nection on behalf of Scottish and Southern Energy to export renewable energy from Caithness in the far north of Scotland – read the articles on pages 8-11 for more information.

Major regulatory announcements towards the end of 2014 have created more certainty in the UK’s electricity market (see page 14 for more details). One of the certainties is that operators are now look-ing to make the most out of their existing

assets and ABB can help with its innovative service technologies (see page 22). New technologies also have a part to play, with one example being the Is-Limiter and we are implementing the first UK installation for Electricity North West Limited (see page 20).

As a major supporter of innovation and talent, ABB has been supporting a number of initiatives to reward and recognise engineering talent and to reach out to young people to attract them to the engineering profession. Read about our support for the Science Museum’s ‘Engineer your future’ exhibition and the IET’s Innovation and Young Woman Engineer Awards on page 36 onwards.

I hope that you enjoy reading about ABB’s latest work in the UK’s power transmission and distribution sector.

Power products and power systems

ABB Power ProductsPower Products are the key components for transmitting and distributing electricity. The division incorporates ABB’s manufacturing network for transformers, switchgear, circuit breakers, cables and associated equipment. It also offers all the services needed to ensure products’ performance and extend their lifespan.

ABB Power SystemsPower Systems offers turnkey systems and services for power transmission and distribution grids and for power plants. Substations and substation automation systems are key areas. Additional highlights include flexible alternating current transmission systems (FACTS), high-voltage direct current (HVDC) systems and network management systems. In power generation, Power Systems offers the instrumentation, control and electrification of power plants.

3Power products and power systems abb.com/ffwd

Contents

36 Inspiring young people at the Science Museum20 UK utility first for IS-limiter

30 SCADA renewal to use ABB RTUs

News 4 Latest project news from ABB

Project focus 8 Special feature on Caithness Moray project

HVDC Light 12 Leadership in VSC technology

Regulation 14 The UK’s regulatory environment

Transformers 16 eDevices

Grid systems 18 Meet Anders Gullerfelt

Smart grids 20 ENWL Respond project

Service 22 Innovation in power asset management

Substation automation 24 Relays with inbuilt arc fault protection

Asset management 26 Enterprise software

Medium voltage 28 SafeGear HD 28 CEF fast acting fuses 29 UniSec HBC

Protection and control 30 telent and Network Rail

High voltage 32 First UK order for PASS M0H

Power protection 34 PCS 100 medium voltage UPS

STEM 36 Science Museum 38 IET Young Woman Engineer of the Year Awards

Innovation 39 IET Innovation Awards

4 abb.com/ffwd Power products and power systems

News

ABB has won significant framework contracts for pole mounted transformers from two major electricity distribution utilities, UK Power Networks and Western Power Distribution.

Taking pole position with two electricity distribution utilities

Polemount transformer

Pole mounted transformers play a vital role for the UK’s distribution utilities in delivering electrical services to urban and rural residential and commercial customers. Both UK Power Networks and Western Power Distribution use a great number of them in their networks, both for repairs and refurbishment and new infrastructure.

The contract success demonstrates the utilities’ confidence in ABB in two key areas. First, ABB had to demonstrate that its transformers were competitively priced and second, ABB had to show that it could meet the demanding delivery schedules from receiving a call-off order to delivering the units to depot.

Richard Holliday General Manager for Transformers in the UK said: “ABB’s success in winning the pole mounted transformer framework contracts from UK Power Networks and Western Power Distribution demonstrates our ability to deliver large volume of units with coordinated deliveries across the UK to meet end customer demands.”

5Power products and power systems abb.com/ffwd

News

ABB has appointed Ian Funnell as its UK Managing Director, responsible for continued growth and customer-focused collaboration in the UK, the Faroe Islands, Iceland, Ireland and Norway. Ian has taken over from Trevor Gregory, who is now leading ABB’s Power Systems division in Europe.

Ian first joined ABB in 1999 and has held senior management positions in the power and auto-mation businesses, leaving in 2008 to become head of transmission projects for a power utility. After returning in 2012 Ian became glob-al account manager for EDF and has since performed as interim President and General Manager for ABB in France.

“Ian is an experienced leader with a strong track record, and a true team player,” said Veli-Matti Reinikkala, President of ABB in Europe. “In his roles, he has demonstrated his ability to drive profitable growth by bringing cross-business collaboration and developing strong relationships with customers, while successfully executing large-scale power projects. With these skills and experience, he is well-placed to take ABB’s United Kingdom operations to the Next Level.”

Ian Funnell takes the reins

First UK Power Networks retrofit complete

Retrofitting new circuit breakers enables a 20 year life extension

ABB and its OEM partner P&B Switchgear have completed work to extend the life of time-served circuit breakers at a UK Power Networks substation in London. The project is the first to be carried out under a framework agreement to extend the life of medium voltage QA/QF oil-filled circuit breakers that are no longer supported by their original manufacturer. Completed in late 2014, the initial project covered retrofit of circuit breakers on a 28-panel switchboard with an outage of only one week.

The service is an alternative to complete replacement of switchgear panels, which would require major civil works and long network outages. By retrofitting, UK Power Networks can extend the life of the switchgear by upwards of 20 years without

the major cost of replacement, helping it to meet the requirements of Ofgem’s RIIO (Revenue = Incentives + Innovation + Outputs) model.

The fast-track service enables UK Power Networks to minimise the length of outages and requires little space: a major factor when space is at a premium and construction of new bays is challenging.

The ENA assessed solution is based on the fact that original fixed switchboard equipment, such as the housing and busbars, typically remains in good condition. Installing a new state-of-the-art circuit breaker brings the switchboard up to modern safety and reliability standards while avoiding the need to disturb or replace cabling.

6 abb.com/ffwd Power products and power systems

News

As a technology partner, ABB is supporting the solar powered round the world flight that started the first leg of its epic journey in March. Solar Impulse’s flight will take it from Abu Dhabi over the Arabian Sea, India, Myanmar, China, the Pacific Ocean, United States, Atlantic Ocean and Southern Europe or Northern Africa before closing the loop by returning to its launch point.

ABB’s East Kilbride office has completed work on upgrading Sloy substation near Loch Lomond on behalf of Scottish and Southern Energy. The substation serves Sloy Hydroelectric Power Station and during its work ABB replaced the time-served AIS (air-insulated switchgear) substation built in 1950 with a new GIS (gas-insulated switchgear) substation.

Sloy substation draws to completion

Solar Impulse in Abu Dhabi preparing for its mission

Solar Impulse takes to the air

The new granite-clad Sloy substation

During the project ABB replaced the 152.5 MW capacity substation and upgrad-ed it to meet demand from Sloy’s new pumping station, enabling the power station to generate an extra 100 gigawatt hours (GWh) annually.

Because GIS equipment takes only 20 percent of the footprint of conventional AIS, it was possible to enclose the new

substation in a low profile building that was clad with slate to fit into the substation’s National Park environment.

ABB fast tracked construction to com-plete the new substation by the end of 2013 and has since dismantled the old AIS sub-station and carried out land remediation to return the land to its natural condition.

7Power products and power systems abb.com/ffwd

News

Network Rail will install more than 100 of ABB’s FSKII+ vacuum circuit breakers at seven trackside substations on the East Coast Main Line (ECML). The major order is part of Network Rail’s ECML power upgrade to meet growing demand for passenger and freight traffic. The ECML is a major rail artery that provides a direct link between London, the north east of England and eastern Scotland and is designated as having Trans European Network (TEN) status.

ABB developed the FSKII+ specifically for single and two-phase railway traction power supply applications. Its advantages are its compact installation footprint, as well as simple and easy installation and low maintenance requirements. Plus it is currently the only medium

voltage AIS (air insulated switchgear) that has Network Rail product approval for trackside substations.

FSKII+ circuit breakers have Network Rail product approval for trackside substations

To prepare for installation of a number of modules on its 132 kV transmission network in the East of England, UK Power Networks has approved ABB’s compact PASS M0 switchgear.

The modules will act as the main grid connection points for major new solar photovoltaic (PV) farms, which will be connected to the 132 kV network to help spread the demand on UK Power Networks’ 11 kV and 33 kV networks.

PASS M0 is a form of hybrid high-voltage switchgear that combines air-insulated busbars with a GIS housing that integrates circuit breaker, one or more

UK Power Networks adopts PASS M0 switchgear

Network Rail to install 100 FSKII+ circuit breakers

combined disconnector/earthing switches, bushings for connection to single or double busbar systems and a current transformer in one compact module. Not only is the switchgear extremely compact but it also gives flexibility as it can be connected with various combinations of busbar and cable to suit individual site requirements. It also has full approval from the Energy Networks Association (ENA).

Another advantage is that PASS M0 can perform as a metering breaker that measures the quantity of power fed into the grid as it integrates high quality tariff-code current transformers (CTs) and voltage transformers (VTs).

8 abb.com/ffwd Power products and power systems

Project news

Creating Scotland’s Caithness Moray subsea HVDC power link

In 2014 ABB was awarded an order worth around £500 million by Scottish Hydro Electric (SHE) Transmission plc, part of the SSE Group, to create the Caithness Moray high-voltage direct current (HVDC) power transmission link, which will connect the electricity grid on either side of the Moray Firth in northern Scotland. This followed a favourable decision by Ofgem (Office of Gas and Electricity Markets), an independent National Regulatory Authority, on the need for the link.

The southern coastline of the Moray Firth near Blackhillock

9Power products and power systems abb.com/ffwd

Project news

The generation of electricity from renewable sources in the north of Scotland has been growing fast in recent years. That growth is forecast to continue in the years ahead, with proposed wind, wave and tidal generators contracted to connect. To provide the capacity needed to accommodate this significant new generation capacity, a major reinforcement of the transmission network serving the north of Scotland is needed.

As a key element in this reinforcement, Scottish Hydro Electric Transmission (SHE Transmission), part of Scottish and Southern Energy (SSE), identified the need for a subsea power link, capable of carrying up to 1,200 megawatt (MW) of electricity – equivalent to the needs of around 2 million Scottish residents – between Caithness and Moray. With associated reinforcement of the existing onshore network, this project represents the largest investment in the North’s electricity network since the hydro development era of the 1950s.

Reinforcement of the onshore trans-mission network between Dounreay and Mybster in the north; and between Loch Buidhe and Beauly further south will further improve the use of the existing network in combination with the HVDC link.

For the project, ABB will design, engi-neer, supply and commission two 320

Subsea HVDC link capable of delivering 1200 MW of clean energyEnough power to meet the needs of about two million people in Scotland

Spittal

London Birmingham

Blackhillock

Moray Firth

Spittal

Blackhillock

Around 1200 MW of wind, wave and tidal energy is planned for integration into the grid in Northern Scotland. A key enabler of this inte-gration is the HVDC link, capable of carrying 1200 MW of electricity, equivalent to the electricity needs of around two million Scottish residents*

* Based on average national consumption

2

million

160 kmLength of HVDC cable (subsea and land):

Same distance as between London and Birmingham

Subsea HVDC link capable of delivering 1200 MW of clean energy. Enough power to meet the needs of about two million people in Scotland

kilovolt (kV) land-based HVDC Light con-verter stations, one rated at 1,200 MW at Blackhillock in Moray and another rated at 800 MW situated at Spittal in Caithness.

ABB’s scope of supply also includes submarine and underground cables covering a total transmission length of nearly 160 kilometres. The link is scheduled to become operational in 2018.

Under the contract SSE also has an option for a future HVDC link to Shetland.

ABB and SSE’s Open 4 Business – supply chain development

SSE is committed to creating a sustainable local supply chain, maximizing the opportunity for local businesses – large and small – to share in its investment in Scotland’s power infrastructure. ABB is actively supporting this initiative and where possible we are utilising this approach to source local suppliers

through SSE’s Open 4 Business portal. This portal facilitates trade and engagement between SSE and local suppliers and service providers enabling them to register and respond to notices free of charge. Suppliers such as ABB, are able to advertise local opportunities through the portal to pre-qualified companies, and then create a short-list. Once a short-list has been created then ABB’s standard processes are applied.

sseopen4business-highlands.com

The equipment delivered under the contract will have the capability to handle such a multi-terminal set up.

The Caithness Moray project further reinforces ABB leadership position in HVDC VSC (Voltage Source Converter) technology. ABB has already delivered 13 of the 14 commissioned VSC links in the world. And HVDC Light continues to be a preferred solution for long-distance underground and underwater power transmission links.

10 abb.com/ffwd Power products and power systems

A major focus of ABB’s work in Scotland, and the Highlands and Islands in particular, is to strength-en transmission and distribution networks, as well as working with power generators, distributors and users to pave the way to make use of the excellent natural resources for renewable electricity generation.

Since establishing an East Kil-bride office, as an integral part of our UK Power Systems business, ABB has continued to forge close relationships with our Scottish cus-tomers and supply chain, and these are playing a key role in the effective delivery of major power projects.

In addition to the ABB office in East Kilbride (which will support delivery of the substation pro-jects), ABB also has staff based in a shared project office with SSE in Inverness delivering the Caithness Moray HVDC project.

ABB also has strong links with many of the country’s universities as well as trade bodies such as Scot-tish Renewables. Most recently, we have decided to extend our sup-port of the Special Olympics Great Britain (SOGB) to include Inverness. We are also working closely with local communities and have made a donation to a local hospice.

Project news

Spittal AC substation

The substation will feature ABB’s state-of-the-art ELK switchgear

ABB has a shared project office with SSE in Inverness

ABB has had a long standing presence in Scotland, with Aber-deen the headquarters of our thriving service organization that serves the oil and gas industries, as well as employing service pro-fessionals throughout Scotland. Currently, our team in Scotland is over 300 and is expanding up to 400 people.

At the Spittal HVDC project site, ABB is also working in consortium with Balfour Beatty on a turnkey project for SHE Transmission, part of the SSE Goup, to construct a new indoor High Voltage AC substation that will provide a 275 kV connection to the HVDC Light converter station.

Building ABB’s team in Scotland

The new gas insulated switchgear (GIS) substation will comprise an 11-bay 275 kV GIS double busbar and 5-bay 132 kV GIS single busbar. Two 240 MVA 275/132 kV supergrid transformers (SGTs) will provide the connection between the two busbars.

The substation wil l also provide a connection between the 275 kV busbar and new 132 kV overhead line reinforcement works to Mybster, via two 360 MVA 275/132 kV SGTs. In addition two 275 kV feeder bays will connect to a new overhead line connection to Thurso, while two 132 kV feeder bays will connect to the existing 132 kV overhead line circuit to Mybster.

At the heart of the Spittal substation

will be ABB’s state-of-the-art ELK GIS technology. GIS incorporates all of the same functional elements as air-insulated switchgear (AIS), but condenses them inside a sealed housing that occupies one tenth of the space. GIS is ideal for use in harsh environments, such as corrosive, salty air or extreme temperatures. Its reduced footprint means that GIS is ideally suited for sites, like Spittal, where aesthetic issues are important. ABB pioneered the development of GIS technology, delivering the world’s first GIS substations in 1967. Since then, we have delivered well over 10,000 high-voltage GIS bays.

11Power products and power systems abb.com/ffwd

Project news

Signing the Health and Safety charter

The official start of the Caithness Moray HVDC project was marked in a ceremo-ny in November 2014 at the Inverness offices that ABB shares with SSE. Togeth-er, Ulrich Spiesshofer, ABB’s CEO and Alistair Phillips-Davies, SSE Chief Exec-utive signed the charter that confirms our joint total commitment to Health and Safety across every activity.

Safety lies at the heart of all of SSE’s activities and all ABB employees are accountable for safety through our “Don’t look the other way” approach to ethics. The Caithness Moray project’s Health & Safety Charter brings together both our codes of conduct.

CEOs of ABB and SSE Ulrich Spiesshofer and Alistair Phllips-Davies

The charter extends to employees and contractors working on the project and engages their commitment to take account-ability for the safety of their colleagues, contractors, customers and others affect-ed by our operations.The principles of the Health and Safety Charter are that: – All accidents are preventable so we do everything safely and responsibly or not at all.

– We are committed to preventing injury, ill health and pollution caused by our activities.

– We are committed to complying with legal and other obligations to ensure safe working.

12 abb.com/ffwd Power products and power systems

Global focus

Leading the way in HVDC Light

Since ABB introduced HVDC Light in the late 1990s it has secured its place as market leader in the voltage source conversion (VSC) technology and has delivered 15 out of the 18 projects completed worldwide to date.

ABB recently commissioned the Skagerrak 4 HVDC Light® link between Norway and Denmark

13Power products and power systems abb.com/ffwd

Global focus

HVDC Light offers the same benefits as HVDC Classic, namely that it enables transmission of large amounts of elec-tricity over long distances, connection of asynchronous power grids and inte-gration of renewable energy sources in remote and challenging locations.

The difference between the two is that HVDC Classic uses line commutated converter (LCC) technology whereas HVDC Light uses VSC technology using IGBTs (integrated-gate bipolar transistors) to convert between AC and DC.

While HVDC Classic offers higher voltages and power transmission of up to 1,100 MW, HVDC Light’s main advantage is its relatively compact size, with each converter station taking approximately half the footprint of HVDC Classic.

HVDC Light has extended the range of applications to include remote offshore converter stations, weak system inter-connections, long land cables and black start capability. Another benefit for wind parks is that HVDC Light has the ability to act as a Statcom (static var compensator light) by providing variable reactive power in response to the voltage transients that result from natural variation in the wind.

InterconnectorsA common appl icat ion for HVDC is interconnectors and HVDC Light brings advantages of black start capability and voltage support to weak grids. Eight of ABB’s HVDC Light projects have been interconnectors.

One of these is EirGrid’s East-West Interconnector, which links the grids in Ireland and the UK. It has the highest power rating of VSC technology to date with 500 MW and ± 200 kV. ABB was responsible for system engineering, including design, supply and installation of the converter stations as well as sea and land cables.

Another project completed in 2014 is fourth pole in the Skagerrak link, an HVDC transmission system that connects asyn-chronous grids owned by Statnett in Norway and Energinet.dk in Denmark. The new link is based on HVDC Light and is the first time that HVDC Classic and HVDC Light links have been tied together in a bipole con-figuration. It has boosted the transmission capacity between Norway and Denmark by an additional 700 MW with a voltage rating

of 500 kV and enables both networks to integrate more renewable energy.

Looking ahead, ABB has orders to engi-neer a further four interconnectors: Åland in Finland, NordBalt between Scandinavia and the Baltic region, Canada’s Maritime Link and the Caithness Moray link, which is detailed on pages 8 to 11.

Connecting asynchronous gridsThe Mackinac back-to-back converter station created by ABB for the America Transmission Company in Michigan in 2014 is the world’s first large-scale VSC-based back-to-back system. HVDC Light was selected because of its capability of working as a Statcom and because it provides voltage support to weak grids. The station will help to integrate renewable energy.

Offshore windGiven that offshore wind speeds can give an energy yield up to 70 percent higher than that generated on land, the potential for offshore wind is huge but the farther out to sea, the greater the challenge of transmitting energy ashore. HVDC Light is ideally suited to this application, having relatively compact converter stations and voltage support. The trend today is towards large offshore platforms that house both

converter stations as well as operations personnel.

ABB completed the BorWin1 grid con-nection for one of the most remote offshore wind farm clusters in the world in 2014 on behalf of TenneT. ABB designed, supplied and installed the offshore converter, 125 km sea cables and 75 km land cables and onshore converter station. The link transmits 400 MW ±150 kV from the BARD Offshore 1 wind farm to the German grid at Diele.

Building on the BorWin1 project for Ten-neT, ABB is also delivering the transmission systems for the DolWin1 and DolWin2 links to connect offshore wind farms in the Ger-man North Sea.

Power from shoreBy using HVDC Light connections from shore gas production platforms can access low cost electricity, avoid using large quantities of fossil fuels, improve efficiency and safety and minimise emissions. An HVDC link supplied in 2011 to BP’s Valhall platform replaced the power generated by gas turbines. Elsewhere, the first two HVDC Light connections to Statoil’s Troll A platform were completed in 2005 and ABB is now adding a further two circuits, with HVDC Light supplying a total of 188 MW to the platform.

An indoor HVDC yard

14 abb.com/ffwd Power products and power systems

Regulatory focus

Setting the foundation for investment

ABB’s Head of Regulatory Affairs and Technology Colin Green shares his views on the UK’s regulatory environment in the wake of the RIIO proposals in late 2014 and asks what the future might hold.

The second half of 2014 saw growing regulatory certainty in the UK’s power sector with publication of Ofgem’s final determination for RIIO-ED1, the outcome of the first Capacity Market auction publication of the first CfD (Contracts for Difference) allocation round. Together, these announcements set the tone for new investment in power infrastructure over the next few years. This is not the whole story however since common themes are emerging across electricity, railways, water and other industries which are driving a wider need for infrastructure investment.

RIIO determinationFollowing on from the RIIO-T1 package that was introduced in April 2013 for

encouraged to make the most of their existing assets. The proposed settlement also provides an innovation stimulus package to encourage the deployment of new technologies and business approaches.

New technologiesThe approach places more emphasis on retrofit and refurbishment and is an opportunity to introduce innovative new technologies that have not previously been adopted in the UK.

This will manifest itself in different ways across different networks. One example is Electricity North West’s IS-limiter (see page 20) and another solution is using a ‘soft link’, which is a power electronic converter that bridges between two asynchronous networks like a small back-to-back HVDC converter substation.

Other solutions that are a good fit with the RIIO settlement are ABB’s transformer remanufacture service and its ENA (Elec-tricity Networks Association) approved solution to retrofit new breakers to time-served switchboards that are no longer supported, which we are delivering along-side OEM partner P&B Switchgear.

Both of these solutions bring legacy sub-

transmission network companies, Ofgem’s RIIO ED1 determination sets a strategy for distribution networks from April 2015 until March 2023 and sets out proposals for investment of £24.5 billion to upgrade, operate and maintain the distribution networks over the next eight years.

The objective is to deliver what power customers value most across all the DNOs (Distribution Network Operators), which are to improve reliability, ensure high availability and also increase the speed of connection for new loads and new generators alike.

The settlement’s drivers are towards innovation and more resilience, which are both areas where ABB has a lot to contribute as a major supplier to the sector. While there is certainly room for asset replacement as well as new build, DNOs are being

15Power products and power systems abb.com/ffwd

Regulatory focus

High-voltage cable test station for testing ABB’s 525 kV rated HVDC cable system

station equipment up to modern standards of efficiency and safety within the footprint of the existing equipment, which eliminates civil engineering work or the requirement to disturb cabling.

InterconnectorsSecurity of supply was at the fore in September when Ofgem announced that it had shortlisted five electricity interconnector projects to France, Ireland, Norway and Denmark. The regulator also published its initial project assessment for the Norwegian interconnector in late 2014 as well as its final decision on the Nemo interconnector.

The UK government also made a decision in December to allow interconnectors to participate in the capacity mechanism from 2015, which offers new commercial opportunities to interconnectors. These are important steps forward. With policy and regulatory frameworks in place, there is greater certainty that these projects are likely to go ahead and that the UK will see a doubling of interconnector capacity by the early 2020s.

For interconnectors I get a real sense of technological development and regulation coming together at the same time. For example, we announced at Cigré in August that ABB has developed the world’s most powerful XLPE underground and subsea power transmission cable system. The cables, which can operate at 525 kV, represent a significant advance from the 320 kV cable systems using XLPE cable technology. The innovation has extended the power capacity of cables to 2,600 MW and increased the reach of cable systems to 1,500 kilometres. This advancement comes at a t ime when a number of new interconnector projects are under development, ushering in new possibilities for some of these projects.

Meeting changing demandsThe overall picture is that ABB is now having a different type of dialogue with the industry and innovation is at the top of the agenda more than ever before. Operators are more open to practical innovations that lead to improved performance and reduced cost

of operating the network.One trend is in asset health services to

enable predictive insight into asset health and performance. Software systems, such as Asset Health Centre, can be used throughout electricity generation, transmission and distribution and when combined with real-time communication and monitoring are able to proactively predict, prioritise and act on potential risks.

At the same time, we’re also getting to the point where our own programme of research and development is bringing forward new solutions like the new 525 kV cable system or the new relay retrofit service, which enables the replacement of protection and control equipment within hours, and also in using products in different and new ways.

And although Ofgem’s settlement has set the strategy of the next eight years investment, it will be interesting to see how the market evolves and what role the maturing tidal and wave sector will play in the UK’s energy mix.

16 abb.com/ffwd Power products and power systems

Transformers

eDevices make transformers smarter

The fast growing trend for smart grids now calls for transformers at all levels, from distribution to transmission, to become more intelligent. There is an increasing need for them to have the capability to provide network operators with a high level of information on their performance and loading. At the same time, the large, global installed base of transformers is ageing, with many assets approaching their expected end-of-life. This is driving the trend towards transformers that can provide OLCM (On-Line Condition Monitoring) functions that enable their owners to establish if they remain fit for use, and also to make fully informed decisions on the need for repair, refurbishment or replacement programmes.

ABB COMEM has responded to these challenges by developing the eDevices product family, a comprehensive suite of solutions that enable continuous monitoring of the most critical transformer performance and safety parameters including: – Air humidity – Gas accumulation – Oil level – Winding and Oil temperature – Internal pressure

COMEM eDevices are ideally suited to a condition based maintenance approach driven by intelligent information available via analog output (4-20 mA) and the Modbus communication protocol. They have been developed to offer a best in class combi-nation of conventional electro-mechanical devices with robust electronic circuits

embedded within the same casing. The trip functions still remain electro-mechan-ical and the redundancy is guaranteed by the bus communication.

The newest members of the eDevices family are the electronic Winding and Oil Temperature Indicators – eWTI and eOTI. They are designed to provide high accuracy measurements based on well proven, maintenance free Bourdon technology. The continuous monitoring of the temperature of vital elements in the transformer contributes to a fundamental understanding of the overall performance of the unit, avoids the risk of unacceptable thermal degradation and ensures a longer lifetime. The eWTI and eOTI feature a compact and robust construction, customizable installation and user friendly operation.

Self-dehydrating air breather portfolioAir breathers are crucial transformer com-ponents that reduce the maintenance cycle of both the transformer and tap changer by limiting moisture ingress in both the trans-former tank and tap changer compartment, respectively. A pipe system is in most cases connected from the top of the conservator to the breather, which is placed at ground level for easy access. Traditional breathers consist of a drying agent (such as silica gel) which dehydrates the air passing through, and retains the moisture. Regular inspec-tions and replacement are needed to ensure the drying agent is not fully saturated, and can still absorb moisture.

The ABB COMEM self-dehydrating air

17Power products and power systems abb.com/ffwd

SDB portfolio

breather (SDB) portfolio was developed to provide the safest and most reliable control of the air drying function, while lowering environmental impact and reducing overall maintenance costs.

Saturation control and drying is automatic which drastically reduces maintenance time because the drying agent no longer has to be replaced. By using a patented double

air breather tank system, it is ensured that the air intake in the transformer conservator is always passing through a tank with dehydrated drying agents, as the second tank is simultaneously regenerating. In addition, the entire SDB portfolio is smart grid enabled, with a digital output available.SDB devices are currently being deployed by several UK utilities.

In addition to the eWTI, eOTI and SDB, the complete eDevice family currently includes other devices intended for use with oil insulated power transformers:

electronic Buchholz Relay eBRThe eBR Buchholz relay is an innovative evolution of the standard device. Thanks to its digital interface, the eBR provides accu-rate monitoring of two important parameters to ensure correct functioning of the trans-former: gas accumulation and insulating fluid flow speed toward the conservator.

An electro pneumatic valve can be directly operated by the eBR to discharge gas, which avoids the disconnection of the transformer.

electronic Oil Level Indicator eOLIThe eOLI oil level indicator is a perfect combination of standard features with the new digital and analog output for easy interfacing to the smart grid. It offers reliable, accurate and continuous monitoring of the insulating fluid level inside the transformer.

electronic Pressure Relief Device ePRDThe ePRD pressure relief device is specially designed to provide improved monitoring of the pressure within the transformer tank thanks to the pre-alarm warning threshold. The digital interface allows this device to be easily connected to the smart grid.

In the case of operation, the ePRD can avoid the contamination of the surrounding area as the expelled insulating fluid can be contained.

DeviceseImproved alarm functionality

Remote control

Digital and analog output

Data monitoring and storage

18 abb.com/ffwd Power products and power systems

Grid systems

Meet Anders Gullerfelt

ABB’s General Manager for Grid Systems in the UK shares what’s in store for the high-voltage transmission business.

Since starting in my role in February 2014, my main focus has been mobilising the Grid Systems team to start execution of the Caithness Moray project. It’s very exciting to be leading ABB’s project team on what is the largest investment in northern Scotland’s transmission network in more than half a century.

The role is a natural progression for me. I started my career at ABB in 1982 in my native Sweden and since then I have gained experience of technologies including HVDC, substations and service across ABB’s portfolio.

The heart of my expert ise l ies in operational management and business development. Over the course of my career I have lived and worked in 10 countries in the Middle East, Africa and Europe and have overseen the execution of major turnkey projects.

At Grid Systems I am drawing on my 30 plus years of experience to manage the expert team that develops and delivers projects characterised by HVDC, transmission links, high voltage cables, offshore wind connections, semiconductors for power applications along with related service activities.

UK potential for HVDCAs an electrical engineer I’m excited by the potential for HVDC and particularly for HVDC Light. It has the capabilities for long-distance water crossing, low losses, asynchronous interconnections, a high level of controllability and limitation of short circuit currents. It also has inherent environmental benefits as it tends to be installed below ground or underwater, giving it low aesthetic impact and flexibility.

These lend the versatility that means that HVDC Light can be adapted to suit connection of remote generation, intercon-necting grids, connecting remote offshore wind, city centre infeeds, supplying pow-er from shore, AC grid enhancement and connecting remote loads.

A converter station for EirGrid’s East-West Interconnector

19Power products and power systems abb.com/ffwd

Grid systems

the goals of securing power supplies and connecting conventional and renewable power generation whilst minimising the impact on the environment.

This includes all the onshore requirements for the delivery of HVDC, HVDC Light and high-voltage DC and AC cables including substations, converter stations, grid connections and other solutions that use semiconductors for power applications. Our expertise covers the entire value chain from tendering to warranty service. We can also offer support in terms of service, training and consulting services.

A future supergrid? Since ABB announced the development of an HVDC circuit breaker in 2012, there

has been a lot of discussion about multi-terminal systems in general and about a European supergrid in particular.

In my belief the European Supergrid is quite far off still. The planning for such a network will be very complex and will need to take account of the necessary technological development, particularly in the areas of system protection and power flow control in a meshed HVDC grid, which still needs to happen.

Plus, the planning process will call for a high level of coordination amongst all of the countries, companies and stakeholders affected. My prediction is that it will develop over time in a modular fashion as more and more connections across and beyond Europe are realised.

The western terminus of the East-West Interconnector between Ireland and the UK

Building a teamWith applications like these, there’s huge opportunity for ABB’s Grid Systems business in the UK to build on our success and secure more exciting projects, which is my main objective in the longer term.

With this in mind I am planning to build up the critical mass of expertise in the team to meet the growing demand, particularly in the HVDC field.

Onshore capabilitiesRight now, we’re focusing the Grid Systems business towards ABB’s natural advantage, that being the expert knowledge and expe-rience of delivering onshore transmission projects. Our key skills lie within the area of grid systems technologies, which have

20 abb.com/ffwd Power products and power systems

Smart grids

Electricity North West gives UK utility debut to IS-limiter

The world’s fastest fault current limiting and switching device, ABB’s Is-limiter, will make its UK utility network debut as part of Electricity North West’s ‘Respond’ project, which is supported by Ofgem’s Low Carbon Networks Fund (LCN Fund), which supports innovative new technologies.

The smart grid project will demonstrate how the Is-limiter can enable DNOs (Distribution Network Operators) to adapt their existing distribution networks to handle the fault current challenges created by increasing levels of low carbon generation.

The four-year Respond project will actively monitor demand and generation on the Electricity North West network, continually assess the fault level and automatically enable innovative techniques when necessary. This is the first time that fault level will be actively managed on 6.6, 11 and 33 kilovolt (kV) networks in the UK.

As part of the project, ABB Is-limiters will be installed at up to seven Electricity North West substations. Normal substation circuit-breakers cannot provide protection against fault currents, as they are too slow to respond. In contrast, the Is-limiter can detect and limit a fault current at its first

inception – in less than a millisecond – this ensures that the maximum instantaneous current is limited to a safe level that will not cause damage to substation equipment.

Inside the Is-limiter an extremely fast switch is able to carry a high rated current but has a low switching capacity, and a high rupturing capacity fuse is arranged in parallel. The short opening time is achieved by using a small charge similar to those used in automotive airbags to open the main conductor switch.

“The Respond project is an important UK grid first for ABB’s Is-limiter. However, it is already a tried and tested technology, with over 600 reference applications worldwide,” said Peter Jones, ABB Technology Strategy Manager. “We are delighted to be involved in this trial showcasing a technology capable of delivering significant value and very short payback periods for DNOs and their stakeholders.”

21Power products and power systems abb.com/ffwd

Smart grids

What is a fault current?Normal current and fault current are very different. Normal current is a steady flow of electricity through the network. Fault current occurs only when there is a fault on the network. It is an instantaneous surge of electrical energy, which is significantly higher in magnitude than normal current and flows towards the point of the fault.

The maximum size of fault current, known as fault level, can change throughout the day depending on the network configuration and the connected loads and generators. The ability to actively manage and mitigate fault level is a valuable tool for DNOs.

In recent years there has been a signif-icant growth of Low Carbon Technologies (LCTs) such as combined heat and power plant or renewable generators connected to the grid. This has led to more two-way flows of current, which can increase fault current.

The cost of controlling fault currentIn the UK the conventional approach to controlling fault currents has been to safely interrupt the flow of fault current within three seconds with a circuit breaker. However as new connections lead to growing demand, the potential maximum fault current may rise above the switchgear’s maximum current rating for brief periods as the fault current varies throughout the day. This means that circuit-breakers may not be able to interrupt the flow of fault current.

The traditional solution to this issue is to replace existing switchgear with a type that has a higher fault level rating.

In Ofgem’s RIIO (Revenue=Incentives+ Innovation+Outputs) – ED1 framework for setting price controls for network companies, the cost of replacement for a single substation is around £500,000 for high voltage (HV) and starts at £1.2 million for extra high voltage (EHV).

DNOs are required to maintain safe operation, so even if the switchgear rating is only exceeded infrequently, this would trigger asset replacement. Install ing expensive, higher specification switchgear in these circumstances could mean the extra fault level capacity installed is effectively unused for the majority of the time.

The cost of resolving this fault current issue and the connection time associated with the design, procurement and installation

of new switchgear or complete substations can often make it uneconomic for a cus-tomer to accept a connection offer.

The Respond approachRespond will be the first demonstration of near real time fault level assessment and adaptive mitigation to overcome the fault level challenge faced by all DNOs at much lower cost. Electricity North West’s approach is to handle fault level fluctuations using existing assets. This will be achieved by deploying intelligent software together with innovative technical and commercial fault level mitigation.

A fault level assessment tool will assess the potential maximum fault current. When the potential fault current exceeds the existing switchgear rating, this software will issue an “enable” command to one of the innovative fault current mitigation tech-niques featured in the trial, such as ABB’s Is-limiters, retrofitted alongside existing substation equipment.

The IS-Limiter limits short circuit currents

Electricity North West’s low carbon networks manager Simon Brooke said, “The Respond trial will allow us to explore new technical and commercial solutions to get more from our existing network. This will ensure customers continue to get the power they need and give them the flexibility to connect renewable energy sources such as combined heat and power plants, without us having to invest in new expensive infrastructure. And by using these innovative techniques to intelligently manage fault current, customers could see lower bills. We are looking forward to working with ABB and demonstrating how effective the Is-limiter can be in helping us do this.”

Further information on the Respond project, including a video presentation, is available at: http://www. enwl.co.uk/about-us/the-future/respond

22 abb.com/ffwd Power products and power systems

Service

Innovation in power asset management

Being an operator in the power and utility industries brings many challenges. Asset managers must balance competing priorities to manage the financial, economic and engineering factors of physical assets with the aim of safely and cost-effectively providing the required level of service throughout the asset’s life cycle.

In 2013, a global survey of the power and utility industry identified that senior managers believe there is great scope for improvement in asset management, with 73 percent of respondents identifying asset performance management as an area for improvement and a further 60 percent citing asset risk management.

Elsewhere, a study into utility operations by Black & Veatch identified that reliability, aging infrastructure and long term invest-ment are three of the top five issues faced by the utility industry, alongside environ-mental and economic regulation.

In practice, operators must manage a complex framework of resources and com-petencies while meeting safety standards,

regulatory demands and balancing against business risks.

As technology advances, it’s important that asset managers should be aware not just of industry best practice but also of the latest innovations in maintenance, testing, life extension and retrofitting. Emerging technologies have the potential not just to reduce costs but also to future proof equipment and competencies, improve diagnostics and condition monitoring, extend life and retrofit additional capabilities, such as intelligent devices.

Towards a smarter gridSmart grid technologies are creating opportunities to improve security of supply, reduce costs and reduce carbon emissions,

helping operators get more out of network assets for the same or less investment.

In transmission and distribution sys-tems, technologies including Wide Area Monitoring Systems, demand response, fault management, interconnection and meshing of networks, energy storage and condition monitoring will all have a role to play. Advanced asset health modelling will have a key role in predicting where actions are required.

Relay retrofit in one hourConventionally, the process of replacing a time-served relay takes a month, while engineers identify several hundred settings and parameters used by the old relay and transfer to a new IED (Intelligent Electronic Unit).

ABB has re-engineered its approach by exploring the logic of the relays and creating a set of software and installation tools for the job. An ABB engineer can arrive on-site with the new IED, a pre-prepared set of wiring and a specialist toolkit and can install the new relay within an hour.

The new approach opens up the potential for retrofitting IEC 61850 enabled IEDs to

23Power products and power systems abb.com/ffwd

Service

existing installations, bringing the benefits of smart grid communications with a minimum of process down time.

Radiographic inspectionAnother emerging service technology is radiographic inspection of GIS (gas insulated switchgear). Inspection once called for scheduled downtime, disconnection, handling of SF6 gas, dismantling and subsequent reassembly. It’s now possible to use the technique of X-ray radiography to inspect ABB’s own equipment and that supplied by other manufacturers. The equipment still needs to be taken out of service, disconnected and earthed but can remain intact for a far simpler and much less invasive inspection, reducing downtime from days to hours.

SF6 re-manufactureThe normal approach at the end of its life is for safe disposal through costly and energy intensive gas destruction. But a new technique means that contaminated SF6 can now be comprehensively recycled.

At its dedicated SF6 gas recycling cen-tre in New South Wales, Australia, ABB can return SF6 gas to purity levels of around 99.99 percent, which is a higher level of purity than traditional methods. The patent-ed technique could result in cost savings of up to 30 percent.

On-load tap changers: managing an ageing fleetThe on-load tap changer (OLTC) is a tool that varies the output of a transformer while it is under load, enhancing the flexibility of

distribution systems. Changing trends in the industry mean less maintenance, more integration of renewables and greater focus on environmental and safety matters.

Asset health managementABB’s service approach means that rather than delivering main-tenance on a reactive schedule, monitoring and diagnostics help operators to proactively identify when the asset requires mainte-nance, retrofit or overhaul. The tactic can minimise outages by extending service intervals to as much as 14 years.

Retrofitting arc protectionSolutions from ABB’s arc protection portfolio can offer either integrated or stand-alone protection from the risks of arc flash. When updating IEDs on legacy switchgear or new installations, our 610, 615 and 620 series offer the option of three-channel arc protection. Alternatively, the REA arc protection relay is a stand-alone solution for super fast detection and tripping. The Ultra-Fast Earthing Switch (UFES) can also be a retrofit or new build solution and can extinguish an arc in less than 10 ms by earthing all of the busbars.

Recycling SF6 can return it to 99.99 percent purity

National Grid’s 2x30 MVAr shunt reactor from Willesden

Transformer remanufactureAnother service option gives operators the opportunity to have ABB completely remanufacture transformers when they reach the end of their life. Not only does the remanufactured unit fit precisely into its existing footprint with the potential to upgrade size and control systems, but is also has lower cost and lower lead time than a new product, while having the same life expectancy and level of testing.

The process starts with an on-site inves-tigation and evaluation before remanufacture at ABB’s transformer facility in Drammen, Norway. One National Grid 2x30 MVAr reac-tor at Willesden benefited from the service in 2014 with a new core design and materi-als as well as new or refurbished bushings, tank and sensors.

Substation automation

IEC 61850 relays: now with Integrated arc fault protectionNot only are relays becoming smarter but they’re also becoming safer. The latest IEC 61850 compliant Relion 615 series intelligent electronic devices (IEDs) have fast-acting three-channel arc fault protection built in. This means that operators can engineer out the risk of arc faults arising.

24 FFWD 1/15 abb.co.uk/ffwd Focus on power products and power systems

25Power products and power systems abb.com/ffwd

Substation automation

The Relion 615 series of IEDs now integrates arc fault protection

The basis of the technology has already been established on ABB’s REA arc protection system and it has now been integrated into Relion 615 relays. The IEDs are particularly well suited to critical switchgear installations such as those in the oil and gas industries, where the potential dangers of arc flash incidents are highly regulated.

Ultra-fast detection and quenching of arcing incidents means that operators can reduce the required levels of personal protective equipment and cut out the regular certification and maintenance regime that it calls for.

Older switchgear installations can also benefit from the relays as they are more prone to arc faults. A Relion 615 relay can not only enable the integration of IEC 61850 communications to legacy equipment but can also extend its lifetime, delaying asset replacement and extending return on investment.

Arc flash riskThe energy released during an arc flash incident is proportional to the arc’s duration so time is critical when it comes to detecting and minimising the effects of an electric arc.

Left unchecked, arc faults that last any-thing up to 500 milliseconds (ms) or more may cause severe damage to the installa-tion and injury to personnel, whereas if the duration of the arc is kept to less than 100 ms the damage can be minimal. On the other hand if the arc is extinguished in less than 35 ms its effect is almost unnoticeable.

Conventional relays are not fast enough to ensure safe fault clearance when arc faults are experienced. The operation time of the overcurrent relay controlling the incoming circuit breaker may, for instance have been reduced increased to hundreds of milliseconds for selectivity and grading reasons.

By adopting a relay with built in arc protection (or a standalone arc protection relay scheme) the total fault clearance time, in the event of an arc, can be reduced to just a few tens of milliseconds, accounting for a few milliseconds for fault detection, tripping and the travel time needed to open the circuit breaker contacts.

Light-speed detectionWhen an arc fault initiates, it leads to a flash of light and release of heat, which itself leads to an explosive expansion of air. Although the heat and explosive forces represent the majority of risks in an arc flash, it is the flash of light that holds the key to ultra-fast detection for the Relion 615 relays.

Long fibre-optic sensors capture the sudden intense light of an arc flash and notify the relay of an incident at the speed

Replace a time served relay in an hourAnother option available for the 615 series is a new service that cuts the time needed to replace time-served SPACOM relays in power distribution networks. The Relay Retrofit Programme reduces the time to replace a relay from one month to just one hour.

Conventionally, it takes around one month to replace a relay. The bulk of the effort is in the time required for engineers to manually identify the operating parameters of the existing relay and transfer them to a new unit individually. Because a unit can have as many as several hundred parameters, the process is extremely time consuming and because it’s manual, errors can be introduced.

The Relay Retrofit Programme is currently available for ABB SPACOM relays installed in the 1980s. These include the SPAJ140C series for overcurrent and earth fault protection, the SPAM150C motor protection relay and the SPAU130C over and under voltage relay. These can be replaced with state-of-the-art Relion 615 series relays, which are native IEC 61850 devices.

Recognising that there is a vast global installed base of SPACOM units, ABB has re-engineered the relay replacement process by developing a set of software and hardware tools called the Relay Retrofit Programme that enables an engineer to completely replace a time-served relay in less than one hour. This enables the retrofit of modern numerical IEDs to an existing distribution system, opening up the potential for enhanced condition monitoring, records, flexible communications and additional functionality (such as arc flash protection).

ABB has developed a set of tools to install a new relay within an hour

of light. The relay will then instruct the cir-cuit breaker to open without delay. This can also be verified by detection of current with a high set instantaneous element requiring just 1ms surge of fault current, ensuring that only genuine arc flash incidents are acted upon.

This will minimise the likelihood of injury to employees and damage and allow power distribution to be smoothly and safely restored.

26 abb.com/ffwd Power products and power systems

Asset management

Outage Lifecycle ManagementABB’s Outage Lifecycle Management (OLM) was named overall winner in the Product Innovation Awards at the European Utility Week conference and exhibition in Amsterdam in November 2014.

On top of numerous daily challenges, new threats like extreme weather conditions, cyber security issues and rising global demand have created the ‘perfect storm’ for utilities to rethink how they manage energy outages. OLM is designed to help ABB customers weather the storm through better planning, preparing and responding to outages to minimise their overall impact and duration.

Originality – the software is the first to address the full scope of outages, from planning and preparation, to customers, through to final restoration of service and regulatory reporting.

Sustainability and efficiency – the solution captures event information and feeds it into the planning and preparation for future events, creating a continuous improvement loop that drives ever-increasing operational efficiency and sustained savings.

Practicality – OLM is based on a suite of products that are already proven and tested, making it more economical for customers to adopt if they already have one or more of the existing components.

The software is the first complete solution for outage lifecycle management. Its purpose is to help utilities manage the end-to-end process for minimising the impact of major storm outages.

The award judges selected it as overall winner as well as the winner of the Smart Metering, ICT and Grid Security category based on three criteria:

27Power products and power systems abb.com/ffwd

Asset management

The benefits of OLMIn today’s environment, utilities must plan for super storms, cyber threats, energy losses and rising global demands. This has generated a need to rethink how energy outages are managed. Smart equipment and industrial software can play a role in better planning and preparation for outages to minimise their impact and duration.

ABB’s Outage Lifecycle management software provides util ities with a way to manage every key business process in the outage management l i fecycle – from planning and preparation, to communications with stakeholders, through to final restoration of service and regulatory reporting.

Use resources efficientlyBy improving collaboration between central coordinators and work crews, repairs can be quickly identified and prioritised. Ensuring the closest crew with the right tools and expertise is sent to restore power will keep operational and maintenance costs under control.

Improve satisfactionOLM supports customers and stakeholders with proactive, timely and usable information that will enhance relationships and improve satisfaction.

OLM connects the control room with the grid in real time, allowing utilities to isolate and restore the outage quickly and prioritise repair work with the right crews and the right equipment for fast restoration of power. At the same time the solution helps to keep stakeholders such as utility executives, customers and the media team proactively informed about the forecasted impact and restoration time.

Smart equipment and industrial software combine to support planned and unplanned outages, outage management, mobile work-force management and business analytics across the entire lifecycle of outages.

OLM software can play a key role in better planning and preparation for outages

Reduce impact of outagesPlanning and preparation for events such as major storms helps utilities to implement res-toration plans quickly and efficiently based on the type and severity of the outage.

Reduce duration of outagesUtilities can assess and isolate outages then take action to restore power fast by putting scenario plans into action, using data generated by smart grid equipment and using their workforce effectively.

Regulatory complianceThe software can help utilities comply with regulatory reporting requirements, such as system and customer average interruption and duration indices.

28 abb.com/ffwd Power products and power systems

Medium voltage

SafeGear High Duty

In 2014 ABB extended its SafeGear range of arc-resistant switchgear for primary distribution substations up to 15 kV to include the HD (High Duty).

The SafeGear range is designed for maximum safety to reduce risk to operators, reduce damage to equipment and improve reliability. Panels are built with double sidewalls to contain damage from arc flash in the compartment where the fault originated, as well as isolating the low voltage instrumentation compartment from the potential fault compartments.

The new SafeGear HD model has a 0.5 second 63 kA arc withstand time, Type 2B accessibility and incorporates ABB’s Is-Limiter fault current limiting device (see page 20 to find out more). A 3-way spring loaded vent flap system vents through the centre of the switchgear and does not require additional space for side-mounted venting chimneys.

The compact panels have a low overall footprint and a low height, which helps to minimise the costs of enclosing buildings. They integrate ABB’s low maintenance ADVAC spring charge breaker and are designed to be simple to operate and maintain.

Dave Knapper, general manager for ABB’s medium voltage systems business in the UK said: “SafeGear HD follows ABB’s tradition of providing the smallest, safest and most reliable arc resistant switchgear on the market.”

ABB has introduced new fast-acting fuses that are ideal for protecting onshore and offshore wind power systems. They are designed to achieve the lowest possible breaking current while acting at a speed of 100 ms. This makes them particularly well suited to protect distribution transformers in wind farms, where superior performance of fuses is required.

The fast-acting CEF fuses offer very good protection against faults in the low voltage side of distribution transformers. One version is supplied with a Temperature Control Unit, which protects against high temperatures in enclosed panel compartments.

CEF fast-acting fuses

29Power products and power systems abb.com/ffwd

Medium voltage

Smaller secondary switchgearABB’s UniSec medium voltage switchgear is now available in an extremely compact size in the form of the UniSec HBC panel. The new unit makes use of multifunctional HySec switchgear, which integrates a circuit breaker, line disconnector and earthing switch in the same panel that is just 500 mm wide.

HySec switchgear

The HBC unit makes the UniSec switchgear perfect for substations, utilities, industry, commercial and residential buildings where compact size is a fundamental requirement.

Inside the HySec unit, its upper part provides the circuit-breaker function and features an epoxy resin enclosure housing three vacuum interrupters. A stainless steel lower part performs the functions of line disconnector (to isolate the cables from the busbars) and earthing switch (to earth the cables themselves). The stainless steel part also provides metallic separation between the cable and busbar compartments to ensure operator safety.

ABB has been able to minimise the size of the HySec unit overall while ensuring a higher level of protection by using resin for the upper part and SF6 as the insulating medium in the switch-disconnector part.

The vacuum system, which acts as the circuit-breaker is installed in the resin section and is operated by a dedicated operating mechanism. The disconnector contacts are housed in the SF6 gas insulated lower part and offer the three classic positions: line/isolated/earthed.

UniSec HBC is available at voltages of up to 24 kV and for busbars rated at 1,250 A with the HySec multifunctional apparatus handling currents of up to 630 A.

30 abb.com/ffwd Power products and power systems

Rail

ABB remote terminal units to play vital role in telent’s Network Rail SCADA renewal project

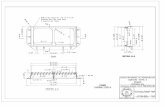

Typical RTU configuration

Host communication

Control system

Integrated HMI

Extension I/O modules

IED

IED

IED

Multimeter for metering and fault current detection

31Power products and power systems abb.com/ffwd

Rail

Hundreds of ABB’s new generation RTU 540 remote terminal units (RTUs) will be integrated into Network Rail substations during a project being carried out by telent to renew the SCADA (Supervisory Control and Data Acquisition) system in the rail operator’s Southern Electric region.

The new SCADA master station system will control traction power and distribution for Network Rail as an essential part of the planned electrification investment being made in the UK Rail network. The new system will provide the complete control interface for Network Rail to monitor the network remotely, carry out isolations and implement automatic execution and service restoration.

The RTUs will provide the vital telemetry and remote control l inks to the main traction substation equipment, including transformers, rectifiers, switchgear and circuit breakers as well as important ancillary services such as door entry alarms and other

security functions. Using high-speed fibre optic connectivity, the RTUs will interface with telent’s head end SCADA system in Network Rail’s control centre.

telent and Network Rail have stand-ardised on the RTU 540 – the medium size module in ABB’s new generation 500 series – as it provides a flexible, scalable and compact solution that delivers maxi-mum functionality within the restricted space available in trackside substation enclosures. The RTUs will use classic hard-wired inputs while at the same time utilising the DNP 3.0 protocol for communications with the telent Control centres. However, they also have built-in cyber security features and capa-bility to interface with equipment based on the IEC 61850 standard for substation communications, ensuring they are totally future-proofed to operate with any new pri-mary equipment that incorporates modern IEDs (intelligent electronic devices).

Danny Lyonette, ABB UK Sales & Mar-keting Manager for Substation Automation said: “Network Rail’s new SCADA is a very

prestigious project that provides the first large scale UK deployment for our new generation RTU 540 modules. Our selection was based on the successful completion of telent’s stringent approval process, one of the key factors was the module’s compact design, capable of handling up to 5,000 information points.”

telent is due to complete the project in 2017 and ABB has already supplied the first 20 RTU 540s out of a total of 242 RTU 540 modules for traction substations across the region, which covers south London, Dorset, East and West Sussex, Hampshire and Kent where trains are powered by a 750 V DC supply to the third rail.

32 abb.com/ffwd Power products and power systems

High voltage

UK first for PASS M0HA brand new data centre campus that is now under construction will be the home of the UK’s first installation of ABB’s innovative PASS M0H switchgear. The site is being created as the country’s greenest data centre development and its first phase is a 130,000 square foot building that will consume 10 MW of power.

Engineering and utility services firm Freedom Group is delivering the grid connection for the new site through its Colchester office and is engineering a connection with a 2N level of security that will connect to two separate incoming 132 kV transmission feeds. Freedom turned to ABB to supply the high-voltage switchgear that will control the incoming power as well as medium voltage 11 kV switchgear to control power distribution inside the centre.

H-configuration switchgearFor the high-voltage switchgear element, ABB is supplying its PASS M0H switchgear, which is the latest addition to its PASS (Plug and Switch System) high-voltage switch-gear family.

The hybrid switchgear integrates ele-ments of AIS and GIS and includes all of the functions of a complete switchgear bay with an H configuration in a single sub-assem-bly. These include circuit breaker, combined disconnector and earthing switches, current transformers and fast acting earth switch.

On one side of the H, traditional air-insu-lated connections control equipment and on the other side, bay functions are enclosed in a single-phase gas-insulated housing. A changeover switch in the cross bar of the H will enable the operator to seamlessly switch between the two incoming or outgo-ing circuits when required. This represents flexibility and security of supply.

Freedom will connect the module to two separate incoming 132 kV feeds from the local UK Power Networks transmis-sion grid via silicon rubber outer insulated

33Power products and power systems abb.com/ffwd

High voltage

bushings and will feed two 132/11 kV pow-er transformers using plug-in type cable connections.

Compact footprintThe PASS M0H includes the functions of a complete switchgear bay with an H configuration in a single unit and has a significantly smaller footprint than a conventional AIS bay.

This offers major advantages for the data centre operator. Firstly, the small size enables the operator to dedicate more space to servers without any loss of performance or availability of the grid connection. This helps the operator make the most of its centre in the long term by maximising income-generating space for servers.

It also reduces the civil engineering and enabling works required during the construction phase, helping to control costs.

Factory assembled and testedAnother benefit is that the PASS M0H is delivered to site as units that have been completely factory assembled and high-

voltage tested. This means that they can be installed quickly, reducing the need for on-site logistics, vehicle movements and associated costs.

Plus there is no need for on-site manage-ment or handling of SF6 gas as the PASS M0H is completely assembled and sealed at ABB’s factory.

By eliminating on-site assembly, testing and commissioning of the switchgear bay, Freedom Group will not only reduce the need for site work but also its associated cost and risks.

Product approvalsAs high-voltage switchgear that is installed on the transmission network, products in ABB’s PASS M0 family have passed the stringent product approvals processes of both UK Power Networks and the Energy Networks Association.

Other PASS M0 switchgear is being installed elsewhere on UK Power Networks’ transmission network to connect major new solar farms (see page 5 for more information) and the switchgear family has a long track

record of performance, with more than 5,000 bays installed worldwide.

Medium-voltage distribution Freedom has also ordered ABB’s UniGear ZS1 medium-voltage switchgear rated at 11 kV to control the power distribution circuits inside the new data centre campus.

Each UniGear ZS1 panel is a single unit that can be equipped with a circuit breaker, contactor or switch-disconnector as well as accessories. The switchgear is extremely well established, with more than 150,000 panels installed in more than 100 countries. It is available in variants for single level, double level and double busbar applications.

Because it does not require rear access for installation or maintenance, all operations are carried out from the front, enabling installation within a limited footprint, with the potential to position the panels with their backs to the wall.

34 abb.com/ffwd Power products and power systems

Medium voltage

Protecting critical equipmentRapidly growing importance of safe and reliable data storage has driven innovation and development of UPS (uninterruptible power supply) and power conditioning equipment in recent years. Large, sensitive and critical loads like computing equipment can be damaged by sudden power outages and power quality issues and UPS systems are now a vital component of any data centre.

The PCS100 MV UPS

35Power products and power systems abb.com/ffwd

Medium voltage

ABB has launched the PCS100 Medium Voltage UPS to provide complete power protection for mega data centres, other critical data processing sites and large manufacturing sites. It can be used to protect the entire supply of an installation or just selected sensitive loads.

John Penny, general manager for ABB’s Power Conditional Global Product Line said: “Medium voltage becomes very useful for factory designers who can now locate the power protection equipment more remotely in a centralised location away from the production floors. At the same time, facilities can benefit from the improved reliability, efficiency, ruggedness and small footprint that were the focuses of our design team.”

In operation In the case of a voltage sag or outage, the PCS100 UPS detects the sag and instantly takes over the load, continuing to supply the load with a perfect regulated voltage. Once the sag or outage is over, the UPS judges that the incoming feed from the utility is stable and will transfer the customer’s load back to the utility.

UPS at medium-voltageTraditionally UPS systems tend to be fitted at the low voltage level but this can often pose a challenge when limited space is available. Also, when many devices are to be protected, the sheer number of UPSs

needed can present problems in terms of management, supervision, maintenance and availability.

The solution is to install a UPS at the medium voltage level, which means that it can be put in less crowded spaces such as MV electrical rooms or plant substations, freeing up space for servers or manufac-turing tools.

Another benefit of operating at the MV level is energy efficiency and the UPS has energy efficiency greater than 99.5 percent. The lower currents at MV result in lower losses and higher efficiency than a comparable LV UPS. The arrangement inside the PCS100 MV UPS also uses a single-conversion arrangement to minimise losses.

The power converter and energy storage components remain at low voltage with a transformer coupling these to the medium voltage components. Another component at the MV level is a thyristor-based utility disconnect switch which prevents backfeed into the grid in the event of a power loss or voltage sag.

Energy storage at LVBecause energy storage is kept at LV levels a wide range of energy storage options is available and maintenance and system costs are kept low.

The most popular options for energy storage are ultracapacitors, lithium-ion (Li-ion) batteries and high-discharge sealed lead-acid batteries. It is expected that ultra-

capacitors will be widely used in industrial applications due to their long life and com-pact size.

For applications that will need to run autonomously for longer periods, Li-ion bat-teries offer reduced footprint and increased life when compared with the lowest-cost lead-acid solutions.

Together with the small system footprint and low maintenance requirements, the high efficiency of the UPS leads to low ownership costs of the system for operators.

Modular approachThe modular UPS enables operators to build up a subsystem in blocks of 2 MVA capacity up to a maximum of 6 MVA. Because it is part of ABB’s broader PCS family of power quality products, it can be paired with other LV power conditioning equipment.