Effects of Chemicals and Blending Petroleum Coke on the Properties of Low-rank Indonesian Coal Water...

Click here to load reader

-

Upload

rizal-ahmad-mubarok -

Category

Documents

-

view

44 -

download

4

description

Transcript of Effects of Chemicals and Blending Petroleum Coke on the Properties of Low-rank Indonesian Coal Water...

-

ini

nHag Te

iver

In this study, the effects of different chemical additives including dispersant and stabilizer

1. Introduction

the utilization of low-rank coals is far from satisfying in the

mechanical compression drying and upgraded brown coal

An efficient technology is to use low-rank coals in the

F U E L P R O C E S S I N G T E C H N O L O G Y 8 9 ( 2 0 0 8 ) 2 4 9 2 5 3

omworld.It is necessary to solve above problems in order to use low-

rank coals as efficiently as possible. One of the efficientmethods is to upgrade low-rank coals. Various dewatering andupgrading processes have been developed since the 1920s.

preparation of a coal water mixture (CWM). CWM withadvantages such as the production of high solids concentra-tion, saving from transport, storage and dewatering costs areregarded as an alternative to fuel oil [10]. CWM can be storedwithout the danger of coal-dust explosion, pumped, trans-Low-rank coals, such as sub-bituminous coal and lignite,cannot be conveniently used like anthracite and bituminouscoal due to low caloric value and high moisture content, beingrich in oxygen and high tendency to spontaneous combustion.As a result, low-rank coals are mainly used for powergeneration by firepower plant around the colliery. Therefore,

processes [19].Coal blending is becoming a normal practice in large

combustion and gasification plants, which utilize low-costimported coals for blending with local coals, as operatorsattempt to increase the flexibility of fuel types. By blendingwith high-rank coals, such as anthracite and bituminous coal,low-grade factors in low-rank coals will be weakened.Among them are the superheated anddrying, hot and supercritical water dry

Corresponding author.E-mail address: [email protected]

0378-3820/$ see front matter 2007 Elsevidoi:10.1016/j.fuproc.2007.11.026Keywords:Petroleum cokeLow-rank coalCoal water mixtureDispersantStabilizeron the solid loading, viscosity, rheological behaviour and static stability of coal watermixtures have been investigated. In the experiments, naphthalene sulfonate formaldehydecondensate (NSF) was selected as dispersant and carboxymethyl cellulose sodium salt(CMC-Na) and nano-stabilizer were employed as stabilizers. An Indonesian low-rank coal,taken from Berau, East Kalimantan, was used for the study. To obtain high-loaded slurry,Liaohe petroleum coke was used to blend with Indonesian coal sample. The results of theexperiments showed that adding chemical additives and blending Liaohe petroleum cokecan effectively improve the slurryability of Indonesian low-rank coal.

2007 Elsevier B.V. All rights reserved.Article history:Received 11 April 2007Received in revised form7 November 2007Accepted 13 November 2007A R T I C L E I N F O A B S T R A C TEffects of chemicals and blendproperties of low-rank Indones

Renfu Xua, Qihui Hea, Jun Caia, Yi Panb, JiaaSchool of Chemistry and Chemical Engineering, Nanjing University,bResearch Center of Surface and Interface Chemistry and Engineerin210093 Nanjing, Jiangsu, ChinacCollege of Chemistry and Environment Science, Nanjing Normal Un

www.e l sev i e r. cpressurized steaming, hydrothermal

(B. Hu).

er B.V. All rights reservedg petroleum coke on thean coal water mixtures

Shenb,c, Baixing Hua,

nkou Road No. 22, 210093 Nanjing, Jiangsu, Chinachnology, Nanjing University, Hankou Road No. 22,

sity, Ninghai Road No. 122, 210097 Nanjing, Jiangsu, China

/ l oca te / fup rocported in pipelines and combusted like fuel oil in anenvironmentally benign manner [11,12]. CWMs prepared

.

-

from low-rank coals have shown excellent combustioncharacteristics in the gas turbine [13].

In CWM technology, onemajor problem is how tomaintainthe highest possible coal concentration and stability simulta-neously, at a given optimum viscosity. To resolve thisproblem, it is necessary to manipulate two major factors:the addition of suitable dispersants and stabilizers and thesize distribution of the coal particles. The chemical additivesmust be chosen such that they should provide sufficientviscosity, electrokinetic potential and the desired stability.Numerous studies have been made of CWM rheologicalproperties in an effort to obtain acceptable fluidity andmaintain sufficient stability against sedimentation of thecoal particles [1420].

This study focused on the effects of different chemicalsused as dispersing agent and stabilizer on the solid loading,viscosity and stability of CWM prepared from Indonesian low-

The raw coal and petroleum coke were crushed in jaw and

thoroughly mixed by stirring to ensure homogeneity. Thesolids loading of the CWM was determined from the weightdifference upon drying in an oven at 105 C for 2 h.

An anionic surfactant, naphthalene sulfonate formalde-hyde condensate (NSF), was selected as a dispersant. Carbox-ymethyl cellulose sodium salt (CMC-Na, weight averagemolecular weight: 7.6104) and inorganic nano-stabilizerwere used as stabilizers. The nano-stabilizer was the com-pound of spherical nanoparticles and fibrous nanoparticles,and their weight proportion was 1:1 [16]. Two kinds ofnanoparticles were based on different manufacturing pro-cesses and sourced from attapulgite clay, which was very richand cheap in China. The dosage of dispersant and stabilizerwas based on dry coal, unless otherwise stated.

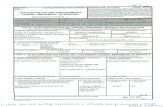

Table 2 Particle size parameters of coal and petroleumcoke samples

Sample D25 (m) D50 (m) D75 (m) D90 (m)

Indonesian coal 17.23 40.92 80.92 133.31

250 F U E L P R O C E S S I N G T E C H N O L O G Y 8 9 ( 2 0 0 8 ) 2 4 9 2 5 3roll type crushers to obtain particles of sizes less than 3 mm,respectively. Then the crushed particles were comminuted ina bill mill to obtain samples. The particle size distributions ofthe samples were determined by LS-CWM (2) type particlesizer produced by Omec Science and Technology Ltd., Zhuhaiof China. The particle size distributions and some size

Table 1 Chemical analyses of coal and petroleum cokesamples on dry basis

Parameter Indonesiancoal

Liaohe petroleumcoke

Inherent moisture (wt.%)a 12.15 1.22Ash (wt.%) 2.29 0.34Volatile matter (wt.%) 44.34 10.90C (wt.%) 68.51 85.48H (wt.%) 4.71 3.82N (wt.%) 1.72 1.71S (wt.%) 1.51 1.52O (wt.%, by difference) 23.55 7.47Hardgrove grindabilityindex

50.5 74.2

Calorific value (MJ/kg) 29.34 35.60rank coal. At a given optimum viscosity (about 1000 mPa s at ashear rate of 28.38 s1), to obtain high loading slurry, Liaohepetroleum coke sample was used to blend with Indonesiancoal sample. Based on the results, the factors governing thesolid loading, viscosity and stability of slurries have beendiscussed.

2. Experimental

2.1. Materials

Indonesian low-rank coal taken from Berau, East Kalimantan,and Chinese Liaohe petroleum coke samples were used for thestudy. The chemical analyses of experimental samples aregiven in Table 1.a Air dried basis.parameters of two samples are shown in Fig. 1 and Table 2,respectively.

The particle size is corresponding to the accumulativeweight percentage of particles that pass the size on thedistribution curve. D25, D50, D75 and D90 in Table 2 refer to theparticle sizes that 25%, 50%, 75%, 90% of coal particles byweight can exactly pass, respectively. As seen from both Fig. 1and Table 2, Liaohe petroleum coke sample contains signifi-cant amount of finer particles than Indonesian coal sample.

The CWM preparation procedure was identical for alltested samples. The weighed coal sample was slowly pouredinto a beaker containing predetermined quantity of additive,stabilizer and distilled water. The contents were continuouslystirred by a propeller-type agitator during addition of coal, andthen the stirring of the slurry was continued for further20 min. Before testing, the slurry samples were always

Fig. 1 Particle size distributions of Indonesian coal andLiaohe petroleum coke samples.Liaohe petroleumcoke

6.32 18.17 47.26 99.78

-

2.2. Viscosity and static stability measurements

The apparent viscosity of CWMwas measured using NXS-11Arotary viscometer made in Chengdu of China, which wasequipped with a circulating water bath. The geometry of NXS-11A viscometer was a rotational concentric cylinder (rotor-cylinder) system. There were five sets of rotor-cylindermeasure systems (A, B, C, D and E) for different viscosityranges. At a constant temperature of 25 C, measures wereperformed using B system and required sample volume was60 ml. For B system, cylinder inner diameter and rotor outerdiameter were 4 and 3.177 cm, respectively, and the gap sizebetween rotor and cylinder was about 0.41 cm. A wholeviscosity measurement was spent about 150 s. Based on thecomputer program, when the recorded numerical valuesunder different shear rates were input the computer, theapparent viscosity at 28.38 s1 shear rate would be obtained.

3. Results and discussion

content of petroleum coke is correlation to low hydrophilicity.The hydrophilic behaviour of low-rank Indonesian coal has anegative effect on the viscosity of the suspension by increasingthe absorption of waterwithin the coal particles. Due to the lackof oxygenated functional groups, a low absorption of water bythe particles of petroleum coke can be assumed, which allows alarger amount of water to fluidize the suspension [21].

In addition, because of the differences in the surfaceproperties of the low-rank coal and petroleum coke, thedispersant NSF employed in this study can be expected todifferently react with them. Anionic dispersant NSF should notadsorbwell on the surface of low-rank coals since such coals are

F U E L P R O C E S S I N G T E C H N O3.1. Effect of coal loading on apparent viscosity fordispersant

In order to evaluate the performance of dispersant towardsthe coal loading of CWM prepared from Indonesian coalsample and its effect on the viscosity, the studies were carriedout with dispersant dosages of 0.6, 0.8 and 1.0% based on drycoal, respectively. The coal loading was varied and theviscosity datawas recorded. The results are presented in Fig. 2.The measured apparent viscosity in the paper was corre-sponding to this shear rate, unless otherwise stated.

The evaluation of static stability was based on the CWMQuality Testing Methods (CCUJ Unified Methods, Center forCoal Utilization, Japan, 1994). The static stability of slurrycould be estimated according to the particles sedimentationrate. The average static sedimentation rate could be deter-mined after the slurry sample statically held for 7 days [14].Details on the operation for static sedimentation rate mea-surements could be found in reference [16].Fig. 2 Effect of coal concentration on apparent viscosity atdifferent dispersant dosages.It is seen in Fig. 2 that the solid loadings of slurries withviscosity values about 1000 mPa s were 52.2, 52.8 and 53.6%when the dispersant concentrations are 0.6, 0.8 and 1.0%,respectively. The solid contents were so low that the slurrieswere not practical.

The rank of the coal, hence its porosity, volatile matter, Cand O contents are the factors causing different slurryviscosities. Usually, the higher the rank of the coal, the moresolids the slurry can be fed. Whenmixed with water to prepareCWM, low-rank coals in a way dilute the suspension with theinherent moisture presenting on the coal surfaces. Therefore,CWMs prepared from low-rank coals exhibit much lower solidcontents at the same viscosity as those obtained from high-rank coals, naturally hydrophobic coals [9,10]. Depending on theproperties of low-rank Indonesian coal, the limitations on theviscosity values forced it to be worked with lower solid loading.

3.2. Blending process

Slurrieswerepreparedby blending Indonesian coal samplewithLiaohe petroleum coke in different weight proportions on drybasis. Considering the high heating value and the goodcompatibility between low-rank coal and petroleum coke, it isinteresting to prepare coalpetroleum cokewater slurry. Thecharacteristics of slurries with dispersant concentration of 0.8%are given in Table 3. As is observed in Table 3, when blendingprocesses were adopted, solid loadings of slurries with viscosityvalue about 1000 mPa s were effectively increased.

The improvement in the slurryability when partial Indone-sian coal particles is replaced by ground Liaohe petroleum cokemay be attributed to the lower water absorption capacity of thelatter. Since it is generally accepted that the absorption of waterinvolves the interaction of water molecules with the functionaloxygenated surface sites on the particles, the low oxygen

Table 3 The characteristics of slurries prepared fromblending of Indonesian coal with Liaohe petroleum coke

Sample Blendratio

(wt/wt)

Solidloading(wt.%)

Apparentviscosity(mPa s)

Indonesian coal 52.75 1000Coal/coke blending 2:1 59.61 1050

1:1 62.02 9601:2 65.74 1030

Liaohe petroleum coke 69.11 1020

251L O G Y 8 9 ( 2 0 0 8 ) 2 4 9 2 5 3highly negatively charged due to, mostly, the high content ofoxygen groups [22,23]. As is observed in Fig. 2, low-rank coal

-

3.4. Static stability

252 F U E L P R O C E S S I N G T E C H N O L O G Y 8 9 ( 2 0 0 8 ) 2 4 9 2 5 3slurries donot respondwell to increasing dosages of NSF. Itmayturn out that high solid loading of the slurry prepared fromblending of low-rank coalwith petroleumcoke is a result of veryselective adsorption of NSF on the coke component of the blendand not on the low-rank coal component.

As is seen from both Fig. 1 and Table 2, Liaohe petroleumcoke contains significant amount of finer particles thanIndonesian coal sample. The small coke particles may enterthe voids between the larger coal particles, and less water isrequired to fill the inter-particle voids. Furthermore, thesmaller particles filling the gaps between larger particles caneven act as a lubricant, in turn leading to higher relativemobility of the coal particles in the suspension and conse-quently to lower the viscosity.

Some disadvantageous factors on slurryability in Indone-sian low-rank coal are weakened by blending with Liaohepetroleum coke. Additional, the difference in particle sizes oftwo samples are useful for obtaining high loading slurries with

Fig. 3 Effect of shear rate on the apparent viscosity of slurry.low viscosity.

3.3. Rheological behaviour

The apparent viscosities of slurries prepared from the blend-ing of Indonesian coal with Liaohe petroleum coke were

Table 4 Effects of stabilizer on static sedimentation rates of In

Coal/petroleum coke(wt/wt)

Solid loading(wt.%)

Stabilizer Stabilizer(

2:1 59.6 CMC-NaNano-

stabilizer1:1 62.0

CMC-NaNano-

stabilizer1:2 65.7

CMC-NaNano-

stabilizermeasured under different shear rates, and the weight propor-tion of two sampleswas 1:1. For each slurry sample, a constantconcentration of 0.8% dispersing agent and a solid loading of62.0% were used. The results for addition of differentstabilizers are given in Fig. 3.

As it is seen in Fig. 3, the slurries exhibited shear-thinningor pseudo-plastic behaviour with an apparent viscositydecreasing with increasing shear rate. The use of CMC-Naresulted an increase in the viscosity of slurries, and there wasno remarkable effect on the viscosity when nano-stabilizerwas used. When 0.3% nano-stabilizer and 0.02% CMC-Na wereused, the viscosity was varied from 750 to 790 and 1150 mPa sat 128 s1 shear rate, respectively. Consequently, at a givenviscosity, use of nano-stabilizer would result in a higher solidloading than use of CMC-Na under the same condition.

Fig. 4 Effect of nano-stabilizer concentration onsedimentation rate.Slurries were prepared from different blend compositions ofIndonesian coal and Liaohe petroleum coke, and a constantconcentration of 0.8% dispersant was used. Static sedimenta-tion results of the slurries with and without stabilizer aregiven in Table 4. When the static sedimentation rate was

donesian coal-Liaohe petroleum cokewater slurries

concentrationwt.%)

Apparent viscosity(mPa s)

Sedimentation ratefor 7d (wt%/day)

0 1050 2.520.02 1460 0.320.3 1090 0.27

0 960 2.350.02 1390 0.210.3 1030 0.18

0 1030 1.860.02 1560 0.160.3 1080 0.12

-

measured, a slurry sample would statically hold for 7 days.

significant effect on the sedimentation rate when nano-

stabilizer is 0.250.35%.

[3] D.J. Allardice, L.M. Clemow, G. Favas, W.R. Jackson, M.Marshall, R. Sakurovs, The characterisation of different forms

253F U E L P R O C E S S I N G T E C H N O L O G Y 8 9 ( 2 0 0 8 ) 2 4 9 2 5 3In sum, the slurryability of Indonesian low-rank coal can beeffectively improved by adding chemical additives and blend-ing petroleum coke.

R E F E R E N C E S

[1] Mahidin, Y. Ogaki, H. Usui, O. Okuma, The advance ofvacuum-treatment in the thermal upgrading of low-rankcoals on the improvement of dewatering and devolatilization,Fuel Processing Technology 84 (2003) 147160.

[2] D.F. Umar, H. Usui, B. Daulay, Change of combustioncharacteristics of Indonesian low rank coal due to upgradedbrown coal process, Fuel Processing Technology 87 (2006)10071011.stabilizer concentration exceeds 0.25%. Thus, it is establishedthat the optimum concentration of nano-stabilizer should be0.250.35%.

4. Conclusions

In the investigation of the slurryability of Indonesian low-rankcoal sample in the presence of naphthalene sulfonateformaldehyde condensate (NSF) as a dispersant and Carbox-ymethyl cellulose sodium salt (CMC-Na) and inorganic nano-stabilizer as stabilizers, the following results are obtained:

Slurries with acceptable viscosities (about 1000 mPa s)made by Indonesian low-rank coal are not practical because oflow solid loadings.

Blending petroleum coke is an effective approach toimprove the solid loadings of Indonesian low-rank coalwater mixtures. Furthermore, it can increase calorific valuesof coal slurries.

Indonesian coal-Liaohe petroleum cokewater slurriesexhibit shear-thinning or pseudo-plastic behaviour. At agiven viscosity, use of nano-stabilizer would result in a highersolid loading than use of CMC-Na due to the viscosity increaseeffect of the latter.

The experimental results of static stability show thesedimentation rate decreases with increasing amount ofnano-stabilizer and the optimum concentration of nano-to per day, and the resulting unit was wt.%/day. As is observedin Table 4, while the sedimentation rates of CWMs in theabsence of the stabilizer are 2.52%, 2.35% and 1.86%/day,respectively, these rates evidently decrease with addition of0.3% nano-stabilizer or 0.02% CMC-Na.

The static sedimentation rate of slurries with respect tonano-stabilizer concentration is given in Fig. 4. As it is seen inthe figure, static sedimentation rates rapidly decrease whennano-stabilizer is added, and sedimentation rates decreasewith increasing amounts of nano-stabilizer. Also, there is noof water in low rank coals and some hydrothermally driedproducts, Fuel 82 (2003) 661667.

[4] G. Favas, W.R. Jackson, Hydrothermal dewatering of lowerrank coals, 1. Effects of process condition on the properties ofdried product, Fuel 82 (2003) 5357.

[5] G. Favas,W.R. Jackson,M.Marshall, Hydrothermal dewateringof lower rank coals, 3. High-concentration slurries fromhydrothermally treated lower rank coals, Fuel 82 (2003) 7179.

[6] C. Bergins, Kinetics and mechanism during mechanical/thermal dewatering of lignite, Fuel 82 (2003) 355364.

[7] C. Bergins, J. Hulston, K. Strauss, A.L. Chaffee, Mechanical/thermal dewatering of lignite, Part 3: physical properties andpore structure of MTE product coals, Fuel 86 (2007) 316.

[8] Y. Artanto, W.R. Jackson, P.J. Redlich, M. Marshall,Liquefaction studies of some Indonesian low rank coals,Fuel 79 (2000) 13331340.

[9] M. Pawlik, Polymeric dispersants for coalwater slurries,Colloids and Surfaces. A, Physicochemical and EngineeringAspects 266 (2005) 8290.

[10] G. Atesok, F. Boylu, A.A. Sirkeci, H. Dincer, The effect of coalproperties on the viscosity of coalwater slurries, Fuel 81(2002) 18551858.

[11] G. Papachristodoulou, O. Trass, Coal slurry fuel technology,Canada Journal of Chemical Engineering 65 (1987) 177201.

[12] Y.J. Shin, Y.H. Shen, Preparation of coal slurry with2-propanol, Journal of Hazardous Materials B 137 (2006)152156.

[13] K.K. Tiwari, S.K. Basu, K.C. Bit, S. Banerjee, K. Mishra,High-concentration coalwater slurry from Indian coals usingnewly developed additives, Fuel Processing Technology 85(2003) 3142.

[14] NEDO(New Energy and Industrial Technology DevelopmentOrganization), CWM in Japan NEDO International Committee,1997.

[15] N.S. Roh, D.H. Shin, D.C. Kim, J.D. Kim, Rheological behaviourof coal water mixtures, Fuel 74 (1220-1225) (1995) 13131318.

[16] R.F. Xu, B.X. Hu, Q.H. He, J. Cai, Y. Pan, J. Shen, Effect ofcompound inorganic nano-stabilizer on the stability of highconcentration coal water mixtures, Fuel 85 (2006) 25242529.

[17] Z. Akta, E.T. Woodburn, Effect of addition of surface activeagent on the viscosity of a high concentration slurry of alow-rank British coal in water, Fuel Processing Technology62 (2000) 115.

[18] H. Diner, F. Boylu, A.A. Sirkeci, G. Ateok, The effect ofchemicals on the viscosity and stability of coal water slurries,International Journal of Mineral Processing 70 (2003) 4151.

[19] F. Boylu, H. Diner, G. Ateok, Effect of coal particle sizedistribution, volume fraction and rank on the rheology of coal water slurries, Fuel Processing Technology 85 (2004)241250.

[20] F. Boylu, G. Ateok, H. Diner, The effect of carboxymethylcellulose (CMC) on the stability of coalwater slurries, Fuel 84(2005) 315319.

[21] S. Vitolo, R. Belli, M. Mazzanti, G. Quattroni, Rheology ofcoal water mixutures containing petroleum coke, Fuel 75(1996) 259261.

[22] J.S. Laskowski, G.D. Parfitt, Electrokinetics of coalwatersuspensions, Interfacial Phenomena in Coal Technology,Surfactant Science Series, New York, 1989, p. 279.

[23] J.S. Laskowski, Coal flotation and fine coal utilization,Developments in Mineral Processing, vol. 14, Elsevier,Amsterdam, 2001.The sedimentation rate was an average value corresponding

Effects of chemicals and blending petroleum coke on the properties of low-rank Indonesian coal .....IntroductionExperimentalMaterialsViscosity and static stability measurements

Results and discussionEffect of coal loading on apparent viscosity for dispersantBlending processRheological behaviourStatic stability

ConclusionsReferences