Detector Metal Cu Puls

-

Upload

florin-hyd -

Category

Documents

-

view

183 -

download

57

description

Transcript of Detector Metal Cu Puls

©2005 Carl W. Moreland all rights reserved Page 1

“Hammerhead” is a pulse induction(PI) metal detector design. It is intendedprimarily as a learning platform forexperimenters, and as a base design onwhich to expand. This design is verymuch like other commercial PI detec-tors, which tend to have similar circuitdesigns, so it has the potential for goodperformance.

Metal detectors generally are not easyprojects, especially the induction bal-ance variety, and usually haveperformance that falls far short of eventhe least expensive commercial models.Three goals for this design were: makeit easy to build, make it flexible, and getdecent performance.

Pulse induction is a good choice for ado-it-yourself project because the cir-cuitry is straightforward, and “mono”coils are easy to make. There are alsovery few critical internal settings — thatis, it’s not hard to get the circuit to basi-cally work — although finalperformance will depend heavily on anumber of parameter settings. Thisproject includes a layout for a simplesingle-sided PCB using commonthrough-hole components, as well as amuch smaller two-sided surface mountPCB for those with steady solderingirons.

Flexibility is achieved with severalbuild options. They include:

• Passive or active MOSFET turn-off (through-hole only)

• Generic preamp support for NE5534, LM318, and others

• Single-ended or differential integrator• VCO or non-VCO audio• Extra component pads around the

preamp to support experimentation (through-hole only)

This design also makes most of theimportant circuit parameters variable:

• Transmit pulse rate• Transmit pulse width• Integrator sample delay• Integrator sample pulse width• Secondary integrator sample delay• Threshold• Sensitivity• Autotrack speed• Volume

Any or all of these parameters canalso be set to fixed values, simplifyingthe control interface. The various designoptions, and parameter adjustments,will be described as we go.

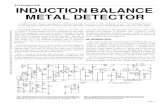

CircuitA simplified diagram of the circuit is

shown in Fig. 1. It can be divided intofive sections: power supply, clocking,transmit plus receiver front-end,receiver back-end, and audio. Each sec-tion can be built and tested sequentially.An oscilloscope is useful for probingthe circuitry to see what is going on, but

is not absolutely necessary, providingthe circuit is built correctly. A digitalmultimeter (DMM) is needed.

The complete circuit is shown inFig. 2 and, at first glance, appears to becomplicated because of all the optionsthat were designed in. However, thedesign options really don’t add muchcomplexity, and allow for different con-figurations and performance compari-sons. Simplified circuits will be shownin the descriptions of the hook-upoptions.

Power supplyPower for Hammerhead is provided

by a single 12-volt battery pack, prefer-ably an 8-pack of AA’s. A 9-volt packcan be used with a reduction in batterylife, and even a 9-volt transistor-radio-type battery can be used, with a signifi-cant reduction in battery life, providinga proper supply tank is used at the coilswitch (I’ll discuss this later). Combin-ing the surface-mount circuit with a 9-volt transistor-radio battery, results in avery compact detector, ideal for a hand-

HammerheadPulse Induction Metal Detector

by Carl MorelandRevision 1.5 — 21 July 2006

Fig. 1: Block Diagram

©2005 Carl W. Moreland all rights reserved Page 2

held probe.The power supply circuitry (Fig. 3)

consists of a voltage doubler, and 3 reg-ulators. The voltage doubler, builtaround a 7660 supply chip (IC1), gener-ates a voltage that is roughly twice thebattery voltage.

At this point, the easiest way to visu-alize the supply voltages is to considerthe positive side of the battery to be“ground”, the negative side of the bat-tery to be the “minus rail” (-VB), andthe voltage doubler output to be the“plus rail” (+VB). See Fig. 4. The sche-

matic is labeled as such, with thebattery connected between ground and“-VB”.

A 7805 regulator (IC2) produces +5volts from the output of the voltagedoubler, and is used as the positive sup-ply for the analog opamps. There aretwo 7905 regulators, one for the -5 voltopamp (analog) supply (IC3), and onefor a -5 volt digital supply (IC4). A sep-arate digital regulator is used to helpisolate digital noise from the noise-sen-sitive analog path.

Voltage doubling by the 7660 is

achieved through the use of a chargepump that must be clocked. Normally,the 7660 is used with its internal clockwhich operates at around 10 kHz, but italso has an option for overriding theinternal clock with an external one. Byusing an external clock, we can ensurethat power supply switching noise issynchronous with the sampling. R37and C11 couple the clock signal to the7660 for this purpose. Unfortunately,the 7660 cuts the external clock fre-quency in half, and at the lowest clockrate may result in poor efficiency. R37

Fig. 2: Complete Hammerhead Schematic

©2005 Carl W. Moreland all rights reserved Page 3

and C11 may be omitted, and the 7660will run on its internal clock.

ClockingThe master clock generator is a 555

timer (IC5) connected as an astableoscillator (Fig. 5). Four different clocksare potentially needed, depending in thedesign options used. The main clockdrives the coil switch Q3 which pulsesthe search coil. A second clock, delayedfrom the trailing edge of the main clock,controls the main sampling switch(IC7a) after the preamp (IC6). A thirdclock, delayed from the second one,controls an optional secondary sam-pling switch (IC7b), used fordifferential integration. Fig. 6 shows atiming diagram of these three pulses. Afourth clock can be used to gate thespeaker for non-VCO audio.

The 555 oscillator has two controls.R2 varies the frequency of the mainpulse (and all derived pulses), and R3varies the pulse width of the main pulseonly (TP1). There is a slight amount of

frequency variation with pulse widthadjustment. The frequency of the mainpulse determines how many times persecond the coil is pulsed, and also howmany samples per second the integrator(IC8a) is integrating. Generally, ahigher pulse frequency allows for afaster coil motion and perhaps a littlebetter noise performance, while con-suming more power. Varying the main

pulse width determines how long thecoil is turned on, which can affect depthof detection (up to a point) and powerconsumption.

The frequency range for this design is900Hz to 2300Hz, and the pulse widthcan be adjusted from 10µs to 75µs. R1-R4 can be modified for other frequencyand pulse width ranges. Note that theseranges, and subsequent ones, are sub-ject to variation due to componenttolerances. The numbers presented hereare measured from a single build andmay not be representative of nominalranges.

The remaining pulses are generatedby dual monostable multivibrators IC11and IC12. IC11 creates the first delayedpulse for the main sampling switch(TP6), and IC12 creates an additionaldelay for the secondary sampling pulse(TP7). In each case, the first half of themultivibrator chip is used to delay theinput pulse, and the second half sets theoutput pulse width. The delays, and thepulse widths, are set by RC time con-stants. The R-component consists of apotentiometer for adjustability, plus afixed resistor to set a minimum delayand pulse width.

For the differential integrator to workproperly, both sampling pulses need tohave the same pulse width, so bothpulse width monostables (IC11b &IC12b) are controlled by the same RCtime constant, R46/R46a/C26, by usingisolation diodes D6 and D7. This

scheme1 works nicely, as long as thetwo pulses have a sufficient amount ofdelay time between them, which is eas-

1. Suggested by Eric Foster.

Fig. 3: Power Supply

Fig. 4: Power Diagram

Fig. 5: Oscillator & Transmit

©2005 Carl W. Moreland all rights reserved Page 4

ily met in this application.Thus, potentiometer R42 sets the

main sampling delay, which is variablefrom around 10µs to 75µs. The second-ary sampling delay tracks the delay ofthe main sample, with an additionaldelay set by R45, variable from 75µs to350µs. R46 adjusts both pulse widthsfrom 3µs to 50µs. Note that extremelimits of various settings may not becompatible. For example, at the highestfrequency (2300Hz), a combination ofhigh pulse width, large sample delay,and maximum secondary delay mightplace the secondary sample pulse intothe next transmit pulse. There is no dan-ger in this, but it may result in bizarrebehavior.

Transistor level shifters Q8 and Q9convert the 0/-5 volt logic levels of themonostable outputs, into +5/-5 volt lev-els needed to drive the samplingswitches IC7a and IC7b. Transistor Q10is also a level shifter, and drives thesampling switch IC7c, which is used forthe non-VCO audio option. If the VCOoption is used, Q10, R49, and R50 arenot needed.

Transmit/Receiver Front-endThe main device in a PI detector is

the coil switch, usually a MOSFET orbipolar transistor with a high currentcapacity and a high breakdown voltage.The coil switch serves two functions: toshort the coil across the battery voltage,which creates a large coil current; andto turn the coil current off as quickly aspossible. During the “on” time, currentflowing through the coil creates a mag-netic field around the coil which, when

static, does nothing2. But when the coilis switched off, the current ceases, andso does the magnetic field. It is the col-

lapse of the magnetic field that induceseddy currents in a nearby metal targetwhich, in turn, generates a counter-mag-netic field. The higher the initialmagnetic field, and the faster it is col-lapsed, the greater the target field that isgenerated.

The output of the 555 oscillatordrives buffer/level-shifter transistor Q1,which primarily converts the 0/-5 voltlevels of the 555 into 0/-VB levels. Fig.5 shows an NMOS drive circuitry usingpassive turn-off via R9. Transistor Q2 issimply a buffer, with low-value emitterresistor (R9) used as a fast pull-downfor the main coil switch transistor Q3.For this setup, R7, R8, and R15 areshorted. For other options, see theOther Options section.

Coil switch Q3 must have sufficientcurrent capacity during the time it isshorting the coil, and it should also havea high breakdown voltage to allow for ahigh flyback voltage. NMOS deviceIRF740 is rated for 10 amps and 400volts. Other devices can be substituted,including NPN’s and IG-BJT’s, withslight differences in performance.

R10 and C10 form an RC tank forproviding the transient current of Q3.These are not absolutely necessary, butcan reduce supply noise, especiallywhen using a 9-volt transistor-radio-

type battery3. If not used, omit C10 andshort R10. In use, C10 should be largeenough to supply the needed charge forthe time Q3 is on. This depends on three

2. However, the exponential“charging” of the coil currentdoes induce a target field, whichcan degrade performance if it isnot settled out.

Fig. 6: Timing

parameters: the gate pulse width, theaverage coil current, and the supplyvoltage. As an example, assume that thepulse width is 25µs, the coil current is2A (limited by its internal resistance),and the supply is 10v. Furthermore,assume we want the capacitor voltage toripple no more than 100mV. Capacitorcurrent is given by the equationi=C×dv/dt, so C=i×dt/dv, or 2A×25µs/0.1v = 500µF. To find the value of R10,we assume the remainder of the clocktime is available to charge C10 back up,so we can set the R10×C10 time con-stant appropriately. But this is a circuitthat need not be operated optimally, sowe can just as easily oversize C10 to,say, 1000µF and set R10 equal to 1Ω.With 100mV of ripple across R10, thebattery will source 100mA of currentover a longer time period, instead of aninstantaneous 2A.

Resistor R11 is the coil dampingresistor and prevents ringing when Q3turns off. Ringing will occur because ofthe L-C tank created by the inductanceof the coil, and the total parasitic capac-itance, including the self-capacitance ofthe coil, capacitance of the cable, and ofQ3. The optimal value of R11 is depen-dent on the coil, and is best determinedexperimentally. If the resistor value istoo low, it will overdamp the coil andreduce sensitivity. Typically, R11 is inthe range of 200-800 ohms, with 680Ωused for the coils described in thisarticle.

The coil signal is applied to preampIC6, which is connected as an invertingopamp. R13/R12 sets the gain to 1000.Diodes D3 and D4 provide clamping toprotect the opamp. Because the coilpulse of 200-400 volts will absolutelydestroy the opamp, do not attempt tooperate the circuit without them!

IC6 needs to be a high-speed opamp,with good transient recovery. TheNE5534 and LM318 have been popularchoices, but there are many more tochoose from now. Different opampshave different schemes for nulling off-

3. This type of battery should beavoided in standard PI detectorsbecause of its relatively highinternal resistance. However, fora PI-based pinpointing probe, itwould be fine.

©2005 Carl W. Moreland all rights reserved Page 5

sets, sometimes using one or more ofthe “extra” pins. This design provides ageneric method of nulling the offset byapplying an offset current to the non-inverting input via R16. Because of thehigh gain, this current needs to be verysmall, so R16 must be large. Since thisopamp operates on the smallest signalin the circuit, it is desirable to have thecleanest supply voltages possible, soR20-C14 and R21-C15 provide low-pass noise filtering for both rails.

The output signal of the preamp canbe optionally filtered by R22-C16,which can be installed as a low-pass fil-ter as shown in Fig. 2, or transposed toprovide high-pass filtering. Both filtertypes have shown up in some commer-cial designs, and values for R22 andC16 will depend on the application.They are not used in this project so val-ues are not provided; omit C16 andshort R22.

The final part of the receiver front-end is the sampling switches. IC7a andIC7b are 4066 gates that sample thesame output signal of the preamp, but atdifferent times. Potentiometer R23 pro-vides a method of fine-tuning the signalbalance between the two switches,which will be explained in the Calibra-tion section. IC7a is the main samplingswitch, and will sample the signal dur-ing the decay of the target signal. Thesample delay and sample pulse widthare set by R42 and R46 as described inthe Clocking section.

IC7b samples the signal at a latertime, determined by R45, and is usedfor interference cancellation in the dif-ferential integrator. This scheme is usedin many commercial designs, but isoften lacking in other PI projects. It isoptional, and the Other Options sec-tion describes how to set up a single-ended integrator.

Receiver Back-endThe remaining circuitry consists of

the differential integrator, amplifier, andaudio. The purpose of the integrator(IC8a) is to average the sampled sig-nals from the preamp. Noise, which israndom in nature, averages to zero — orso we hope — while even weak targetsignals will correlate and remain. Ashort time constant will result in anexcessively fast decay of the target sig-nal, while a long time constant willsmear adjacent targets and reduce

Important note: R11 absorbs the energy that was stored in the coil just prior toflyback, and dissipates the energy as heat. The amount of time-averaged energy isdependent on several factors: coil resistance, transmit pulse width (turn-on time),and transmit frequency. Low coil resistance, large pulse width, and high fre-quency combine to give the highest energy, and R11 can get very hot! It isrecommended that R11 be no less than a 1/2-watt resistor, preferably metal film. Ifyou intend to run it hot, consider a 1-watt resistor, and/or heatsinking it. Note thatQ3 should not run hot, unless it is breaking down during flyback.

selectivity.Fig. 7 shows the differential version

of the integrator. Gain is set to 100 byR26/R24. C17 is the integration capaci-tor, and its value should be chosen toprovide a sufficient, but not excessive,integration time constant. For differen-tial integration, the secondary signalfrom IC7b should be applied to adivider that matches the inverting gainnetwork, such that the non-invertinggain is the same as the inverting gain.Usually, this will call for either preci-sion-valued resistors, or at least well-matched resistors. However, standard5% resistors are sufficient if R23 is usedto calibrate the differential gain. Thesingle-ended integrator option isdescribed in the Other Options section.

The output of the integrator is ACcoupled through C19 to the final gain

Fig. 7: Differential Integrator

Fig. 8: Third Gain Stage

©2005 Carl W. Moreland all rights reserved Page 6

stage, opamp IC8b (Fig. 8). The gain ofthis amp is set to 100 by R29/R28. C20provides some additional low-pass fil-tering. With the integrator signal ACcoupled, resistor R34/R34a is used toprovide a discharge path for the non-inverting input of the opamp. Thus,static signals are rejected and onlydynamic signals will be amplified. Thismeans that when the coil is swept over atarget, the signal will rise and fall andget amplified by IC8b. But if the coil ismoved over a target and held steady, thesignal will rise and then quickly fall as

C19 is discharged4. The rate of dis-charge, or the allowable motion speed,can be controlled by varying R34. Sincesetting R34 to zero will completely killthe signal (although with no risk of cir-cuit damage), R34a is used to set amaximum discharge rate.

This type of motion circuit is com-mon in PI detectors and helps rejectslowly changing ground conditions.However, the need to keep the coil inmotion makes pinpointing targets diffi-cult. If R34 is removed (opened), andthe inputs of IC8b have zero bias cur-rent, then the capacitor will notdischarge and even static signals willpass, resulting in a no-motion mode.Therefore, IC8b (and thus IC8a) needsto be either a JFET-input opamp, or aCMOS opamp. Even a JFET-inputopamp has a slight bias current, per-haps several picoamps, which willdischarge C19 in a short time (15 sec-onds or so). So this no-motion modelikely is not useful for continuous hunt-

4. Actually, C19 will charge untilthe input to IC8b saturates.

ing, unless a true zero-bias currentCMOS opamp is used.

To easily switch between motionmode and zero-motion mode, the PCBincludes pads for a panel-mountedswitch. The mode switch should eitherbe a momentary-contact pushbuttonswitch located for easy thumb access, ora momentary toggle switch for indexfinger control. If a CMOS opamp isused for IC8, then a SPDT switch withone side momentary (ON-OFF-MOM) canbe used, similar to the mode triggerused on White’s brand detectors. Ifthere is no desire for a zero-motionmode, then the pads on the PCB can beshorted. R34 can also be panel-mountedto easily change the retune rate, thoughthis is rarely done.

AC coupling the integrator signal intoIC8b also causes the output of IC8b tohave a quiescent (average) value, plus adynamic target signal. R30-R31-R32-R33 provide a way to adjust the quies-cent output level of the amp which, as itturns out, is a useful way of setting anaudio threshold. C21 filters the adjust-ment voltage applied to R33. See Fig. 8for an alternate drawing of IC8b, thatmight be clearer.

The last part of the backend is theaudio circuitry. There are two majoroptions for the audio: VCO, and non-VCO. The VCO audio is normallytuned to a low growl, and a target givesa rising pitch, much like the old BFOdetectors. The non-VCO audio has afixed frequency, and a target producesan increase in loudness, much like TRand VLF detectors. Although the humanear is more sensitive to frequencychanges than loudness changes, some

people don’t like VCO audio. The non-VCO option will be presented in theOther Options section.

With the VCO option (Fig. 9), a 555is used as a voltage-to-frequency con-verter, such that changes in the voltagelevel from IC8b result in changes in theaudio frequency. R35 (plus R36) drivesthe common-base transistor Q6, whoseemitter is biased to 0v by Q5-R38.Since R35 has signal on one side andvirtual ground on the other, it acts as avoltage-to-current converter. Q6 passesthis current to the 555 oscillator’s RCtiming, making the oscillator frequencyincrease with increasing current. Theoutput of the 555 drives buffer transis-tor Q7, which drives a speaker orheadphones.

Normally, the output audio fre-quency is adjusted to a certain quiescentvalue, and a target signal causes the fre-quency to increase. Setting thequiescent audio frequency is done withthe threshold adjustment R31, describedpreviously. The value of R35 deter-mines the amount of VCO current thatis generated for a given target signal,therefore it can be made variable foradjusting sensitivity. R36 sets the maxi-mum VCO current.

The addition of NPN transistor Q7provides current boosting for drivingthe speaker, in case of weak volume(Q6 & Q7 form the equivalent of anSCR). There is no provision on the PCboard for connecting Q7 in this configu-ration, so it must be kludged in. Ifvolume is adequate, Q7 may be omittedand the volume pot driven directly withQ6’s collector. A similar boost transis-tor may also be added to the real Q7 in

Fig. 9: VCO Audio

©2005 Carl W. Moreland all rights reserved Page 7

Fig. 10: Option 1: VCO Audio

Figs. 9 & 10 for louder volume. Again,it must be kludged in.

Once the threshold loudness isadjusted for the non-VCO option, a tar-get signal will cause an increase inloudness. The non-VCO option poten-tially offers better performance than theVCO option. Driving a speaker (orheadphones, to a lesser extent) createslarge current spikes that can feedthrough to the supply voltages, andcause interference with the receiver.With the non-VCO option, the audiofrequency is synchronous with the sam-pling frequency, and if feedthroughoccurs, it can be moved in time by

delaying the chopping signal until it isplaced at a non-sensitive point in thesampling period. With VCO audio, theinterference is asynchronous and can-not be controlled. No tests have beenperformed to see if this is really aproblem.

Construction & CalibrationBuilding the Hammerhead project is

fairly straightforward, and can be donein discreet stages. As already men-tioned, a DMM is needed, and while anoscilloscope is useful, it is not neces-sary. Waveforms will be shown so thosewith an o-scope can verify circuit oper-

ation, and those without can see whatthe circuitry is supposed to be doing.The remainder of this section willdescribe the construction of the VCOaudio option. Other options will be dis-cussed in the Other Options section.

In building circuits, I generally like touse IC sockets. It allows for the re-useof ICs if you decide later to scrap thecircuit, and it enables the easy swap-ping of ICs if one is bad, or if youdecide to experiment with a differentIC. In this design, I would suggest sock-eting at least IC6, and perhaps IC8.These opamps are the most likely candi-dates for experimentation.

©2005 Carl W. Moreland all rights reserved Page 8

Also, there are several resistors andcapacitors that can be experimentedwith. To make these easy to swap out,pin sockets can be used, or any othercomponent socket that can be split intosingle pins. Make sure to use socketsthat are big enough for the componentleads, as there are sockets available forseveral different lead sizes. In buildingthe surface-mount version, sockets arenot an option, so SMT is best for thosewho don’t wish to experiment withcomponents.

The schematic for Option 1 is shownin Fig. 10, and a complete list of com-ponents for this option is given in thesidebar. Resistors are 1/4-watt 5%,except for R11 which should be 1/2-watt, preferably metal-film. Electro-lytic caps should be rated for at least16v on the VB lines, and 10v else-where. For the other caps,polypropylene and polystyrene offer thebest stability, but monolithic is gener-ally sufficient.

As with the circuit description, we’llstart with the power supply section.Install IC1-IC4, C1, C3-C7, and D1-D2.Watch the polarities on the electrolyticcaps, as well as the diodes. C11 andR37 can be installed at any time, oromitted entirely. Temporarily shortSW1, apply 12v to the circuitry and usea DMM to measure the voltage outputsof IC2 (pin 1 = +5v), IC3 (pin 3 = -5v),and IC4 (pin 3 = -5v), with respect toground. Remember that “ground” is thepositive side of the battery, not the neg-ative. Since IC1 is a voltage doubler,the input to IC2 (pin 3) should beroughly equal to the battery voltage, butcould be as low as 80% or so due to theinherent inefficiency of the chip. Bat-tery voltages drop quickly from theirrated voltage, so the output of IC1 couldbe as low as 8 or 9 volts for a 12v bat-tery. Other measured voltages shoulddiffer by no more than a few percent.

Next is the clocking circuitry. InstallIC5, R1-R4, and C8-C9. Also installIC11-IC12, R42-R48, R50, C24-C26,and D6-D7. Do not install Q8-Q9.Make sure all appropriate shorting wiresare placed for this option. Power up thecircuitry again, and measure the supplyvoltages on IC5 (pin 1 = -5v), IC11 (pin8 = -5v), and IC12 (pin 8 = -5v). Theoutput of IC5 (TestPoint 1) should mea-

sure slightly negative, and vary with theFrequency and Pulse Width adjust-ments. It should fall between -0.25 and-1.25 volts, and be roughly -0.5v withboth adjustments centered.

The transmit circuitry and thereceiver preamp are next: IC6, R6-

R215, C10, C14, C15, C27, D3-D4, andQ1-Q3. Do not install R5. Remember toinstall only the components needed, andjumpers where appropriate. As men-tioned before, R9 normally sees shortpulses of current, and should not over-heat. However, if the output of IC1should get stuck in a low state, R9 candestructively overheat (burn up), aswell as MOSFET Q3. Therefore, makesure IC1 is always operating, or pull R5(or R9 or R15) out if you need to debugthe circuit (this will also protect Q3).

Damping resistor R11 will depend onthe coil used, but for the 500uH coilsdescribed in the Coil section, it shouldbe 680Ω. R11 should also be rated at1/2-watt, as it can get a bit warm, espe-cially when both the frequency and theTX pulse width are set high. Leave thecoil L1 off for now. Set R18 to its cen-ter position. Power up the circuitry andcheck the supply pins on IC6: pin 7 =+5v and pin 4 = -5v (roughly; R20 andR21 will slightly reduce these values).Adjusting R18 should vary output ofIC6 (pin 6, TP4) from about -1.6v, to+1.6v.

Continue with the remainder of thereceiver: IC7, R23-R34, and C17-C21,plus any needed jumpers. Do not installIC8 at this time. Temporarily short SW2and set R34 to its maximum value.Again, apply power and measure thepower pins on IC7 (pin 14 = +5, pin 7 =-5v) and the power pins on IC8 (pin 8 =+5, pin 4 = -5v).

For proper differential integration, thedifferential gain paths of IC8 should bereasonably well matched. The inverting

path gain is . The non-

inverting path gain is

which simplifies to R26/R24, when

5. R7, R8, and R15 may beshorted. See the OtherOptions section

AinvR26R24----------=

AnoninvR27

R25 R27+---------------------------

R24 R26+R24

---------------------------×=

Parts List (Opt. 1)Resistors (5% 1/4-watt)R1 56kR4, R42a 1.5kR5, R6, R15, R37, R43, R44, R45a, R47, R48, R50 10kR9 220R10 1R11 See TextR12, R24, R25, R28, R36, R39 1kR13, R16, R17, R19 1MR20, R21 27R17, R19, R26, R27, R29, R32, R33, R34a, R38 100kR30 150kR46a 330R40 3.3k

PotentiometersR2, R18, R31 100kR3, R42, R46 10kR23 100R34 1MR35 5kR41 5k Audio TaperR45 50k

CapacitorsC1 100µF elect.C3 22µF elect.C4, C5, C6,C7, C14, C15, C27 47µF elect.C8, C24, C25, C26 10nF poly.C9, C17, C18, C22, C23 0.1µF poly.C10 1000µF elect.C11 1nFC19, C20, C21 0.47µF poly.DiodesD1-D4, D6, D7 1N4148

TransistorsQ1, Q5, Q6, Q7 2N3906Q2, Q8, Q9, Q11 2N3904Q3 IRF740

Integrated CircuitsIC1 ICL7660(Voltage inv)IC2 78L05 (+5v ref)IC3, IC4 79L05(-5v ref)IC5, IC9 NE555 (Timer)IC6 NE5534(Opamp)IC7 4066 (Bilateral switch)IC8 TL072 (Opamp)IC11, IC12 74HC221 (Multivibrator)

MiscJ1 Audio jackSP1 SpeakerSW1, SW2 SPST switchSP1 Speaker

Search coil (see text), 12v battery,battery clip, housing, knobs, coax, etc.

©2005 Carl W. Moreland all rights reserved Page 9

R25=R24 and R27=R26. Therefore,when the resistor ratios are matched, theinverting and noninverting gains willmatch. One way to match resistors is touse 1% or 0.1% precision resistors.Another way is to calibrate the gain. Inthe spirit of making this project easy tobuild, without specialty parts, we willcalibrate.

Short pad 1 of IC8 to a convenientground (simple to do when using ICsockets — IC9 pin 4 is ground). Thisshould never be done with IC8installed. R24-R26 is now a simplevoltage divider, the same as R25-R27.A DC voltage can be applied to R23,and if there is a mismatch in the twodividers, R23 can be adjusted to null itout. This should be done with the ana-log gates turned on, which will be thecase as long as Q8 & Q9 are notinstalled.

Use a voltmeter to measure the volt-age at TP4. Adjust R18 until thisvoltage is maximum. Now measure thevoltage across pins 2 and 3 of IC8, andadjust R23 until it is zero. Readjust R18until the output of IC6 (TP4) is 0 volts.Remove power to the board, remove theground short to IC8’s pad 1, and installR5, IC8, Q8, and Q9. Set R31 to itsmidpoint.

At this point, we’re ready to installthe audio circuitry. Refer to the OtherOptions section for details on buildingthe non-VCO option. Install R35-R41,Q5-Q7, Q11, C22-C23, IC9, and neces-sary jumpers. Set R35 to its midpointand R41 to maximum value. At thispoint, the circuitry is ready to be pack-aged and completed. Using a suitableenclosure (remember to allow for a bat-tery pack) add SW1, SW2, the speakerand/or headphone jack, and mountwhichever pots will be user-accessible.

CoilThis design, like most other PI

designs, is set up to use a simple monocoil. A mono coil has only one wind-ing, as opposed to coils with multiplewindings, which often require delicatealignment. Important coil parametersare coil diameter, number of windings,and wire gauge.

For all-purpose coin hunting, a goodcoil size is 10 inches (25cm) in diame-ter. A smaller coil will be more

sensitive to smaller targets, but willachieve less depth. A larger coil willgain depth, but lose sensitivity to smalltargets. One popular setup for PI detec-tors is to use a very large coil, such as 1meter, for deep cache hunting. Thisdesign can be adapted for this; see theSubstitutions section.

The number of windings affects thestrength of the magnetic field that isgenerated. Theoretically, field strengthis proportional to the square of the num-ber of turns, so doubling the number ofturns results is four times the fieldstrength. This seems to be a fantasticreturn on wire investment, except forthree drawbacks; more windings resultsin more coil weight, higher coil resis-tance, and more parasitic capacitance.

Coil weight must be kept reasonablefor comfortable usage. Coil resistancecan easily limit the amount of “on” cur-rent, which is one of the limitations onthe initial field strength. Resistance canbe reduced by using a larger wiregauge, but this again adds to the weightof the coil. Another effect of additionalwindings is an increase in interwindingcapacitance, which tends to limit dI/dtduring turn-off, again reducing the tran-sient field strength dB/dt.

The standard coil for this design has adiameter of 10-inches (25cm), with 26

turns of 26 AWG6 enameled wire. Asimple way to wind a coil is to drive acircle of nails of the correct diameterinto a piece of plywood, and wind thewire around the nails. Then, pull out afew nails and slide the coil off the jig.

Before removing the coil, ensure thatboth ends have loose leads (pigtails) atleast 2 to 3 inches (5-8 cm) long. Alsoslide some short pieces of tape underthe wire, between nails, and wraptightly to keep them bundled after thecoil is removed from the jig. It is best tooverlap the pigtails and wrap a piece oftape at the overlap, as shown in Fig. 11.

This is really all that’s needed to winda mono coil, and the pigtails can be sol-dered to a length of coaxial cable thatfeeds the main circuitry. However, acritical addition is a ground shieldwhich, for PI detectors, is mostly

6. 26AWG = 27SWG = 0.4mm. Aslightly larger wire gauge isfine.

needed to shield from outside electricalinterference.

There are a number of ways to shieldcoils, including foil, wire wrap, metal-lic tape, and conductive spray coatings.A simple method is to wrap the coilwith aluminum duct tape, the kind eas-ily found at the local homeimprovement center. This is the tapethat is true aluminum, not the silverymetallic-looking fabric duct tape. Stan-dard duct tape is slightly conductive,

Fig. 11: Wound coil

Fig. 12: Notched aluminum tape

Fig. 13: Applying the tape

Fig. 14: Shielded coil

©2005 Carl W. Moreland all rights reserved Page 10

but not enough for shielding.Begin by cutting a length of tape

equal to the coil circumference, minusabout 1/4” (6-7mm). Duct tape is usu-ally wide, so cut lengthways to get apiece about 1/2” (12.5mm) wide. Nowcut notches every inch or so along bothedges of the tape, such that the notchesare about 1/3 - 1/2 the width of the tape,and are staggered with the other side.See Fig. 12 for details.

Remove the backing and, starting atone of the pigtails, lay the tape aroundthe outside of the coil, sticking the coilin the center of the tape (Fig. 13). Whenthe shield is placed all the way aroundthe coil, stop just short of the pigtails,such that the two ends of the shieldwrap do not touch. If the shield com-pletes a short all the way around thecoil, it will allow significant eddy cur-rents to flow, which will severelydegrade performance. Now begin fold-ing down the 1-inch tabs along one sideof the tape, and then fold the tabs on theother side, such that they overlapslightly.

One end of the coil shield will beconnected to the cable shield. Since alu-minum forms a thin oxide very quickly,soldering to it is not easy, and the sol-der joint can be unreliable. Instead,wrap a few turns of tinned wire tightlyaround the shield, and solder this wireto the cable shield. See Fig. 14.

The final challenge of coil-building isto mount it to something rigid. This isactually the biggest challenge, as thereis a limited selection of decent coilhousings available. Metal detector man-ufacturers use vacuum-formed plasticshells. The coil is placed in the shell,and liquid epoxy (or some other filler)added to secure it and provide rigidity.For homebrewers, contact informationis given at the end of the article for asource of coil shells.

Besides using an epoxy-filled plasticshell, there are some other alternatives.One of the simplest solutions is toepoxy the coil winding to a round pieceof plywood of roughly the same diame-ter. Although this is an easy solution, itis not especially attractive or durable,and it would not be advisable to sub-merge it in water. But it is sufficient forexperimentation.

Another solution is to simply buy a PI

coil from a detector manufacturer.Some PI detectors use plug-in coils, andhave accessory coils available. Othermodels have hard-wired coils, but areplacement coil should still be avail-able. In most cases, the value of thedamping resistor (R11) will have to betailored to the coil used. The best valueto use for R11 is the same value usedfor the damping resistor in the detectorthat the coil was made for, as mostfront-end designs are the same. Contactthe manufacturer for this information.

Once the coil construction is com-plete, solder the pigtails to a length ofcoaxial cable, with the coil shield con-nected to the cable shield. Make surethe cable is securely clamped to the coilin some manner, so that there is nostress on the solder connections. Do notuse any metal fittings in the construc-tion of the coil, as they will desensitizethe detector. Use plastic and nylon fit-tings instead. Connect the other end ofthe coax to the circuit at L1, with theshield soldered to the ground side andthe center conductor connected to Q3.

Adjustment & UsageWith the detector completely assem-

bled and packaged, make sure thevolume is turned down and applypower. SW2 should be closed. Youshould be able to adjust the Thresholdand vary the audio tone from deadsilence to a high pitch. Set the Thresh-old to get a very low frequencyputtering audio. Wave a metal targetclose to the coil and the audio fre-quency should increase. If the metal isheld absolutely still over the coil, theaudio should retune itself back to thethreshold tone.

With all the other pots set to the posi-tions prescribed in the Construction &Calibration section, you should be ableto detect a medium-sized coin severalinches from the coil. Increasing the Sen-sitivity (by decreasing R35) mightslightly improved depth, but the detec-tor quickly becomes unstable, especially

in noisy environments7. Increasing the

7. Such as inside a house, which isa poor environment for testing aPI detector. You might experi-ence significant instability dueto interference.

Pulse Width also improves depthslightly, at the expense of powerconsumption.

The most interesting controls are theSample Delay (R42) and Sample PulseWidth (R46). Varying these can changesensitivity, even to different types ofmetal. In general, a short delay (around15−20µs) gives the best sensitivity tolow-conductance metal like gold.

Once the detector is operating andstable, you can turn SW2 off and testthe non-autotrack mode. Now when ametal target is held absolutely still overthe coil, the audio should not retune tothe threshold tone. This is normallyused for pinpointing targets, not forgeneral searching. In fact, unless aCMOS opamp is used for IC8, it islikely that this mode will become unsta-ble after 15 seconds or so. Even JFET-input opamps have a small input biascurrent that will quickly charge C19.

This design is intended to be a learn-ing platform for how a PI detectorworks, so it has a lot of knobs to turn.Thus, it is quite easy to loose track ofhow adjustments interact, so when test-ing different settings it is best to keep agood record. As you find an optimalsetting for a certain knob, mark theposition on the panel.

Other OptionsThe article has primarily covered the

standard setup with the VCO audiooption. Other build options will bedescribed here. Some options are onlyavailable with the through-hole PCB.

In the standard setup, Q2 activelypulls up the gate of Q3 (with almost thefull battery voltage applied) to turn iton, while R9 passively turns Q3 off. Anadditional resistor, R8, is available todivide down the voltage applied to thegate (or base) of Q3. This is more use-ful if an NPN transistor is used for Q3(see Substitutions). The default is toshort R8.

In a PI detector, the turn-off of thecoil switch should be done as quickly aspossible. If passive pull-down is used,then different resistor values for R9 canbe tried. Because the signal applied toR9 is a low duty cycle pulse, even a lowvalue like 100Ω will not cause exces-sive average power dissipation.

However, an active device pulling

©2005 Carl W. Moreland all rights reserved Page 11

down the gate/base of Q3 will achievefaster turn-off than a resistor. Q2 offersthe experimenter the option of investi-gating active pulldown, with R7providing passive pull-up (see Fig. 15).The value for R7 is a bit of a guess, andmay need adjusting depending on thegate capacitance of Q3. Also, Q2 shouldhave base resistor R15 of about 10kΩ,which can be shorted for the normalpassive pull-down option.

This configuration inverts the pulseapplied to Q3, so the timing of IC5 willneed to be modified to produce aninverted (“positive”) pulse at TP1. Ihave not worked out the resistor values(R1-R4) for this. Furthermore, the pulsewill need to be delivered to pin 1 ofIC11 instead of pin 2, and this willrequire a minor PCB modification.

R22/C16 can provide for low-pass fil-tering, as shown in the completeschematic (Fig. 2), or high-pass filter-ing by transposing the two components.Normally, R22 is shorted and C16 omit-ted. If filtering is desired, componentvalues will be need to be determined forthe desired corner frequency.

IC8a can be configured as a differen-tial integrator (standard setup) or asingle-ended integrator. For single-ended, omit R25 and C18, and shortR27 (or use a 1kΩ resistor). R23 is notneeded, and can be replaced with ashort from IC7a, pin 1 to R22. There isalso no need for IC12 and its assort-ment of components unless the non-VCO audio option is being used, inwhich case only R47, R48, and Q9 canbe omitted.

For a quick comparison between sin-gle-ended and differential modes, try

building the standard setup, and place ashorting switch (e.g., toggle) acrossR27-C18. Then single-ended or differ-ential mode can be selected with a flipof the switch.

Autotrack may be permanently con-figured to auto mode by shorting SW2.It can also have a fixed setting byreplacing R34 with a fixed-value resis-tor. The resistor value can bedetermined by initially using a potenti-ometer to find the desired setting.

The non-VCO audio circuit, shown inFig. 16, produces a change in loudnessinstead of frequency. IC7c chops theoutput signal of IC8b, so the audio fre-quency is constant and equal to themaster clock frequency. Keep in mindthat if the sample frequency is varied(via R2), the audio frequency will fol-low. They cannot be set independentlyin this design.

As with the VCO option, R35(plus R36) converts the outputvoltage of IC8b to a current. Q6is a common-base transistorwhose emitter is biased to vir-tual ground, and IC7c shorts thebase to +5v, thereby choppingthe current. This produces a con-stant-frequency tone that variesin loudness in response to thevariation in R35’s current.

Q6 then directly drives Q11 inthe same SCR configuration thatwas shown in Fig. 9 with Q7/Q11. For the non-VCO option,R49, R50, and Q10 must beinstalled as shown in Fig. 2.

SubstitutionsComponent substitution options will

be described here.If a large coil is desired (1 meter

square) then R1-R4 should be modifiedto give a lower clock frequency, such as100 Hz. You will also need to run ahigher pulse width, and possibly heatsink Q3 and R11. R11 may need to be a1-watt resistor.

For IC1, a number of manufacturersmake 7660-compatible chips; most have“7660” as a portion of their part num-ber, but some may not. The 7660 isavailable with different voltage ratings,and for this design, you will need theone rated for at least 12 volts.

IC2-IC4 are 100mA regulators (TO92for the through-hole board). Any com-patible regulator may be substituted. A

Fig. 15: Active Pull-down

Fig. 16: Non-VCO Audio

©2005 Carl W. Moreland all rights reserved Page 12

low dropout voltage will result in longerusable battery life.

IC5 should be a CMOS version of thevenerable 555 timer. A TTL versionmight work, but might need a pull-upresistor (to ground) on pin 3.

Most “small-signal” devices are notcritical. About any signal diode may beused in place of the 1N4148’s (avoidrectifier-type diodes, i.e. 1N400x).Likewise, NPN & PNP transistors arefairly non-critical.

Transistor Q3 can be just about any700-series NMOS device, and can alsobe an NPN transistor like a 2N3055.Though I haven’t tried one, an insu-lated-gate BJT might also work.Generally, try to use a fast transistorwith lowest junction capacitances (espe-cially drain capacitance), while meetingthe current and breakdown voltage con-straints. When using a bipolar devicefor Q3, it is possible that applying thefull 12 volts across the base-emittercould damage the part. Therefore, useR8-R9 as a voltage divider —R8=330Ω results in a little less than 5volts and a Thevenin resistance of130Ω.

Some experimenters have had bettersuccess at running a lower gain in thepreamp. Try using a 2kΩ (or 2.2kΩ)resistor for R12.

D3 & D4 should be low-capacitancefast-recovery diodes. 1N4148’s arecommonly used here, but there arefaster diodes that might improve tran-sient settling. I’ve tried Schottky diodesand found they offered noimprovement.

IC6 can be just about any fast-recov-ery opamp. The NE5534 is popular, butthere are many newer opamps that arefaster and lower noise. Avoid current-feedback opamps.

A CD4016 can be used in place of theCD4066.

IC8 can be just about any FET-inputopamp. The TL072 and TL082 are pop-ular but, as in the case of IC6, manynewer opamps are available. Perfor-mance is not as critical as with IC6,either in speed or noise. The lower theinput bias current, the longer the no-motion mode will operate, so a trueCMOS-input opamp will be best.

You cannot substitute a TTL-compat-ible 74221 (such as a 74LS221) for the74HC221. You can substitute other

CMOS compatible versions, such as the74C221.

The listed component values for thepulse timing offer quite a bit of adjust-ment range. If a 1kΩ resistor is used forR42a, the minimum pulse delay can betaken down to 8µs. Reducing R45a to5kΩ results in a minimum secondarydelay of about 45µs. If R46=2kΩ andR46a=220Ω then the resulting pulsewidth is 3 - 20µs, probably a more prac-

tical range.

PC BoardsAlthough this project can be built on

perf board using point-to-point wiring,it is much easier to use a PC board, andthe layout is already done. Fig. 17shows the PCB layout; because it is sin-gle-sided, it is very easy to fabricate.However, a ready-made PCB is avail-able, see the Sources section at the end

Fig. 17: Through-hole PCB (1x)

Fig. 18: PCB Parts Placement

©2005 Carl W. Moreland all rights reserved Page 13

of the article. Fig. 18 shows the partsplacement for all the possible parts.Remember, though, that some parts areomitted, and some shorted, dependingon the option.

This project is an ideal candidate tobuild using surface-mount components.Fig. 19 shows both sides of a surface-mount (SMT) PC board (shown 2X theactual size), which is also available. It isroughly one-third the size of the normalPC board. Fig. 20 shows the parts place-ment, again for all the parts.

TroubleshootingHere are some common problems andpotential solutions.

Output voltage of the 7660 is not right.• Check the polarity of the diodes.• Check the polarity of the electrolytic

cap C3.• Try disconnecting C11.

No pulses or strange pulse widths com-ing out of the 74221’s.• Make sure they are CMOS versions

of the 74221 (C, HC, AC). TTL versions such as the 74LS221 will not work.

• Check polarities of D6 & D7.

Coil pulse is ringing badly• Oscilloscope probe capacitance is

loading the coil. Use a low-capacitance probe.

• Incorrect damping resistor value.• Excessive cable or shield capacitance.

Valid pulse on the coil, but no output onopamp IC6:• Misadjusted offset R18 can saturate

the output.• An incorrect (low) value for R16 can

saturate IC6.• Bad clamping diode D3/D4 can fry

the opamp.

Calibration of IC8a via R23 doesn’twork:• For this procedure, R44 & R48

should be installed, but Q8 & Q9 should NOT be installed. If Q8 & Q9 have been installed already, simply short R44 & R48.

• R5 (or R15) should not be installed. If they are installed and Q3 is being pulsed, then the coil should be

disconnected. There will be a slight (but acceptable) error in calibration.

• Is R22 installed (low-pass filter) or shorted (no filter)?

• If R22/C16 was installed as a high-pass filter, temporarily short C16.

Audio is not working or is erratic:• Make sure TP9 is close to zero volts

for no target.• Try reducing sensitivity via R35.• If testing indoors, try going outside,

well away from noise sources.

Fig. 19: SMT PCB, Top & Bottom (2x)

©2005 Carl W. Moreland all rights reserved Page 14

Detection depth is poor:• If testing indoors, try going outside,

well away from noise sources.• Make sure autotrack speed (R34) is

not too fast.• Try reducing the pulse delay (R42).• Try increasing pulse width (R3).The last page of this article shows vari-ous waveforms as probed with anoscilloscope, including the relationshipbetween waveforms, and how they varywith potentiometer settings.

SourcesEither a through-hole PC board, or aSMT PC board, (etched, drilled, nickel-plated, & silk-screened) is availablefrom:

GeotechP.O. Box 184Oak Ridge, NC 27310

Cost is $10 (US/Canada/Mexico) andincludes S&H. Cost to other localesworldwide is $12, including S&H.

Most through-hole components can bepurchased from the local Radio Shack(some must be special ordered). Thefollowing mail-order companies havean extensive selection of both through-hole and SMT components:

Digi-Key: http://www.digikey.com

Futurlec: http://www.futurlec.com

Jameco: http://www.jameco.com

Mouser: http://www.mouser.com

Coil shells are available in several sizesfrom:

Hays ElectronicsP.O. Box 26848Prescott Valley, AZ 86312http://www.hayselectronics.com

Further information is available on theGeotech web site:

http://www.thunting.com/geotech

• Latest version of this article• Technical help forums• More info on building coils• Other detector projects

Fig. 20: SMT Parts Placement

©2005 Carl W. Moreland all rights reserved Page 15

Fig. 21: Output of IC5 (TP1) — top trace is low freq (~900 Hz), bottom

trace is high freq (~2kHz).

Fig. 23: Same as Fig. 22, but now 50us pulse width results in ~320v

flyback peak.

Fig. 24: Output of the preamp (TP4) in relation to the flyback

signal (TP2).

Fig. 25: Same as Fig. 24, but pulse width is now 50us. Note that preamp

decay is extended.

Fig. 26: Preamp output (TP4) and main sampling pulse (TP6) with

~15µs delay and narrow pulse width.

Fig. 27: Same as Fig. 26, but now the sample pulse is delayed further,

and pulse width increased.

Fig. 28: Output of the preamp (TP4), along with the main (TP6) & secondary (TP7) sampling pulses.

Fig. 29: Output of the preamp(TP4), and output of the main sampling

switch (IC7 pin2).

Fig. 30: Same as Fig. 29, sampling further out.

Fig. 22: Output of IC5 (TP1) and coil flyback signal (TP2). 10us pulse width results in ~120v flyback peak.