CRTS 02 UK.pdf

-

Upload

hepcomotion -

Category

Documents

-

view

239 -

download

0

Transcript of CRTS 02 UK.pdf

-

8/7/2019 CRTS 02 UK.pdf

1/12

CRTS

Commercial Ring Slides

And Track SystemThis catalogue is a supplement to the Ring Slides and Track

System product and is intended for customers who require a

lower precision, lower cost solution. It should be read in

conjunction with Hepco's Precision Ring Slides and Track

System Catalogue as illustrated.

Customers should please take note of the following:

1 Commercial Ring Slides and Tracks are hardened but not

ground. They are suitable for less demanding applications

which do not require the degree of smoothness, quietness and integrity of shape

associated with the Precision System. Running quality may vary between straight

slides and curved segments in Track Systems due to the wider tolerances to which

these components are made. The above characteristics are not detrimental in

applications for which the Commercial System is intended.

2 The bearing assemblies, carriages and lubricators

which form part of the Commercial System are not

detailed in this supplement. These components

are identical* to those for the Precision

System, and customers should refer to that

catalogue for details. * Fixed centre

carriages however, have different hole centres

for the bearings and therefore have different

part numbers (see ordering example

page 7). Customers wishing to make

their own carriages should refer to

Hepco for revised dimensions.

3 Load capacity and life

expectancy for Commercial

Rings is the same as for the

precision versions, and may

be taken from the Precision

System catalogue.

HepcoMotion

-

8/7/2019 CRTS 02 UK.pdf

2/12

Data & Dimensions

2

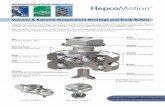

Assembled Commercial Ring System

The Hepco Ring system may be used in either complete ring form or as segments. The carriage may be used to run on the ring

track (see below) or constructed in order to embrace the complete ring where the bearing assemblies may be placed internally

and / or externally. In all cases either the ring or the carriage may be the moving component. The specially developed Hepco

'R' series bearing assemblies have sufficient adjustment to enable complete removal of the ring slide from the carriage in most

cases.

Notes:1. Two lengths of stud are availab le for each size beari ng assembly. Choose according to your required carriage thickness.

2. Of fset holes in carr iage for eccentric bear ing assemblies, necessitate adjustment rotation in direction shown.

3. Standard p inions are available from most manufacturers to suit gear drive option slide rings.

4. Exact theoretical values have been given for 'Q ' ' R' and 'S'. Positional accuracy of dimension 'S' wi ll determine the axis of the ring. Positional accuracy for

dimensions 'Q ' and ' R' are not normally cri tical. Holes for bear ing assemblies should be reamed to tolerance as per dimension ' R' on page 17 of the Precision

System catalogue.

5. Lubricators (see Precision Systems Catalogue) greatly enhance system life. It is recommended to specify at least 10% of carr iages (minimum 1) in a system

with lubricators.

6. Fixed centre carr iages supplied wi th Commercial Ring or Track systems wi ll not necessarily be suitable for use on precision systems. Customers should not

attempt to make these themselves without reference to Hepco.

G15.9

15.9

15.9

26.5

26.5

51

51

H2.7

2.7

2.7

2.9

2.9

4

4

I9.8

9.8

9.8

13.8

13.8

17.8

17.8

J19

19

19

22

22

30

30

M ax13

13

13

14

14

20

20

Min2.5

2.5

2.5

5.5

5.5

6

6

KRing Slide

Ref No.CR25 159

CR25 255

CR25 351

CR44 468

CR44 612

CR76 799

CR76 1033

A159

255

351

468

612

799

1033

~

B25

25

25

44

44

76

76

C19.3

19.3

19.3

24.2

24.2

38.7

38.7

D73.1

72.2

72.2

106.9

106.9

173.8

173.8

E29.3

29.3

29.3

38.2

38.2

56.7

56.7

F22.8

21.9

21.9

38.6

38.6

65.4

65.4

B

=

E

=

CM L

G

Ring slide or segmentLubricator (optional)

Hepco fixed centre carriage (see note 6)

Customer constructedcarriage

See note 1

I

K min

H

Kmax

JSee note 1

Eccentricbearing assembly

P

O

N

D F

See note 2

Concentricbearing assembly

-

8/7/2019 CRTS 02 UK.pdf

3/12

Data & Dimensions

3

Assembled Commercial Ring System

When using rings as shown below it is recommended that two concentric bearing assemblies should be placed 120apart in

order to provide a datum reference. The other bearing assemblies used should be the eccentric type. All eccentrics may be

used where positional adjustment of the ring is required. One or more lubricators may be fitted at convenient positions to take

advantage of the increased load/ life afforded by lubrication.

T

Eccentric blind holefixing bearing assembly

90O

S

S

Concentric bearingassembly

A

Eccentric bearing assembly

120O

90O

V

WU

Lubricator (optional)

Concentric bearingassembly

See note 3

X

R

Q

CR25 159

CR25 225

CR25 351

CR44 468

CR44 612

CR76 799

CR76 1033

L12.7

12.7

12.7

15.9

15.9

24.4

24.4

M10.3

10.3

10.3

12.7

12.7

19.7

19.7

P80

80

80

115

115

185

185

Q

1.4

1.4

1.4

1.8

1.8

3.2

3.2

R24.9

24.9

24.9

38.1

38.1

63.0

63.0

S23.5

23.5

23.5

36.4

36.4

59.8

59.8

T50

50

50

60

60

89.5

89.5

U

23

23

23

35

35

57.5

57.5

N

95

100

105

145

150

190

210

0

43

42

42

61

60

96

96

Drilling positions (see note 4)

V16

16

16

22

22

33

33

W18

18

18

25

25

38

38

X

39.3

39.3

39.3

57.6

57.6

94.4

94.4

Ring Slide

Ref No.

Ordering details:Simply list the components required and if relevant, bracket those you wish to be factory assembled.

Example: Assembled1 x CR25-159-R180 180

oRing segment

1 x CFCP-25-159-L Commercial fixed centre carriage with lubricators (see notes 5 & 6){

-

8/7/2019 CRTS 02 UK.pdf

4/12

Data & Dimensions

4

Commercial Ring Slides and Segments

Hepco CR series slide rings are manufactured from high quality steel, zone hardened on the V edges with datum register faces

provided both internally and externally for ease of location. Gear drive options are available with teeth machined into either

the internal or external register face. The number of teeth on the standard external option is divisible by 12 in order to provide

maximum choice of pinion size for exact ratio requirements. Customers may also choose the tapped hole option 'N' which

enables the slide ring to be bolted from below.

V (cutting allowance)U

TO

TO

SO

RO

TO

TO

SO

XX

P (pitch circle )

M

J

I

L ( x depth)

N

KH

(pitch circle )

Q

Tapped hole option NOchamfer x 45O

(internal & external)

70O

G

F

sharp

register faceB

sharp

D1

hole centresA

register faceC

sharpD

E~

Slide ring section X - X Standard gear driveoption P (external)

Special gear driveoption Q (internal)

-

8/7/2019 CRTS 02 UK.pdf

5/12

Data & Dimensions

5

Commercial Ring Slides and Segments

Hepco CR series ring segments are cut from complete 360o

slide rings and held in stock in nominal 90o

and 180o

sections.

Any length segment can to be cut to customer's special order and additional holes drilled as required. Although suitable for

most applications, some out of roundness and flatness may be experienced with slide rings and segments in their free

unmounted condition. This may be substantially overcome by installing against a register and bolting to a flat surface.

Notes:1. Standard r ing segments wi ll be slightly less than 90

oand 180

obecause of the cutting allowance. Full 90

oand 180

osegments can be supplied to customer's

special order.

Special comm ercial rings up to 1.8m in outside diam eter are now availa ble. Please see pa ge 10 .

F

26.6

26.6

26.6

45.6

45.6

77.6

77.6

G

15.9

15.9

15.9

26.5

26.5

51

51

H

12.7

12.7

12.7

15.9

15.9

24.4

24.4

I

10.3

10.3

10.3

12.7

12.7

19.7

19.7

J

4.7

4.7

4.7

6.2

6.2

9.2

9.2

L

9 x 6.2

9 x 6.2

9 x 6.2

11 x 7.5

11 x 7.5

20 x 13.7

20 x 13.7

M

5.5

5.5

5.5

6.8

6.8

14

14

N

M8 x 1.25

M8 x 1.25

M8 x 1.25

M8 x 1.25

M8 x 1.25

M16 x 2

M16 x 2

M5

M5

M5

M6

M6

M12

M12

SOCKET CAPHEAD SCREW

ISO4762

Part

Number

CR25 159

CR25 255

CR25 351

CR44 468

CR44 612

CR76 799

CR76 1033

A

159

255

351

468

612

799

1033

0.13

B

143.1

239.1

335.1

441.5

585.5

748

982

0.13

C

174.9

270.9

366.9

494.5

638.5

850

1084

D

185.6

281.6

377.6

513.6

657.6

876.6

1110.6

D1

132.4

228.4

324.4

422.4

566.4

721.4

955.4

~

E

25

25

25

44

44

76

76

CR25-159

CR25-255

CR25-351

CR44-468

CR44-612

CR76-799

CR76-1033

O

1.0

1.0

1.0

1.0

1.0

1.5

1.5

P

172.8

268.8

364.8

492

636

846

1080

Internal GearExternal Gear

MOD

0.8

0.8

0.8

1.0

1.0

1.5

1.5

216

336

456

492

636

564

720

Q145.6

241.6

337.6

444

588

751.5

985.5

MO D

0.8

0.8

0.8

1.0

1.0

1.5

1.5

182

302

422

444

588

501

657

90

90

90

90

90

90

90

R180

180

180

180

180

180

180

360

360

360

360

360

360

360

8

8

12

12

16

16

20

S

45

45

30

30

22.5

22.5

18

O U

29.4

47.8

44.4

58.6

57.7

75.9

78.8

V

1

1

1

2

2

2

2

0.77

1.2

1.65

5.1

6.7

25

32

T

22.5

22.5

15

15

11.25

11.25

9

ONO OF TEETH(R=360) NO OF TEETH(R=360)

NUMBEROF HOLES(R=360)

HOLES WI THIN 0.2OF TRUE POSITION MASS-

kg(R=360)

STOCK SEGMEN TS(SEE NOTE 1)

O

Part

Number

Ordering details:

Example:

N - Tapped hole option

Q - Internal gear drive option

P - External gear drive option

90o

segment

180o

segment

Full 360o

ring slide

Part Number

CR25 -35 1 (R36 0) (R180 ) (R90 ) (P) (Q) (N)

-

8/7/2019 CRTS 02 UK.pdf

6/12

Data & Dimensions

6

See orderingdetails

Carriage play atjoin (see note 1)

Fixed centre carriage

(see note 3)Optional jacking screwalignment facility (see note 4)

Adjustment key

Jacking screwsfor alignment

Commercial Track Systems

Hepco track systems provide a unique method of achieving an almost limitless variation of controlled routing. Any number of

carriages can be accommodated, either the fixed centre economy type which is suitable for unidirectional bends of the same

radius or the bogie type which enables 'S' bends of varying radii to be negotiated and provides a larger platform for mounting

purposes. Various drive possibilities exist some of which are illustrated in the applications section on pages 6-9 of the Precision

System Catalogue. Please note that commercial track systems are manufactured to commercial tolerances as complete systemsand that spare parts ordered subsequently cannot be guaranteed to fit. Customers requiring identical spare part replacement

and optimum smoothness of transition across joints should consider the Hepco precision system.

Installation Procedure:

Hepco commercial track systems are supplied in separate sections ready for installation marked with an individual sequence

number. Track system slides should be assembled and clamped in position as a complete circuit prior to dri lling through all the

holes and bolting down the straight sides. Final adjustment of the joins should be carried out using the keyway alignment facility

if provided, ensuring both jacking screws are subsequently locked and all curved segment fixing screws are tightened. A final

stoning of the 'V' faces is necessary to blend the joints.

-

8/7/2019 CRTS 02 UK.pdf

7/12

Example:

1 x (1) TNM-44-P3-B1020 Track system straight slide (see note 4)(2) TCR-44-468-R180/ C Clockwise curved segment (see note 4)

(3) TNM-44-P3-B1020 Track system straight slide (see note 4)

(4) TCR-44-468-R180/ C Clockwise curved segment (see note 4)

4 x CFCP 44-468 Fixed centre carriages without lubricators

2 x CFCP 44-468L Fixed centre carriages with lubricators

Data & Dimensions

7

Track system curvedsegment (see note 2)

Track system straight slide

See ordering details

Bogie carriage

Commercial Track Systems

Notes:1. W ith the fixed centre carriage an amount of play is experienced as each pair of opposing bearing assemblies traverses the join between straight and curve.

This is not normally detrimental in most applications.

2. Due to the cutting procedure, Hepco 90O and 180O curved segments are supplied slightly shorter than their theoretical length (see page 9). This is not

detrimental to the smoothness of travel across the join, provided installation has been carried out according to procedure (see page 6).

3. Bearing assembly hole positions in the commercial f ixed centre carriages differ f rom those of the Precision System. Lubricators are optional but should be

specified for at least 10 % of carriages on a system. Due to these differences, part numbers vary slightly from those of the Precision System (see ordering

example below)

4. The optional jacking screw alignment facility greatly assists installation and setting. This may be specified by quoting the adjustment key reference for the

straight slides (page 8) and the alignment facilitiy reference for the curved slides (page 9).

Ordering details:Simply list the curved segment and straight slide part numbers in sequential order in clockwise direction (see arrows in

illustrations), starting at any point according to preference. Viewing plan elevation as per illustrations and travelling

clockwise round the circuit curved segments should be designated suffix 'C' for clockwise bend and suffix 'A' for

anticlockwise bend. The final item should indicate the quantity and part number of the carriages required.

-

8/7/2019 CRTS 02 UK.pdf

8/12

-

8/7/2019 CRTS 02 UK.pdf

9/12

Data & Dimensions

9

G

5

5

56

6

7

7

H

6.5

6.5

6.57.5

7.5

11.5

11.5

I

3

3

34

4

6

6

J

M4 x 4

M4 x 4

M4 x 4M5 x 6

M5 x 6

M8 x 16

M8 x 16

RO

90

90

9090

90

90

90

180

180

180180

180

180

180

Part

Number

TCR25 159

TCR25 255

TCR25 351TCR44 468

TCR44 612

TCR76 799

TCR76 1033

A

159

255

351468

612

799

1033

~

B

25

25

2544

44

76

76

C

7

7

78

8

10

10

D

18

20

2025

25

30

30

0. 2

E

1.5

1.5

1.52.5

2.5

2.5

2.5

F

7

7

710

10

18

18

G*

H*

J* (socket headset screws ISO4026 supplied)

B

I*

C*

F*

Centre line of cut

RO

A

D E

Additional fixing hole(standard size)

Commercial Track System Curved Slides

Hepco commercial track system curved segments are modified from stock 90oand 180

oslide ring segments. The segment ends

are ground square to a specified dimension relative to the true shape of the segment and an optional clearance keyway and

tapped hole facility may be incorporated in each end to provide an easy method of alignment when assembled together with

the optional mating key of the track system straight slide. An additional fixing hole is provided at each end of the segment to

give extra support at the join position. All track system curved segments are marked with a sequence number to aid assembly.

Ordering details:

Example:

Alignment facility required

Tapped hole option N180

osegment

90o

segment

Part number

TCR4 4-612 (R90 ) (R180 ) (N ) (A)

For all other details and dimensions see pages 4 and 5

* Optional alignment facility

-

8/7/2019 CRTS 02 UK.pdf

10/12

Special Commercial Rings, Segments & Track Systems

10

Commercial rings are now available up to 1.8m outside diameter. Although customers are recommended to choose standard

catalogue components for reasons of economy and off the shelf availability, Hepco's specials department welcomes enquiries

for non-standard commercial rings and track systems. Our team of highly skilled technicians working with the most up to date

equipment is able to cope with complex special requirements producing a cost effective solution with surprisingly short delivery

times.

The V profile can often be incorporated with the customer's own design, resulting in a single multipurpose component.

Hepco's highly sophisticated heat treatment techniques can provide a choice between zone hardening and through

hardening depending on size and shape.

Rings of non-standard section and diameter can be produced, often from material held in stock. Stainless steel rings and track

systems can be manufactured depending upon size and degree of hardness required. Alternatively, various plating processes

may provide adequate corrosion resistance. Hepco application engineers are always on hand to provide advice and

recommendations. Please consult us for your special requirements, preferably at an early stage of the design process.

A small selection of special ring components is shown below.

Rings can be manufactured with single V profile only either internal, or external.

Gear cutting can be carried out as shown with full face available for gear cutting opposite the V.

Hepco P3 grade flat slides can be rolled into special ring segments

of various lengths and diameters (see separate Hepco GV3

catalogue for slide section details).

Ring disc. V may be internal, external or both.

Rings can be made with the Hepco Heavy Duty Slide profile. These are compatible with a number of

bearing assemblies with a load capacity up to 2.0 tonnes per bearing. Please see Hepco Heavy Duty Slide System catalogue.

-

8/7/2019 CRTS 02 UK.pdf

11/12

CAD and Catalogue Request Form

11

Please send me the:

Hepco Slide Systems CAD Library set, covering GV3, HDS, PRT, HPS, SL2, DLS, MCS

and Dual Vee products in both .DW G and .DXF formats.*

GV3 Linear Guidance and Transmission System*

HDS Heavy Duty Slide System Catalogue*

PRT Ring Slides and Track System Catalogue*

HPS Powerslide-2 Guided Rodless Cylinder Catalogue*

SL2 Stainless Steel Based Slide System Catalogue*

DLS Linear Transmission and Positioning System Catalogue*

LoPro Aluminium Based Slide System Catalogue*

BSP Ballscrew Premier Catalogue*

DTS Driven Track System Catalogue*

Dual Vee Single Edge Slide System Catalogue*

MCS Aluminium Frame and Machine Construction System Catalogue*

SH Shock Absorbers Catalogue*

* See back cover for product illustrations

Name

Company

Address

Postcode

Tel

Fax

E-mail

Please photocopy this form and fax it to Hepco on

01884 243500

-

8/7/2019 CRTS 02 UK.pdf

12/12

GV3

Linear Guidance andTransmission System

HDS

Heavy Duty Slide System

HPSPowerslide-2 Guided

Rodless Cylinder

DLSLinear Transmission and

Positioning System

UtiliTrakLightweight U Channel

Guideway

BSPBallscrew Premier

DTSDriven Track System

M CSAluminium Frame and

Machine Construction System

Single Edge Slide System

Vee Slide Linear

Guidance Systems

PDU2Profile Driven Unit

Lower Moor Business Park, Tiverton Way, Tiverton, Devon, England EX16 6TG

Tel: +44 (0)1884 257000 Fax: +44 (0)1884 243500

E-mail: [email protected]

HepcoMotion

HepcoMotion

For further information on HepcoMotionproducts

please request our leaflet FPL

CATALOGUE No. CRTS 02 UK 2005 Hepco Slide Systems Ltd.

Reproduction in whole or part without prior authorisation from Hepco is prohibited. Although every effort has been made to ensure the accuracy of the information in thiscatalogue, Hepco cannot accept liability for any omissions or errors. Hepco reserves the right to make alterations to the product resulting from technical developments.

Many Hepco products are protected by: Patents, Copyright, Design Right or Registered Design. Infringement is strictly prohibited and may be challenged in law.TheCustomers attention is drawn to the following clause in Hepcos conditions of sale:

It shall be the Customers sole responsibility to ensure that goods supplied by Hepco will be suitable or fit for any particular application or purpose of the Customer, whetheror not such application or purpose is known to Hepco. The Customer will be solely responsible for any errors in, or omissions from, any specifications or information theCustomer provides Hepco will not be obliged to verify whether any such specifications or information are correct or sufficient for any application or purpose

LoProAluminium Based

Slide System

Product Range

HDLSHeavy Duty Driven

Linear System

SL2

Stainless Steel BasedSlide System

PRT

Ring Slides andTrack System

HepcoMotion Exclusive European partners and distributors for Bishop-Wisecarver since 1984.

Product Range

HTSTelescopic Ball

Bearing Slides

LBG

Linear Ball Guides

PSD120Profile Screw Driven Unit