CR_Injection System Basics Disney Dream

Transcript of CR_Injection System Basics Disney Dream

2010/05/06© MAN Diesel SE 2010/05/06© MAN Diesel Common Rail - Basic Training <1 >

Robert MeierEESI (Injection Systems)R&D Engineering Medium Speed

MAN Diesel & TurboCommon Rail – Basic Training

2010/05/06© MAN Diesel SE <19 >

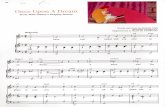

Accumulator

Injection valveHigh pressure pump

High pressure pipes

Camshaft (3 loop cam)None return valve

Valve block

CR-BasicsSystem overview 48/60 CR

48/60 CR

2010/05/06© MAN Diesel SE

CR-BasicsHydraulic layout (simplified)

<20 >

referencewheel

5 bar

10 bar

Valve block

AccumulatorUnit

Injection valve

Valve group

High pressure pump

None return valve

Pickup

Pressure sensor

Pressure limiting valve

(high pressure)

Scavengingvalve

Accumulator

Pressure limiting valve

(low pressure)

2010/05/06© MAN Diesel SE

CR-BasicsPressure generation / control / release

<21 >

Low pressure 10 bar

Low pressure 5 bar

High pressure max. 1600 bar

Holding pressure 100 bar

referencewheel

5 bar

10 bar

2010/05/06© MAN Diesel SE

CR-BasicsPressure generation / control / release

<22 >

2010/05/06© MAN Diesel SE

CR-BasicsInjection process

<23 >

referencewheel

5 bar

10 bar

Low pressure 10 bar

Low pressure 5 bar

High pressure max. 1600 bar

Holding pressure 100 bar

2010/05/06© MAN Diesel SE

CR-BasicsInjection process

<24 >

2010/05/06© MAN Diesel SE

CR-BasicsScavenging process

<26 >

referencewheel

5 bar

10 bar

Low pressure 10 bar

Low pressure 5 bar

High pressure max. 1600 bar

Holding pressure 100 bar

2010/05/06© MAN Diesel SE < 30 >

Main ComponentsHigh Pressure Pump 48/40 CR

High pressure pump48/60 CR

Feature:

quantity controlled bythrottle valve

Note:

without electrical signal thethrottle valveis fully opened

Throttle valve

Valve solenoid

Delivery valve

Valve carrier

Mono block cylinder

Plunger

2010/05/06© MAN Diesel SE <32 >

Main componentsAccumulator

Valve groupControl valve carrier

Flow limiterTubular shell Pressure pipe

To HP pump,next accumulator,

valve block

To Injection valve

To non return valve

2010/05/06© MAN Diesel SE <33 >

Main componentsAccumulator

Flow limiterFunctionality

avoids permanent injection

Note:

after closing one time the flow limiter keeps closed until the next release of the rail pressure

Piston movement at each injection

2010/05/06© MAN Diesel SE <34 >

Main componentsAccumulator

Valve groupFunctionality

controls the injection

Note:

the 3/2 WV (main valve) is controlled by a 2/2 WV

2/2-wayvalve

3/2-wayvalve

Valvesolenoid

2010/05/06© MAN Diesel SE <35 >

Main componentsAccumulator – Function valve group

Begin of current feed – opening of 2/2 way-valve

pRailComponent movement

Spring force

Hydraulic forceFuel flow

2/2 way-valve opened

Pressure loss above the piston of the 3/2 way-valve; due to narrow feed bore chamber can not be refilled

2010/05/06© MAN Diesel SE <36 >

Main componentsAccumulator – Function valve group

Opening of 3/2 way-valve piston

pRail

Piston of the 3/2 way-valve moving up due to hydraulic force

Canal to cut off system blocked

Fuel flow to injection nozzle

To cut off system

Component movement

Spring force

Hydraulic forceFuel flow

2010/05/06© MAN Diesel SE <37 >

Main componentsAccumulator – Function valve group

Opening of the injection nozzle

pRailpRail

Injection nozzle needle opens when opening pressure reached

Component movement

Spring force

Hydraulic forceFuel flow

2010/05/06© MAN Diesel SE <38 >

Main componentsAccumulator – Function valve group

End of current feed – closing of 2/2 way-valve

pRailpRailpRail

Ball of 2/2 way-valve closes

Component movement

Spring force

Hydraulic forceFuel flow

2010/05/06© MAN Diesel SE <39 >

Main componentsAccumulator – Function valve group

pRail

Due to increasing pressure above the 3/2 way-valve’s piston the piston moves down

Canal from rail to injection nozzle is closed

Closing of 3/2 way-valve piston

Component movement

Spring force

Hydraulic forceFuel flow

2010/05/06© MAN Diesel SE <40 >

Main componentsAccumulator – Function valve group

Closing of injection nozzle

pRail

To cut off system

Pressure in injection pipe drops down

Injection nozzle needle closes, end of injection

Amount of fuel not injected leaves the valve group to the cut off system

Component movement

Spring force

Hydraulic forceFuel flow

2010/05/06© MAN Diesel SE

Main componentsNone return valve

<42 >

None return valve with volume adapterFunctionality

pressure discharge of the injection pipe

holding pressure to avoid cavitation

Volume fordamping

2010/05/06© MAN Diesel SE

Main componentsValve block

<44 >

Valve block

Valve blockFunctionality

Scavenging valve

Pressure limiting valve

Rail pressure sensors

2010/05/06© MAN Diesel SE

Main componentsValve block

<45 >

Scavenging valve Functionality

Scavenging

High pressure release(Emergency stop)

Carries the pressure sensors(Two redundant sensors)

Fuel return line

Rail pressure

2010/05/06© MAN Diesel SE

Main componentsValve block

<46 >

Pressure limiting valveFunctionality

Prevents the system fromoverpressure

Fuel return line Rail pressure

Mechanical pressure controlfor emergency operation mode

2010/05/06© MAN Diesel SE <55 >

Leakage

Note:All leakage cross sections of the high pressure pipes are connected to the leakage cross sections of the accumulators.

Leakage detection systemConcept

2010/05/06© MAN Diesel SE <57 >

Capacitive sensorFunctionality:

Locating of the affectedaccumulator

Leakage fitting

Accumulator

Leakage pipe

Capacitive sensor

Leakage detection systemConcept

2010/05/06© MAN Diesel SE <58 >

Detection screwsFunctionality:

Locating of the affected high pressure pipe

Leakage detection systemConcept

© MAN Diesel CR Importance of cleanness PrimeServ Academy 07.10.2009

Never remove screwed unions from the fuel high- pressure side of the common-rail system while the engine is running or immediately after stop

< 2 >

Warning notes

While the engine is running, the lines are constantly under a fuel pressure of up to 1600 bar

© MAN Diesel CR Importance of cleanness PrimeServ Academy 07.10.2009

After switching off the engine wait for at least two minutes for the pressure to drop.Press emergency stop to ensure that the scavenging valve

(flushing valve) is activated

< 4 >

Warning notes

Make sure that compressedair supply valve ( 7172) for the emergency stop remains open.

© MAN Diesel CR Importance of cleanness PrimeServ Academy 07.10.2009

The workplace must be absolutely clean.

Thoroughly clean the components you disassemble

Make sure your work clothes are clean before commencing work.

Adjacent workplaces must not cause contamination, raise dust etc. (eg grinding ).

Follow job and assembly instructions (Working cards)

Removed parts are to be handled as genuine spare parts, ie they are to be packed separately and the connections are to be closed up.

< 5 >

Cleanliness in CR injection systems

© MAN Diesel CR Importance of cleanness PrimeServ Academy 07.10.2009 < 6 >

Protective sleeve for hi pressure pipeCR - medium speed

When disassembling, immediately close up all connections with caps.

© MAN Diesel CR Importance of cleanness PrimeServ Academy 07.10.2009 < 7 >

Valve group CR-medium speed

All openingsmust beprotected

© MAN Diesel CR Importance of cleanness PrimeServ Academy 07.10.2009

Use only lint-free cleansing tissue

< 9 >

Cleansing tissue

© MAN Diesel CR Importance of cleanness PrimeServ Academy 07.10.2009 < 10 >

Should be avoided

Cleanliness in CR injection systems

© MAN Diesel CR Importance of cleanness PrimeServ Academy 07.10.2009 < 11 >

Protective sleeve - InjectorCR - medium speed

To avoid contamination with particles and mechanical damage of the sealing surfaces

© MAN Diesel CR Importance of cleanness PrimeServ Academy 07.10.2009 < 12 >

Common Rail components Sizes

© MAN Diesel CR Importance of cleanness PrimeServ Academy 07.10.2009 < 14 >

Particle on nozzle needle

Field findings

© MAN Diesel CR Importance of cleanness PrimeServ Academy 07.10.2009 < 15 >

Field findings

Contaminant at the needle seat

2010/05/06© MAN Diesel SE <66 >

12V 48/60 CRDiesel-electric drive

propulsion system

Thank you for your attention!

Common Rail System