Cogeneration in Europe

Transcript of Cogeneration in Europe

Issue 10Cogeneration in Europe

2 - Wärtsilä NSD

Wärtsilä NSD Energy News is published fourtimes a year for business friends and employeesof Wärtsilä NSD.

Editorial Board: Stefan Fant, Jussi Heikkinen,Clas-Eirik Strand, Anci SandåsEditor: Anci SandåsEnglish Editing: Andrew GardinerLayout: Bock’s Office

Please address correspondence to:Wärtsilä NSD, Anci SandåsP.O.Box 252, 65101 Vaasa, Finlande-mail: [email protected]

ISSN 1456-3274

Information in this publication is subject tochange without notice. © Wärtsilä NSDCorporation.Printed in June 2000.

All rights reserved.

Also in this issue

CHP for the BSc’s! . . . . . . . . . . . . . . . 16

Improved performance ofthe Wärtsilä 28SG. . . . . . . . . . . . . . . . 18

Energy Partner proves its worthin Denmark . . . . . . . . . . . . . . . . . . . . . 20

Top quality in Colombia. . . . . . . . . . . . 22

Reciprocating compressors in natural gasunderground storages in Germany . . . 24

Owners split Cummins Wärtsiläoperations . . . . . . . . . . . . . . . . . . . . . 27

Cogen takes off at Detroit airport . . . . . 28

Diesel plant orders highlight Indiansuccess . . . . . . . . . . . . . . . . . . . . . . . 28

96 MW Power Master to El Salvador . . 29

Appointments . . . . . . . . . . . . . . . . . . . 29

Wärtsilä NSD worldwide . . . . . . . . . . . 30

Product Programme . . . . . . . . . . . . . . 32

In this issue

The decade of cogeneration in Europe

Countries throughout Europe are currently exploring the advantages offered bycogeneration technology as the EU gears up to promote its more widespread use. . 4

Modigen Ltd – trading electricity for Wärtsilä NSD

From saving Metra Corporation’s energy costs Modigen Ltd, a Wärtsilä NSD subsidiary,now offers electricity trading services to industrial companies and hotels. . . . . . . 10

Energia-Tietola – Pure Energy for paper industry town

Energia-Tietola is a new Pure Energy cogeneration plant recently supplied to theelectricity and district heating utility of Valkeakoski, one of Finland’s main pulp andpaper industry centres. A key advantage is independence from outside electricitysuppliers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Meeting Turkey’s power needs

Turkey needs some 3000 MW of new power generation annually for the next tenyears to meet burgeoning demand. Innovative new ideas to help meet immediateneeds include the “autoproducer” and “mobile power plant” concepts. . . . . . 14

Energy News - 3

Dear Reader,The first International Cogeneration Conference on 1-2 February in Washington DCwas a very positive experience. Organized by International Cogeneration Alliance ICAit attracted over 200 delegates from more than 20 countries. The voice of thecogeneration community was loud and clear – the future of power and heatgeneration lies in cogeneration.

Many OECD countries have set a target of doubling the share of cogeneration inelectricity production from about 10 % to 20 % by 2010. This means that about 200

GW of new cogeneration capacity should be builtby then and annual demand for new cogenerationplants will be 20 GWe. Hence, more than 10 billiondollars will be invested in cogeneration facilitiesevery year.

These aggressive policies are the result of thecarbon emission targets set in the Kyoto protocols.The OECD countries have promised to reducegreenhouse gas emissions by 8–12 %. About half ofthe reduction could be achieved by doubling theshare of cogeneration in electricity production.

To make a fast start towards this goal, severalcountries have taken various initiatives to promotecogeneration. Development started in the USA withthe PURPA legislation in 1978, which givescogenerators the right to sell power at a fair rate tothe grid. The Scandinavian countries were the firstto introduce the CO2 taxes at the beginning of 1990.

This will now be followed by Germany and the UK, which will introduce newecotax systems or CCL levies on traditional and less effective means of generation. Thenew taxes will make cogeneration the preferred and also the most competitive form ofgeneration.

This issue of Energy News presents some of the benefits and experience ofcogeneration from the user’s point of view. It also shows the benefits of localizedpower production in the new liberalized electricity markets, where transmission tariffsmake local plants the most economical option. So please, join the cogenerationcommunity. It represents the future of power and heat generation for the wholeworld.

Stefan FantGroup Vice PresidentPower Plants

The decade ofcogeneration in EuropeCogeneration is already an established concept in theNordic countries and, increasingly, in other parts ofEurope. The EU as a whole is now examining theconcept in detail with countries across the regionpassing new legislation that will radically change thestructure of local power and heat markets. Cogenerationoffers undisputed advantages. But it remains to be seenwhether all EU member states grasp them fully.

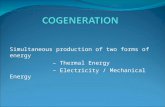

Cogeneration, also called combined heat and power(CHP), is based on the simultaneous production anduse of both electricity and heat. The concept, accordingto COGEN Europe, the European Association forpromotion of cogeneration, is the most efficient way todeliver heating, cooling and electricity. Countries acrossEurope have enthusiastically adopted the concept.Finland, Denmark and the Netherlands, for example,today employ cogeneration extensively to provideelectricity and district heat to local communities andindustry, but the range of possible applications islimited only by the imagination. Examples include

hospitals, universities, department stores, greenhousecomplexes and industrial facilities in countries fromBelgium to Spain.

The benefits in briefCogeneration is by no means the solution to all powerneeds. So what makes the method so popular? Thereason is that the technology, according to COGENEurope, results in ‘win-win’ solutions to energyproblems facing today’s industrial societies, andespecially those with access to natural gas.

Conventional generation of electricity in large centralpower stations is normally only 30-40 % efficient(Figure 1). These electricity-only stations release largeamounts of energy as waste heat, normally via largecooling towers or cooling with sea or river water. Theyare also typically located far from where the electricityis consumed, which therefore requires expensivetransmission costs. More recent combined cyclegeneration can improve the efficiency of such plants to

4 - Wärtsilä NSD

Decentralized energy in focus

Fuel 100

Fuel 100

Conventional system

Conventionalpower station

35 % electricity or more

Up to 65 % losses

CHP system

CHP system

Up to 90 % electricityand heat

10 % losses

Industry

Commerce

Domestic heating/cooling

Fig. 1 Why cogeneration.Source: COGEN Europe

55 %, but this excludes losses for the transmission ofelectricity, which can be as great as 20 % of thedelivered efficiency.

By reusing the heat produced in electricitygeneration, the cogeneration plant can reach anefficiency of 90 % or more. Cogeneration, therefore,offers energy savings ranging between 15-40 % whencompared with the supply of electricity and heat fromconventional power stations and boilers.

The fundamental principle underlying cogeneration isthat, in order to maximize its many benefits, systemsshould be based according to the heat demand of the

application. Provided this isdone, cogeneration offers thefollowing benefits:

• Increased efficiency ofenergy conversion andenergy efficiency at thepoint of use

• Lower emissions to theenvironment, in particularof CO2, the maingreenhouse gas

• Large cost savings,providing additionalcompetitiveness forindustrial and commercialusers, and offeringaffordable heat for domesticusers

• An opportunity to movetowards more decentralizedforms of electricitygeneration, where the plantis designed to meet theneeds of local consumers,providing high efficiency,reducing transmission lossesand increasing flexibility insystem use

• Improved local and generalsecurity of supply. Localgeneration, throughcogeneration, can reducethe risk that consumers areleft without supplies ofelectricity and/or heating. Inaddition, the reduced fuelneed which cogenerationprovides reducesdependency on imports, a

key challenge for Europe’s energy future.

The EU takes noteCalculated on a European scale, cogeneration stillaccounts for only a fraction of installed capacity,roughly 9 % according to COGEN Europe. A majorreason, of course, is the structure of the power marketin large markets like Germany and France, wherecentralized nuclear and coal-fired power plants are thenorm.

The benefits of cogeneration have not goneunnoticed by the EU Commission, however. The

Energy News - 5

Commission has identified cogeneration as the toppriority measure to reduce CO2 emissions in the EU andis committed to an 8 % cut in greenhouse gas emissionsto meet the binding targets set by the Kyoto Protocol.Cogeneration has been identified as the biggest singlemeasure to reduce greenhouse gas emissions in the EU,with a potential of 150 million tonnes of avoided CO2.

The EU Commission published a Strategy forCombined Heat and Power in May 1998, a landmarkdocument in which it confirmed the importance ofcogeneration in the future energy market of theEuropean Union. In this document the Commissionstated its intention to double the current level ofcogeneration in Europe (9 %) to 18 % by 2010. This isnot a legislative commitment; rather, a guide toEuropean policymakers and member states. Ifimplemented, the increase would raise the installedcapacity of cogeneration from today’s 65-70,000 MWe to130,000 MWe, which translates into annual investmentstotalling some 5 billion euros/year (Fig. 2).

From strategy to actionThe next step is the EU’s Action Plan, which is currentlybeing devised to co-ordinate EC activity to achieve theincrease in cogeneration throughout the EU. If adopted,it would greatly accelerate the use of cogenerationthroughout Europe although it is up to individualcountries how far and how fast they wish to proceed.

This raises the question of obstacles to the freeadoption of cogeneration that certain countries appearwilling to use to safeguard their monopolistic powerindustries. One example is discrimination against localoperators by erecting regulatory barriers. France, forinstance, requires all cogenerator operators to apply thesame employment conditions on workers as applies toEdF. This is unfair as the conditions apply to a principalnuclear operator and not on-site generator.

More serious is the potential lack of fair access bycogeneration operators to the electricity system. Thereare now calls for the EU to pass a directive establishingfair and transparent rules and pricing for connection toelectricity systems, top-up and back-up prices, andexport prices that reflect real costs.

Another barrier is the use of Article 18.2 of the GasDirective to apply a minimum-size ‘threshold’ oncogeneration projects. This, in effect, would preventsmaller but more efficient cogeneration installationsfrom accessing the competitively priced gas which willautomatically be available to all big but less efficientcombined cycle power stations. Both Spain and Francehave indicated that they might use the threshold.Proponents of cogeneration point out, however, thatsmall-scale cogeneration will not disturb the balance ofthe electricity market. If anything, the market is morelikely to be distorted by uncontrolled growth inelectricity-only production based on CCGT plants whichare not designed to meet local heat and power needs.

6 - Wärtsilä NSD

Investment opportunitiesCurrent use of cogeneration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 %Installed capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65-70,000 MWeCurrent level of investment in cogeneration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2.5 billion Euros/yearEU target for 2010 . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 % of all EU electricity to come from cogenerationIf target reached, the installed capacity of cogeneration will be at least . . . . . . . . . . . . . . . . . . . . 130,000 MWeAdditional capacity is approx. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60-65,000 MWeInvestment opportunity to reach the target . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50-60 billion EurosEquivalent to. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . approx. 5 billion Euros/yearor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . at least twice current activity

In additionReinvestment in existing plant will be . . . . . . . . . . . . approx. 30 % of existing stock 20-25,000 MWe over 10 yearsInvestment opportunity of . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . approx. 1.5 billion Euros/yearFurther investment opportunities in Eastern and Central Europe conservatively estimated to be . . 1.5 + billion Euros/yearTHE OVERALL INVESTMENT OPPORTUNITY IS . . . . . . . . . . . . . . . . . . . . . . . . . . 80-90 BILLION EUROSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4 TIMES CURRENT ACTIVITY

Fig. 2 Investment opportunities offered by cogeneration in Europe.Source: COGEN Europe

Decentralized energy in focus

As mentioned, the Nordic countries and particularlyFinland have made perhaps the greatest progresstowards widespread adoption of cogeneration, largelyfor reasons of climate and infrastructure. Looking atEurope as a whole, however, it could be instructive tosee how and why cogeneration is being applied inother widely differing European environments. We usethe UK and Portugal as two examples.

The UK – a fertile market for cogenerationThe UK energy market has undergone fundamentalchange over the past decade. Gas was privatized in1986 and electricity in 1989, which opened up themarket to progressively increasing competition duringthe 1990s. Electricity prices fell by 20 % and gas by40 % between 1990-98. This provided a fertileenvironment for cogeneration, which was furtherboosted by the government’s policy to "promote CHPwherever economic and to work to ensure there are nobarriers to wider uptake".

The original CHP target of 4000 MWe wasmet and a target of 5000 MWe isexpected to be reached in 2000/1on the way towards a target ofat least 10,000 MWe by2010. The use ofcogeneration in the UKis predominatelyindustrial sincecommunity (district)heating has beenexploited to only avery small degree.

An importantdevelopment wasthe introduction of astricter consentspolicy which providedexception for ‘goodquality CHP’. No consentsare needed, for example, inthe case of CHP power stationsbelow 10 MW in size. The criteriafor ‘good quality CHP’ include thestipulation that efficiency, averaged over a year,should be significantly higher than that achievable withthe same fuel source in a power-only unit.

This concept is further developed by Quality Index(QI) methodology, which is built on the rationale thatelectricity supplied is more valuable than heat supplied.It compared CHP to separate electricity-only and

heat-only alternatives. The QI therefore offers scope fora major improvement over conventional approachesbased simply on overall efficiency. The proposedmethodology is designed both to reward existing andfuture ‘good quality’ CHP schemes, and to provide anincentive for improving scheme performance.

Portugal – cogeneration has legal statusThe concept of cogeneration was adopted in Portugal atthe end of the 1980s when Heavy Fuel Oil (HFO)reciprocating engines were introduced to the market.High electricity prices encouraged numerous industrialinvestments in independent power production. Withmost industries needing heat (mostly steam) in someform as well, the cogeneration principle was an obvioussolution.

Because Portugal has some HFO refinery capacity ofits own and in the 1980s there was no natural gasavailable, the logical fuel for the cogeneration businesswas HFO. There are currently about 70 HFO engines

running in cogeneration applications inPortugal, amounting to between 8 and

10 % of the country’s annualelectrical consumption.

Wärtsilä’s share of thatcapacity is about 50 %, or

167 MW.In 1992, the

Portuguesegovernment made astrategic decision todiversify its primaryenergy sourcestowards natural gas.A multi-national gaspipeline project was

started and in spring1997 the first users

began consuming naturalgas. Gas flows from

Algeria, through Spain to theLisbon area where a

north-south main trunk linedistributes the gas throughout the

country.With the availability of natural gas, the

demand for gas-fuelled engines has risen sharply. In thefirst year, nearly 20 gas engines were sold for industrialcogeneration applications. Nowadays the governmentand the gas industry is promoting gas as the mainchoice of fuel for cogeneration plants. HFO projects are

Energy News - 7

becoming less common for environmental reasons anduncertainty of future emissions legislation.

The cogeneration LawInitially, there was no clear legal framework forinstalling private power stations; permits and powersales agreements were very muchdependent on the attitudes of theauthorities. This situation resultedin long delays and problemswhen planning investments,and ultimately legislationwas passed in which theconditions forcogeneration weredefined. The cogenlaw was in forceduring the 1990s withsome updates duringthe decade.

The followingcondition defines thecogenerator (Update ofDecret-Law No: 186/95dt 27.06.1005):1. The first main principle ofthe law is to define who (whatkind of power plant set-up) isconsidered a “cogenerator”:

E + 0.5 x T > 0.45 x C

where:E = electricity produced by cogeneration

station annually (kWh)T = thermal energy consumed by the

customer produced by the cogeneration stationannually (kWh)

C = fuel consumed by the cogenerationstation annually (kWh)

If the above equation is “true” then the case can behandled as a cogeneration station. It should be notedthat the conditions are related to the annual energyproduced and consumed and not to the maximumcapacity values (kW) of the station. Since Portugal’sclimate is quite warm, traditional space heatingapplications are rare, so the cogeneration conditionmust usually be met with steam production. In practicethis means that a typical 6.5 MWe station must be ableto recover an average 0.5 MW of heat as steam fromexhaust gases (and consume it in an industrial activity).

2. The second fundamental principle of the cogen lawdefines the maximum power that can be sold to the grid:

Eer = (4.5 x ((E+T)/(E+0.5 x T)) - 4.5) x E

where:Eer = electricity that can be sold to the

grid (kWh)E = electricity produced by

cogeneration station annually(kWh)

T = thermal energyconsumed by thecustomer produced bythe cogenerationstation annually(kWh)

This secondconditionemphasizes theimportance of a high

amount of heatrecovery, i.e. high total

efficiency. The more heatyou can recover, the more

power you can sell to thegrid. Consequently, even with a

smaller level of electricalconsumption on-site, you can still install

high electrical capacity.The effect of this clause can be calculated as follows

(data are simplified to outputs, not to annual energies,for a typical 6.5 MWe unit):

Heat recovery Electrical production Allowed electricity“Export” to grid

500 kWt 6500 kWe 1080 kWe1500 kWt 6500 kWe 3020 kWe2500 kWt 6500 kWe 4720 kWe3899 kWt 6500 kWe 6500 kWe

Other aspects of the legislation, together with the aboveconditions, limit the practical plant sizes to between 4to 7 MWe. In some rare cases with exceptionally highheat consumption in their industrial processes, theinstalled electrical capacity has been above 10 MWe.

With liberalization of energy legislation in Europe,the Portuguese cogen law also needed amending sinceit was originally written to function in parallel with afully monopolistic electrical production and distributionsystem. A new law was drafted between 1998-99 andwas introduced at the beginning of 2000.

8 - Wärtsilä NSD

Decentralized energy in focus

The new law (Decret-Law No: 186/95) makes fourmajor changes to the old law and some of the majordifferences are mentioned here:

1. In the old law the electricity selling prices to thepublic grid were guaranteed by the government for thefuture in accordance with a certain formula. This is nolonger the case. Now the selling price is defined using acomplex calculation giving priority to environmentalissues. In practice this means that the chosentechnology must be “low-emission technology” and thedegree of cogeneration must be high. A total efficiencyof about 75-80 % results in a level of electricity sellingprices that makes projects feasible (the new law sets alimit of a minimum total efficiency of 55 % in order tobe qualified as a cogenerator). Electrical selling tariffsare defined separately for cases with electrical outputsless than 10 MWe and above 10 MWe.

2. The old law permitted excesspower to be supplied only to thepublic grid. Now it isrecognized that thecogenerator has the rightto sell power also tothird parties either viathe public grid orthrough their owndirect lines.

3. The old law wasquite unclear on thequestion ofmanaging theelectricalinterconnection to thegrid. The new lawguarantees a largertransparency of proceedingsin the bureaucracy and moreequal treatment of the players inquestion.

4. One of the major hindrances to allowingcogeneration full rein for development under the oldlaw was the in-built protectionism of limiting theinstalled power to 5 % of the short circuit power at theconnection point. In practice this limited project sizes to4-6 MWe. The new law now allows connection ofsystems at the connection point up to 8 % of the shortcircuit power.

A number of other new aspects to the law notmentioned here naturally also need to be studied andunderstood when evaluating new projects. Existingplants are governed under the old law. They canchange to the new one by expressing their wish to doso during a period of 24 months calculating from thedate when the new law was passed.

Looking to the futureThe EU will need to issue directives and apply rules toensure fair play for all in the rapidly liberalizingelectricity and gas markets. Nonetheless, cogenerationhas come to stay and its widespread increase can onlybe delayed, not prevented. There is no doubt thatinvestment in cogeneration plants across Europe,including central and eastern Europe, will soar in thenext decade or two, though the rate of activity will ofcourse vary by country.

Technologically, the next majordevelopment in the cogeneration

market will bemicro-cogeneration systems

(below 15 kWe). These willbe based on new prime

movers: very small gasengines, Stirlingengines and fuelcells. Their targetmarkets will includeindividual houses,small groups ofhouses, small hotelsand retailestablishments.

The potential forthis technology is vast.

In the UK alone, thedomestic gas boiler market

is 12 million euros. If 25 % ofthis is suitable for

micro-cogeneration, the result couldbe 10,000 MWe of new installed

cogeneration, or one-quarter of the UK’s electricitydemand. �

Authors:

Andrew Gardiner, Impress Helsinki Ltd.

Kari Punnonen, Area Sales Manager, Wärtsilä NSD Finland Oy

Source: The information in this article is largely based on material supplied byCOGEN Europe.

Energy News - 9

Modigen Ltd – tradingelectricity for Wärtsilä NSD

Wärtsilä NSD started electricitytrading in Finland through itssubsidiary Modigen Ltd in 1997.The original aim was to achievesavings in the electricity bills of theparent company MetraCorporation’s factories and offices.This became possible when Finlandopened up the electricity market tocompetition, first for 500 kWe sitesin October 1995 and then for allconsumers at the beginning of 1997.

A crucial decision was taken in1996 to adopt a point tariff systemin electricity transmission, wheredistance has no effect ontransportation costs. This made itpossible to buy electricity from anysupplier in the country. The onlyexception is on-site suppliers, whodo not need to pay for transmissioncharges since they do not transmitanything.

Competitive bids forlargest sitesMetra Corporation has about tenelectricity consumption sites inFinland and some one hundred sitesabroad. The natural starting point,therefore, was the largest sites in theliberalized Finnish market. A marketstudy was made on these sites in1996. The average purchasing priceswere about EUR 33/MWh for theelectricity component and aboutEUR 13/MWh for transmissionexcluding VAT, giving a total priceof EUR 46/MWh.

The company asked forpreliminary bids for summer andwinter electricity separately. It wasfound that electricity prices would

drop to about half in the summerand remain constant in the winter.This was because the prices arehydro-based in the summer andcoal-based in the winter. Thesecond finding was that the priceswould generally fall and the bestresult would be achieved by makingonly six-month contracts forsummer and winter separately.

Trading started for summerelectricity in 1997. Modigenprepared a call for bids for thelargest sites where earlier contractshad expired. In the new contractsthe summer prices had fallen toabout EUR 17/MWh, or about 40 %.The average yearly electricity pricehad fallen to EUR 25/MWh, or 24 %lower than earlier.

Trading strategyToday, about three years from thestart of liberalization, Modigen hasbegun to offer this service to othercompanies in the metal andmechanical engineering industryand also the hotel sector. Thetrading volume is now about threetimes higher than consumption byMetra’s own facilities. Combiningthe engineering and hotel sectorshas helped to smooth the totalconsumption curves so that theutilization time of the maximumload corresponds to about 4500 h/a.This is then a very good package,which all power suppliers want toserve.

Electricity prices have stabilized ata very low level and the averageprice on the Nord Pool electricityexchange has been about EUR

10 - Wärtsilä NSD

Decentralized energy in focus

14/MWh for two years in a row (seeFigure 1).

In this new situation the strategyhas been changed from short-termelectricity contracts to two- orthree-year contracts. A detailedanalysis indicates that prices couldnot fall very much more, and thereis even the possibility of pricesrising.

There are several reasons for this.Consumption is rising at an annualrate of 2-3 %, while supply remainsconstant or is decreasing as theBarsebäck nuclear units in Swedenare decommissioned. The secondreason is higher prices in Germany,which tend to encourage Danishand Norwegian exporters to selltheir electricity to continentalEurope.

Future prices in ScandinaviaThe prices of long-term contractsclosely follow the forward prices onthe Nord Pool electricity exchange.The prices in the next three yearsare as follows (EUR/MWh):Summer 2000 . . . . . . . . . . . . 11.0Winter 2 2000. . . . . . . . . . . . . 16.1Winter 1 2001. . . . . . . . . . . . . 17.1Year 2001. . . . . . . . . . . . . . . 15.9Year 2002. . . . . . . . . . . . . . . 16.7Year 2003. . . . . . . . . . . . . . . 17.6

These prices can be compared tothe variable costs of a coal-firedcondensing plant, which are alsoabout EUR 16/MWh. Thus pricescannot be expected to fall muchlower and EUR 16/MWh is a fairprice for making contracts for thenext two to three years.

The consumer should then payEUR 13/MWh above this forelectricity transmission. The totalprice of future electricity will thenbe about EUR 30/MWh at the sitefor the next two to three years,which is about 35 % lower thanprices before liberalization began.

Future strategiesPrices are not expected to remain solow in the future. The best strategywill then be to combine electricitytrading with on-site powerproduction. This can be done inplaces where gas is available andconsumption is high enough tomake an on-site plant economical,i.e. about 2-10 MWe.

Power can be generated for EUR25-30/MWh using an on-sitegas-fired cogeneration plant. Thebest strategy is to generate powerduring the winter and purchasepower during the summer at aboutEUR 11/MWh. The average annual

price would then be about EUR20-23/MWh, which is only about50 % of the original price beforeliberalization started.

These prices also indicate thatconstruction of large-scale powerplants, which feed to the powerpools, has essentially halted inScandinavia, at least for the timebeing. The generating costs of anew coal, gas or nuclear plant areabout EUR 25-30/MWh, which istoo high compared with the poolprices.

The only plant commissioned inFinland last year was the 11 MWeValkeakoski Pure Energy gas CHPplant with two Wärtsilä 5.5 MWegas engines for a municipal utilitycustomer (pages 12-13). The onlyplants at the planning stage are amunicipal CHP plant in Tampereand some industrial on-sitegeneration plants. The electricitymarket has already changedfundamentally in Scandinavia. Othercountries will follow as theliberalization process spreadsaround the world. �

Asko Vuorinen

Managing Director

Modigen Ltd

Energy News - 11

0

5

10

15

20

25

1 2 3 4 5 6 7 8 9 10 11 12 Aver.

Aver. 1998 1999 2000

€/MWh

Fig. 1 Nord pool system prices.

Valkeakoski, about 150 km north ofHelsinki, is one of Finland’s maincentres of pulp and paperproduction. Almost 70 % of thetown’s 20,000 inhabitants areconnected to the district heatingnetwork, which is operated byValkeakosken Energia Oy(Valkeakoski Energy Ltd), a 100 %municipality-owned energycompany that provides heat,electricity and gas to the consumersin Valkeakoski. The district heat isproduced by a Pure Energy plantdelivered by Wärtsilä NSD in 1999.

Deregulation has opened up theenergy market in Finland in anumber of ways. Manymunicipalities have adopted await-and-see approach to themarket but Valkeakosken Energiadecided instead to invest in theirown CHP plant to make sure thattheir customers get a reliable supplyof affordable heat and electricity.With electricity prices fluctuatingheavily, Valkeakosken Energia sawthe new Pure Energy plant as thecornerstone on which to build theirfuture. Independence was one of

the major factors why ValkeakoskenEnergia decided to invest in theirown power plant.

A plant with a long historyValkeakosken Energia had beeninvestigating several options forindependent energy productionsince the beginning of the 1990s.One option under considerationwas to expand existing co-operationwith the local paper industry.However, intensive analysisrevealed that an independent gas

12 - Wärtsilä NSD

Decentralized energy solutions

Energia-Tietola – Pure Energy

engine power plant would be thebest option.

The saying “well planned is halfdone” aptly describes howEnergia-Tietola set about the task.Negotiations began in late 1997, theprecontract was signed at the end ofApril 1998, and the final contractwas signed early in August 1998, bywhich time the foundation workswere already under way. Theextension of the existing boilerhouse was ready in December andthe topping-out ceremony was heldon 2 February 1999. The plant wasstarted up in August, and thehanding over and test run periodsstarted in September 1999. Theofficial opening ceremony and alsothe name-giving party were held inmid-November 1999. The plant iscalled Energia-Tietola (EnergyKnowledge Centre) and the enginesare named Helka and Kaino afterValkeakoski’s legendary mayor andhis wife.

Wärtsilä, the turnkeycontractorWärtsilä NSD Finland Oy deliveredthe power plant on a turnkey basis,but as always using severalsubcontractors. Most of these werealready familiar from previousprojects in Kerava and Ikaalinen.

Forming the heart of the plant aretwo Wärtsilä 34SG gas engines bothproducing 6 MW of electricity. Eachengine and its generator were puton a common base frame andtransported from Vaasa toValkeakoski in one piece eachweighing 100 tons.

There is no emission legislationfor gas engine power plants inFinland, but TA-luft is used as the

standard and this has been the casein Valkeakoski as well. The locationof the plant was also a challenge.Energia-Tietola, like almost all PureEnergy plants, is situated in adensely populated area and there isan elementary school only 80metres from the power plant. Thenoise level was not permitted toexceed 45 dB(A) at 25 metres fromthe wall of the Pure Energy plant.This requirement was fulfilled andnow the only way of knowingwhether the plant is running or notis to look at the stack for signs ofsteam.

Organization unchangedAlthough the establishment ofEnergia-Tietola marked a newsituation for the personnel ofValkeakosken Energia, there was noneed to change the existing

organization. The plant is rununmanned and someone from theheat department visits the plantdaily during weekdays. The PLC isremotely connected to theheadquarters of ValkeakoskenEnergia and the duty manager canconnect his portable PC to theplant’s modem. The plant can alsobe directly monitored by Wärtsilä’sservice department in Vaasa (300km north of Valkeakoski) via amodem, allowing them to analyzeany problems that arise and suggestthe best maintenance alternative.This ensures rapid reaction timesand minimizes downtime if theplant’s operation is interrupted forany reason.

Valkeakosken Energia personnelhandle minor maintenances (under4000 h), while larger maintenancetasks are performed by WärtsiläNSD under a 5-year maintenancecontract.

The situation todayThe plant has now been inoperation about 6 months and bothof the engines have almost 4000running hours behind them. Theowner has been happy with theperformance of the plant andreports that co-operation withWärtsilä has been very satisfactory

Visits to Energia-Tietola will bearranged in connection with thePower Gen exhibition in Helsinkion 19 June 2000. If you are visitingthe show, you are most welcome tojoin the group. Energia-Tietola is amodern plant well worth a visit. �

Author: Jukka Hakola

Key Account Manager

Wärtsilä NSD Finland Oy

Energy News - 13

for paper industry town

FinlandValkeakoski

MeetingTurkey’spowerneedsThink about Turkey and orientalimages spring to mind such asexotic food, belly dancing andsultans with harems and eunuchs.If you happen to follow politics,you might remember more recentmatters like the Kurdish problemand Turkey’s candidacy formembership of the EuropeanUnion. Seldom, however, do peopleassociate Turkey with modernmanufacturing, fast economicgrowth, cellular phones and largeinternational projects, but that is thereality today.

In the past decade Turkey had anaverage 8 % growth in GNP, 1999being the only regressive year withabout 6 % negative growth. Theyear 2000 looks to be positive onceagain and, partly because of itsapplication for EU membership, theTurkish Government is enactingnew laws and stipulations with notime to lose. These new laws willsupport steady business growth inthe country for some years to come.

The social structure of Turkey haschanged rapidly during the past twodecades as well; large-scaleurbanization is taking placesimultaneously with fast populationgrowth. To give you an idea,Greater Istanbul has over 12 millioninhabitants today compared to only5 million ten years ago, and thepopulation is growing by about300,000 each year.

Electricity consumption per capitais still very low in Turkey, 1160kWh per annum, compared toaverage consumption of 6100 kWhin the European Community. Thishas created annual demand for 3000MW of new power generation andthis demand is estimated to

continue at the same level for atleast ten years from now. Turkey’sElectricity Generating andTransmission Corporation (TEAS), apublic company that owns andoperates 15 thermal and 30hydroelectric plants totalling over20,000 MW of electrical capacity,has been trying together with theMinistry of Energy and other statebodies to add generation capacity tomeet the increase in demand.However, they have not beensuccessful owing mainly to delays inthe availability of natural gas,Turkey’s very slow legislativeprogress in the past and lack ofmoney.

Private power generation capacityhas been increasing steadily andtoday amounts to about 5000 MW.About 1900 MW of this has beenbuilt under the so called“autoproducer” concept in morethan 89 power plant installations.An autoproducer is a company, or a

group of companies, that producesits own electrical and thermalenergy. The model offers interestingopportunities for private investorswho are willing to form jointventures with local factories thatconsume the power and energy.

14 - Wärtsilä NSD

Energy in focus

140

120

100

80

60

40

20

080 90 91 92 93 94 95 96 97 98 99

GWh x 1000

Fig. 1 Electric energy consumptiondevelopment in Turkey

In their long-term planning, TEAScovers hydro, nuclear, coal andgas-fired thermal power plants.However, these plants will takesome years to be operational. Tomeet the immediate needs forpower capacity, TEAS introduced a“mobile power plant concept” in1998. This concept involvesprivately owned power plants withcapacities from 10 to 42 MWoperating under a short-term PPAfrom TEAS. A total of 75 MWdiesel-fired power plants were builtin 1999, all of them with athree-year take-or-pay PPA whoseprice is fixed to the US dollar.

Despite these efforts, the Turkishpopulation, Turkish industry andthe whole economy are suffering asevere shortage of electrical powerevery day. Heavy fuel-fired dieselpower plants are a good solutionfor Turkey as hundreds ofmegawatts can be operational inless than 12 months. These powerplants run on cheap and “almostdomestic” fuel, HFO #6, which is

the low-grade product of all sevenTurkish refineries.

Such power plants have provento be a reliable and economicalmeans of power generationworldwide, and Turkey is noexception. Wärtsilä NSD hasinstalled 154 MW in nine powerplants in Turkey so far, 37 MW ofwhich is dual fuel-fired (natural gas- fuel oil) and the rest heavy fuel oil(HFO #6) applications. A further133.5 MW of heavy fuel powerplants are under construction andall will be operational this year.Most of our heavy fuel-fired enginescan be converted for gas operation

if desired, when natural gas isavailable.

Wärtsilä NSD is at the momentnegotiating three 20 MW heavyfuel-fired power plant orders. Theseplants will produce electricity forTEAS’s grid under the mobile powerconcept mentioned above. All ofthem, in fact, will be extensions toexisting plants, so the owners areKaradeniz Energy, EnerPower andAKSA, which is a new customer toWärtsilä. Each of the three powerplants will have four Wärtsilä 18V32generating sets and the plants willbe operational in just six monthsfrom signing of the contract.

This expansion project shows thatTEAS is comfortable with thetechnology of our Power Mastersand this gives us a goodopportunity to expand ourrelationship with TEAS and localenergy companies in the future. �

Author: Jari Kartano

Director, Power Plant Business

Wartsila NSD – Enpa Dis Ticaret A.S.

Energy News - 15

Fig. 2 24 MW Power Master in City of Van

Fig. 3 45 MW Power Master inSilopi, Turkey

The Imperial College of Science,Technology and Medicine, London,has been working with WärtsiläNSD and London Electricity Servicesto create an efficient,environmentally friendly andeconomical combined heat andpower plant on campus.

Founded in 1907, ImperialCollege is one of the world’sleading institutions in the world forresearch, teaching and education inscience, engineering and medicine.Recent mergers with Charing Crossand Westminster Medical Schooland the Royal Postgraduate MedicalSchool have contributed to therecent increases in numbers. TheCollege is now home andworkplace to around 9000 students.

The existing boiler plant, for theCollege’s heating, was installed inthe late 1950s. This plant consistedof four heavy fuel oil-burning steamboilers. London Electricity was

supplying electricity from the localgrid at 6.6 kV. During 1996 theseboilers were identified as coming tothe end of their economical life.This gave Imperial College theopportunity to review its energyneeds and potential solutions. Aftercareful consideration the Collegechose the option of a CombinedHeat and Power (CHP) scheme.

Imperial College entered into apartnership agreement with LondonElectricity Services (LES) in whichLES would design, build, operateand maintain the CHP plant for a15-year period. The CHP plant isowned by the College. A majorproblem for LES was the need toremove the four existing boilersfrom the basement of the college,then install the new CHP systemwithout interruption to the College’sheating supply.

When it came to choosing anengine supplier it became clear to

LES that the engine solution offeredby Wärtsilä NSD best met the needsof the project. To achieve therequired output of 9 MWe at 6.6 kVand 4 MWth, Wärtsilä NSD’ssolution was based on two Wärtsilä18V28SG gas engines with anelectrical efficiency of 41.5 %.Competitive solutions from otherengine manufacturers were basedon three engines to achieve thepower and heat levels required.

Tight fitLack of space was a critical factor.After the boilers had been removedthe new Pure Energy plant had tobe installed in the old boiler house.To gain access, all new equipmenthad to be lowered through a hole inthe road outside the College.

The complexity of the projectmeant that the installationprogramme spanned over twoyears. As the heat supply to the

16 - Wärtsilä NSD

Decentralized energy solutions

CHPfortheBSc’s!

Photo: Jan Chlebik

College had to be maintainedduring installation, a way had to befound to achieve this during theproject’s implementation. Atemporary boiler-house wasdesigned and constructed within theCollege grounds. During thesummer of 1997 the temporaryboiler house was connected to theCollege’s existing system.

Once this temporary boiler housewas up and running, workcommenced on thedecommissioning of the existingboiler plant and chimney. The newgenerator sets were tested inWärtsilä NSD’s works beforedelivery. As the complete generatorsets would not fit through theaccess hole in the road, they werebroken down into their three maincomponents: engine, alternator andbase-frame, for delivery to theCollege.

The delivery of the generator setsthrough central London had to becarefully co-ordinated, as timingwas critical. They had to arrive at

the correct time, and in the correctorder, as each component had to beoff-loaded directly to the basementsince there was no room to storeanything on site. The base frameswere lowered in first, followed bythe engines, then the alternators.Once reassembled, the completegenerator sets were manoeuvredinto position and cocooned to allowthe rest of the plant to be installed.

Heat recovery and re-useImperial College will improve theefficiency of the system even furtherby modifying its existing systems touse the low-grade heat produced bythe gas engines. A full-dumpcooling system, using heatexchangers, has been supplied toremove the heat. Even before theuse of this low-grade heat theCollege will benefit from an energy

saving of around £800,000 per year.The environment will also benefitthrough a reduction of 7500 tonnesof CO2 per year.

“We are delighted with the newheat and power plant,” commentsMr Ron Jeeves, Imperial College’sOperations Manager. “It willgenerate considerable savings for uson our energy costs. It will alsoprovide the College with heating,hot water and air conditioningthroughout the campus. It was alsoimportant to us that this was anenvironmentally friendly package.”

“LES is extremely pleased andproud to be associated with thisproject. After two interesting yearsin construction, we are lookingforward in putting the plant intobeneficial operation.” �

Energy News - 17

Photo: Jan Chlebik

Photo: Jan Chlebik

Improved performanceof the Wärtsilä 28SG1 December 1999 marked thebeginning of a new era for theWärtsilä 28SG gas engine. On thatday, the first Wärtsilä 28SG gasengine built in the Netherlandsstarted commercial operation. Thistook place in a power plant inMeaux, France, with two Wärtsilä18V28SG engines. It was followedby a third engine in Lüneburg,Germany, where the warrantyperiod started on 19 January 2000.The two plants are now performingvery well and running 24 hours aday.

When the decision was made tomove manufacturing of the Wärtsilä28SG engine from Sweden to theNetherlands in October 1998, wewere faced with the challenge oftransferring not only the knowledgebut also all documents andhardware. However, this periodgave us the opportunity toimplement improvements based onthe experience collected from theoperating engines that were built inSweden. Both minor and majorimprovements were made. Thepositive impact of the changes can

now be seen in the excellentperformance and reliability of thenewly built engines.

Design improvementsThe overall vibration levels havebeen decreased considerably bychanging the stiffness of the engineblock. This in combination with anew gas pipe arrangement, newwastegate arrangement and theaddition of some supports hasminimized the vibration levels.

A fine-tuned piston designtogether with a new piston ring

18 - Wärtsilä NSD

Technology in focus

package has made the combustionprocess more stable and lesssensitive to knocking. It has alsodecreased the lube oil consumptionto about 0.25 g/kWh.

The Wärtsilä 28SG incorporatesthe WECS8000, the new version ofthe engine control system. The newcontrol system has proven to be alot more stable than the old systemand no problems have beenrecorded since it was fine-tuned onthe first installations.

Lüneburg, GermanyThis installation, with one Wärtsilä18V28SG, is operating in the townof Lüneburg, about 40 km fromHamburg. The Pure Energy plant isowned and run by Avacon AG, oneof the biggest energy providers inGermany. The plant has anelectricity output of 4560 kWe andproduces 4.9 MW heat for thedistrict heating system. Whensuitable, the heat can also beaccumulated in a large heataccumulating tank. The plant will

run between 4500 and 5500 hoursper year. Emissions comply with the½-TA-Luft regulations and theelectrical efficiency is 40.7 %.

Once the installation work wasover, the Pure Energy plant wasgiven a performance commissioningtest for 14 days during which theengine did not trip once. Since thewarranty period started, the enginehas run extremely well. So far, theengine has run for 1900 hourswithout any major stops except forthe changing of spark-plugs.

Wärtsilä NSD’s turnkey supplywas split between the Netherlandsfactory for the performance packageand the Hamburg network office forthe local adaptation, installation andsupervision. Wärtsilä NSD’s servicedepartment in Germany has made along-term service contract withAvacon.

Meaux, FranceThis Pure Energy plant,incorporating two Wärtsilä 18V28SGengines, is located in Meaux, atown just outside Paris. The plant is

owned by Energie Meaux, the localdistrict heating company. Theelectricity produced is sold to thenational utility Electricité de Franceand the heat is distributed as districtheating. The plant is scheduled torun 3624 hours, 24 hours a day inthe winter season between 1November and 31 March. The plantwill remain closed the rest of theyear.

Until now the Pure Energy planthas accumulated 2550 hours/engine.The performance has been veryhigh and only a few stops haveoccurred. Since then the availabilityhas steadily increased and inFebruary and March it reached98 %.

Energy Meaux closely followedthe work on site to make sureeverything was being done inaccordance with the specificationsand expectations. They are verysatisfied and have just signed arepeat order for an identical PureEnergy plant to Aulnay, also a townoutside Paris. Operation of theAulnay plant is scheduled for 1November 2000.

Wärtsilä NSD France acted as theturnkey contractor for the MeauxPure Energy plant, providing alldetailed engineering, and supplyingand installing all equipment neededin the cogeneration plant. WärtsiläNSD France also has a 12-yearoperation and maintenance contractfor the plant, ensuring its properoperation and maintenance.

These two references illustratethat the Wärtsilä 18V28SG gasengine is now a mature productoffering excellent performance inthe field. �

Author: Tomas Ryckenberg

Expert, Gas Engine Technology

Wärtsilä NSD Nederland B.V.

Energy News - 19

Energy Partner proves itsworth in DenmarkEnergy Partner agreements areagreements made by Wärtsilä NSDwith its power plant customerscovering performance optimization,modernization, reliabilityenhancements and other proactiveservices. The exact scope and mixof services specified in theseagreements are tailored to the needsand operating conditions of eachcustomer.

Agreements that have beenoperative for a number of years arenow being revised to cover thecustomer’s current requirements,which have often changedconsiderably. All variations of theseagreements continue to exist afterupdating, from simple co-operationto full Operation & Maintenance. In

general, however, the updatedEnergy Partner agreements containmore and wider maintenance work,although this will continue to beperformed by the customer himself.

The escalating base of WärtsiläNSD gas engines in Denmark nowtotals 181 MWe. An additional 6MWe is under construction, whichmakes a total of 33 installations. Allthese installations are covered by aWärtsilä Energy Partner serviceagreement offering numerousadvantages. The most important ofthese are described below.

Energy Partner agreements canbe quite extensive. They can covermachinery breakdown, anavailability guarantee, lubrication oildelivery and cleaning etc., but not

fuel supply. Alternatively they maycomprise supply of materials,including spare parts, as well asservices according to the customer’srequirements.

Daily support to maximizeavailabilityOne of the most important factorscontributing to our customers’financial success is to maximize theavailability of the power plantequipment. Wärtsilä NSD’s efficientservice organization offers dailysupport for all power plantscovered under Energy Partneragreements.

Every day the power plantinstallations receive on-line callsfrom Wärtsilä NSD Danmark’sOperation Support Centre. Thisensures that the operationalparameters are continuouslyassessed by an experiencedtechnical advisor from theOperation Support Centre enablingthe operator to form a rapidoverview of the current operatingconditions at the power plant. Anyirregularities are addressedaccording to their nature. It is oftenenough, for example, to call thepower plant in question and makearrangements for corrective actionin co-operation with the operator.

From time to time it is necessaryto send a Wärtsilä NSD serviceengineer to the power plant if theoperator is not present or is unableto solve the irregularities on hisown. If difficult irregularities occur,it is an advantage to our customerthat the Wärtsilä service engineer is

20 - Wärtsilä NSD

Optimizing performance

Picture 1. A technician in the field is receiving remote guidance from theOperation Support Center via telephone and modem.

fully aware of the cause of theirregularity on arrival at the site.While on his way, the Wärtsilä NSDservice engineer can discuss theproblem with a technical adviser atthe Operation Support Centre andprepare a detailed solution inadvance, which ensures that theproblem is solved quickly andefficiently.

Remote troubleshootingKent Hastrup Jensen, manager ofWärtsilä NSD Danmark’s technicaldepartment, performs remoteinspections of the plants coveredunder the Energy Partneragreements via a modemconnection from the OperationalSupport Centre at Wärtsilä NSDDanmark (Picture 2). When atechnician is sent to a power plant

requiring assistance, he receivesremote guidance from theOperation Support Centre viatelephone and modem (Picture 1).

Our customers also benefitgreatly from the advancedtroubleshooting features of theWärtsilä Engine Control System(WECS), which ensures thattroubleshooting is handledsystematically. The OperationSupport Centre is equipped with acomplete WECS model fortroubleshooting and training etc.This supports the customer throughboth higher availability and betterfuel consumption.

Our customers consider thatWärtsilä NSD provides a consistentlyhigh standard of service. One factorof great importance to maintainingthis standard is the service

organization and the way it works.Wärtsilä NSD has been workingaccording to ISO 9001 since 1994.However, the most important factorcontributing to good deliveredquality is the competence andcommitment of our personnel. �

Author:

Mogens Jakobsen

Area Manager

Power Plant Field Service

Wärtsilä NSD Danmark A/S

Energy News - 21

Picture 2. Remote inspection and monitoring of the power plants covered under the Energy Partner agreements

Top quality in ColombiaIn mid-1998, a team of people wasselected by Wartsila NSDOperations, Inc. to operate andmaintain the 24.7 MW Pure Energyplant under construction at theCementos Diamante cement factoryin Ibagué, Colombia. The factory isowned by Cemex, a multinationalMexican corporation. At the end ofthe same year, Colombia EnergyOperators S.A. was established tooperate this and future power plantprojects in the country.

Colombia Energy Operators S.A.has a clear vision to establish andmaintain a standard of excellence inits power plant operations. Thecompany emphasizes that teamworkbased on achieving customersatisfaction and exceeding thecustomer’s expectations is essentialto putting this vision into effect.Wartsila NSD Operations, Inc. choseColombia Energy Operators S.A.and the Cementos Diamante power

plant as an ISO 9002 QualityAssurance System pilot project inMay of 1999.

The project began in Annapolis,Maryland, in mid-May with anaccelerated training program. Aninterdisciplinary team was formed totranslate the procedures and toprovide guidance and approval ofthe procedures to ensurecompliance with the ISO standard.The basic engineering of the projectin Colombia continued, and by thebeginning of September 1999procedures had been written andtranslated, 345 (MP2) tasks hadbeen written, and 134 forms hadbeen customized.

At the same time, and with theNorth American Quality Committeeserving as judges, Colombia EnergyOperators S.A. created the phrase,“With Human Quality, We GeneratePure Energy,” as their qualityslogan. On 9-10 November 1999,

Colombia Energy Operators S.A.successfully passed the third-partypre-audit conducted by ICONTEC.On 6 December ICONTECconducted the Certification Audit,which Colombia Energy OperatorsS.A. passed with flying colors.

On 9 February 2000 the directorof ICONTEC presented ColombiaEnergy Operators S.A. with the ISO9002 and the IQNET Certificates in asimple ceremony at the CementosDiamante power plant. The IQNETCertificate, which is valid in 27countries, guarantees that theOperations and Maintenanceactivities performed by ColombiaEnergy Operators S.A. comply withthe International Standards of theISO 9002 Quality System.Participants at the ceremonyincluded the President, the QualityPrograms Manager and theAdministrative Manager of WartsilaNSD Operations, Inc.

22 - Wärtsilä NSD

Optimizing performance

Today, Cementos Diamante ofIbagué can rest assured, with thecertificate as its guarantee, that thepower plant is being operated and

maintained under internationallyrecognized procedures as anintegral part of the QualityAssurance Program.

At this moment, the ColombiaEnergy Operators S.A. team is closeto completing implementation ofthe ISO 14001 EnvironmentalManagement System. Theexperience of Colombia EnergyOperators S.A. and all the associateddocumentation will be used byWärtsilä NSD Operations Group asa guide when implementing ISO9002 in all plants under theiroperation. �

Author: Gustavo Fierro P.

Plant Manager

Colombia Energy Operators S.A.

Energy News - 23

Reciprocating compressors in naturalgas underground storages in GermanyDuring the past decade natural gas increased inimportance as a source of prime energy. Theexploration of new gas fields and expansion of thenatural gas grid in many countries has generatedthousands of applications for compressors.

Pipelines are often run with turbo compressors,whereas reciprocating compressors are almostexclusively used for gathering, gas lifting andre-injection close to the well. Underground storages,however, are normally not located close to the well oralong the gas transportation route. Instead, they areusually close to the consumer and are run usingreciprocating compressors. Underground storagesbalance seasonal demand for gas (day/night and/orwinter/summer).

Compressors fornatural gas storageNatural gas is stored in intermediate storage facilities toincrease the security of supply and also to balance gassupply as consumption varies. The gas is injected intonatural gas-tight geological formations or into artificiallyconstructed caverns. When required, the gas is releasedfrom the storage and fed into the gas grid.

Natural gas storages are typically former oil and gasfields, aquifers (similar geological formations, but filledwith water) and salt caverns especially made for thestorage of natural gas.

Seasonal fluctuation (summer/ winter) and peakconsumption are the critical reference figures whenoperating a natural gas storage. The ideal economictarget is constant gas purchasing over a year and 100 %use of the storage at the end of the period. The ability

to reach this target depends on the accuracy of theconsumption forecast and is limited by the existingsupply reserve. Injecting and withdrawing equipmentmust have a very high degree of flexibility in order toavoid further operational limitations. Only under theseconditions can the storage be operated close to actualdemand.

The liberalization of the gas market is now creatingadded scope for applications besides the need fornatural gas storage, which is always related to theindividual providers and their areas. The use of freecapacity in another grid, independent of actualconsumption and spot trading of gas, only makes senseif storage capacities can be utilized. In this case varyingsupply prices can be used to generate added value.

Maximum storage pressures vary between 100 barand 320 bar and they are fixed by the depth and thegeological conditions. Equally invariable are theminimum storage pressures, between 40 bar and 120bar, which must also comply with the conditions in thefield or the salt cavern.

Following the line for gas consumption related to theline for gas supply, periods of excess gas (=injection)show up as well as periods of additional demand(=withdrawal). The amount of deviation determines thenecessary rates of injection or withdrawal.

Operational requirementsof compressorsThe operational requirements for the injection andwithdrawal units can be fixed based on the aboveparameters. The injection equipment mainly consists offilters, a flow measuring device, gas compressor, gascooler and separator. In this article, however, weconsider only the design data of the compressor.

The injection rates mentioned will be viewed inconnection with the suction pressures – given by thesupply pipeline – and the necessary redundancy. Basedon a safety factor of at least 2 x 50 % for availability,compressors in a natural gas storage will have thefollowing typical design criteria:

Suction pressure . . . . . . . 40 – 85 bar(pipeline pressure)Discharge pressure . . . . . 50 – 320 bar(storage pressure)Flow rate . . . 12,000 – 200,000 m3 (Vn)/h

24 - Wärtsilä NSD

Inside view – underground storage of natural gas

7.10 4.11 2.12 30.12 27.1 24.2 24.3 21.4 19.5 16.6 14.7 11.8

Gas demandGas delivery

Fig. 1 Comparison between gas delivery and gasdemand.

The following operational conditions must beconsidered in order to select the optimum compressor:

• The compressor must be designed to compress theavailable excess volume under pipeline pressure upto the actual storage pressure.

• The compressor works non-continuously. It will runfor long periods in the summer, but short injectionperiods will be necessary when gas consumption islow, for instance at weekends.

• The annual operating hours are about 2000 hrs, ie.the availability of the equipment must be guaranteedfor 6000 hrs.

• The compressors must be designed for different gascompositions and for the permissible level ofimpurities.

• Since the investment costs of the compressor unitand the related energy costs for the injection of thegas make up a considerable proportion of the totalinvestment, the main criteria for purchasing thecompression equipment are the procurement costsand the economic operation of the compressors.

Given these criteria 38 out of 41 natural gas storages inGermany are provided with reciprocating compressors.Turbo compressors are used in only three larger storagelocations. The reason for the much higher population ofreciprocating compressors in natural gas storage isgiven by the advantages and disadvantages of themachines themselves.Advantages:

• The actual pressure ratio arises automatically withoutany additional control.

• The flow rate can be controlled exactly according tothe operators’ requirements.

• Partload operation is economically possible.

• The compressors can easily be maintained instand-by operation.

• Reciprocating compressors are lower in price thanturbo units for the same pressure ratios and flowrates.

Disadvantages:

• Pulsation in the gas stream

• Lubricants in the gas

• Gas leaks.

Specification and offersNatural gas is defined by giving either a gascomposition or a description of the gas with the limitsof fluctuation and the associated components. Thecompressor itself will be defined mainly by fixing thesuction and discharge pressures and the required flow.The definition of a clear design point will be the basisfor the compressor selection and for future guarantees.

Energy News - 25

Fig. 2 Typical natural gas underground storage.

Flensburg

Rostock

Lübeck

Hamburg

Bremen

BerlinHannover

Kassel Leipzig

Dresden

Frankfurt

Würzburg

Nürnberg

Stuttgart

FreiburgMunich

Fig. 3 Underground gas storages in Germany.

Area Design

Suction pressure bar, a 30 - 85 50

Suction temperature, °C 5 - 25 10

Discharge pressure bar, a 70 - 180 180

Flow rate, Nm3/h 50,000

Control range, % 25 – 100

Lubrication Mini lube

Leak rate, Nm3/h <4

Prime mover Electric motor/gas engine

Fig. 4 Example of specification

A prime mover (electric motor or gas engine) and apre-selected rotating speed are also sometimes required.

The demands for control, lubrication, low emissionsfrom leaking and low residual pulsation form the basicrequirements for the size and type of compressor.Additional requirements and features will depend oneach project and the experience of the owner.

Based on this data Wärtsilä Compression Systemsselects the most suitable machine from the portfolio andthe most economical compressor taking intoconsideration the customer’s specification.

Calculation of the total scope of supply will give thesales price. The compressor unit will normally beoffered as a package so the bare shaft compressor oftenmakes up only approx. 20 % of the total price.

Finally the most economical solution will bedetermined based on how accurately the compressormanufacturer can fulfil the customer’s specification.

The example chosen showed the following offers:The result shows different solutions for the same

task. All the alternatives in common are based oncomposing available standard accessories.

EvaluationWhen evaluating the various offers the customer’sessential criteria were considered and weighted inimportance. The following ranking will show as anexample that the selection is based mainly onoperational and economic factors. The specific designcriteria of the offer only indirectly influence theevaluation criteria.

Covering of working area 10 %Efficiency at design and at part load 7 %Flow control range 8 %Smoothness of running; pulsation 5 %Accessories 3 %Lifetime 5 %Spare parts, spare part costs 5 %Leakage rate 3 %Lube oil consumption 4 %Maintenance intervals 5 %Service 10 %References installed 5 %Price 30 %

When evaluating the price, the purchase costs stated inthe offer are considered as well as indirect expendituresuch as construction volumes, size of necessaryfoundations and technical equipment for the building.

SummaryReciprocating compressors are ideally suited to meetingthe requirements for operating a natural gas storage.

The multitude of possible solutions available with thesecompressors also demonstrates their adaptability to theever changing conditions of the market. It is veryimportant to make use of the existing potential and atthe same time to avoid costly accessories and designswhich are not required in the operation of natural gasstorage plants at all.

• Costs for compressor

• Costs for prime mover

• Costs for armatures

• Costs for pipelines

• Costs for instrumentation

• Costs for control system

• etc.

Fig. 6 The various costs of a compressor unit.

To offer gas consumers a safe and cost-efficient gassupply, suppliers must make use of all opportunities topurchase their gas under optimum conditions to keeptheir own market shares. This can only be done byusing storage capacities in a flexible way. Oneinteresting option for small companies might becommon rental of a storage area which can be operatedindependently. The more the market is deregulated, thehigher the demand for storage space will become. It isalso likely that existing injection capacities will beincreased in order to be able to inject available gas atshort notice. This market worldwide offers WärtsiläCompression Systems excellent sales potential for gasengine driven compressors. �

Author: Siegmund Cierniak

Vice President

Wärtsilä Compression Systems

26 - Wärtsilä NSD

Inside view – underground storage of natural gas

A B C

Design Boxer Boxer Boxer

No. of stages 1 1 2

No. of cylinders 4 6 4

Rotating speed 1000 750 420

Power 2000 2200 2300

No. of valves 32 48 24

Capacity control Bypass Valve unloading Valve unloadingand bypass

Performance 90 % 100 % 105 %

Dimensions 8 x 4 10 x 4 8 x 5

Weight 45 55 50

Price 100 % 115 % 125 %

Fig. 5 Table of possible data

Owners split Cummins Wärtsilä operationsThe operations of Cummins Wärtsilä, a 50/50 joint venture ownedby Wärtsilä NSD and Cummins Engine Company, have beendivided between the owners.

“The Cummins Wärtsilä joint venture has developed twofamilies of new-generation heavy duty high-speed diesel and gasengines and brought them to market. Now that these engineshave been introduced, both parent companies have decided tofocus on the engines which best suit their core business. In thisway synergy benefits will be achieved to improve efficiency andprofitability from the current unsatisfactory level,” stated Mr OleJohansson, President and CEO of Wärtsilä NSD.

Wärtsilä NSD has taken over the manufacture, global sales andservice of the CW200 and 220 engines (now Wärtsilä 200 andWärtsilä 220SG), as well as the factory in Mulhouse, France, whichproduces the engines. The corresponding responsibilities for theCW 170 and 180 engines have been transferred to Cummins,along with the factory in Daventry, England. The global service forthe engines manufactured by the joint venture’s predecessor,SACM Diesel, as well as manufacturing and service of the UDXand Poyaud engines in Surgères, have been transferred toWärtsilä NSD. The split was based on the net asset value of therespective businesses on 31 December 1999.

Wärtsilä NSD and Cummins Engine Company formed theCummins Wärtsilä joint venture in 1995 to develop andmanufacture the CW170 and CW200 high-speed engine families.The scope of the joint venture was expanded in 1997 to includemarketing, sales, engineering and service.

To achieve synergy benefits the Mulhouse and Surgèresactivities have been merged into Wärtsilä NSD France, creating anew entity headquartered in Mulhouse. Cummins Wärtsilä’s ownsales and service distribution has mainly been integrated intoWärtsilä NSD’s global network.

The operations transferred to Wärtsilä NSD will generate netsales of approximately EUR 133 million this year and haveapproximately 830 employees. This represents approximatelytwo-thirds of the business volume of Cummins Wärtsilä.

The new Wärtsilä NSD FranceThe new Wärtsilä NSD France is focusing on systems supply,manufacturing and service of Wärtsilä 200SG diesel andWärtsilä 220SG gas engines and on the UDX engines. It also hasservice responsibility for the SACM/ Poyaud, Crepelle and SulzerZ40 range of engines. The installed 13,500 MW engine baseprovides a sound foundation for the service business. In addition,

the company is responsible for salesand service of all Wärtsilä NSD enginesand systems for France andFrancophone markets. The main unitsof the company are in Mulhouse,Surgères and Mantes. The new WärtsiläNSD France’s pro forma net sales in1999 were approximately EUR 260million and it has 1060 employees. Thepresident of the new company is MrClas-Eirik Strand. �

Energy News - 27

What's New?

Changes within the Top Managementof Wärtsilä NSD CorporationBusiness Area Power PlantsThe current head of Wärtsilä NSD Corporation’s Business AreaPower Plants, Mr Stefan Fant (Eng.) has been appointed VicePresident, Service from August 1, 2000. Mr Fant will beresponsible for integration of O&M and Service activities within thecompany.

Mr Pekka Ilvonen, 46, MSc (Eng.) MBA has been appointed GroupVice President, Power Plants and a member of the Board ofManagement of Wärtsilä NSD Group from August 1, 2000. PekkaIlvonen, currently Vice President of Systems Group in ABB IndustryOy, brings over 20 years of experience in global project relatedbusiness.

TechnologyMr Daniel Paro BSc (Eng.), who has headed Research &Development within Wärtsilä NSD for many years, will as of 15July, 2000, from a technology standpoint take responsibility for thelaunch of Wärtsilä NSD´s new-generation smokeless engines.Professor Matti Kleimola, 54, Lic.Tech. has been appointedGroup Vice President, Technology and a member of WärtsiläNSD´s Board of Management from 15 July, 2000. Mr Kleimola iscurrently professor of internal combustion engine technology atHelsinki University of Technology, where he previously held thechair of machine design.

Both Business Area Heads will be located at the Wärtsilä NSDheadquarters in Helsinki. �

U.S.A.

Detroit

India

Madurai, Tamil Nadu

28 - Wärtsilä NSD

What's New?

Cogen takes off at Detroit airportA major US airport is turning on to the benefits of cogenerationwith the installation of an industrial plant to supply heat and powerto the complex.

Wärtsilä NSD has recently received the order, through its UScooperative venture with Cummins Power Generation America,Combined Energy Systems (CES), for a 17.2 MW Pure Energyplant, for the new $1.2bn Midfield Terminal at Detroit MetroAirport. The Metro’s continuing expansion means a reliable,on-site power supply far moreefficient and profitable thanelectricity from the grid.

The new plant will provide forMidfield Terminal’s energy needsand supports the US Department ofEnergy’s commitment to double theamount of combined heat andpower usage in America by 2010.

Part of a public-private partnershipbetween Wayne County, MI and NorthwestAirlines, the Midfield Terminal project is in themidst of a five-year design and construction process.When it opens in late 2001, it will rank among the world’s finestair facilities.

Wärtsilä’s Pure Energy plant, supplied by CES, will include3 x Wärtsilä 18V34SG gas engine gensets with hot water recoveryunits. Auxiliary equipment will comprise of piping module,

radiators, catalysts for CO and VOC control, silencers, switchgear,neutral grounding resistors, and purge and explosion venting.

Detroit Metro is an international airport serving the uppermid-west region and the cityof Detroit. Electricity and hotwater will be supplied primarilyto the Northwest AirlinesExpansion by the energy

service company, Metro EnergyLLC, which will also be able to sell

any excess power to the nationalgrid.

As the airport is accessible to thepublic and in constant use, CES must

ensure the Pure Energy plant meets airportappearance and line-of-sight requirements

for the control tower. Fitting all the systemshas proved to be a challenge, given the limited space available.The Pure Energy plant will be commissioned at the end ofSeptember 2000. �

Diesel plant orders highlight Indian successTwo new IPP Power Master plant orders have highlighted WärtsiläNSD’s continuing success in India.

A 107 MWe power plant for the Balaji Power Corporation Pvt.Ltd is underway in the Indian district of Madurai.Wärtsilä NSD is supplying the power plant on a turnkeybasis. The 7 x Wärtsilä 18V46 engines are beingshipped from Finland, along with the necessaryauxiliary equipment.

When completed, the Power Master plant,based in Tamil Nadu state, will supplyelectricity to the local grid. The almost US$70million EPC contract is scheduled forcompletion in autumn 2001.

Meanwhile, Wärtsilä NSD is also supplyinganother Power Master plant to the town ofSamalpatti, also in Tamil Nadu.

This 106 MWe plant, built for the Samalpatti PowerCompany Private Limited, is similarly based on 7 xWärtsilä 18V46 diesel engines. Wärtsilä in Finland issupplying the generating sets, plus auxiliaries, whilstthe company’s Indian subsidiary will construct thepowerhouse and supply tanks and pipes for the project.

Overseas supply of the engines for both projects hasmeant careful planning of land transportation in India, with a

number of roads and bridges strengthened to ensure safedelivery.

The US$70 million EPC Samalpatti contract will be completedin spring 2001. A huge shortfall in capacity has been themain reason behind these two new-build projects. Thegap between supply and demand in the Tamil Nadu state

is approximately 12 %. �

El Salvador

Generadora Acajutla

Energy News - 29

96 MW Power Master to El SalvadorDuke Energy International has recently signed a contract withWärtsilä NSD to supply a 96 MW Power Master heavy fuel plant toGeneradora Acajutla, west of the city of Acajutla in El Salvador.Acajutla is located on the coastal plain in the western part of ElSalvador and the Generadora Acajutla site is two kilometres fromthe Port of Acajutla, the largest port in El Salvador.

In mid-1999, Duke Energy International (DEI) was thesuccessful bidder in the international tender for the thermal powergenerating assets of the Salvadorian utility,Comisión de Energía Eléctrica del Río Lempa (CEL),located in Acajutla. As part of its privatizationprogram, CEL has privatized its distribution andthermal generation assets.

DEI will expand the 200 MWgenerating capacity at GeneradoraAcajutla by 96 MW to meet the region’s10 % annual growth in electricity demandwith a Wärtsilä NSD Power Master plant.This will result in the most efficient andlowest thermal power generation cost inEl Salvador.

On 27 January 2000 Wärtsilä NSD affiliates signed separatesupply contracts and a construction contract for the 96 MWPower Master power plant with Generadora Acajutla. The facilitywill consist of six Wärtsilä 18V46 generating sets together with anelectrical substation to step the voltage up to 115 kV. The EPC

contract called for 48 MW of power in seven months and 96 MWof power in nine months. The plant complies with theEnvironmental Impact Study (EIS) made according to the WorldBank 1998 Guidelines.

DEI, a wholly owned subsidiary of Duke Energy with assetsvalued at approximately $30 billion, is one of the world’s leading

international energy companies. It offersenergy trading and marketing, riskmanagement, natural gas and powerdevelopment expertise and operationsservices across Latin America,Asia-Pacific and Europe. Within LatinAmerica, DEI’s energy portfolio includesnearly 3460 gross megawatts of hydroand thermal power generation, 125 miles

of natural gas pipeline, 245 miles of electrical transmission, andenergy trading and marketing activities in Argentina, Belize, Brazil,Ecuador, El Salvador and Peru.

Wärtsilä NSD appreciates the opportunity to supply such afacility to DEI and looks forward to a long and fruitful relationshipwith one of the world’s leading international energy companies. �

AppointmentsWärtsilä NSD Finland OyMr Tore Björkman was appointed AreaDirector with Finland, Russia and EasternEurope as his area of responsibility on 1March 2000. He has previously worked asDirector, Power Project Development,Middle East and Africa at WärtsiläDevelopment and Financial Services, andbefore this he was Managing Director ofWärtsilä NSD Pakistan Ltd.

Wärtsilä Development &Financial Services OyMr Jussi Heikkinen has been appointedVice President as of 1 February 2000. Hewill be responsible for developing theEnergy Services business concentrating onselling total energy solutions to industrialcustomers. Mr Heikkinen will be based inHelsinki. He has previously worked as AreaDirector for Eastern Europe.

Jussi Heikkinen has also been appointedManaging Director of Power Partners Oy, ajoint venture company between WärtsiläDevelopment & Financial Services Oy andMeritaNordbanken. PPO provides a vehiclefor the leasing of equipment manufacturedby Wärtsilä NSD Corporation.