CHARACTERIZATION OF AERONAUTICAL AND AEROSPACE METAL MATERIALS THROUGH THE COMPARISON BETWEEN THE...

-

Upload

jamie-howland -

Category

Documents

-

view

216 -

download

0

Transcript of CHARACTERIZATION OF AERONAUTICAL AND AEROSPACE METAL MATERIALS THROUGH THE COMPARISON BETWEEN THE...

CHARACTERIZATION OF AERONAUTICAL AND AEROSPACE METAL MATERIALS THROUGH THE COMPARISON BETWEEN THE XRF vs. ICP-OES

AND FESEM-EDS TECHNIQUESV. Brusadin, C. Iacovella, G. Modesti, M. Bernabei

Aeronautica Militare - Centro Sperimentale di Volo - Reparto Chimico (Aeroporto “M. De Bernardi” - Pratica di Mare – Pomezia, Roma)

The aim of this study is the characterization of metal materials by the quantitative chemical

analysis of aeronautical massive samples performed with the XRF technique and comparing this technique with the ICP-OES and FESEM-EDS

techniques.

OBJECTIVE

E-mail address: [email protected] (Dott.ssa Brusadin Valentina)

Fig. 1: AMX aircraft;

evidence of DRAWING,

aircraft’s aluminium

alloy structural

component fixed on

trailing edge of half-wing

between fuselage and flap (yellow

circle)

TWIN AGENT FOAM/POWDER WHEELED UNIT

DRAWING – AMX FIGHTER BOMBER AND RECONNAISSANCE AIRCRAFT

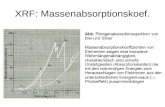

QUANTITATIVE ANALYSIS performed by the XRF technique allows to determine the exact chemical composition of metal materials, as well as the ICP-OES, the reference technique used for the characterization of alloys (UNI EN 10351:2011; UNI EN 14242:2004).The XRF technique, already normed for High Alloy Steels (UNI EN 10315:2006), can be performed also for Aluminium and Titanium alloys.

SEMI-QUANTITATIVE ANALYSIS can be performed by XRF technique as well as EDS microanalysis for screening analysis of unknown metal samples.The XRF technique, operating at a higher power respect to the EDS, gives an error measure lower than that obtained with the EDS.

CONCLUSIONS

XRF technique non-destructive no chemical risk for operator and/or ambient reduced analytical times cost cut

MATERIALS AND METHOD

XRF INSTRUMENTATION

Fig. 2: TORNADO aircraft; evidence of Wing Diffusion Joint (WDJ, white

circle)

WDJ is composed by an aluminium alloy panel (Wing Lower Skin Panel –

WLSP) to contact with a titanium structure (Wing Lower Pivot

Lug – WLPL)

WING DIFFUSION JOINT – TORNADO COMBAT AIRCRAFT