CHAPTER 14 BOLLARDS MAIN PAGE · 2. All steel reinforcement bars shall conform to BS 4449:1997 and...

Transcript of CHAPTER 14 BOLLARDS MAIN PAGE · 2. All steel reinforcement bars shall conform to BS 4449:1997 and...

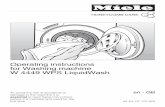

SPRING LOADED POST & FLEXIBLE POST

BOLLARDS

60km/h & 70km/h (SHEET 1 OF 2)

SAFETY BOLLARD AT BUS STOP - POSTED SPEED :

60km/h & 70km/h (SHEET 2 OF 2)

SAFETY BOLLARD AT BUS STOP - POSTED SPEED :

60km/h & 70km/h

SAFETY BOLLARD AT TURFED AREA - POSTED SPEED :

A

B

A

A

A

DRAWING TITLE DRAWING NO. REVISION

LTA/SDRE14/14/BOL2

LTA/SDRE14/14/BOL1

LTA/SDRE14/14/BOL3

LTA/SDRE14/14/BOL4

LTA/SDRE14/14/BOL5

CHAPTER 14

BOLLARDS

Lc

DETAIL 2

SCALE 1:5

OF SYMMETRY

GRANOLITHIC FINISH

30 THK

FOR CIVIC DISTRICT)

(SOLID BRASS RING

ALUMINIUM RING

22 X 20

RETROREFLECTIVE SHEETING

WHITE HIGH INTENSITY

(TYPE IV OF ASTM D4956-04)

MORE THAN 5 DIA)

(GRADE OF CHIPS NOT

GRANOLITHIC FINISH

10 THK

10 WIDE GROOVE

CIVIC DISTRICT)

(BRASS GRID FOR

ALUMINIUM FLAT GRID

30 X 5 THK

22

12

10

30

10

SCALE 1:5

DETAIL 1

PLAN

SCALE 1:5

25

25

5040

30

70

20

30

20

750

1200

250

CONCRETE BOLLARD ON PAVEMENT

SCALE 1:20

(FOR CIVIC DISTRICT)

FOR REINFORCEMENT DETAILS

REFER RIGHT-HAND SIDE

FOOTPATH LEVEL

4R6-225 LINK

PRECAST CONCRETE BOLLARD

250 DIA C20/25

DOWEL BAR

BOLLARD BASE &

EPOXY GROUT ON

APPLY HIGH STRENGTH

6T10

IN CONCRETE SLAB

200 EMBEDDED

75

500 500

STAINLESS STEEL BOLLARD ON PAVEMENTSCALE 1:20

BE EMBEDDED IN CONCRETE

(WITH FISHTAIL WELDED) TO

CIRCULAR PLATE, SATIN FINISH

3 THK STAINLESS STEEL

R6-225 LINK

(CHS 3 THK) SATIN FINISH

230 DIA STAINLESS STEEL

CEMENT SCREED

WALKWAY FINISHING /

C16/20 CONCRETE

350 X 350 X 450

6T10

900

450

50

A

B

OCT 2015

BOLLARDS LTA/SDRE14/14/BOL1

AS SHOWN 1 OF 1

14-1

foundation and 30mm for others.

1. Minimum concrete cover to nearest reinforcement shall be 50mm for the

2. All steel reinforcement bars shall conform to BS 4449:1997 and SS 560.

CONCRETE

REINFORCEMENT

SEPT 2017

STANDARD DETAIL

REV. DATE

DRAWING NO.

DATE OF ISSUE

1st APR 2014

SCALE SHEET NO.

REV.

B

NOTES:

2

-

300

450

BOLLARD TO PREVENT VEHICLE ENTRY / PARKING

SCALE 1:20

WITH C16/20 CONCRETE

75 DIA G.I. PIPE FILLED

6 THK G.I. CHAIN

POST FOR LOCKING DEVICE

6 THK M.S. BAR WELDED TO

CONCRETE FOUNDATION300 X 300 X 450 C16/20

1000

1

-

50

CONCRETE BOLLARD ON GROUND

SCALE 1:20

FOUNDATION

C16/20 CONCRETE

ROAD KERB

G.I. CHAIN

6 THK

AND NUT

6 DIA G.I. BOLT

TO M.S. PIPE

M.S. PLATE AND WELDED

40 X 30 X 6

10 DIA HOLE IN

CONCRETE

3 THK M.S. PLATE

AT 1m (MINIMUM) CLEAR SPACING

CONCRETE BOLLARD SPACED

5R6-225 LINK

YELLOW PAINTS WITH 2 COATS

WITH BANDS OF 300 WIDE OF BLACK AND

WITH C16/20 CONCRETE AND PAINTED

230 DIA PRECAST PIPE TO BE FILLED UP

250

200

750

500 X 500 X 450

6T10

600

NOTE FOR INSTALLATION OF SPRING LOADED POST (SLP):

the names of the supplier and the reflective sheeting.

Date of installation of the post shall be pasted on the post with5.

post component.

damage as a result of impact on the high density polyethylene (HDPE)

One-year manufacturer's warranty shall be provided against permanent4.

12mm diameter x 100mm long.

divider by minimum 4 nos. of stainless steel anchor bolts with a size of

The base of the spring loaded post shall be secured to the concrete3.

width not more than 700mm.

impact and it is meant for installing on raised kerb / divider with a

the post to rebound back to its original vertical position upon any

Spring loaded post shall consist of a spring mechanism which enables2.

self-certification.

Research Programme (NCHRP) Report 350, Category 1 with manufacturer's

Spring loaded post shall comply to National Cooperative Highway1.

(12 DIA X 100)

STEEL ANCHORING BOLTS

4 HOLES FOR STAINLESS

TO FASTEN THE POST

TO THE LINE OF TRAFFIC

BE POSITIONED AT 45°

SCREW HOLES SHALL

TRAFFIC FLOW

SCALE 1:10

BASE - (PLAN VIEW)

GUIDELINES ON APPLICATION OF FLEXIBLE POST (FP):

0.5°0.2°

30° 30°-4°

54110135270SQUARE METRE)

(CANDELAS PER LUX PER

COEFFICIENT OF RETROFLECTION

ENTRANCE ANGLE

OBSERVATION ANGLE

-4°

SPECIFICATIONS OF FLEXIBLE POST (FP)

divider, the damaged slp can be replaced with flexible post.

If there are two or more damages on the slp per year on the centrea)

On centre divider3.

They shall not be installed on top of the existing chevron marking.c)

shall be 2.5m and at the centre of the chevron marking.

chevron marking starting from the crash cushion. spacing of flexible post

Installation of flexible post shall be confined to one-third length of theb)

two or more damages on the crash cushion per year.

Flexible post can be installed in front of crash cushion if there area)

At gore areas with crash cushion:2.

They shall not be installed on top of the existing chevron marking.c)

at 2.5m and 1.8m respectively and at the centre of the chevron marking.

areas on expressway and arterial road, flexible post can be spaced

installed, can be replaced with flexible post. for chevron marking

One-third length of the chevron marking area where the slp areb)

or more damages on the existing spring loaded posts (slp) per year.

Flexible post can be installed on road pavement if there are twoa)

On road pavement:1.

Flexible post can be applied on the following locations:

2

22

and flexural strength of 35N/mm.

should have at least a compressive strength of 65n/mm, tensile strength of 13N/mm

the epoxy resin mortar used to embed the post base into concrete / asphalt surface7.

flexibility under S2. reboundable sheeting requirements.

The yellow flexible prismatic reflective sheeting shall comply with ASTM D4956-S2.2.26.

as follows:

sheeting which comply with ASTM E810 with minimum coefficient of retroreflection

Flexible post shall be in black and pasted with yellow flexible prismatic reflective5.

vertical position.

be impact tested to at least 1,000 impacts without failure and bounce back to original

every impact in any direction, therefore eliminating the need for re-straightening. It must

Flexible post is to return to its original vertical orientation with quick rebound after4.

to state that the flexible post shall not pose any risk to impacting vehicle occupants.

(at least an 800kg passenger car). In the manufacturer's certification, it is also required

speed at the time of impact (range from 35 to 100 km/h) and to state the vehicle mass

include a means, other than the test vehicle's speedometer, for determining the vehicle

flying wheel test or equivalent. the crash testing is to be recorded on videotape, and

Flexible post shall be tested in an established laboratory with test facility such as3.

three (3) years warranty period.

performance when exposed to prevailing weather and traffic conditions within the

10 degrees from the vertical position and capable of retaining its structural

impacts and wheel-overs in all directions. The post shall not deform more than

Flexible post shall be made of polyurethane and capable of withstanding repeated2.

these devices are allowed for use under the manufacturer's self certification.

to be tested to be crashworthy and years of demonstrable safe performance.

and delineating devices that have been in common use for many years and are known

or equivalent. Category 1 includes small and lightweight items, such as channelizing

category 1, National Cooperative Highway Research Programme (NCHRP) Report 350

The manufacturer is to certify that flexible post complies with the requirements of1.

100

150

150

150

150

SPRING LOADED POSTFOR NARROW DIVIDER ( <700mm WIDE )

SCALE 1:10

POST

5 THK HIGH DENSITY POLYETHYLENE

(TYP)

BLACK VINYL CUT-FILM

D4956-04

MICROPRISMATIC SHEETING, TYPE IX OF ASTM

FLUORESCENT YELLOW RETROREFLECTIVE

JOINT OF THE SHEETING

SHALL BE APPLIED ALONG THE BUTT

APPROVED ACRYLIC ADHESIVE

MECHANISM

POLYETHYLENE BASE WITH SPRING

SOLID WHITE HIGH DENSITY

35

15

POLYURETHANE BLACK POST

(AT LEAST 50 DIA X 60 DEPTH)

EMBEDDED ANCHOR BASE

CONCRETE / ASPHALT SURFACE WITH SINGLE

POST BASE TO BE ANCHORED INTO

FLEXIBLE POST

SCALE 1:10

120

120

120

120

120

120

(MINIM

UM)

(MINIMUM)

60

150

150

700

80

120

120

50

60

FLEXIBLE POST

SPRING LOADED POST &

A OCT 2015

LTA/SDRE14/14/BOL2

1 OF 1AS SHOWN

14-2

CONCRETE

REINFORCEMENT

foundation and 30mm for others.

1. Minimum concrete cover to nearest reinforcement shall be 50mm for the

2. All steel reinforcement bars shall conform to BS 4449:1997 and SS 560.

STANDARD DETAIL

REV. DATE

DRAWING NO. REV.

A

DATE OF ISSUE

1st APR 2014

SCALE SHEET NO.

NOTES:

RETROREFLECTIVE SHEETING - (4 BAND)

YELLOW FLEXIBLE PRISMATIC

(SHEET 1 OF 2)

60 km/h & 70 km/h

STOP - POSTED SPEED :

SAFETY BOLLARD AT BUS

A OCT 2015

LTA/SDRE14/14/BOL3

AS SHOWN 1 OF 2

14-3

THE SPECIFIED STRUCTURAL STRENGTH OF THE COMPONENTS SHALL BE CHECKED BY PROFESSIONAL ENGINEER

THE DIMENSION OF THE COMPONENTS IN THE DRAWINGS SHALL BE TAKEN AS THE MINIMUM SIZE REQUIRED.

GENERAL NOTES:-

STEEL WORK

and in such manner that they are not bent, twisted or damaged.

SS EN 1993, BS EN 1090, SS EN 1994. All steel work shall be fabricated from new sections

Fabrication of all structural steel work shall be carried out In accordance with 1.

Parts 1 to 3 of BS EN 10210-1:2006

Parts 1 to 3 of BS EN 10025:2004, BS 7668:2004, BS EN 10029:2010,

The material for all structural steel work shall comply with 3.

shall be approved by S.O.

Fabrication of all structural steel work including welding, trimming & painting 2.

and two coats of compatible paint shall be applied to all damaged surfaces.

All steel section shall comply to CODE BS EN ISO 1461:1999 for hot-dipped galvanised 4.

All cut edges shall be dressed to a neat finish and shall be free from distortions.5.

BS EN 1011-2:2001 & electrodes to BS EN ISO 2560:2005.

All welding shall be in accordance with BS EN 1011-1:2009, 6.

All steel bollards and base plates to be of GRADE S275 steel.8.

No site welding shall be allowed unless approved by the S.O.7.

The general dimensions & tolerances of bolts shall comply with BS 4933:2010.9.

GRADE 8.8 unless otherwise stated.

All bolts strength grade used are as specified in BS 4190:201410.

Nuts shall be at least the strength grade appropriate to the grade of bolt used.

All bolts shall be fitted with washers and locking nuts complying with BS 4320:1968. 11.

BS EN ISO 3506:2009 unless otherwise stated.

All stainless steel bolts shall comply to Part 1 to 2 of12.

satisfaction of the S.O.

galvanised metal surface and galvanised steel pipes to the

approved two pack polyurethene paint (dry firm thickness of 50 microns) to all

two pack epoxy undercoat (dry film thickness 150 microns) and two coats of

Prepare and apply one coat of approved two pack etching primer, one approved 13.

magnetic particle flaw detection concrete.

by ultrasonic or radiographic tests and the other 50% of the welds shall be tested by

All the welds between bollard and base plate shall be tested. 50% of the welds shall be tested 14.

CONCRETE

REINFORCEMENT

Minimum concrete cover to nearest reinforcement shall be 50mm for the foundation.15.

Concrete to be used shall have minimum concrete strength as specified in drawings.16.

All existing concrete surface shall be primed with bonding agent prior to casting of new concrete.17.

All steel reinforcement bars shall conform to BS 4449 and SS 560.18.

.Reinforcement mill certificates must be submitted for acceptance prior to concreting work19.

RETROREFLECTIVE SHEETING

Butt joint shall be used at the end of the retroreflective sheeting.20.

10mm wide approved acrylic adhesive shall be applied along the butt joint.21.

3. Spacing of safety bollard to be at 3m c/c.

equi-potential bonding is achieved and certified by licensed electrical worker.

shall be welded to the reinforcement steel of the bus shelter platform to ensure

2. Safety bollard installed within 2m from the perimeter of the new / upgraded bus-stop

with posted speed limit of 60 km/h and 70 km/h.

1. The structural details shown above are for bollard installed at bus-stop along road

STANDARD DETAIL

REV. DATE

DRAWING NO. REV.

A

DATE OF ISSUE

1st APR 2014

SCALE SHEET NO.

NOTES:

DRAFT

T

EXISTING BUS-STOP : 150mm < T < 200mm

CONNECTION DETAIL OF SAFETY BOLLARD

EXISTING BUS-STOP : T > 200mm

CONNECTION DETAIL OF SAFETY BOLLARD

SCALE 1:20

SCALE 1:20

DIMENSIONS h, d & F REFER TO TABLE IN DWG NO: SDRE14/14/BOL4

hh

EXCEEDING 3

8 THK GRANOLITHIC FINISH WITH PEBBLE SIZE NOT

(REF DWG NO: SDRE14/14/BOL4)

(TYPE XI OF ASTM D4956-11a)

MICROPRISMATIC RETROREFLECTIVE SHEETING

BLACK ARROW ON FLUORESCENT YELLOW

NOTES - STEELWORK NO 13.)

EXISTING BUS STOP COLUMN'S COLOUR (SEE GENERAL

SURFACE OF STEEL BOLLARD TO BE PAINTED TO MATCH

50 THK MASS CONCRETE (C16/20)

(WELD LENGTH = 200 PER BAR ON 2 SIDES)

WELD 6mm FW TO EXISTING REINFORCEMENT

NEW WSFR (AS SHOWN IN TABLE BELOW)

CONCRETE

C16/20

1.5 RECESS ALL ROUND

2(MINIMUM 30N/mm )

CEMENTITIOUS GROUT

10 THK NON-SHRINK

RC SLABEXISTING

HARDCOREEXISTING

NEW HARDCORE

C25/30 CONCRETE

T13

T13-200 LINK

450(L) X 1000(W) FOOTING

HARDCORE

150 THK WELL COMPACTED

CARRIAGEWAY

A

RETROREFLECTIVE SHEETING IS NOT SHOWN FOR CLARITY.

AT TOP OF BOLLARD

2 X R6 U-BARS

(EXISTING BUS STOP: T < 200)

SAFETY BOLLARD

SIMILAR TO DETAIL OF

STEEL BOLLARD DETAIL

MAXIMUM HACKING 35EXISTING KERB

CARRIAGEWAY

BY MILLING DOWN THE CHS

BAND SHALL BE PROVIDED

RECESS OF 1.5 X 300

(C16/20)

50 THK MASS CONCRETE

EXISTING FINISHES

GRADE 20 CONCRETE

EXISTING SLAB MINIMUM

LINE OF HACK

EXISTING HARDCORE

2

30 CONCRETE (REFER TO TABLE BELOW)

ULTIMATE PULL OUT STRENGTH (F) PER BOLT IN GRADE

APPROVED EPOXY RESIN IN HOLE DIA (d) HAVING

)

(MINIMUM 30N/mm

10 THK NON-SHRINK CEMENTITIOUS GROUT

NOTES FOR EXISTING BUS STOP

EXISTING SLAB THICKNESS 150mm < T < 200mm

engineer's approvalcontractor shall proposed slab strengthening method toFor existing slab, T< 150mm or concrete class C25/30

Concrete class at least C25/30

T > 200mm

For existing concrete class C25/30,

Concrete class at least C25/30

engineer's approvalContractor shall proposed slab strengthening method to

2

Posted speed

60 km/h

Posted speed

70 km/h

Posted speed

60 km/h

Posted speed

70 km/h/m (distribution bar)

200mm(b) 2

/m (traffic direction)

450mm(a) 2

/m (distribution bar)

200mm(b) 2

2 /m (traffic direction)

800mm(a) 2 /m (distribution bar)

200mm(b)

2 /m (traffic direction)

550mm(a)

/m (distribution bar)

200mm(b) 2

/m (traffic direction)

900mm (a) 2

nearer to the top surface & soffit of the slab for top & bottom reinforcement respectively.The added reinforcement shall cover an area of 1500mm x 1500mm. Main bars shall be placed parallel to traffic direction and New reinforcement shall be added using either of the 2-method below:

not satisfiedIf item (2) is(3)

60 km/h

Posted speed

Posted speed

70 km/h

2 layers of top & bottom reinforcement of WSFR A13 (i)

T10-200 (distribution bar)1 top layer T13-100 (traffic direction), (ii)

2 layers of top & bottom reinforcement of WSFR B13 (i)

T10-200 (distribution bar)1 top layer T20-125 (traffic direction), (ii)

2 layers of top & bottom reinforcement of WSFR A13 (i)Posted speed

60 km/h

Posted speed

70 km/hT10-150 (distribution bar)1 top layer T13-100 (traffic direction), (ii)

2 layers of top & bottom reinforcement of WSFR A13 (i)

T10-200 (distribution bar)1 top layer T13-125 (traffic direction), (ii)

1000

R=85

25

85

300

600

550 NTS

T

550

65°

450

250

600

(SEE NOTE 2 & 3)

EXISTING REBARS

Minimum concrete class(1)

reinforcement area Minimum existing (2) ) shall not be less than the areas specified below.

Each layer of existing top & bottom reinforcement (fy =460N/mm

WALL

CHS

CHS

INSIDE

10

127

(NEW BUS-STOP)

CONNECTION DETAIL OF SAFETY BOLLARD

SCALE 1:20NOTES:

2) REFER TO NEW BUS STOP DRAWING FOR SLAB REINFORCEMENT DETAILS.

(EXISTING BUS STOP: T < 200mm)

SAFETY BOLLARD

1) FOR BOLLARD, FOOTING & PLATE DETAILS, REFER TO CONNECTION DETAIL OF

RELEVANT SPEED LIMIT

REFER TO DRAWING OF

REINFORCEMENT

CAST-IN ANCHORAGE AND

CARRIAGEWAY

(REF DWG NO:SDRE14/14/BOL3)

REINFORCEMENT

MINIMUM SLAB

(MINIM

UM)

150

SPEEDPOSTED

60 km/h

70 km/h

0

BLA

CK

BLA

CK

BLA

CK

90

(POSTED SPEED: < 60 km/h) (POSTED SPEED: < 60 km/h)

(POSTED SPEED: 70 km/h) (POSTED SPEED: 70 km/h) DETAILS OF RETROREFLECTIVE SHEETING

SCALE 1:10

YELL

OW

YELL

OW

YELL

OW

YELL

OW

150

150

42

182706070607010

10

10

522

SECTION A-A

150mm < T < 200mm

REF DWG NO: SDRE14/14/BOL3

SCALE 1:10

REF DWG NO: SDRE14/14/BOL3

SCALE 1:10

SECTION B-B

T > 200mm

REF DWG NO: SDRE14/14/BOL3 REF DWG NO: SDRE14/14/BOL3

TABLE

ANCHOR DEPTHOF BOLT

ULTIMATE PULLOUT STRENGTH

[F](kN)

[h](mm)

125

12550

5318

18

(mm)[d]ROD

(mm)

AT NEAR FACE

5mm SINGLE V BUTT WELD

NEAR FACE

8mm FILLET WELD AT

EMBEDDED INTO CONCRETE

WASHER, MINIMUM 500mm

H.D. BOLTS FITTED WITH

8 NOS. M22 (GRADE 8.8)

22 THK M.S. PLATE

C16/20 CONCRETE

22 THK M.S. PLATE

FITTED WITH WASHER

THREADED RODS & NUTS

8 NOS. GRADE A4-80 SS

(REFER TO TABLE)

16

16

DIAMETER OFTHREADED

DIAMETEROF HOLE

350

EQ EQ35350

EQ

EQ

35

35

35

EQ EQ

EQ

EQ

350

350

5

8

7

12

1. For notes, refer to LTA/SDRE14/14/BOL3.

(SHEET 2 OF 2)

60 km/h & 70 km/h

STOP - POSTED SPEED :

SAFETY BOLLARD AT BUS

OCT 2015A

LTA/SDRE14/14/BOL4

AS SHOWN 2 OF 2

14-4

STANDARD DETAIL

REV. DATE

DRAWING NO. REV.

A

DATE OF ISSUE

1st APR 2014

SCALE SHEET NO.

NOTES:

SECTION A-A SECTION B-B

150mm < T < 200mm T > 200mm

SCALE 1:10SCALE 1:10

AT NEAR FACE

7mm SINGLE V BUTT WELD

NEAR FACE

12mm FILLET WELD AT

EMBEDDED INTO CONCRETE

WASHER, MINIMUM 500

H.D. BOLTS FITTED WITH

12 NOS. M22 (GRADE 8.8)

25 THK M.S. PLATE FITTED WITH WASHER

THREADED RODS & NUTS

12 NOS. GRADE A4-80 SS

(REFER TO TABLE)

25 THK M.S. PLATE

C16/20 CONCRETE

EQ

350

EQEQ

350

EQ EQEQ

350

EQ

EQ

EQ

EQ

EQ

EQ

350

35

35

35

35

CHS

INSIDE

WALL

CHS

8

85

2(AT LEAST 30N/mm )

CEMENTITIOUS GROUT

25 THK NON-SHRINK

500

DETAIL OF BOLLARD AT TURF AREA

SECTION A-A

(POSTED SPEED LIMIT OF 60 km/h)

SECTION A-A

(POSTED SPEED LIMIT OF 70 km/h)

(POSTED SPEED LIMIT OF 70 km/h)

60 km/h & 70 km/h

- POSTED SPEED :

TURFED AREA

SAFETY BOLLARD AT

LTA/SDRE14/14/BOL5

AS SHOWN 1 OF 1

14-5

OCT 2015A

or S.O.'s approval.

between the beam and the ground shall be grouted to Engineer's details

4. Ground surrounding the tie beam shall be properly compacted and any gap

3. Concrete used shall be of C28/35.

2. Tie beam shall be tied to at least 2 bollards.

1. For notes and details of bollard, refer to LTA/SDRE14/14/BOL3.

STANDARD DETAIL

REV. DATE

DRAWING NO. REV.

A

DATE OF ISSUE

1st APR 2014

SCALE SHEET NO.

NOTES:

(POSTED SPEED LIMIT OF 60 km/h)

SECTION B-B

SCALE 1:25

SCALE 1:25

SCALE 1:25

SCALE 1:25

7T13 (POSTED SPEED LIMIT OF 70 km/h)

4T13 (POSTED SPEED LIMIT OF 60 km/h)

GROUND

COMPACTED

WELL-

CONCRETE HAUCHING

GROUND

WELL-COMPACTED

50 THK LEAN CONCRETE

7T16 (POSTED SPEED LIMIT OF 70km/h)

4T16 (POSTED SPEED LIMIT OF 60km/h)WELL COMPACTED GROUND

REF DWG NO: SDRE14/14/BOL4 600 X 550 TIE BEAM

1100 X 600 TIE BEAMREF DWG NO: SDRE14/14/BOL4

LINK

2T10-200

B

-

-

7T13

7T16

75

150

600 (POSTED SPEED LIMIT OF 70 km/h)550 (POSTED SPEED LIMIT OF 60 km/h)

A

2T10-200 LINK

3000250 250

600

3000 250250

1100

1100

600

150

3m

PLAN VIEW OF BUS SHELTERSCALE 1:150

FOOTPATH CUM DRAIN

TURFED AREA AREA

TURFED

(BY OTHERS)

POST

BUS STOPKERB

AT BUS STOP)

(REFER TO SAFETY BOLLARD

BASE CONNECTION DETAILSDIRECTION OF TRAVEL

AT 3m C/C

SAFETY BOLLARD

PROPOSED

SECTION B-B

SCALE 1:25

LINK

2T10-200

4T13

4T16

150

550

600