Ch01

-

Upload

ganaga-lax -

Category

Business

-

view

287 -

download

0

Transcript of Ch01

- 1. 1 Introduction toIntroduction to QualityQuality Chapter One What is Quality? Example : A customer expects a different performance from original and counterfeit product. When a product/service satisfy or surpasses customers expectations we consider Quality

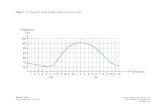

2. 2 Defining QualityDefining Quality The word quality is broadly used in many fields and carries numerous definitions To a layman, what is meant by quality is probably associated with grade, luxury, or degree of goodness of a product or service provided. From a production perspective, many practitioners, academicians and experts believe that quality is fitness for purpose or fulfilling the purpose intended. Which means matching design specifications to function and ensuring that output conforms to specifications, making sure that products are safe to use and appropriate for purpose (Garvin, 1988; Juran, 1988; Besterfield et al., Dahlgaard et al., 1998) 3. From a customers perspective, quality id defined as conformance to customers requirements, not elegance, and doing it right the first time (Crosby, 1980; Feigenbaum, 1986; Besterfield et al., 1995) In addition, Quality in the eyes of the customer is always much more than just the quality of the product or the basic service offered. In other words, QUALITY concerns, reliability, consistency, speed of delivery, accuracy, reliability courtesy of telephone answering, value of information given, reputation of the company, and etc. (Oakland,1993). 3 Defining QualityDefining Quality 4. Modern Quality DefinitionModern Quality Definition Quality is inversely proportional to variability This definition acknowledges that variability is present in all processes. Sources of variability include: I. Process variability : raw materials, machines, operators, environmental conditions II. Measurement variability III. Sampling variability Given that quality is inversely proportional to variability, ensuring quality is containing variability and improving quality is reducing variability 4 5. Essence of Quality DefinitionsEssence of Quality Definitions Assuring and ensuring that all products and services will ultimately be able to satisfy the needs of customers. Thus, vital for everyone in the organization to understand the role of quality for the survival of the organization and embed it in his/her work culture 5 6. MEM 650 Quality Control 6 Stouts ViewStouts View Modern Quality DefinitionModern Quality Definition Quality = where: Q= quality ; P=performance; and E=expectations If Q>1.0 then the customer has a good feeling about the product/service P & E are determined based on perception P is determined by the organization & E by the customers Customer expectations are becoming more demanding from day-to-day. Performance Expectation 7. The Dimensions of Quality (Garvin. 1988)The Dimensions of Quality (Garvin. 1988) Dimension Meaning and example Performance Primary product characteristics, such as brightness of the picture Features Secondary characteristics (i.e. added features), such as remote control Conformance Meeting specifications or industry standards, workmanship Reliability Consistence performance over time, average time for the product/unit to fail Durability Useful life, includes repair service Resolution of problems and complaints, ease of repair Response Human-to-human interface, such as courtesy of the dealer Aesthetics Sensory characteristics, such as exterior finish reputation Past performance and other intangibles, such as being ranked first/best 7 8. The Dimensions of QualityThe Dimensions of Quality These 9 dimensions are independent, therefore a product may be excellent in one dimension and average or poor in another. Very few products excel in all 9 dimensions Example : in 1970s, the Japanese were cited for high quality cars based only on the dimensions of RELIABILITY, CONFORMANCE and AESTHETICS. 8 9. Quality Control-Quality Control- use of following techniquesuse of following techniques and activities to achieve, to sustain and toand activities to achieve, to sustain and to improve qualityimprove quality I. Specifications of what is needed II. Product/service design to meet specifications III. Productions/installation to meet specifications IV. Inspection to determine conformance to specifications V. Review of usege to provide information for the revision of specification if needed 9 10. Statistical quality control (SQC)Statistical quality control (SQC) A branch of quality control (QC) It is the collection, analysis & interpretation of data for use in QC activities SQC comprise of 2 major components: I. Statistical process control II. Acceptance sampling Quality Assurance (QA) All planned/systematic actions necessary to provide adequate confidence to the customers/users that a product/service will satisfy their requirements for quality 10 11. Historical review of QualityHistorical review of Quality 1875 Frederick W.Taylor 1920s Walter Shewhart at bell Labs 1920s Harold F.Dodge and Harry G.Romig also at bell Labs 1940s-50s (After WW II) W.Edwards Deming 1940s-50s Joseph M. Juran 1946 American Society for Quality Control (ASQC) formed 1950s-60s Quality revolution I Japan 1951 Armeand V.Feigenbaum 1960 Halpin- Zero defects 1979s P.Crosby- Quality is free In Japan: 1960s Kaoru Ishikawa Genechi Taguchi 11 12. Middle Ages quality controlled by long period of training to instilled pride in workers for quality of a product. Industrial revolution introduce concept of specialization. Taylor (1875) Pioneered division of labour. Workers have narrow view of the product (i.e. component). Initially created increases in productivity, but eventually led to losses in pride of workmanship (and hence quality) and, as a consequence, the need to improve productivity. 12 Historical review of QualityHistorical review of Quality 13. Historical review of QualityHistorical review of Quality Shewhart (1924) at bell labs developed a statistical chart (SQC) for controlling product variables He noted the positive relationship between consistency and quality Detect a lack of control in progress through continual monitoring of variability Work standard hindered adoption of Shewharts ideas: focus of work standard was productivity; process assumed acceptable (in control) if the work standard was being met; work standard moved quality outside the process job of production was to meet quotas, someone else had to look after quality 13 14. Dodge and Romig (1920s) also at Bell Labs Developed acceptance sampling ideas: making inferences about the whole lot (batch) based on a sample. Tended to emphasize detection and containment of defective items, which led to scrap being an acceptance part of production. Widely adopted during WW II. reject and return policy little investigation as to why a lot was not acceptable 14 Historical review of QualityHistorical review of Quality 15. Deming (1950)- helped in the reconstruction of Japanese industry; found willing listeners in Japan. Deming teach Japanese engineers SQC techniques and quality responsibility to Japanese CEO. Keys of demings 14 points: 1. Continual improvement 2. No work standards 3. Cannot inspect quality into a product 4. Statistical techniques 5. Involvement of top management essential 15 Historical review of QualityHistorical review of Quality 16. Juran (1940s-50s)- emphasized the role of top management for achieving quality According to Juran-organizational change, need management participation- managerial breakthrough Feigenbaum (1951)- Total Quality Control- Company- wide involvement Halpin (1960s)- Zero Defects emphasized prevention of defects, but focus on improving the workforce rather than on management. Crosby(1979) quality is Free. He argued that quality programs save money (see for quality and costs- prevention costs, appraisal costs, internal costs & external costs) 16 Historical review of QualityHistorical review of Quality 17. Ishikawa (1960s) professor of engineering at Univ. of Tokyo. Quality circles(QC): participative management ; a team of workers forms and brainstorms on problems of productivity and quality. Use simple tools including: histograms, pie charts, Pareto diagrams, cause-and- effect diagrams. Taguchi (1960s)- Emphasize offline QC, quality of design of processes and product. Dont wait until production to do QC. Idea: design product to withstand variations in quality of materials, labour, environment, etc. Find out what factors are critical (experimental design) and change design so that the product ismore tolerant minimize the transmission of variance throughout the process (also called robust design). 17 Historical review of QualityHistorical review of Quality 18. 18 Responsibility for QualityResponsibility for Quality Customer Marketing Design Engineering Procurement Process Design Production Inspection and Test Packaging and Storage Product Service Quality Product Figure 1 19. Evaluate level of product quality that the customer wants, needs and willing to pay. Provide the product-quality data and helps to determine quality requirements. Info on satisfaction-customer complaints, sales representative reports, product service and product liability cases, etc. Marketing evaluates all the data and determine the quality requirements for the product. Essential to have an information-monitoring and feedback system to collect data on a continuing basis Marketing provide the company with product brief. Translates customer requirements into a set of preliminary specifications. 19 1.Marketing1.Marketing 20. Among product brief elements are: I. Performance characteristics, such as environmental, usage and reliability considerations II. Sensory characteristics, such as style, colour, taste and smell. III. Installation, configuration, or fit. IV. Applicable standards and statutory regulations V. Packaging, and VI. Quality verification Marketing is the liaison with the customer and a vital link to the development of a product that surpasses customer expectations. 20 1.Marketing1.Marketing 21. Translates the customers quality requirement into operating characteristics, exact specification, etc. Early involvement of marketing, production, quality, procurement and the customer is essential to prevent problems before they occur (i.e. concurrent engineering) Whenever possible, design engineering should utilize proven designs and standard components. Tolerance is the permissible variation in the size of the quality characteristics. Selection of tolerances has a dual effect on quality. In general, tolerances are set using standard dimensioning and tolerance systems. 21 2.Design Engineering2.Design Engineering 22. Designer determines the materials to be used in the product Material quality is based on written specifications(i.e. physical characteristics, reliability, acceptance criteria, and packaging) A quality product can be: use safely, repaired or maintained easily In the product development stage. Design reviews are conducted at appropriate phases. Purposes: to identify and anticipate problems areas and inadequacies, and initiate corrective action to ensure that the final design and supporting data meet customer requirements. 22 2.Design Engineering2.Design Engineering 23. Responsible of procuring quality materials and components. Quality requirements will vary with respect on the category of the purchase. Conduct a supplier quality survey by visiting the suppliers plant to determine their capability in providing quality materials and components 23 3. Procurement3. Procurement 24. Methods to obtain proof of conformance to quality standards: I. Small quantities-inspection of incoming materials and components from the supplier. II. Large quantities- inspection is conducted in the suppliers plant. Method-statistical evidence of quality using process control charts and process capability. III. 2 way communication between the supplier and procurement is a necessity to improve the quality of purchased materials and components. Both positive and negative feedback should be given to the supplier. IV. Procurement should be concerned with the total cost and not price 24 3. Procurement3. Procurement 25. Responsible of developing processes and procedures that will produce a quality product. It can be achieved through, for example: process selection and development, production planning and support activities. When process capability information indicates that a tolerance is too tight for satisfactory manufacturability, there are 5 options; purchase new equipment, revise the tolerance, improve the process, revise the design, or sort out the defective product during production. Process selection and development is concerned with cost, quality, implementation time, and efficiency. 25 4.Process Design4.Process Design 26. Conduct process capability study to determine the ability of a process to meet specifications. Process capability information provides data make-or- buy decision, equipment purchases and selection of process routes. Sequence of operations is developed to minimize quality difficulties (e.g. location of precision operation in the sequence) Additional responsibilities, includes design of equipment, design of inspection devices and maintenance of the production equipment. 26 4.Process Design4.Process Design 27. Responsible to produce quality product. Note: quality cannot be inspected into a product; it must built into the product. First line supervisor is the key to manufacture of a quality product (i.e. represent management). First line supervisor must be able to convey quality expectations, good employee relations, and providing motivation to employees to build quality into each and every part and, thus into the final unit. Training sessions should be provided periodically to discuss sources of quality variation, develop an attitude of quality mindedness and methods of improving quality. 27 5.Production5.Production 28. Everybody must not only do their jobs but search for ways to improve them. Deming-15% of quality problems can be attributed to operating personnel; 85% to be rest of the system Statistical process control effectively controls quality and is an invaluable tool for quality improvement. Operating personnel should be trained to perform their own statistical process control 28 5.Production5.Production 29. Responsible to appraise the quality of purchased and manufactured items and to report the results. When needed, these reports can be used by other departments to take corrective actions Inspection and test may be an area by itself, part of production, or part of quality assurance or both. In order to perform the inspection activity, accurate measuring equipment is needed. Inspection and test should concentrate the majority of its efforts on statistical quality control in improving quality. 29 6.Inspection and Test6.Inspection and Test 30. Responsible to preserve and protect the quality of the product Control of the product quality must extend beyond production to the distribution, installation, and use of the product. A dissatisfied customer is not concerned with where the nonconforming condition occurred. Quality specifications are needed for the protection of the product during transit by all types of common carrier. E.g. truck, rail, air Also in handling the product during loading and unloading and warehousing 30 7.Packaging and Storage7.Packaging and Storage 31. Specifications includes vibrations, shock, and environmental conditions (e.g. temperature, dust and moisture) on the product 31 7.Packaging and Storage7.Packaging and Storage 32. Responsible to provide the customer with the means for fully realizing the intended function off the product during its expected life. Responsibility includes: sales and distribution, installation, technical assistance, maintenance and disposal after use. Product should be serviced quickly whenever they are improperly installed or fail during the warranty period. Prompt service can change a dissatisfied customer into a satisfied one. Product service and marketing work closely with each other to determine the quality then customer wants, needs, and obtains. 32 8.Product Service8.Product Service 33. It does not have direct responsibility for quality. Therefore it is not shown in Figure 1 It assists/supports the other areas as they carry out their quality control responsibilities. It is directly responsible to continually evaluate the effectiveness of the quality system. It determine the effectiveness of the system, appraises the current quality, determine quality problems areas or potential areas, and assists in the correction or minimization of these problem areas. Overall objective: Improvement of the product quality in cooperation with the responsible departments. 33 Quality AssuranceQuality Assurance 34. Responsible for each of the areas in the closed loop of Figure 1 and quality assurance area (i.e. ultimate responsibility for quality) Therefore, he/she must be involved directly in the quality effort. Direct involvement requires the creation of the quality council, participation in meetings, being a member of quality improvement project team, participating in recognition ceremonies, developing a mission statement, having a quarterly employee meeting, writing a column in the monthly newsletter. Practice Management-By-Walking-Around (MBWA). 34 Chief Executive OfficerChief Executive Officer (CEO)(CEO) 35. CEOCEO Ceos quality performance can be effectively measured by a proportion (%nonconforming) chart that covers that area of responsibility If the percent of nonconforming is increasing or is constant (i.e. CEOs performance is poor) If the percent of nonconforming is decreasing (i.e. CEOs performance is good) This concept, measured of quality performance can be adapted for all managers, departments and operating personnel MBNQA criteria can also be used as a performance measure. Approx.35% of the CEOs time should be allocated on quality matters. 35 36. SummarySummary Learned about the: Introduction to quality Quality definitions Dimensions of quality Quality Control (QC) Historical review of quality Quality Control (QC) TOOLS Areas responsible for quality 36