Boiler Furnace Desaign Steps

-

Upload

trisha1234567 -

Category

Documents

-

view

234 -

download

0

Transcript of Boiler Furnace Desaign Steps

8/22/2019 Boiler Furnace Desaign Steps

http://slidepdf.com/reader/full/boiler-furnace-desaign-steps 1/21

Design Steps : Furnace Of A Steam Generator

P M V Subbarao

Professor

Mechanical Engineering Department

Selection of Geometric Parameters….

8/22/2019 Boiler Furnace Desaign Steps

http://slidepdf.com/reader/full/boiler-furnace-desaign-steps 2/21

Heat available to the furnace

• Incomplete combustion loss

• Unburned Carbon loss

• Loss due to slag

• Energy brought in by preheated air & fuel.

• A part of this total heat should be absorbed in furnace.

• The designer should provide an environment for the same.

ai slag C COc fuQQQQ LHV mQ

COQ

slag Q

C Q

aiQ

8/22/2019 Boiler Furnace Desaign Steps

http://slidepdf.com/reader/full/boiler-furnace-desaign-steps 3/21

Heat Release Rate per Unit Volume, qv

• The amount of heat generated by combustion of fuel in a unit effective

volume of the furnace.

3/mkW

V

LHV mq

c

v

burning r

r

cv t t

Vt LHV mq

*

• Where, mc = Design fuel consumption rate, kg/s.

•

V = Furnace volume, Cu. m.• LHV= Lower heating value of fuel kJ/kg.

• A proper choice of volumetric heat release rate ensures thecritical fuel residence time.

• Fuel particles are burnt completely.

• The flue gas is cooled to the required safe temperature.

8/22/2019 Boiler Furnace Desaign Steps

http://slidepdf.com/reader/full/boiler-furnace-desaign-steps 4/21

8/22/2019 Boiler Furnace Desaign Steps

http://slidepdf.com/reader/full/boiler-furnace-desaign-steps 5/21

Heat Release Rate per Unit Cross Sectional Area,qa

• The amount of heat released per unit cross section of the furnace.

• Also called as Grate heat release rate.

2/mkW A

LHV m

q grate

c

A

• Agrate is the cross sectional area or grate area of the furnace, Sq. m.

• This indicates the temperature levels in the furnace.

• An increase in qa, leads to a rise in temperature in burner region.

• This helps in the stability of flame

•Increases the possibility of slagging.

8/22/2019 Boiler Furnace Desaign Steps

http://slidepdf.com/reader/full/boiler-furnace-desaign-steps 6/21

A

8/22/2019 Boiler Furnace Desaign Steps

http://slidepdf.com/reader/full/boiler-furnace-desaign-steps 7/21

Heat Release Rate per Unit Wall Area of the Burner Region

• The burner region of the furnace is the most intense heat zone.

• The amount of heat released per unit water wall area in the burner region.

2

/2 mkW H ba

LHV m

qb

b

• a and b are width and depth of furnace, and H b is the height of burner

region.• This represents the temperature level and heat flux in the burner

region.

• Used to judge the general condition of the burner region.

• Its value depends on Fuel ignition characteristics, ash characteristics,

firing method and arrangement of the burners.

8/22/2019 Boiler Furnace Desaign Steps

http://slidepdf.com/reader/full/boiler-furnace-desaign-steps 8/21

8/22/2019 Boiler Furnace Desaign Steps

http://slidepdf.com/reader/full/boiler-furnace-desaign-steps 9/21

Selection of Furnace Design Parameters

• A suitable value for ;

• the rate of heat generated by combustion of fuel in a unit

effective volume of the furnace, qv

.

• the rate of heat released per unit cross section of the

furnace, qA.

• The rate of heat released per unit wall area of burner

section of the furnace, q b

.

8/22/2019 Boiler Furnace Desaign Steps

http://slidepdf.com/reader/full/boiler-furnace-desaign-steps 10/21

General Guide Lines for Design

• The furnace should provide the required physical environment and the

time to complete the combustion of fuel.

• The furnace should have adequate radiative heating surfaces to cool

the flue gas sufficiently to ensure safe operation of the downstream

convective heating surface.

• Aerodynamics in the furnace should prevent impingement of flames on

the water wall and ensure uniform distribution of heat flux on the

water wall.

• The furnace should provide conditions favoring reliable natural

circulation of water through water wall tubes.

• Furnace should proved an exit and path for free fall of ash, without

major heat loss.

• The configuration of the furnace should be compact enough to

minimize the amount of steel and other construction material.

8/22/2019 Boiler Furnace Desaign Steps

http://slidepdf.com/reader/full/boiler-furnace-desaign-steps 11/21

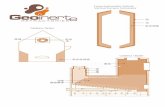

Basic Geometry of A Furnace

v

c

q

LHV m

V

A

c

grate

q

LHV mba A

b

cb

q

LHV m H ba

2

Any limit on minimum height of furnace?

Any limit on depth of furnace C.S.?

8/22/2019 Boiler Furnace Desaign Steps

http://slidepdf.com/reader/full/boiler-furnace-desaign-steps 12/21

Furnace Depth & Height

•Depth (a) to breadth (b)ratio is an important parameter from bothcombustion and heat absorption standpoint.

• Following factors influence the minimum value of breadth.

– Capacity of the boiler

– Type of fuel

– Arrangement of burners

– Heat release rate per unit furnace area

– Capacity of each burner

• The furnace should be sufficiently high so that the flame does not hit

the super heater tubes.

• The minimum height depends on type of coal and capacity of burner.

• Lower the value of height the worse the natural circulation.

8/22/2019 Boiler Furnace Desaign Steps

http://slidepdf.com/reader/full/boiler-furnace-desaign-steps 13/21

8/22/2019 Boiler Furnace Desaign Steps

http://slidepdf.com/reader/full/boiler-furnace-desaign-steps 14/21

Modfications in Geometry of A Furnace

8/22/2019 Boiler Furnace Desaign Steps

http://slidepdf.com/reader/full/boiler-furnace-desaign-steps 15/21

8/22/2019 Boiler Furnace Desaign Steps

http://slidepdf.com/reader/full/boiler-furnace-desaign-steps 16/21

Boiling process in Tubular Geometries

Water

Heat Input

H e a t

I n p u tWater

Water

Steam

Steam

Partial Steam Generation Complete or Once-through

Generation

8/22/2019 Boiler Furnace Desaign Steps

http://slidepdf.com/reader/full/boiler-furnace-desaign-steps 17/21

Further Geometrical Details of A Furnace

8/22/2019 Boiler Furnace Desaign Steps

http://slidepdf.com/reader/full/boiler-furnace-desaign-steps 18/21

Determination of Furnace Size

• What is the boundary of a furnace?

• The boundary of a furnace is defined

by

– Central plane of water wall and roof

tubes – Central lines of the first row super

heater tubes.

• = 30 to 50O

• > 30O

• = 50 to 55O

• E = 0.8 to 1.6 m

• d = 0.25 b to 0.33 b

8/22/2019 Boiler Furnace Desaign Steps

http://slidepdf.com/reader/full/boiler-furnace-desaign-steps 19/21

Heat Transfer in A Furnace

• The flame transfers its heat energy to the water walls in the furnace by Radiation.

• Convective Heat Transfer < 5%.

• Only Radiation Heat Transfer is Considered!

• Complexities:

• Non uniform temperature of tubes.

• Fouling of surfaces of tubes.

• Variation of furnace temperature along its

– Height

– Width – Depth.

Non uniform Heat Flux !!!!!

8/22/2019 Boiler Furnace Desaign Steps

http://slidepdf.com/reader/full/boiler-furnace-desaign-steps 20/21

Simplified Approach

• Emitted Radiation heat flux of flames:

• Emitted Radiation = Available Heat

• Heat flux absorbed by walls :

• Thermal efficiency factor, y.

•The rate of heat absorption

24/ mkwT J fl fl fl

fl abs J q y

kW T AQ fl fl abs 4

y

444

fl fl wa fl eff rad abs T AkW T T AQQ y

8/22/2019 Boiler Furnace Desaign Steps

http://slidepdf.com/reader/full/boiler-furnace-desaign-steps 21/21

Coal fired furnace

Structure of

water walls*Hot Exhaust gases

Burner

Flame

Furnace Exit

Heat Radiation

& Convection

*www.directindustry.com

• Two functions of coal fired

furnace:

Release of chemical energy by

combustion of fuel

Transfer of heat from flame to

water walls

• Combustion space

surrounded by water walls

![INSTALLATION AND SERVICE INSTRUCTIONS English [ 02.18 ].pdf · 5 BOILER OR FURNACE PREPARATION A) Clean the boiler or furnace thoroughly and remove all grates and obstructions. Check](https://static.fdocuments.net/doc/165x107/5ff316f08aedd72b463af5bf/installation-and-service-english-0218-pdf-5-boiler-or-furnace-preparation.jpg)